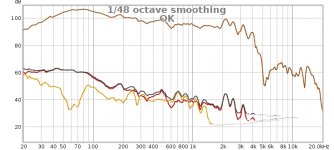

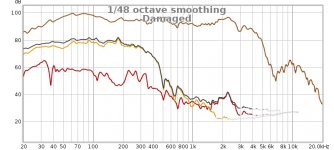

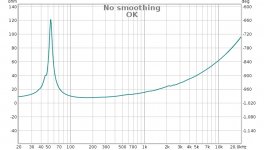

Some time ago, I bought two Eminence Delta12LFA speakers - I actually bought them for the boxes they were in. I wanted to try them now in a closed box but I got some strange impedance readings. I came to a conclusion, that one is seriously damaged. It has very high distortion and the impedance looks really bad (see attachments). When moving the cone, I can hear scratching noises and it feels kind of loose. The other one is silent and behaves normally as one would expect. There is no visual damage at all.

Could someone guess what the failure is and how it happened? Is there any way other than re-coning to fix? As far as I know, re-coning this low end speaker is not worth it 🙁 I am ready to dispose of it, I would just be interested in what may have happened.

Anyway, from now on, no secondhand speakers without impedance measurements🙂

Could someone guess what the failure is and how it happened? Is there any way other than re-coning to fix? As far as I know, re-coning this low end speaker is not worth it 🙁 I am ready to dispose of it, I would just be interested in what may have happened.

Anyway, from now on, no secondhand speakers without impedance measurements🙂

Attachments

Some possibilities are that (1) the cone has sagged, which does not seem likely to me as this is a PA woofer with a stiff suspension and light weight cone, (2) the coil has been burnt and some of the windings came loose. If so, reconing is the only option. Or (3) the voice coil former has slammed into the back plate and now is deformed.

Do both woofers have the same dc resistance value? Is a visual inspection of the coil possible? What exactly feels loose?

Do both woofers have the same dc resistance value? Is a visual inspection of the coil possible? What exactly feels loose?

Last edited:

Check out the spider (lower suspension) to see if its loose. Watch it while moving the cone to see if gluing has given up.

Thanks for the inputs, I will investigate more and come back. The DC resistance is the same, as far as I remember. Or very similar. The damaged one measured 6.6 Ohm with a multimeter connected by a short cable measuring inside a Speakon male connector, so it sounds right.

The suspension looks ok, I need to look better at the spider. When pushing the cone by hand, I hear scratching sounds.

When I shake the speaker a bit, the cone moves, on the good one it does not move even tiny little bit. I will try to make some short videos.

The suspension looks ok, I need to look better at the spider. When pushing the cone by hand, I hear scratching sounds.

When I shake the speaker a bit, the cone moves, on the good one it does not move even tiny little bit. I will try to make some short videos.

I tried moving the cone up and down. The spider looks fine and what I could see from the coil looks also ok, I tried to pull it out as much as I could. Bu I think the magnet cannot be removed without removing the cone. Can it be taken off in a non destructive way, like heating up or something like that? If not, I will just cut it apart and see what happened.

That speaker is unusable, consider it dead.

IF voice coil unglued from cone or winding block got loose from former, you´ll have to recone it.

If, as suggested above, magnet shifted, it´s beyond the amateur or even average Pro speaker repair Tech to correct, because he´ll need to demagnetize it first for recentering and regluing and then remagnetize it.

And only then he´ll be able to recone it.

IF voice coil unglued from cone or winding block got loose from former, you´ll have to recone it.

If, as suggested above, magnet shifted, it´s beyond the amateur or even average Pro speaker repair Tech to correct, because he´ll need to demagnetize it first for recentering and regluing and then remagnetize it.

And only then he´ll be able to recone it.

I thought it is not repairable. I will dissect it to see what the problem was and take off the magnet. The basket will be used as a 12" mounting hole pattern and baffle cut out template🙂

If the magnet/pole piece have not shifted, it would be theoertically possible to recone but the price of a recone kit would probably be only $5 less than the cost of a new driver, and having it repaired professionally probably double what a new one costs. Just not worth it with lower-end drivers.

I have “fixed” speakers with shifted magnets before, but not anything that large. Biggest was a 10” with a 16 oz. magnet. Popped off the dust cap, shimmed the coil to recenter it, and epoxied the crap out of the magnet. Waited for full cure before removing the shims and putting on a new dust cap. Saved a pair of the old Varco 8’s that way, too. This won’t hold with anything you will really beat on, but for small home speakers it’s better than just throwing it out.

I have “fixed” speakers with shifted magnets before, but not anything that large. Biggest was a 10” with a 16 oz. magnet. Popped off the dust cap, shimmed the coil to recenter it, and epoxied the crap out of the magnet. Waited for full cure before removing the shims and putting on a new dust cap. Saved a pair of the old Varco 8’s that way, too. This won’t hold with anything you will really beat on, but for small home speakers it’s better than just throwing it out.

The dissection showed only some minor former damage. So most probably, it was the magnet. Do you know how to remove the magnet assembly from the basket? I could not find any screws.

Usually held in with rivets and glue. They really don't want those things to shift.

A hard enough impact, though, will do the job. Not a lot that can be done to save this one, I'm afraid.

Chris

A hard enough impact, though, will do the job. Not a lot that can be done to save this one, I'm afraid.

Chris

True. Now it will just be a hole template, I will cut the magnet away so that it is not too heaby.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Damaged Delta12LFA - root cause? Can be repaired?