1 spot on a speaker cabinet measured with an accelerometer.

It would take hours for you to aquire the same coverage of a speaker box as can be done in minutes with a stethoscope.

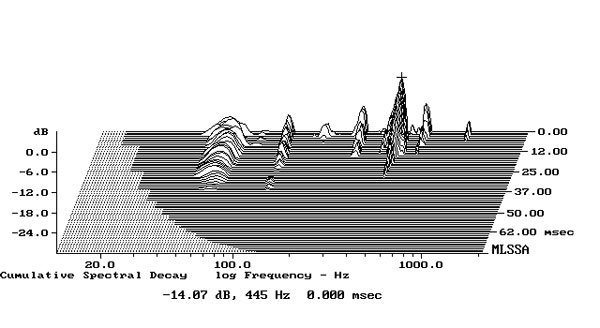

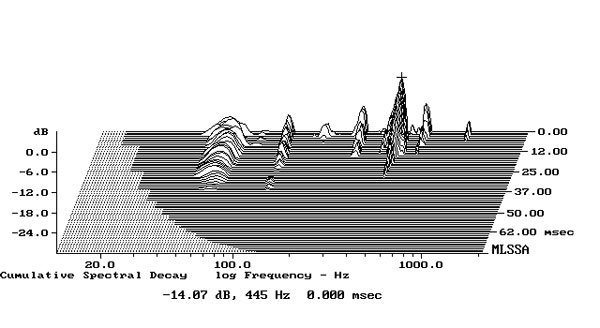

The graph needs to be interpreted*, whereas the ear/brain is directly connected. If you want to gather the analytic data have at at.

*[the graph would be much, much easier to interpret if the time scale was in cycles instead of time. Then the Q of the resonance shows the same across the frequency range).

As a diyer i find the stethescope sufficient to achieve what i am trying to do. Minimize or eliminate activation of box resonances under listening conditions.

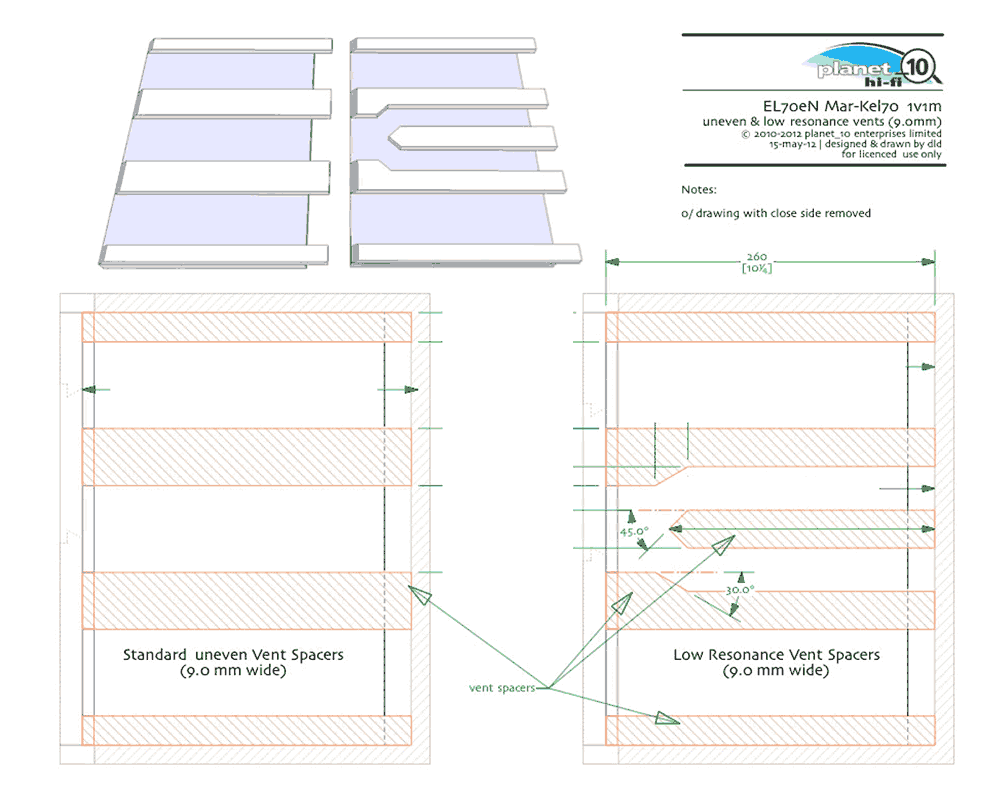

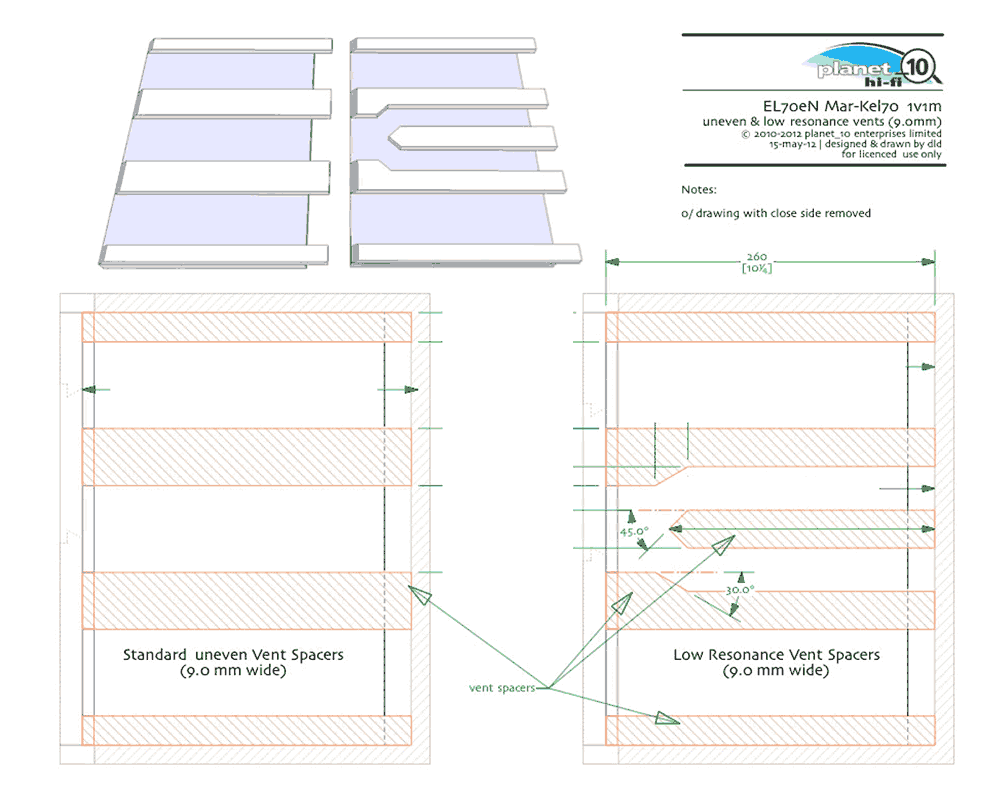

An aother example of a fix for a problem found w one build

dave

It would take hours for you to aquire the same coverage of a speaker box as can be done in minutes with a stethoscope.

The graph needs to be interpreted*, whereas the ear/brain is directly connected. If you want to gather the analytic data have at at.

*[the graph would be much, much easier to interpret if the time scale was in cycles instead of time. Then the Q of the resonance shows the same across the frequency range).

As a diyer i find the stethescope sufficient to achieve what i am trying to do. Minimize or eliminate activation of box resonances under listening conditions.

An aother example of a fix for a problem found w one build

dave

Any speaker cabinet will move when playing music.

A cabinet only moves at the resonant frequencies. If the music being played does not have stimulus within the bandwidth of the resonance with sufficient intensity for long enuff to actually cause the box to move. If the (potential) resonance that is there (everything resonants) then it is as if it is not there.

One could explore those resonances with artificial stimulus, but the whole point is the music.

dave

I meant using the stethoscope and mic together. The mic instead of your ear.

Could well work. The capsule you use would have to be small, you would need a direct readout to be near as quick as just the ear, the results would stil need interpretation, and possibly account for the mic being at the “bottom” of a long cavity.

Let us know if you come up with anything interesting or useful.

dave

I already did 🙂 One advantage over using ears would be reliable before and after modification comparison.

It would've been more interesting if you posted side by side comparison of speaker cabinets made with MDF.The results are excellent in all cases so far

You've compared it?A few tiny voids are negligible.

Voids are one of drawbacks. Bigger drawback is the inconsistency of material.Can anyone seriously say they think they could "hear" those voids, much less measure their effects?

Who did that? Can you please quote?Why brow beat someone for choosing the material they prefer?

My first attempts at speakers was with chip board which is compressed sawdust mixed with glue. I built two disco speakers wit h2 off Fane 12-50WRMS speakers in each.

Matched wit ha 225WRMS Maplin amplifier they were seriously loud.

In later years I have always used 18mm plywood.

Couldn't really tell the difference in sound.

Possibly because the boxes were quite small for the speakers so were pretty rigid.

My local DIY cuts my wood to size in strips and i just cut on the lengths I want from them. They cut very accurately so I have been able to make glued boxes instead of wooden braced and screwed boxes.

Matched wit ha 225WRMS Maplin amplifier they were seriously loud.

In later years I have always used 18mm plywood.

Couldn't really tell the difference in sound.

Possibly because the boxes were quite small for the speakers so were pretty rigid.

My local DIY cuts my wood to size in strips and i just cut on the lengths I want from them. They cut very accurately so I have been able to make glued boxes instead of wooden braced and screwed boxes.

speaker construction

Back when I was a youngin' in the early 60's, I built some folded horns out of 3/4" oak ply... I think the design was "Mello Monsters" or some such... 8" EV 8B's in a 36" x 36" x 36" cabinet, with double internal labyrinth folds. Really sensitive (only had 10's of watts / channel back then) filled gymnasiums with rich full sound but had sharp 40hz cutoff or so. Ended up building 8 or 10 more for various fraternities in Charlottesville back in college in the sixties... lots of partying back then and everyone wanted LOUD. Those were heavy, one complete 4' x 8' sheet in each one. Big bass down to the cutoff, but kind of lumpy.

I think you mean particle board; chip board is what's used for cladding houses here in KY. I built a pentagonal isobaric out of some 20 years or so ago. It's a bitch to work with, hard to cut accurately, warps easily, and doesn't hold screws any better than mdf. After the struggle, tho, it sounded pretty good (2 12" Jensens clammshelled). Particle board is cheap, best thing I can say about it.

Back when I was a youngin' in the early 60's, I built some folded horns out of 3/4" oak ply... I think the design was "Mello Monsters" or some such... 8" EV 8B's in a 36" x 36" x 36" cabinet, with double internal labyrinth folds. Really sensitive (only had 10's of watts / channel back then) filled gymnasiums with rich full sound but had sharp 40hz cutoff or so. Ended up building 8 or 10 more for various fraternities in Charlottesville back in college in the sixties... lots of partying back then and everyone wanted LOUD. Those were heavy, one complete 4' x 8' sheet in each one. Big bass down to the cutoff, but kind of lumpy.

My first attempts at speakers was with chip board which is compressed sawdust mixed with glue. I built two disco speakers wit h2 off Fane 12-50WRMS

I think you mean particle board; chip board is what's used for cladding houses here in KY. I built a pentagonal isobaric out of some 20 years or so ago. It's a bitch to work with, hard to cut accurately, warps easily, and doesn't hold screws any better than mdf. After the struggle, tho, it sounded pretty good (2 12" Jensens clammshelled). Particle board is cheap, best thing I can say about it.

Sometimes. I've seen it called particle board over here too.

Be that as it may, I'm going to quietly defend Pearl and their Sibelius for a moment. And some other manufacturers for that matter.

DIY is DIY. As in DIY. 'You' (i.e. all of us DIYers):

Why is the Sibelius expensive? Because it's built in small numbers, the same way as a piece of custom solid-wood furniture is built, in Europe, by cabinet makers, from slow-grown, properly aged, 30mm thick French oak. With all the above considerations. Not something you can do commercially for a couple of hundred quid I'm afraid. They also have a custom version of the drive unit, which is not just a different label on the back. That's fact, by the way. I am not involved with Pearl, but I know what they use from my contacts with the driver manufacturer. There are MOQs for that drive unit, so they have to buy a good number, and that is more expensive than simply using the off-the-shelf model. According to their site, there are also a handful of 'stock' models currently at Euro 3,000pr if people don't want a pair built specifically to order. They don't sell many: it's created as a low volume, higher margin, luxury brand product. It has to be: businesses are not philanthropic institutions, they need to turn a profit to keep going. That profit isn't anything like as large as some here seem to fondly imagine, because they might happen to have the ability to build a speaker (or other piece of equipment) for themselves. Beauty of DIY, no question, but let's not allow our eagerness to condemn commercial companies for (gasp!) making a profit, rather than running at a loss, blind us to reality, or assume that a high price tag means they are evil, money-grabbing chancers out to rip off the innocent men, women and urchins of our mean streets.

Be that as it may, I'm going to quietly defend Pearl and their Sibelius for a moment. And some other manufacturers for that matter.

DIY is DIY. As in DIY. 'You' (i.e. all of us DIYers):

- Charge nothing for your / our time.

- We don't have business rates to pay.

- We don't have a commercial manufacturing facility / commercial grade woodshop to either build and populate with tools / equipment, or a similar one, with staffed cabinet-makers to commission small-scale production from.

- We don't have commercial costs for electricity, water [gas as appropriate] for the above to pay.

- We don't have an office to set up and populate with equipment and stationary, with the same costs for power, internet, water, gas etc.

- We don't have, as relevant, a reference system for the business to use.

- We don't have staff or contractor wages and pensions to pay.

- We don't have to pay for packaging to be designed and produced.

- We don't have shipping to pay for.

- We don't have a business website to create, have hosted, and run.

- We don't have advertising to pay for.

- We don't have, as relevant, reviews to arrange.

- We don't have social media (increasingly necessary) accounts to manage.

- We don't have shows to pay for, which includes (frequently double-time) staff hours, transport accommodation and food / drink for those staff.

- We don't have, as relevant, a dealership network to create and support, and following the usual rule of 3, only about 1/3 of the retail cost under such conditions goes to the manufacturer, who has to cover all of the above, plus make a profit, out of that 1/3.

Why is the Sibelius expensive? Because it's built in small numbers, the same way as a piece of custom solid-wood furniture is built, in Europe, by cabinet makers, from slow-grown, properly aged, 30mm thick French oak. With all the above considerations. Not something you can do commercially for a couple of hundred quid I'm afraid. They also have a custom version of the drive unit, which is not just a different label on the back. That's fact, by the way. I am not involved with Pearl, but I know what they use from my contacts with the driver manufacturer. There are MOQs for that drive unit, so they have to buy a good number, and that is more expensive than simply using the off-the-shelf model. According to their site, there are also a handful of 'stock' models currently at Euro 3,000pr if people don't want a pair built specifically to order. They don't sell many: it's created as a low volume, higher margin, luxury brand product. It has to be: businesses are not philanthropic institutions, they need to turn a profit to keep going. That profit isn't anything like as large as some here seem to fondly imagine, because they might happen to have the ability to build a speaker (or other piece of equipment) for themselves. Beauty of DIY, no question, but let's not allow our eagerness to condemn commercial companies for (gasp!) making a profit, rather than running at a loss, blind us to reality, or assume that a high price tag means they are evil, money-grabbing chancers out to rip off the innocent men, women and urchins of our mean streets.

Last edited:

Of my interesting/useful thing? You'll have to use your imagination, it's measuring with a microphone rather that your ears. BTW "measuring" with your ears is not a valid form of measurement.Got pictures?

I have, just wondering if there was any detail that would help others duplicate your technique?

dave

dave

There are various motivations for people who visit this forum. Seeking and providing help are very common motivations, but not universal. I'm not telling you anything you don't know already, Dave. Just a reminder.

I have, just wondering if there was any detail that would help others duplicate your technique?

I haven't done it. I thought that was obvious.

- Home

- Member Areas

- The Lounge

- discontinuity