plywood = THWHACKK!!!

Hi frequency, high Q, very little chance music will ever have enuff energy to get it going, end result little or no cabinet noise.

mdf = thud

Low frequency, low Q, good chance the energy in the music wil excite it, and i just imagine from the sound of that word, the time delayed mush that radiates from many mdf cabinets.

ie an argument for plywood.

dave

interesting link?

maybe it's the density and damping thingie, eh? Big thwack vs. little thud, eh?

just saying... don't be talkin' to the architects

Drywall vs OSB vs Plywood vs MDF for Soundproofing: Which is better?

maybe it's the density and damping thingie, eh? Big thwack vs. little thud, eh?

just saying... don't be talkin' to the architects

Drywall vs OSB vs Plywood vs MDF for Soundproofing: Which is better?

A wall is not a speaker. We have different excitation and a wall is typically not anywhere near as stiff as a proper speaker box.

And perhaps is drywall so good, not because it has mass but because it is stiff?

dave

And perhaps is drywall so good, not because it has mass but because it is stiff?

dave

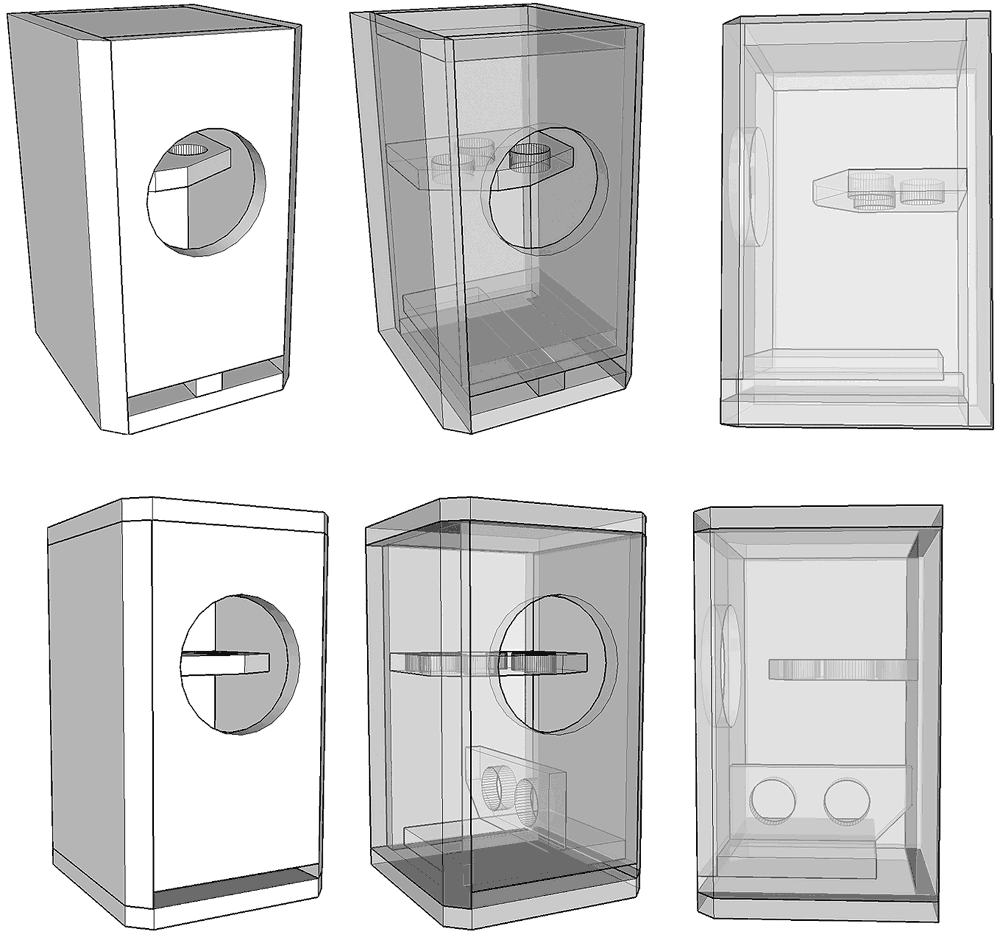

Plywood vs. MDF vs. solid hardwood, which do you find best? Internal bracing plays also role here (which I did not see on the vendor's pictures).

Really? I didn't know that plywood panel property changes when used on the wall vs. speaker cabinet. How long does it take for that change to occur, days, hours, minutes or seconds after installation?A wall is not a speaker. We have different excitation and a wall is typically not anywhere near as stiff as a proper speaker box.

It's one of those things people say, "If you have to ask, you are not ready for it."And perhaps is drywall so good, not because it has mass but because it is stiff?

Plywood vs. MDF vs. solid hardwood

Execution is very important, but desipte near free MDF we have mostly used quality plywood, first Baltic Birch, then Mirphy Ply (better BB) and sometimes Bamboo ply (standed /fossilized the only 1 to use to my mind).

Speakers sound better, have less measured music induced resonance, and the material is way nicer to work with.

Hardwood can be good, but is variable, not only across species but within species, requires a really knowledgeable woodworker and is considerably more prone to failure due to changes in humidity. One can build very nice, very pretty loudspeakers with it, but not so easy.

dave

= I didn't know that plywood panel property changes when used on the wall vs. speaker cabinet.

No change. Consider that a wall typically has plywood on 16” centre studs. I would never build a loudspeaker with unbraced spans that large. As well, despite the picture of what looks like quality plywood, is the actual ply measured the quality that we use building speakers, or much, much cheaper stuff like they sell at Home Depot.

dave

Hi frequency, high Q, very little chance music will ever have enuff energy to get it going, end result little or no cabinet noise.

Low frequency, low Q, good chance the energy in the music wil excite it, and i just imagine from the sound of that word, the time delayed mush that radiates from many mdf cabinets.

ie an argument for plywood.

dave

Do you have any measurements ?

You’d have to stick your ears into my mechanics stethoscope. Quantitatively hard to measure but really easy to hear.

And given the struggles people have getting any meaningful data from a much more practical technique.

dave

And given the struggles people have getting any meaningful data from a much more practical technique.

dave

I've read it's supposedly very difficult to measure that, what's your method?Speakers sound better, have less measured music induced resonance, and the material is way nicer to work with.

You've stated once again that it's about the looks.One can build very nice, very pretty loudspeakers with it, but not so easy.

Inferior rigidity of plywood per given thickness and size is inferior rigidity no matter how you brace it.No change. Consider that a wall typically has plywood on 16” centre studs. I would never build a loudspeaker with unbraced spans that large.

In case you didn't bother to, zoom in on the cross section area of this project, all those dark spots are where the discontinuity is. Some are even void. Talk about the material inconsistency, plywood is the last material you want to build speaker cabinet out of especially when the price is factored in.As well, despite the picture of what looks like quality plywood, is the actual ply measured the quality that we use building speakers, or much, much cheaper stuff like they sell at Home Depot.

You mean it's easy to perceive. Whether it's actually heard or not will need to be verified such as measurements.You’d have to stick your ears into my mechanics stethoscope. Quantitatively hard to measure but really easy to hear.

If you are implying that a microphone placed in the end of the stethoscope wouldn't be able to measure the sound that is heard you need to provide evidence.You’d have to stick your ears into my mechanics stethoscope. Quantitatively hard to measure but really easy to hear.

I've read it's supposedly very difficult to measure that, what's your method?

Take 1 mechanics stethoscope, play music (lots of different types) really loud. The earplugs block most of the sound, but when you press the tip of the stethescope to the box (all over) it becomes very clear if the music is causing parts of the box to move.

You can see a brace running from the baffle to the back on top of the vent shelf is a direct result of finding that teh lower part of the baffle would start moving. The additional brace fixed that.

dave

If you are implying that a microphone placed in the end of the stethoscope wouldn't be able to measure the sound that is heard you need to provide evidence.

You would have to have a different kind of sensor. A mic measures what is happening in the air, the tip of the stethescope directly converts movement of the box wall to changes in air pressure when touched to the box (the part you are touching).

At the same time your ears are plugged from the direct sound.

dave

Interesting, I might try that.Take 1 mechanics stethoscope.....

I don't see the problem? What's the "ir"? Oh, you probably mean the air 🙂 I'm no mic expert but I still don't get it, thankfully there is at least one mic expert in this thread who can explain, cbdb?You would have to have a different kind of sensor. A mic measures what is happening in the ir, the tip of the stethescope directly converts movement of the box wall to changes in air pressure when touched to the box (the part you are touching).

Last edited:

Any speaker cabinet will move when playing music.if the music is causing parts of the box to move.

Most plywood is not a great choice for speakers, but not all plywood is created equally. I took Dave's (and others') advice years ago and purchased the best Baltic Birch plywood (99% void free) that I could source locally to build my first set of speakers. Since then, I have built a few more pairs with Baltic Birch and I plan on building a few more. The results are excellent in all cases so far and there are other big advantages to working with it over MDF. A few tiny voids are negligible. Can anyone seriously say they think they could "hear" those voids, much less measure their effects?

In the end, plenty of people have built great speakers with both of these materials. Nice that we have choices. Why brow beat someone for choosing the material they prefer?

In the end, plenty of people have built great speakers with both of these materials. Nice that we have choices. Why brow beat someone for choosing the material they prefer?

Last edited:

Interesting, I might try that.

$10-$20 very well spent. You can listen to lots of other stuff too.

Laser Tools 1778 Mechanics Stethoscope

Looks like £21 with VAT

dave

I don't see the problem? What's the "ir"?

Sorry air. That is the problem.

One can measure what the air is doing with a microphone (or array like microflon), or one can measure the cabinet (loudspeaker cone) movement with a laser(s) or accelerometer. With one we are measuring what is happening in the air, or directly measuring what is causing what is happening in the air.

dave

- Home

- Member Areas

- The Lounge

- discontinuity