I like the idea but IMO the idler wheel should be between the motor and the platter so it erases motor vibrations.

Wouldn't really help unless the idler is heavy with lots of rotational inertia; might as well put that in theplatter itself. The idea is to keep the belt from pulling sideways on the platter bearing.

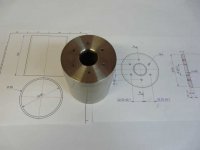

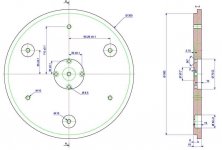

I'll start "big mecanical work", the main rotating plate, first part:

Will this be done with a CNC machine Doitmyself.

Unfortunately not. It's even much more complicated than this. I'll take photos while realising this piece, because I don't want to use a big raw material.Will this be done with a CNC machine Doitmyself.

You'll understand soon.

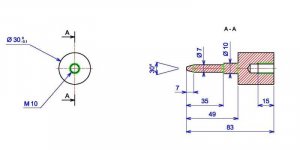

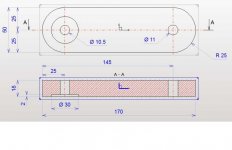

Today, I have done the tangential tonearm support. And I also got the screws, and o'rings. Big day today, don't know if I'll have time to start mounting, if not, tomorrow morning while everyone's sleeping.

Attachments

O-rings? Now I'm scared. Are these just for mounting w/ isolation?

I want to see whether the arm tracks; whether the groove will actually overcome friction and move smoothly with a light-tracking compliant cartridge needle pulling it. I'd have thought you'd throw together a proof-of-concept experiment first.

I want to see whether the arm tracks; whether the groove will actually overcome friction and move smoothly with a light-tracking compliant cartridge needle pulling it. I'd have thought you'd throw together a proof-of-concept experiment first.

O-rings? Now I'm scared. Are these just for mounting w/ isolation?

Yes only for isolating metallic pieces from granite platters

QUOTE]

O-rings?

I'd have thought you'd throw together a proof-of-concept experiment first.

Yes you're right, but for that, I need a base which is the mains platters (granite) and rotating unit.

The tonearms will come later.

OK. First impression: I'm not happy with the result. The rotation is a little bit hard. I thought it will be but not this way.

So I decide to dismantle all and take out the oil seals. Mount again and then much more better. Turns easyly. And the mecanical adjustments are perfect. Instead oh oil, I have filled with grease. Seams not bad, no noise, I'm really happy.

So I decide to dismantle all and take out the oil seals. Mount again and then much more better. Turns easyly. And the mecanical adjustments are perfect. Instead oh oil, I have filled with grease. Seams not bad, no noise, I'm really happy.

OK. First impression: I'm not happy with the result. The rotation is a little bit hard. I thought it will be but not this way.

So I decide to dismantle all and take out the oil seals. Mount again and then much more better. Turns easyly. And the mecanical adjustments are perfect. Instead oh oil, I have filled with grease. Seams not bad, no noise, I'm really happy.

I did read today that dr.Feickert Analogue uses grease in the woodpecker TT. See the drivebelt maybe a good idea.

An externally hosted image should be here but it was not working when we last tested it.

Yes Helmuth, this idea is a good option, not applicable in my case because of the price of the servo motor and servodrive. That's why I used 2 spaced bearings, instead of a copper bush on top. I think that contact surface is higher with a bush than a bearing (that's my opinion, I can be wrong).

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Personal Turntable