Wow, thanks EarlK! I think your measurements confirm what I hear using the Dayton driver with the H6512 horn. Treble (brushed cymbals for example) sound very subdued and 'soft'. I also can't screw the driver completely on and assumed that's just 'normal'. I bet I have that dip at 12.6kHz too.

I purchased this horn in hopes of a more balanced and brighter treble. You don't happen to have that horn lying around for testing? I'm actually afraid to see the results.

https://www.parts-express.com/dayton-audio-h812-1-exponential-horn-100x60-2-bolt--270-304

It does look like the first driver you tested is simply bad. The second one is better but still seems 'sick' especially compared to the other example you provided. Eventually, I may repurpose this driver once I get around to purchasing something else.

Many thanks!

I purchased this horn in hopes of a more balanced and brighter treble. You don't happen to have that horn lying around for testing? I'm actually afraid to see the results.

https://www.parts-express.com/dayton-audio-h812-1-exponential-horn-100x60-2-bolt--270-304

It does look like the first driver you tested is simply bad. The second one is better but still seems 'sick' especially compared to the other example you provided. Eventually, I may repurpose this driver once I get around to purchasing something else.

Many thanks!

I do happen to own a pair of H812 "wannabees" ( purchased years back & made by someone else ).

IME, the specific horn profile used in the H812 is best used for the creation of near flat traces ( to impress the under-educated customer who doesn't understand the trade-offs in achieving that sort of trace ).

FYI, the horn's (HF) off-axis performance is pretty compromised ( due to the deep, curved walls controlling the horizontal dispersion ).

Sonically, (IMHO) you'd be much better owning a pair of PRV, WG35-25 waveguides( especially before they become NLA ).

🙂

IME, the specific horn profile used in the H812 is best used for the creation of near flat traces ( to impress the under-educated customer who doesn't understand the trade-offs in achieving that sort of trace ).

FYI, the horn's (HF) off-axis performance is pretty compromised ( due to the deep, curved walls controlling the horizontal dispersion ).

Sonically, (IMHO) you'd be much better owning a pair of PRV, WG35-25 waveguides( especially before they become NLA ).

🙂

Nice WG. Shipping cost to Russia is $90 [only] so I havn't them 😀Sonically, (IMHO) you'd be much better owning a pair of PRV, WG35-25 waveguides

Last edited:

OMG, I just ordered more components, including two PRV waveguides. I also ordered the Eminence PSD2013 compression tweeter if only to compare it to the Dayton DT250.

Trying to stay within a budget isn't always easy but at least I will have two tweeters and three horns to play around with.

Additionally, the Eminence Lil Buddy has a beautiful and expressive midrange on open baffle. More wood to cut and more music to enjoy!

Trying to stay within a budget isn't always easy but at least I will have two tweeters and three horns to play around with.

Additionally, the Eminence Lil Buddy has a beautiful and expressive midrange on open baffle. More wood to cut and more music to enjoy!

A better version of the DE250 type driver, less expensive and measures better than recent actual DE250s I've seen, is the DNA-360 at diysoundgroup. In case you have more diy audio parts money you need to dispose of!

Compression Drivers DIY Sound Group

Compression Drivers DIY Sound Group

It's just a good driver made by a good manufacturer. It isn't perfect, it's just close enough in the ways that count. There is a mystique surrounding it due to the endorsement by Earl Geddes. Either the clone manufacturers don't understand the concept, or they think we don't...A lot of manufacturers seem to be after the DE250 design...it should speak a lot for the DE250.

As I said, the DNA-360 I've measured did BETTER than the DE250. The later DE250 I measured was significantly worse than the older one, too.

Geddes also said that compression drivers are "commodities" not selected specialties (can't say I agree, though, there seem to be a lot of differences).

Geddes also said that compression drivers are "commodities" not selected specialties (can't say I agree, though, there seem to be a lot of differences).

I agree, the few I've used have all measured very clean.A better version of the DE250 type driver, less expensive and measures better than recent actual DE250s I've seen, is the DNA-360 at diysoundgroup. In case you have more diy audio parts money you need to dispose of!

Compression Drivers DIY Sound Group

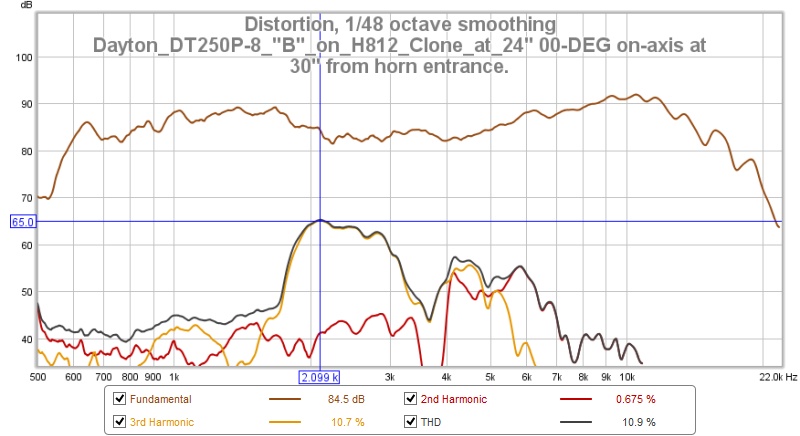

Here's a sweep of my sickest driver on the H812 horn ( though both drivers are bad ).

Somewhat unexpectedly, 3rd harmonic distortion has increased with the H812 clone ( maybe due to the extra loading placed upon the diaphragm by this much deeper horn ).

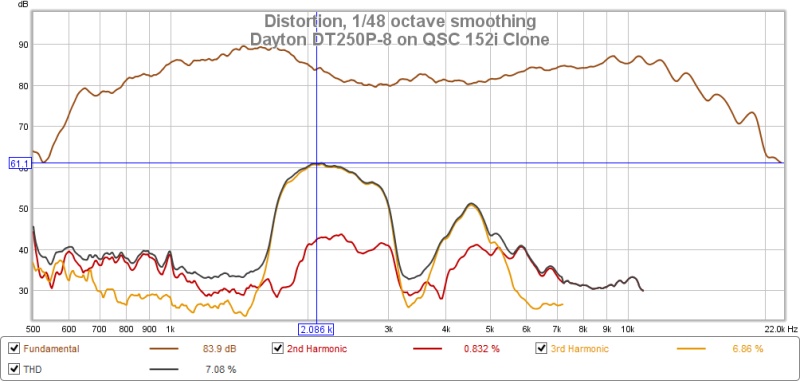

Compare to;

Here's what I consider ( as a visual clue ) for the source of the high measured distortions in my 2 units.

These (cropped) pictures attempt to show that the plastic back-cap ( for both drivers ) is warped ( in the 4 points of a compass ) and will not sit flush or tight onto the drivers top-plate.

- FYI, there doesn't appear to be any included rubber gasket ( as is found on the older pro Lansing type drivers ) as part of the design.

- One gap-opening measures ( using an automotive feeler gauge ) about .03" ( open ), with it's polar opposite measuring .026" ( open ).

- These gaps look to be open to the inside of both drivers.

Warp-age like this causes at least 2 significant problems;

(i) Uneven static pressure is placed on the diaphragm ( from the 4 points where the back-cap clamps down onto the diaphragm's plastic ring, holding it in place ).

- I'd conjecture that this is the source of my drivers distortion problems, since extreme skewing ( of the horizontal orientation ) as to how the diaphragm sits in the gap will result in the voice-coil contacting the gap walls ( which is a no-no for clean reproduction ) .

(ii) The drivers diaphragm is exposed to environmental pressure.

- This will be another source of distortion ( IM type ? ) when the driver gets used within an enclosure that houses a woofer ( & the box is then run up to PA type levels ).

I believe this warp-age is a manufacturing defect ( & perhaps only present on recent batches ) and as such, I'd advise anyone owning these drivers to inspect them for this same defect / and / if found, consider seeking a refund .

🙂

PS; I plan to ship both drivers back to Solen later today or tomorrow.

Somewhat unexpectedly, 3rd harmonic distortion has increased with the H812 clone ( maybe due to the extra loading placed upon the diaphragm by this much deeper horn ).

Compare to;

Here's what I consider ( as a visual clue ) for the source of the high measured distortions in my 2 units.

These (cropped) pictures attempt to show that the plastic back-cap ( for both drivers ) is warped ( in the 4 points of a compass ) and will not sit flush or tight onto the drivers top-plate.

- FYI, there doesn't appear to be any included rubber gasket ( as is found on the older pro Lansing type drivers ) as part of the design.

- One gap-opening measures ( using an automotive feeler gauge ) about .03" ( open ), with it's polar opposite measuring .026" ( open ).

- These gaps look to be open to the inside of both drivers.

Warp-age like this causes at least 2 significant problems;

(i) Uneven static pressure is placed on the diaphragm ( from the 4 points where the back-cap clamps down onto the diaphragm's plastic ring, holding it in place ).

- I'd conjecture that this is the source of my drivers distortion problems, since extreme skewing ( of the horizontal orientation ) as to how the diaphragm sits in the gap will result in the voice-coil contacting the gap walls ( which is a no-no for clean reproduction ) .

(ii) The drivers diaphragm is exposed to environmental pressure.

- This will be another source of distortion ( IM type ? ) when the driver gets used within an enclosure that houses a woofer ( & the box is then run up to PA type levels ).

I believe this warp-age is a manufacturing defect ( & perhaps only present on recent batches ) and as such, I'd advise anyone owning these drivers to inspect them for this same defect / and / if found, consider seeking a refund .

🙂

PS; I plan to ship both drivers back to Solen later today or tomorrow.

Attachments

Last edited:

Love the sweeps EarlK! Thank you! They show the contribution the horn makes on the overall response. Awesome! The H812 lifts the response a bit more. Also, thanks for the photos. I will check my drivers to see if they have a similar gap. I'm sorry you are unhappy with your drivers and hope and expect they can be returned. I bought the Eminence PSD 2013 as a comparison - titanium vs polymide - among other differences. The visuals really help me and I hope this thread helps others.

Wow, is that at true SPL? That's like 10% distortion around 1kHz at only 80dB spl! The fact that it gets (much) better at lower frequency does point toward a leak I'd guess. It would be interesting to seal it with silicone to see, but then you couldn't return it.

Yeah, I would try some foam/gasket tape on the gap just out of curiosity to see if that fixes it. Hopefully, Dayton acknowledges the defect and improves their QC.

Wow, is that at true SPL? That's like 10% distortion around 1kHz at only 80dB spl! The fact that it gets (much) better at lower frequency does point toward a leak I'd guess. It would be interesting to seal it with silicone to see, but then you couldn't return it.

The mic is a calibrated UMIK-1 which includes an SPL header within it's cal. file ( & to date has seemingly been accurate enough to avoid using an actual SPL meter ).

I have only marginal interest in fixing Dayton's QC stumbles with a bead of silicone.

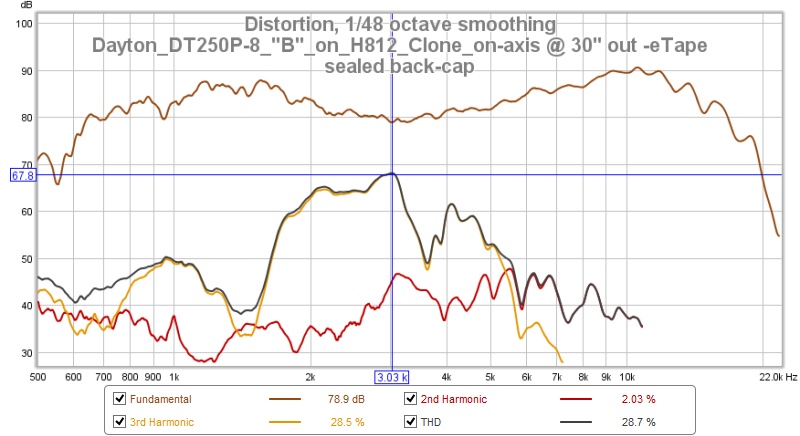

If I was truly adventurous, I'd sweep the driver with the back-cap removed ( & the diaphragm held in place with e-Tape ).

🙂

EDIT: Here's a new pic that quite clearly shows the back-cap warpage.

- The flash looks to have illuminated something internal ( maybe the edge of the diaphragm).

Attachments

Last edited:

Yeah, I would try some foam/gasket tape on the gap just out of curiosity to see if that fixes it. Hopefully, Dayton acknowledges the defect and improves their QC.

I hope to get these reboxed and sent back today.

My relationship is with Solen ( re; these drivers ) and that adds an extra layer of complication.

Solen's position is that if they deem these drivers to be defective they will seek redress from Dayton .

I might try some tie-line ( sash-cord ) as a tourniquet around the mating edges ( somewhat like the ancient Altec 288B's employed ).

- This should be non-invasive enough .

🙂

Okay, (using electrical tape ) I sealed all the gaps ( between back-cap & top-plate ) and here's the result ( this was a real surprise ! );

I rebooted and ran 4 more traces after seeing this first emerge, ( all subsequent sweeps were the same ).

Clearly the earlier 4-corner "venting" of the back-chamber was actually helping moderate the root-cause of this problem.

I really hope that Dayton doesn't now think that this venting is a "feature".

🙂

I rebooted and ran 4 more traces after seeing this first emerge, ( all subsequent sweeps were the same ).

Clearly the earlier 4-corner "venting" of the back-chamber was actually helping moderate the root-cause of this problem.

I really hope that Dayton doesn't now think that this venting is a "feature".

🙂

Attachments

Last edited:

li Buddy might be a better hifi speaker than guitar speaker (? I have a pair un-tried)

here's one of my Dayton D250P at 3044Hz sine on Translyvania's K-tube

then versus a P-Audio BMD440 on a diy brass K-tube at the same frequency and same drive.

BMD440 is 5dB louder at 3K plus much cleaner harmonically speaking with its highest harmonic -54dB down from 0dB

and has around 0.2 percent distortion.

that said, I think D250P sounds "acceptable" on the K-tube.

D250p by itself - not very loud on 3K sine

D250P vs inexpensive titanium P-audio BMD440

here's one of my Dayton D250P at 3044Hz sine on Translyvania's K-tube

then versus a P-Audio BMD440 on a diy brass K-tube at the same frequency and same drive.

BMD440 is 5dB louder at 3K plus much cleaner harmonically speaking with its highest harmonic -54dB down from 0dB

and has around 0.2 percent distortion.

that said, I think D250P sounds "acceptable" on the K-tube.

D250p by itself - not very loud on 3K sine

D250P vs inexpensive titanium P-audio BMD440

Last edited:

btw, D250p on the homemade K-tube has about the same bump at 10KHz as shown above - that's probably part of its character we hear

My DT250P has the same 'warpage'. I took the back off. It's plastic. Everything looked fine (tho I can't remember which was positive and negative and there are no markings so I guessed). I screwed it all back together and there is still warpage but less than there was. I'll connect the tweeters tomorrow to see if they still work. Meanwhile the Eminence PSD 2013 arrived and it sounds noticeably brighter using the same horn - H6512. The problem with it is sibilance, grrr. Maybe it's the titanium? It's not the worst offender I've encountered but it's certainly apparent.

Lil' Buddy is a keeper.

Meanwhile, I've got these two more horns ready to compare.

Lil' Buddy is a keeper.

Meanwhile, I've got these two more horns ready to compare.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Dayton DT250P-8 compression tweeter sings