Thank you. But I didn't quite understand why it wouldn't need any box or baffle. Wouldn't it still form an acoustically shorted circuit near the edges of the cone?

You're welcome!

It will begin at the edge of frame's effective acoustic diameter, which is a bit larger in diameter [lower in frequency], like a pipe/horn end correction; that's what rolls off/flattens its 'Q-ness' broadband peak somewhat, but the driver area IS a baffle, so supports whatever BW is still pistonic [if any] up to the VC's effective diameter [in Hz].

GM

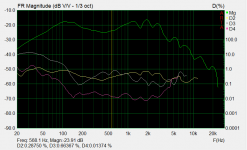

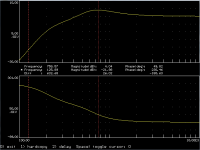

I looked in the equivalent circuits in Thiele's and Small's famous articles and managed to convince myself (hopefully correctly) that a flow resistor in the port should shift one of the zeros of the transfer from voltage to sound pressure from the origin to some negative real value. I then just tried some values and found that when one of the zeros is shifted to -600 rad/s, the simulated response starts looking more similar to your measured response, see the attachments. The simulated response now has a bump of +4.04 dB around 120 Hz and it is at -21.98 dB at 20 Hz.

What I have NOT done yet, is check if it is at all possible to add enough flow resistance to shift the zero that far negative without damping the poles more than they are damped in reality.

Anyway, a zero that's shifted to -600 rad/s would be easy to correct: besides the Linkwitz transform circuit, also put a first-order high-pass with a time constant of 1/600 seconds somewhere in the signal path.

What I have NOT done yet, is check if it is at all possible to add enough flow resistance to shift the zero that far negative without damping the poles more than they are damped in reality.

Anyway, a zero that's shifted to -600 rad/s would be easy to correct: besides the Linkwitz transform circuit, also put a first-order high-pass with a time constant of 1/600 seconds somewhere in the signal path.

Attachments

No clue, so don't know if this will help you decide or find any error, but to flatten >2.0 Qts' systems acoustically, then from post #7:

Upper mass corner [Fhm] = [2*Fs/Qts']*1.56 = Fp

Lp = SoS*/4/Fp

Vp = Vas/1.44

Ap = Vp/Lp

Rs = 0.5 ohm min. [typical for wiring]

Stuff to 'taste'. 😉

*34400 cm/sec in Hornresp

Qts' = Qts + any added series resistance [Rs]: HiFi Loudspeaker Design

Attached example HR sim assuming some specs:

GM

Upper mass corner [Fhm] = [2*Fs/Qts']*1.56 = Fp

Lp = SoS*/4/Fp

Vp = Vas/1.44

Ap = Vp/Lp

Rs = 0.5 ohm min. [typical for wiring]

Stuff to 'taste'. 😉

*34400 cm/sec in Hornresp

Qts' = Qts + any added series resistance [Rs]: HiFi Loudspeaker Design

Attached example HR sim assuming some specs:

GM

Attachments

... Often the biggest problem may be the minimum order quantity, and my lack of cutting tools. Everything would be easier, if I had all the tools to make iron parts with correct shape, and if I wouldn't live in a multi-storey block building...]

Hi Olijo,

while searching for something else, I once stumbled over a CNC online service. Have not checked it out myself, but a search should give you some info about what is possible without cutting tools. Sadly, I can´t provide a link in the moment.

All the best

Mattes