A suggestion I would make : could you offer a version of the Falcon PSU designed to be close to the motor (as mine and yours are) have a female IEC plug, and plug it directly into the motor, skipping the 6 foot power cord that I have bundled up behind my turntable now.

I was going to originally offer 2 options for the cable: NEMA 5-15F (what you received) or IEC C13 which would plug directly into the motor (will limit what you can plug into it). Almost everyone I asked when they bought preferred the NEMA plug, so I stopped asking. I will send you a new cable/rear panel with a 30" cable/C13 socket. They are easy to replace.

Thanks, that would be great. The way your PSU works, it really does not need to be near the turntable or the motor switch. Having them visible down below would work great, since you still just use the original motor switch for on/off.

Bones13-

You shouldn't even have to use the motor switch anymore. You can turn the motor off with a long press of the STBY button instead.

You shouldn't even have to use the motor switch anymore. You can turn the motor off with a long press of the STBY button instead.

Well, I live in switzerland where I have 220v at 50Hz

My TT uses a premotec 24 pole without any fancy electronics... just a cap and some résistors.

I know by experience that reducing voltage to around 70 volts practicaly éliminâtes motor noise but torque is also reduced. Gains in micro detail retrieval are significative but the low torque makes the TT loose some "snap".

I would really like to try one of those PSU's but I Wonder if only one magnet in the subplatter is enough to keep revs going where we need them.

My TT uses a premotec 24 pole without any fancy electronics... just a cap and some résistors.

I know by experience that reducing voltage to around 70 volts practicaly éliminâtes motor noise but torque is also reduced. Gains in micro detail retrieval are significative but the low torque makes the TT loose some "snap".

I would really like to try one of those PSU's but I Wonder if only one magnet in the subplatter is enough to keep revs going where we need them.

Well, I live in switzerland where I have 220v at 50Hz

My TT uses a premotec 24 pole without any fancy electronics... just a cap and some résistors.

I know by experience that reducing voltage to around 70 volts practicaly éliminâtes motor noise but torque is also reduced. Gains in micro detail retrieval are significative but the low torque makes the TT loose some "snap".

I would really like to try one of those PSU's but I Wonder if only one magnet in the subplatter is enough to keep revs going where we need them.

The Falcon is only capable of 120VAC output. You will need a low power step up xfmr to bring it to 220VAC. The wall adapter that powers the Falcon is universal input (100-260VAC) and provides 15VDC @ 1.6A. The wall adapter for the RoadRunner tach is 120VAC input only; the tach will run from any adapter that can supply 8VDC-15VDC, 300mA. One of my customers in Greece substituted his own adapter for the tach.

Regarding reduced voltage, the Falcon always asserts the max voltage at start up (when torque is needed) or when changing speeds. After ~3 secs, it will reduce the voltage to a front panel selectable level (~85-115VAC) for lower noise.

Not sure I understand your question regarding the magnet?

regarding the voltage, it seems perfect because I estimeta 70 volts to be the optimal minimum voltage for ultra low noise operation.

If it starts up at full power, it provides more torque at startup... ok

I do not know if it is a magnet that you use as sensor on the platter to cope with rev speed....

If it starts up at full power, it provides more torque at startup... ok

I do not know if it is a magnet that you use as sensor on the platter to cope with rev speed....

regarding the voltage, it seems perfect because I estimeta 70 volts to be the optimal minimum voltage for ultra low noise operation.

If it starts up at full power, it provides more torque at startup... ok

I do not know if it is a magnet that you use as sensor on the platter to cope with rev speed....

Yes, we use a small magnet on the platter and a hall effect IC on the sensor PCB. We only need one magnet, because we are counting the time it takes to make one rev. It will work on the platter edge or the sub-platter.

The Falcon will work with the Linn LP12, provided there is no Valhalla (or other internal power supply) installed, or it is not set up to work with the Lingo PS. If the motor is 220V, you will need a step up xfmr between the Falcon and the LP12.

The RoadRunner tach requires ~6mm clearance for the sensor, which I believe you have at the platter edge or the subplatter.

The RoadRunner tach requires ~6mm clearance for the sensor, which I believe you have at the platter edge or the subplatter.

I use Lingo, so I couldn't I use the Falcon?

The Lingo has 2 outputs, one for each winding in the motor and the table will have a connector to accept the signals from the Lingo (plugging the Lingo into the Falcon output would not be possible, nor would it give you any benefit). In order to use the Falcon with that table, you would have to restore the cabling and utilize a phase shifting capacitor for the second motor winding.

The Falcon PSU is supplied with a NEMA 5-15 socket (3 prong North American) on the end of a 30" cable. It can be ordered with a IEC C13 socket instead.

I just got around to installing the IEC cord for the back of the Roadrunner. Got rid of a lot of coiled 110vac cable under my table.

Also took a look in the inside, nice stuff on a clean board assembly. Nice work. I love this little box.

Thanks again Pyramid.

Also took a look in the inside, nice stuff on a clean board assembly. Nice work. I love this little box.

Thanks again Pyramid.

Digital PSU and Tachometer

Glad it's working out well for you. I get that reaction a lot from people who look "under the hood". The design is almost all surface mount and is professionally produced on automated pick-and-place machines here in the USA (Anaheim CA).

Some additional photos showing the inner workings:

Glad it's working out well for you. I get that reaction a lot from people who look "under the hood". The design is almost all surface mount and is professionally produced on automated pick-and-place machines here in the USA (Anaheim CA).

Some additional photos showing the inner workings:

Attachments

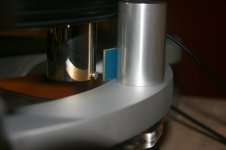

RoadRunner Tach installed on a Michell Gyro SE table.

Hi , sorry my confusion the Tachometer/Roadrunner can control DC motor?.

Quan

Last edited:

The Falcon PSU only works with AC synchronous motors.

The RoadRunner tach can be used with any turntable as long is there is enough clearance for the sensor PCB/magnet (~0.25" or 6cm).

Because of the unusual design of the Michell Gyro, the user mounted the sensor on the aft support leg (4th pic). When originally installed, the platter speed was 31.76 RPM; the user was able to adjust the speed to 33.336 via the Gyro DC power supply.

Both the Falcon and the RoadRunner can be used stand alone or together.

The RoadRunner tach can be used with any turntable as long is there is enough clearance for the sensor PCB/magnet (~0.25" or 6cm).

Because of the unusual design of the Michell Gyro, the user mounted the sensor on the aft support leg (4th pic). When originally installed, the platter speed was 31.76 RPM; the user was able to adjust the speed to 33.336 via the Gyro DC power supply.

Both the Falcon and the RoadRunner can be used stand alone or together.

The Falcon PSU only works with AC synchronous motors.

The RoadRunner tach can be used with any turntable as long is there is enough clearance for the sensor PCB/magnet (~0.25" or 6cm).

Because of the unusual design of the Michell Gyro, the user mounted the sensor on the aft support leg (4th pic). When originally installed, the platter speed was 31.76 RPM; the user was able to adjust the speed to 33.336 via the Gyro DC power supply.

Both the Falcon and the RoadRunner can be used stand alone or together.

Ok thank you. My turntable has only 5mm clearance.

Quan

- Status

- Not open for further replies.

- Home

- Vendor's Bazaar

- Digital Turntable Tachometer and DDS based PSU