Hi all,

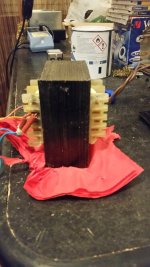

For several years now I have been making some power transformers myself to save money. However, in most cases what I notice is that with the current in steady state they make a sort of audible buzzing, which does not happen with factory transformers (possibly quality ones). Naturally, for the building I followed various theoretical sources, especially the dated ones of '40 or '50, and what I can deduce is perhaps that the winding machine I built for this purpose is too basic and does not allow very precise windings (wires tightly packed next to each other) and absolutely not loose. Could it be the vibration created by this col "looseness" is responsabile of the buzzing, especially when the transformer is working? Another mention could be the laminations not compacted correctly, but on this I have always tried to keep them as tight as possible in particular near the core.

For several years now I have been making some power transformers myself to save money. However, in most cases what I notice is that with the current in steady state they make a sort of audible buzzing, which does not happen with factory transformers (possibly quality ones). Naturally, for the building I followed various theoretical sources, especially the dated ones of '40 or '50, and what I can deduce is perhaps that the winding machine I built for this purpose is too basic and does not allow very precise windings (wires tightly packed next to each other) and absolutely not loose. Could it be the vibration created by this col "looseness" is responsabile of the buzzing, especially when the transformer is working? Another mention could be the laminations not compacted correctly, but on this I have always tried to keep them as tight as possible in particular near the core.

It helps to dip the lamination in varnish.

It reduces vibration which is likely the cause of the hum.

Hugo

It reduces vibration which is likely the cause of the hum.

Hugo

Usually I get them from transformers for UPS or audio equipment supplies that are not overly used.

Lately I've also tried a company from the north west here, specialized in transformers and related components (it's quite cheap after all).

Lately I've also tried a company from the north west here, specialized in transformers and related components (it's quite cheap after all).

get some popsicle sticks and wedge them in between core and bobbin.....then dip in polyurethane varnish...

make sure the vibrations are minimal before dipping, dipping can be done several times till you are rid of vibrations...

what I do with my transformer builds is to stick as many laminations that will fit, for this i use wooden mallets so as not to damage the laminations...

make sure the vibrations are minimal before dipping, dipping can be done several times till you are rid of vibrations...

what I do with my transformer builds is to stick as many laminations that will fit, for this i use wooden mallets so as not to damage the laminations...

the price of copper magnet wires has risen 300% since the pandemic, so making transformers has become expensive since 2020...Hi all,

For several years now I have been making some power transformers myself to save money. However, in most cases what I notice is that with the current in steady state they make a sort of audible buzzing, which does not happen with factory transformers (possibly quality ones). Naturally, for the building I followed various theoretical sources, especially the dated ones of '40 or '50, and what I can deduce is perhaps that the winding machine I built for this purpose is too basic and does not allow very precise windings (wires tightly packed next to each other) and absolutely not loose. Could it be the vibration created by this col "looseness" is responsabile of the buzzing, especially when the transformer is working? Another mention could be the laminations not compacted correctly, but on this I have always tried to keep them as tight as possible in particular near the core.

the windings themselves are fine, the core laminations are your issues and have not been packed tight..

get some popsicle sticks and wedge them in between core and bobbin.....then dip in polyurethane varnish...

make sure the vibrations are minimal before dipping, dipping can be done several times till you are rid of vibrations...

what I do with my transformer builds is to stick as many laminations that will fit, for this i use wooden mallets so as not to damage the laminations...

Some time ago I bought an insulating spray but it is more suitable for printed circuits than for reducing mechanical vibrations.

I guess that the product you say has a certain viscosity. Here I found a product called Elmotherm (with or without its thinner) , I don't know if it's polyurethane based but that man who works for transformers uses it. Maybe I'll try asking him

this is how i do my completed transformer, after verifying the transformer I built, I dip in a tub full of varnish, let is soak for a while until bubbles are gone. then lift to drip and then dip it again, the process takes about help an hour..

Attachments

Nice dipping Tony, a good transormer soup....How long are the final drying and hardening times (to be usable)?

It's a clever trick the household vacuum container...It can be useful since here now we have 8°C outdoor (so I'd have to wait the warm season).

Yet, if I use a black painted transformer with its bells after removing them I should beware a coloured varnish. Anyway from your pics it seems to be transparent so could not be a problem...

Yet, if I use a black painted transformer with its bells after removing them I should beware a coloured varnish. Anyway from your pics it seems to be transparent so could not be a problem...

Ah ok, I have seen a video on the tube where a man attempted to restore an old buzzing transforner with a glossy transparent finish (for wood). I thing it was synthetic, the brand was DEFT.

I did a test with a monocomponent polyurethane varnish, the one for boat coating... However, I didn't completely dip it as you previously suggested but I "soaked" it with a brush after having loosened the lamination core (removed a couple of them) and then I held it tight a daylong using clamps.

The result seems good for now, although it is not bolted, it is completely silent. I'll have to try it with the power running

The result seems good for now, although it is not bolted, it is completely silent. I'll have to try it with the power running

Attachments

Plus one for the vacuum marinator trick. Vacuum impregnating is old technique and will give much better penetration of varnish int windings and laminations.

Update on the transformer situation when it operates...

As usual with no load, absolutely zero buzzing, when the current starts to flow on the KT88 (evident by the LEDs on the cathode of the drivers turning on) the noise is present although overall low.

Before the modification I had noticed that adding an RC filter downstream of the first CLC slightly increased the noise. I should maybe try removing it and see. I was also wondering if the diodes used could possibly be responsible, they are IN5408.

Last thing, now I got the epoxy resin DUROGLASS P5/1 LV,, Maybe it's worth a try on the transformer, this time dipping it thorough bobbing included...

As usual with no load, absolutely zero buzzing, when the current starts to flow on the KT88 (evident by the LEDs on the cathode of the drivers turning on) the noise is present although overall low.

Before the modification I had noticed that adding an RC filter downstream of the first CLC slightly increased the noise. I should maybe try removing it and see. I was also wondering if the diodes used could possibly be responsible, they are IN5408.

Last thing, now I got the epoxy resin DUROGLASS P5/1 LV,, Maybe it's worth a try on the transformer, this time dipping it thorough bobbing included...

- Home

- Amplifiers

- Power Supplies

- DIY power tranformers and buzzing