The spinorama listening window isn't that important from a design point of view. Are you getting into measuring, tmuikku?at least listening window

No its not first but I'm not too pro on this. Listening window is about +-15 degrees or how you what you want to make it, some span that would cover typical listening situation at ones premises. This is to spot diffraction for example, that can make quite heavy dip on-axis and it changes fine at some small angle to side and then a little bit more further out off-axis goes to a peak. Anyway, measuring at least few additional responses even a little outside the main listening axis, if not full spinorama, would help evaluate what can be EQ:d and what cannot be in comparison measuring the listening axis only. Full spinorama would show power response for example, which would further help decisions on the crossover, to estimate in room response. Full data would help to find the best listening axis, many things visualized to help judge the performance.

In my view, the OP has shown that he's got a "good enough" measurement simply by looking at the phase response plot that he posted. He asked about phase response of his SH-50 clone, and I think he already got his answer. It certainly doesn't take 10s or 100s of replies beyond that. Conversing endlessly on measurement techniques doesn't change that.

If you want to ask the OP about his MEH design details and decisions, I recommend doing just that--not rehashing measurement techniques because "that's where the street light seems brightest to look for your keys".

Chris

If you want to ask the OP about his MEH design details and decisions, I recommend doing just that--not rehashing measurement techniques because "that's where the street light seems brightest to look for your keys".

Chris

Problem with only single frequency response measurement is that it does not represent the in-room response (in general) and can contain issues that are not meaningful to adjust with EQ, or vice versa hides issues that could be EQ:d. Perhaps for the OP application and given the narrow dispersion of such construct single measurement is fine. You are right this info is all over the forum so no point rehashing it here, Allen asked and got answers 😉

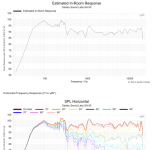

edit. Erin has measured SH50 here https://www.erinsaudiocorner.com/loudspeakers/danley_sh50/

If one compares on-axis response to the Estimated In Room response they look almost the same on a quick glimpse. Perhaps single measurement is enough in case of the particular speaker.

edit. Erin has measured SH50 here https://www.erinsaudiocorner.com/loudspeakers/danley_sh50/

If one compares on-axis response to the Estimated In Room response they look almost the same on a quick glimpse. Perhaps single measurement is enough in case of the particular speaker.

Attachments

Last edited:

To the OP: if you want to stiffen up the entire box, Danley uses through bolts and pre-stresses everything (tension) such that the entire box/horn is very inert and non-resonant. There are long Allen head countersunk bolts and Allen head end ("tee") nuts attaching from the inside of their horns to the outside of the box--significantly strengthening and stiffening the assembly without adding weight, shown below in red color (that I added to the photos):

The countersunk bolts don't detract from the acoustic performance of the horn, because they're too small and too far away from the throat to be acoustically relevant.

The woofers in an SH-50 are on the top and bottom of the horn (symmetrical at 50 degrees coverage, but with flat/level top and bottom sides. It's tight inside the box, however, and they add an extra access port per top and bottom near the front of the box to be removable such that the box can be disassembled/reassembled from the horn without clearance problems with the woofers. I think they make it so tight so they can array these in side-to-side top-to-bottom bunches for arenas, etc.

Chris

The countersunk bolts don't detract from the acoustic performance of the horn, because they're too small and too far away from the throat to be acoustically relevant.

The woofers in an SH-50 are on the top and bottom of the horn (symmetrical at 50 degrees coverage, but with flat/level top and bottom sides. It's tight inside the box, however, and they add an extra access port per top and bottom near the front of the box to be removable such that the box can be disassembled/reassembled from the horn without clearance problems with the woofers. I think they make it so tight so they can array these in side-to-side top-to-bottom bunches for arenas, etc.

Chris

Last edited:

Thanks for pointing this out! I was struggling to find a good mounting system that didn't depend on tons of wood screws and still be serviceable. I like how the design leverages geometry to self-support and stiffen the box system.To the OP: if you want to stiffen up the entire box, Danley uses through bolts and pre-stresses everything (tension) such that the entire box/horn is very inert and non-resonant. There are long Allen head countersunk bolts and Allen head end ("tee") nuts attaching from the inside of their horns to the outside of the box--significantly strengthening and stiffening the assembly without adding weight, shown below in red color (that I added to the photos):

The countersunk bolts don't detract from the acoustic performance of the horn, because they're too small and too far away from the throat to be acoustically relevant.

The woofers in an SH-50 are on the top and bottom of the horn (symmetrical at 50 degrees coverage, but with flat/level top and bottom sides. It's tight inside the box, however, and they add an extra access port per top and bottom near the front of the box to be removable such that the box can be disassembled/reassembled from the horn without clearance problems with the woofers. I think they make it so tight so they can array these in side-to-side top-to-bottom bunches for arenas, etc.

Chris

I appreciate this advice and the logic behind it. I've never analyzed a speaker in great depth and would like to gain more understanding of the process to aid with the subsequent builds. Hopefully Ill get a chance to get some extra measurements this weekend and share the individual high, mid, low testsCertainly, lets see how the thread evolves, nugget of info at a time 🙂 Measuring at least listening window and perhaps even 0-180 would help. It is symmetric device so full set of measurements is just 0-180, input them to VituixCAD and bam, graphs to see what should and what should not be EQd.

Prototype #1

Incorrect bevels, incorrect amp for the CD, particleboard, terrible craftsmanship, but it was great for feasibility testing and part selection. Five prototypes later.....

Im probably going to replace the 5" Pyles of Sh#$ with some sealed back 6.5" Eminence drivers and replace the PRV CD with Faital Pro HF108's. This pair of speakers is going to be used for marathon outdoor DJ sets and pushed hard.

Incorrect bevels, incorrect amp for the CD, particleboard, terrible craftsmanship, but it was great for feasibility testing and part selection. Five prototypes later.....

Im probably going to replace the 5" Pyles of Sh#$ with some sealed back 6.5" Eminence drivers and replace the PRV CD with Faital Pro HF108's. This pair of speakers is going to be used for marathon outdoor DJ sets and pushed hard.

Last edited:

Hey there, just going through the thread and noticed that you mentioned a 48db/Oct hipass on the CD. Not sure if it's worth reworking the xo, but if you were after better phase response switching to a 12db -18db co would help a lot. If I remember correctly you need an extra order on the summed hipass to match the phase offset of the mid driver lowpass (+90 Deg phase rotation at xo), whereas you have an extra ~3-4 orders or so

Not sure if that's 100% correct, but believe it is.

Not sure if that's 100% correct, but believe it is.

This was a great tip and I ended up using this bolt pattern in our final build. Its obvious in hindsight , but I initially failed to realize that the cabinet parallels the inside horn perfectly so the bolts are normal to the sides. Its super secure and I don't see any need for baffling/filling material now.To the OP: if you want to stiffen up the entire box, Danley uses through bolts and pre-stresses everything (tension) such that the entire box/horn is very inert and non-resonant. There are long Allen head countersunk bolts and Allen head end ("tee") nuts attaching from the inside of their horns to the outside of the box--significantly strengthening and stiffening the assembly without adding weight, shown below in red color (that I added to the photos):

The countersunk bolts don't detract from the acoustic performance of the horn, because they're too small and too far away from the throat to be acoustically relevant.

The woofers in an SH-50 are on the top and bottom of the horn (symmetrical at 50 degrees coverage, but with flat/level top and bottom sides. It's tight inside the box, however, and they add an extra access port per top and bottom near the front of the box to be removable such that the box can be disassembled/reassembled from the horn without clearance problems with the woofers. I think they make it so tight so they can array these in side-to-side top-to-bottom bunches for arenas, etc.

Chris

Last edited:

Just put one up!Nice. Do you have any pictures of the bolt arrangement?

A couple of photo updates of the clones in action this summer...

OHello and thanks for tuning in to this thread. This is my first speaker build and post on the forum, so please excuse my ignorance of some of the finer points of speaker design.

This prototype build is a tri-amp clone of the Danley Sh-50 with active DSP processing. My goal is to get 60hz to 16khz with a pretty flat response and operate around 130dBc @ 1m.

So far everything is working great at the desired volumes but I would like to improve the phase of the speaker and maybe get some feedback on ways I can improve this build before I commit to building the final pair in 3/4 Birch. Any comments are appreciated!

***

Attached is a picture of the SPL/ Phase response in REW, measured at the center of the horn opening with calibrated levels and RTA mic.

XO: CD (HP -48 Linkw @1350hz), MIds (-12db Butter Low Pass @ 1350hz and HP -12 DB Butter @ 350hz), Sub (HP -48 Linkw @ 60hz and LP -48 Linkw @350hz)

EQ: Peak EQ boost at each XO q=1 +8db

Build parts list:

3/4 MDF

Ashly Protea SP 4.8 DSP

PRV 290PYS

4x Pyle 5" Sealed Mids

2x Faital 12FH510

Amps:

EV CP1200 - CD

EV CP2200 - Mids

EV CP3000 - Sub

View attachment 1032714View attachment 1032715View attachment 1032716

hello!Hello and thanks for tuning in to this thread. This is my first speaker build and post on the forum, so please excuse my ignorance of some of the finer points of speaker design.

This prototype build is a tri-amp clone of the Danley Sh-50 with active DSP processing. My goal is to get 60hz to 16khz with a pretty flat response and operate around 130dBc @ 1m.

So far everything is working great at the desired volumes but I would like to improve the phase of the speaker and maybe get some feedback on ways I can improve this build before I commit to building the final pair in 3/4 Birch. Any comments are appreciated!

***

Attached is a picture of the SPL/ Phase response in REW, measured at the center of the horn opening with calibrated levels and RTA mic.

XO: CD (HP -48 Linkw @1350hz), MIds (-12db Butter Low Pass @ 1350hz and HP -12 DB Butter @ 350hz), Sub (HP -48 Linkw @ 60hz and LP -48 Linkw @350hz)

EQ: Peak EQ boost at each XO q=1 +8db

Build parts list:

3/4 MDF

Ashly Protea SP 4.8 DSP

PRV 290PYS

4x Pyle 5" Sealed Mids

2x Faital 12FH510

Amps:

EV CP1200 - CD

EV CP2200 - Mids

EV CP3000 - Sub

View attachment 1032714View attachment 1032715View attachment 1032716

Could you share the plans of the speaker?

I would like to build my own so i would gladly pay for it as well.

My email address: pappdani7@gmail.com

Thank you very much!

Hey out of respect for Danley and their patented designs, I won't share the exact plans. I will answer any questions you have so you can design your own!O

hello!

Could you share the plans of the speaker?

I would like to build my own so i would gladly pay for it as well.

My email address: pappdani7@gmail.com

Thank you very much!

Final driver and amp configuration:

1 x Faital Pro HF144 - XO@1khz

4 x Pyle PDMR5, xo @ 1Kz and 350hz

2 x Faital Pro 12HF5010, xo @ 350hz and 50hz

1 x Dynacord CL800

1 x EV CP2200

1 x EX TG-7

We played with each XO slope until square waves were represented as accurately as possible at the XO frequency

1 x Faital Pro HF144 - XO@1khz

4 x Pyle PDMR5, xo @ 1Kz and 350hz

2 x Faital Pro 12HF5010, xo @ 350hz and 50hz

1 x Dynacord CL800

1 x EV CP2200

1 x EX TG-7

We played with each XO slope until square waves were represented as accurately as possible at the XO frequency

I understand. Could you give the drawn distances and diameters then?Hey out of respect for Danley and their patented designs, I won't share the exact plans. I will answer any questions you have so you can design your own!

Thank you very much!

Attachments

It might be worth a phone call to Misco to get the real midranges from the SH-50. I have the PDMR5s and the JC5RTF-Bs and the real ones (the latter) work better. The cone of the Pyle is foam and the cone is treated. This leads to a higher QMS than you want. IIRC, the efficiency is quite a bit lower too.

An issue that I've consistently had with using conventional midranges with a foam or rubber sound in a Unity horn is that the surrounds get ruined.

Basically the accordion surrounds of the Misco driver won't get trashed because they're flat.

An issue that I've consistently had with using conventional midranges with a foam or rubber sound in a Unity horn is that the surrounds get ruined.

Basically the accordion surrounds of the Misco driver won't get trashed because they're flat.

- Home

- Loudspeakers

- Multi-Way

- DIY 3-way SH-50 Synergy Horn Clone: Tuning Phase? Pics and vid Included