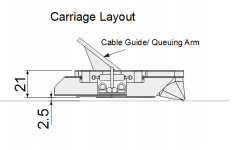

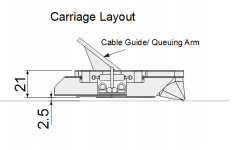

As I have eliminated the armtube in my design I don't have anywhere at the rear of my arm on which to press down. For my cueing device I have added an additional tube that doubles as a cable guide. The cueing mechanism is a cam that runs parallel to the rail. The cam has a 3mm rod glued to the inside of a 10mm tube. The outside of the tube is covered with heat-shrink to give a bit of grip to make cueing easier and safer and to damp the tube. The cueing mechanism can be adjusted by changing the angle that the cueing lever is attached to the 3mm rod.

Niffy

Niffy

Good evening gents,

So i currently have Origin live Aurora mkIV turntable and Onyx arm with a Rega Ania cartridge.

Would anyone hazard a guess as to whether one of these project arms would better that set up please? -any comparisons and descriptions would be interesting as well!

So i currently have Origin live Aurora mkIV turntable and Onyx arm with a Rega Ania cartridge.

Would anyone hazard a guess as to whether one of these project arms would better that set up please? -any comparisons and descriptions would be interesting as well!

So Niffy, the whole tube is cam shaped? That looks like a beautifully simple solution and I think I could probably embody a variation of that. My protoype takes about two minutes to remove from the TT as I suspected it would be a work in progress.

That's a lovely bit of engineering there by the way!

That's a lovely bit of engineering there by the way!

Hi Apache100,

The tube is just a plain round tube, 10mmOD-8mmID. The 3mm axle is epoxy glued to the inside of this tube. The center of the tube will be 2.5mm from the center of the axle so it acts as a cam.

The amount the stylus is lifted from the groove is adjusted by changing the angle of the cam to the lever. The lever is super simple. It is a short piece of 8mm round bar that is internally threaded 3mm all the way through. It also has a 3mm hole drilled through sideways which takes the axle. Two 3mm bars, with the ends treaded, screw into the 8mm bar to lock it to the axle. A single 4mm bar acts as an end stop for both the raised and lowered positions.

View attachment 852582

Niffy

The tube is just a plain round tube, 10mmOD-8mmID. The 3mm axle is epoxy glued to the inside of this tube. The center of the tube will be 2.5mm from the center of the axle so it acts as a cam.

The amount the stylus is lifted from the groove is adjusted by changing the angle of the cam to the lever. The lever is super simple. It is a short piece of 8mm round bar that is internally threaded 3mm all the way through. It also has a 3mm hole drilled through sideways which takes the axle. Two 3mm bars, with the ends treaded, screw into the 8mm bar to lock it to the axle. A single 4mm bar acts as an end stop for both the raised and lowered positions.

View attachment 852582

Niffy

The attachment doesn't work for me, but I get what you mean. It can naturally have an 'overcentre' lock so the carriage can't fall while you slide it back, which is an enormous relief because operating this thing by hand is terrifying!

I really should use the conventional arm until I have a lifter, but I've been smitten with the very different sound quality of this arm. Hard to put into words, and I'm not one for superlatives, but it's so much better.

I've been re-reading the thread and have a lot of things to try in the Mk2. I would value opinions pertaining to arm length. Practically, a longer arm wand makes sense from a useability perspective as the rail can live beyond the platter, but the shorter arm / sled would appear to my gut-feelings to have a more easily controllable resonance characteristic.

I'm sure all of these things have been discussed before, but opinions and reasoning based on the current knowledge would be welcome.

I really should use the conventional arm until I have a lifter, but I've been smitten with the very different sound quality of this arm. Hard to put into words, and I'm not one for superlatives, but it's so much better.

I've been re-reading the thread and have a lot of things to try in the Mk2. I would value opinions pertaining to arm length. Practically, a longer arm wand makes sense from a useability perspective as the rail can live beyond the platter, but the shorter arm / sled would appear to my gut-feelings to have a more easily controllable resonance characteristic.

I'm sure all of these things have been discussed before, but opinions and reasoning based on the current knowledge would be welcome.

Good evening gents,

So i currently have Origin live Aurora mkIV turntable and Onyx arm with a Rega Ania cartridge.

Would anyone hazard a guess as to whether one of these project arms would better that set up please? -any comparisons and descriptions would be interesting as well!

In a word YES. I had a Rega RP8 and Apheta 2, My Technics EPA100 arm and EPC205 cartridge is better than the Rega. The first LTA I built was better again mainly in bass response.

Give it a go. Although I think the Ania will not be a good match if its compliance is very low like the Apheta. Low comp cartridges induce a lot of resonance into the tonearm.

A medium to high compliance cart will be better.

I've been re-reading the thread and have a lot of things to try in the Mk2. I would value opinions pertaining to arm length. Practically, a longer arm wand makes sense from a useability perspective as the rail can live beyond the platter, but the shorter arm / sled would appear to my gut-feelings to have a more easily controllable resonance characteristic.

I'm sure all of these things have been discussed before, but opinions and reasoning based on the current knowledge would be welcome.

The first bending mode of the arm is proportional to its length, so a shorter arm will push this higher in frequency. Stiffness will attenuate the resonance.

My current carriage is identical to Niffy's, using the same Stanton 881s as I had fitted to my first LTA which used an 8mm carbon fibre rod filled with balsa, total length on the rod was 120mm. Not a great difference in total length 20mm infact. Niffy's carriage is significantly better in resonance control, this is clearly audible as bass articulation and fine detail. My only problem is it's too heavy for the 881s and miss tracks on off centre pressings.

From my investigations I have come the conclusion that the greatest source of colouration in a turntable is due to the bending mode resonances of the armtube. Ideally you want the arm to be as stiff as possible with the first resonant mode as high in frequency as possible. With a conventional tonearm with a long armtube there is only so much that can be done (material choices and profile). Even the best conventional arms, like the 20k+ SAT, have a resonant frequency of less than 5khz. Most arms have a resonant frequency less than 500hz which means that there will be loads of harmonic modes within the audio band. By making the arm shorter you massively increase its rigidity. A tube half as long is 8 times as rigid, a quarter the length 64 times. All the same tricks of material choice and profile can still be used. By using a very short arm the first resonant mode can easily be pushed to over 10khz which will result in no harmonics in the audio band. Plus high frequencies are easier to damp.

Using a very short armtube dictates that the arm has to be linear tracking. (Dynavector split plane not withstanding). This can give the additional benefit of reduced lateral tracking error.

There are a couple of downsides to using a very short armtube. First off the rail the arm runs on will need to be over the record and ideally close to it. This will make changing records more involved. You compromise ease of use for improved sound quality. The next problem with a short arm is that they are more sensitive to warps. A good warp flattening clamp is essential. The final problem is getting a bearing system that has low enough lateral friction. This is a difficult problem to get right as bearing friction can result in almost as much LTA error as seen in a conventional arm. Even if you do have a bit of LTA error you will still have the advantages of the short arm so the arm will probably still sound better.

Niffy

Using a very short armtube dictates that the arm has to be linear tracking. (Dynavector split plane not withstanding). This can give the additional benefit of reduced lateral tracking error.

There are a couple of downsides to using a very short armtube. First off the rail the arm runs on will need to be over the record and ideally close to it. This will make changing records more involved. You compromise ease of use for improved sound quality. The next problem with a short arm is that they are more sensitive to warps. A good warp flattening clamp is essential. The final problem is getting a bearing system that has low enough lateral friction. This is a difficult problem to get right as bearing friction can result in almost as much LTA error as seen in a conventional arm. Even if you do have a bit of LTA error you will still have the advantages of the short arm so the arm will probably still sound better.

Niffy

Absolutely awesome! So when these headed out in kit form? ������

Very impressive!

Very impressive!

Many thanks for your thoughts, the Ania is relatively new, as are the OL components, but i would be interested to work on an arm for comparison, but don't currently feel i can invest in a new cartridge to do that. i cannot find any compliance figures for Regas at all, is the Ania a non starter please?In a word YES. ...............Give it a go. Although I think the Ania will not be a good match if its compliance is very low like the Apheta. Low comp cartridges induce a lot of resonance into the tonearm.

By using a very short arm the first resonant mode can easily be pushed to over 10khz which will result in no harmonics in the audio band. Plus high frequencies are easier to damp.

Using a very short armtube dictates that the arm has to be linear tracking. (Dynavector split plane not withstanding). This can give the additional benefit of reduced lateral tracking error.

The next problem with a short arm is that they are more sensitive to warps. A good warp flattening clamp is essential. The final problem is getting a bearing system that has low enough lateral friction. This is a difficult problem to get right as bearing friction can result in almost as much LTA error as seen in a conventional arm. Even if you do have a bit of LTA error you will still have the advantages of the short arm so the arm will probably still sound better.

Niffy

Yes, makes perfect sense. That was my gut feeling regarding length. My day job is EMC / RF and resonance works in similar ways though in a different medium 😉

I actually built an arm using the split plane philosophy, but transferred the tracking force to the rear of the arm using levers and fishing line! It worked OK, and is something I'll return to one day, just for fun.

It seems in the course of the thread you guys have managed to design wheel / rail systems which reduce friction as much as practicable, so hopefully LT error isn't a big issue with a decent wheel design.

Looking forward to getting started on my next version - the first one was built in haste just so I could cut my teeth with one, but there is definitely a hint of magic even with mine. I suspect you're right about the short arm being best though, as I am finding the low end very different to any conventional pivoted arm I've ever heard.

Many thanks for your thoughts, the Ania is relatively new, as are the OL components, but i would be interested to work on an arm for comparison, but don't currently feel i can invest in a new cartridge to do that. i cannot find any compliance figures for Regas at all, is the Ania a non starter please?

Hi Mike,

I'm not the best to ask about Rega as I have had very poor experience with Rega products. My previous TT was an RP8 / Apheta bought new and the Apheta fell apart after less than 20hrs out of warranty Rega's fix was to upgrade me to the Apheta 2 for another $2000, so far total investment $7500 and the rig never sounded better than my digital setup.

I had a AT95 (actually a Linn K9) with an LPGear he stylus and it out performed the Apheta 2 in the RP8. Rega do not publish useful specs for any of their gear so using a Rega cartridge in another arm is hit and miss.

Give it a go and see where it ends up. Just keep in mind what Niffy said about arm wand stiffness. If you use carbon fibre rod 8mm with 1mm wall thickness running on pyrex rod/tubes would be the go.

Looking forward to getting started on my next version - the first one was built in haste just so I could cut my teeth with one, but there is definitely a hint of magic even with mine. I suspect you're right about the short arm being best though, as I am finding the low end very different to any conventional pivoted arm I've ever heard.

That's what I found, I did a back to back with my first LTA and Technics EPA100 using the same EPC205 cartridge and where the LTA shone was in bass response. Really noticeable on bass guitar playing in the lower register.

Thanks for responses.Hi Mike,

I'm not the best to ask about Rega as I have had very poor experience with Rega products. My previous TT was an RP8 / Apheta bought new and the Apheta fell apart after less than 20hrs out of warranty Rega's fix was to upgrade me to the Apheta 2 for another $2000, so far total investment $7500 and the rig never sounded better than my digital setup.

Your experience was disappointing to say the least, i replaced a Rega 3 etc with the OL/Ania, did some other work on isolation at the same time and the OL results were noticeably better, trouble is it was a change in several areas all at the same time. my vinyl is clearly better in terms of getting life out the music than my FLAC based alternative, i think the OL part is a good contributor to that, good kit in my view.

If i could get more, even better, if there is one thing i would like its reduced surface noise and there is some suggestion LT would help there?

I had a AT95 (actually a Linn K9) with an LPGear he stylus and it out performed the Apheta 2 in the RP8. Rega do not publish useful specs for any of their gear so using a Rega cartridge in another arm is hit and miss.

It works well enough in the OL arm, so one can hope?

Give it a go and see where it ends up. Just keep in mind what Niffy said about arm wand stiffness. If you use carbon fibre rod 8mm with 1mm wall thickness running on pyrex rod/tubes would be the go.

I have looked at lots in this thread, what are the simplest/best bearing/wheels currently thought to be please. which post might show a current best thought start point?

I found surface noise was reduced with the LTA over the pivoting arm. This is most likely due to short LTA arm wand not resonating. I also found surface noise reduced again with a micro line diamond over a shibata.

The twin tube 2 bearing rail starts here

https://www.diyaudio.com/forums/analogue-source/238027-diy-linear-tonearm-137.html#post3801558

A good starting point for a basic LTA.

Bearings MR104 is what I used, you can get them open with no shield, this makes it easier to clean out the grease. I warmed them in a frying pan to melt the grease then soaked them in IPA until they spun freely. I then picked out the best 2.

Rail 4mm pyrex rods/tubes. Glue this to a bit of 25x25x3mm aluminium angle to make the rail. If you use rods then fill the rods with silicon so they don't ring. Glue the rods to the aluminium with Araldite.

The twin tube 2 bearing rail starts here

https://www.diyaudio.com/forums/analogue-source/238027-diy-linear-tonearm-137.html#post3801558

A good starting point for a basic LTA.

Bearings MR104 is what I used, you can get them open with no shield, this makes it easier to clean out the grease. I warmed them in a frying pan to melt the grease then soaked them in IPA until they spun freely. I then picked out the best 2.

Rail 4mm pyrex rods/tubes. Glue this to a bit of 25x25x3mm aluminium angle to make the rail. If you use rods then fill the rods with silicon so they don't ring. Glue the rods to the aluminium with Araldite.

I found surface noise was reduced with the LTA over the pivoting arm. This is most likely due to short LTA arm wand not resonating. I also found surface noise reduced again with a micro line diamond over a shibata.

The twin tube 2 bearing rail starts here

https://www.diyaudio.com/forums/analogue-source/238027-diy-linear-tonearm-137.html#post3801558

A good starting point for a basic LTA.

Bearings MR104 is what I used, you can get them open with no shield, this makes it easier to clean out the grease. I warmed them in a frying pan to melt the grease then soaked them in IPA until they spun freely. I then picked out the best 2.

Rail 4mm pyrex rods/tubes. Glue this to a bit of 25x25x3mm aluminium angle to make the rail. If you use rods then fill the rods with silicon so they don't ring. Glue the rods to the aluminium with Araldite.

Many thanks indeed! - i see lots of variants have been tried, i think i had better read a lot more of the thread or i will repeat mistakes others with much more knowledge already resolved!! - current pics i see from Niffy he has moved to single point of contact on each of the wheels, presumably he developed on from the previous one with benefit?

Hi Mike,

"If i could get more, even better, if there is one thing i would like its reduced surface noise and there is some suggestion LT would help there?"

The typical size of the dust motes found in the grooves of records is in the range of 3-10um. The average linear speed of the record past the stylus is around 100,000um per second. Any individual dust mote will be come and gone in a tiny fraction of a second, less than a millisecond. The impact with dust creates a short sharp impulse that's equivalent to half a cycle of a 3-10khz waveform. By itself this is completely inaudible. The Impulse still puts a lot of energy into the system sending waves into the arm and platter. What you actually hear as surface noise is mainly your arm "ringing" in response to the impact with the dust.

The main advantage of the linear tracking arm is that you can have a very short armtube. As previously mentioned having a short arm increases its rigidity and pushes, resonant frequency much higher and is easier to damp. This means that the arm is much less likely to be excited into ringing, the resonant frequency being above the impulse frequency.

The groove modulation also excites the arm to ring but to a lesser extent. Having a less resonant arm will result in lower colouration in the same way that it results in lower surface noise.

Niffy

"If i could get more, even better, if there is one thing i would like its reduced surface noise and there is some suggestion LT would help there?"

The typical size of the dust motes found in the grooves of records is in the range of 3-10um. The average linear speed of the record past the stylus is around 100,000um per second. Any individual dust mote will be come and gone in a tiny fraction of a second, less than a millisecond. The impact with dust creates a short sharp impulse that's equivalent to half a cycle of a 3-10khz waveform. By itself this is completely inaudible. The Impulse still puts a lot of energy into the system sending waves into the arm and platter. What you actually hear as surface noise is mainly your arm "ringing" in response to the impact with the dust.

The main advantage of the linear tracking arm is that you can have a very short armtube. As previously mentioned having a short arm increases its rigidity and pushes, resonant frequency much higher and is easier to damp. This means that the arm is much less likely to be excited into ringing, the resonant frequency being above the impulse frequency.

The groove modulation also excites the arm to ring but to a lesser extent. Having a less resonant arm will result in lower colouration in the same way that it results in lower surface noise.

Niffy

Hi Mike,

The groove modulation also excites the arm to ring but to a lesser extent. Having a less resonant arm will result in lower colouration in the same way that it results in lower surface noise.

Niffy

Many thanks Niffy, the principle appeals!- i shall continue to read and see if that energy grows enough to build something!

Any thoughts please as to whether my Rega Ania has compliance that will negate the possible gains?

many thanks

Mike

Hi Mike,

I can't find any reference as to the compliance of your cartridge. As it's an mid level moving coil I would guess that it probably has a compliance around 15-16um/mN as this seems to be the most common rating. It might not be.

The advantage of high compliance is that less energy is transmitted to the arm which means that the arm will vibrate less.

The advantage of a low compliance cartridge is that the lateral tracking error due to bearing friction will be less. I am using a high compliance cartridge, 2M black 22um/mN, and have very very low lateral tracking error due to bearing friction. Warrjon has a cartridge with a compliance of 30um/mN and has been having some tracking problems.

Most compliances can be made to work just fine with a mechanical linear arm as long as care is taken to minimise lateral bearing friction.

I doubt that the Ania is very high compliance as if it were one of the reviews would have mentioned it.

Niffy

I can't find any reference as to the compliance of your cartridge. As it's an mid level moving coil I would guess that it probably has a compliance around 15-16um/mN as this seems to be the most common rating. It might not be.

The advantage of high compliance is that less energy is transmitted to the arm which means that the arm will vibrate less.

The advantage of a low compliance cartridge is that the lateral tracking error due to bearing friction will be less. I am using a high compliance cartridge, 2M black 22um/mN, and have very very low lateral tracking error due to bearing friction. Warrjon has a cartridge with a compliance of 30um/mN and has been having some tracking problems.

Most compliances can be made to work just fine with a mechanical linear arm as long as care is taken to minimise lateral bearing friction.

I doubt that the Ania is very high compliance as if it were one of the reviews would have mentioned it.

Niffy

The advantage of a low compliance cartridge is that the lateral tracking error due to bearing friction will be less.

Niffy

Mass issues aside, a low compliance cartridge will show less sideways deflection of the cantilever, but that does not mean the problem went away. Even if you no longer see the effects on the cantilever, the sideways forces are still there and rob effective VTF from one groove wall or the other depending on which direction the eccentricity is going.

Ray K

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm