In the new AudioXpress magazine there is a new article about making a ribbon mid/tweeter. It looks very good and I was interested in finding a few thing online. Does anybody have more information on the subjects or some books to propose ?

Thanks in advance

Ilias

Thanks in advance

Ilias

Ilias,

I searched high and low for DIY ribbon information a few years ago. This is the only (semi-useful) link I found:

http://www.geocities.com/ResearchTriangle/8231/mag/index.html

If you've got a construction article, it may be of more use than the majority of the stuff on the web. There seem to be a lot of people out there who can't tell the difference between a ribbon and a planar magnetic. Ribbons, by definition, are unnattached (except at the ends) in a transverse magnetic field, whereas planar magnetics are fixed at the sides and have a front-to-back magnetic field--usually supplied by multiple strips of magnets. Note that even some of the high-end manufacturers use the wrong terminology (e.g. Genesis referring to their tweeters as 'ribbons') because ribbons have such cachet in the market place, and the majority of consumers don't know the difference. You have been warned.

There are several problems to be overcome in a true ribbon driver:

1) Cost of the magnets--if you intend to do a long driver, you'll be spending hundreds on magnets alone

2) Cavity resonance--the fact that the membrane is down in a hole gives a peak in the response

3) Resistance--if you want a direct drive ribbon, you'll need very thin metal for the ribbon (probably aluminum, although there's no reason you can't use other metals--just watch out for mass), which leads to...

4) Availibility of ribbon material--aluminum measured in microns isn't easy to come by, although I did run across one hint that sounded interesting->use the aluminum foil off the back of gum wrappers

Since I wanted a line source midrange to match my Magneplanar ribbon (a true, direct-drive ribbon), I wanted to build something at least five feet long. I beat my head against the wall for a while, then gave up and bought a pair of Bohlender-Graebener RD-75's. Note that the RD-75's are planar magnetics, not true ribbons.

Planar magnetics are easier to build than true ribbons, but are subject to the same problems.

All that said, I have since acquired some magnet stuctures from mainframe disk drives with some prodigious magnets. I am considering building a more point-source oriented true ribbon more like the Orca Raven tweeters (using gum wrapper aluminum foil--anyone know what brand sounds best?...ahem...) as a rainy day project to go with a pair of transmission line midranges (something I've always wanted to try), and probably T-L woofers. For those who've never tried 'em, transmission line subs are capable of excellent sound reproduction, although I don't know whether they will do as well for midrange use.

Grey

I searched high and low for DIY ribbon information a few years ago. This is the only (semi-useful) link I found:

http://www.geocities.com/ResearchTriangle/8231/mag/index.html

If you've got a construction article, it may be of more use than the majority of the stuff on the web. There seem to be a lot of people out there who can't tell the difference between a ribbon and a planar magnetic. Ribbons, by definition, are unnattached (except at the ends) in a transverse magnetic field, whereas planar magnetics are fixed at the sides and have a front-to-back magnetic field--usually supplied by multiple strips of magnets. Note that even some of the high-end manufacturers use the wrong terminology (e.g. Genesis referring to their tweeters as 'ribbons') because ribbons have such cachet in the market place, and the majority of consumers don't know the difference. You have been warned.

There are several problems to be overcome in a true ribbon driver:

1) Cost of the magnets--if you intend to do a long driver, you'll be spending hundreds on magnets alone

2) Cavity resonance--the fact that the membrane is down in a hole gives a peak in the response

3) Resistance--if you want a direct drive ribbon, you'll need very thin metal for the ribbon (probably aluminum, although there's no reason you can't use other metals--just watch out for mass), which leads to...

4) Availibility of ribbon material--aluminum measured in microns isn't easy to come by, although I did run across one hint that sounded interesting->use the aluminum foil off the back of gum wrappers

Since I wanted a line source midrange to match my Magneplanar ribbon (a true, direct-drive ribbon), I wanted to build something at least five feet long. I beat my head against the wall for a while, then gave up and bought a pair of Bohlender-Graebener RD-75's. Note that the RD-75's are planar magnetics, not true ribbons.

Planar magnetics are easier to build than true ribbons, but are subject to the same problems.

All that said, I have since acquired some magnet stuctures from mainframe disk drives with some prodigious magnets. I am considering building a more point-source oriented true ribbon more like the Orca Raven tweeters (using gum wrapper aluminum foil--anyone know what brand sounds best?...ahem...) as a rainy day project to go with a pair of transmission line midranges (something I've always wanted to try), and probably T-L woofers. For those who've never tried 'em, transmission line subs are capable of excellent sound reproduction, although I don't know whether they will do as well for midrange use.

Grey

This is not exactly what you are looking for

but you might have a look at

http://www.proinco.net/staff/mogens/lafolia/

Greg

but you might have a look at

http://www.proinco.net/staff/mogens/lafolia/

Greg

Two quick comments on the site Greg posted:

1) As an alternative to cutting the aluminum foil with blades, it's easy to etch aluminum in much the same way that you'd do a circuit board. That way you could do a layout and make sure that the lines were straight before etching, whereas cutting tends to be an all-or-nothing process.

2) The bass membrane should be corrugated also. The corrugation is to prevent standing waves.

I once built a Magneplanar-style planar driver in an hour, simply by using a piece of plastic and gluing ordinary copper wire to it. It worked first time. (As well it should--the theory is simple enough!) I didn't pursue it, as the ribbon tweeter was the thing I was after at the time, not the bass panels. Anyway, the point is--don't be afraid to use copper wire in place of aluminum if the mood takes you.

Grey

1) As an alternative to cutting the aluminum foil with blades, it's easy to etch aluminum in much the same way that you'd do a circuit board. That way you could do a layout and make sure that the lines were straight before etching, whereas cutting tends to be an all-or-nothing process.

2) The bass membrane should be corrugated also. The corrugation is to prevent standing waves.

I once built a Magneplanar-style planar driver in an hour, simply by using a piece of plastic and gluing ordinary copper wire to it. It worked first time. (As well it should--the theory is simple enough!) I didn't pursue it, as the ribbon tweeter was the thing I was after at the time, not the bass panels. Anyway, the point is--don't be afraid to use copper wire in place of aluminum if the mood takes you.

Grey

Another thing I tried once that worked:

A friend managed to break the leads off of both ends of a Wondercap (metallized polypropylene) and was going to throw it away. I snagged it and threw it in my junk box. Later, I unwound the cap and cut various widths of membrane from it. For magnets, I used the big round ceramic magnets off the back of garden variety 12" woofers--two of them, oriented north to south with a wooden spacer.

Narrower mambranes give you higher R and greater efficiency, due to the magnetic field lines being able to bridge the gap more easily. (I did *not* try any sort of flux return bridging the outside poles of the magnets, but it wouldn't be hard to arrange.) They also give you better dispersion for higher frequencies.

Wider membranes move more air.

The way I had it rigged was as a true ribbon, i.e. fastened on the ends, unsupported in the middle, with the magnets on each side. It was easy to make and fun to play with. I may go back and piddle with it some more some day.

Grey

A friend managed to break the leads off of both ends of a Wondercap (metallized polypropylene) and was going to throw it away. I snagged it and threw it in my junk box. Later, I unwound the cap and cut various widths of membrane from it. For magnets, I used the big round ceramic magnets off the back of garden variety 12" woofers--two of them, oriented north to south with a wooden spacer.

Narrower mambranes give you higher R and greater efficiency, due to the magnetic field lines being able to bridge the gap more easily. (I did *not* try any sort of flux return bridging the outside poles of the magnets, but it wouldn't be hard to arrange.) They also give you better dispersion for higher frequencies.

Wider membranes move more air.

The way I had it rigged was as a true ribbon, i.e. fastened on the ends, unsupported in the middle, with the magnets on each side. It was easy to make and fun to play with. I may go back and piddle with it some more some day.

Grey

You may find the following two links handy when building ribbons

Copper Foil Tape (3M)

http://au.rs-c.dk/servlet/dk.stibo.module.ShowModuleServlet?moduleId=5035415

Clear polypropylene carton sealing tape

http://www.pro-am.com/Catalog/Exec/product.asp?product_id=686

might also be handy for DIY cables?

Copper Foil Tape (3M)

http://au.rs-c.dk/servlet/dk.stibo.module.ShowModuleServlet?moduleId=5035415

Clear polypropylene carton sealing tape

http://www.pro-am.com/Catalog/Exec/product.asp?product_id=686

might also be handy for DIY cables?

The Ribbon Loudspeaker Circuit

The following link may be of interest for you. There is some information on Ribbons there.

http://www.audiocircuit.com/9109-ribbon-circuit/9109IMAI.htm

The following link may be of interest for you. There is some information on Ribbons there.

http://www.audiocircuit.com/9109-ribbon-circuit/9109IMAI.htm

Ribbon DIY

I assembled a DIY Ribbon last month - look at "Lautsprecher" at http://www.michaelgaedtke.de/

I assembled a DIY Ribbon last month - look at "Lautsprecher" at http://www.michaelgaedtke.de/

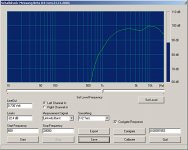

Here are some of my first measurements. Ribbon was driven with aktive 4th Order Linkwitz-Riley crossover at 1000 Hz for security reasons. Amplifier is current feedback type of own construction. Screenshots show step response and SPL, both measured with my soundcard without calibration. SPL is at 1 m on axis.

Here comes the SPL measurement (without calibration; this is not at 2.83 V/8 Ohm, which doesn't make much sense at som 0.1 Ohm).

Hi Michael,

They weren't lost, they hadn't cleared the queue yet. I have past one set and removed the other.

You are no longer under direct moderation so your posts and attachment will show up right away.

Cal

They weren't lost, they hadn't cleared the queue yet. I have past one set and removed the other.

You are no longer under direct moderation so your posts and attachment will show up right away.

Cal

hey micheal. Your website is empty on the link to your program. are you going to share it or use it comercially?

Bas

Bas

Step Response Software

Hi Bas,

sorry, but the program isn't ready yet. I'll have to debug some of the features.

Hi Bas,

sorry, but the program isn't ready yet. I'll have to debug some of the features.

Costs

Hi Promitheus,

costs were around 40 Euros per driver for my smaller tweeters with a 12 x 200 mm ribbon including some 25 Euros for the neodym magnets. The bigger ribbon at 20 x 200 mm needs more magnetic power and will cost around 60 Euros.

Hi Promitheus,

costs were around 40 Euros per driver for my smaller tweeters with a 12 x 200 mm ribbon including some 25 Euros for the neodym magnets. The bigger ribbon at 20 x 200 mm needs more magnetic power and will cost around 60 Euros.

That´s not bad.

60 Euro for a large ribbon is cool.

What do commercial ribbons use as foil?

Alufoil isnt the toughest material, nut ok it works.

Is there something better maybe metalized foils like in capacitors.

They are very thin and dont brake easy.

60 Euro for a large ribbon is cool.

What do commercial ribbons use as foil?

Alufoil isnt the toughest material, nut ok it works.

Is there something better maybe metalized foils like in capacitors.

They are very thin and dont brake easy.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- DIY Ribbon speakers ??