Sreten,

I have some resistors to try your suggestion. But the circuit is more complicated than I thought.

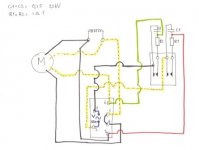

Underneath the lid of the switch I discovered 2 caps and two resistors. I measured the resistors and the are 1 Ω ???. The caps are to save the connectors I think, but why add the resistors? And only 1Ω.

The 2 coils in the motor are in series. And also are the resistors.

The light is not a bulb type but the same type as a red nightlight what you have got in the room for the children.

Where to put the resistor(s)? Can I place it instead of the bridge between connector 4 and 5?

I have some resistors to try your suggestion. But the circuit is more complicated than I thought.

Underneath the lid of the switch I discovered 2 caps and two resistors. I measured the resistors and the are 1 Ω ???. The caps are to save the connectors I think, but why add the resistors? And only 1Ω.

The 2 coils in the motor are in series. And also are the resistors.

The light is not a bulb type but the same type as a red nightlight what you have got in the room for the children.

Where to put the resistor(s)? Can I place it instead of the bridge between connector 4 and 5?

Attachments

Hi Triumph,

is it a 401 you're owning?

With my 401 I dismantled the motor, cleaned anything, polished the anchor, and cleaned both the upper and the lower anchor guides (sorry, I'm searching for the right words). If you rearrange the motor parts, you can even center the anchor 'on the fly', meaning, you can run the partly dismanteld motor to find the perfect fit in terms of vibrations. Don't tighten the scews to much!

You can tweak out the vibrations up to an amazing degree this way!

Sorry, I'm tired...

is it a 401 you're owning?

With my 401 I dismantled the motor, cleaned anything, polished the anchor, and cleaned both the upper and the lower anchor guides (sorry, I'm searching for the right words). If you rearrange the motor parts, you can even center the anchor 'on the fly', meaning, you can run the partly dismanteld motor to find the perfect fit in terms of vibrations. Don't tighten the scews to much!

You can tweak out the vibrations up to an amazing degree this way!

Sorry, I'm tired...

301 or 401 wish it was true. No a Zero 100 S. Nothing to adjust at the bearings here. Cleaned and greased them thats all.

Triumph said:Sreten,

I have some resistors to try your suggestion. But the circuit is more complicated than I thought.

Underneath the lid of the switch I discovered 2 caps and two resistors. I measured the resistors and the are 1 & ???. The caps are to save the connectors I think, but why add the resistors? And only 1&.

The 2 coils in the motor are in series. And also are the resistors.

The light is not a bulb type but the same type as a red nightlight what you have got in the room for the children.

Where to put the resistor(s)? Can I place it instead of the bridge between connector 4 and 5?

Hi,

It seems it can be connected for 120VAC or 250VAC.

(For 120VAC the coils are in parallel.)

In that case your "neon" will not turn off on a lowered 240VAC.

The 1R resistors one would assume suit the operating current.

Yes you can put the R between 4 and 5 as the coils are in series.

🙂/sreten.

Hi,

That article is about 2 phase synchronous motors, which you do not have.

I believe your motor is a variation of synchronous shaded pole.

🙂/sreten.

That article is about 2 phase synchronous motors, which you do not have.

I believe your motor is a variation of synchronous shaded pole.

🙂/sreten.

Long thread, I looked through some of it. I don’t know what Garrard you have. I will assume that it is a changer with an AC shaded pole synchronous motor. It isn’t really synchronous because the shaded pole allows it to slip under load. I have worked on vintage changers for years and have encountered the problem of the motor running too slow or too fast. There are ways to cure these problems, but this is not the issue here.

When varying the AC voltage the motor will stay at one rpm until you get down to a certain voltage and it will simply stop turning.

I think you are wasting your time trying to vary the voltage to reduce vibration. AC motors tend vibrate by nature because of the modulating field in the stator. What you need to do is replace the motor mounts with the right rubber. I make my own, but the rubber stock may not be available to you. There are precision changer motors from the 50s and 60s. Telefunken motors are excellent. It is hard to tell whether they are turning or stopped.

You can’t get rid of all the rumble. But it can be greatly minimized. If the changer is too cheap then the motor will not be balanced. Then you can’t get much done with vibration.

Some of the better changers of the console era such as the Magnavox/Collaro have fairly well balanced motors. The better Garrards have good silent motors. I have a Garrard RC98 from the 1950s. It has a speed control knob for the AC motor, but there is an extra coil on the motor for this. Very low rumble.

The idler doesn’t transmit vibration so much as it comes up through the deck, to the platter, and then to the stylus.

Put a plastic bottle top on the deck under the headshell. Put the stylus on the bottle top with the motor running. If the platter is in neutral (with the motor turning) the idler will not be involved. With the idler engaged (if the rubber is still pliant) you will probably hear little or no increase in rumble.

With rare exception you can’t vary the rpm of the motor with phase controls etc. The motors are designed to take wide variations in voltage. I saw two ceramic caps in a picture. These may be across the switch contacts.

As pertains to motor RPM (thought I would mention this in case someone was curious), the only speed control I have ever seen for a common shaded pole “squirrel cage” motor was on a Sears console. It worked very well. It was a 2W 50-ohm wire potentiometer in series with one of the motor leads. There was a common 1N4007 rectifier strapped across the potentiometer. I can’t recall exactly how the rectifier was connected to the pot. I tried this on other changers and it had minimal effect. I don’t know what was different about this Sears motor. It looked like all the others.

I put the information about the RPM in so you would have a better idea of what you are dealing with. You may find that it runs a little fast or slow. Dual used the variable pulley to set the speed. Good Luck, Mark

When varying the AC voltage the motor will stay at one rpm until you get down to a certain voltage and it will simply stop turning.

I think you are wasting your time trying to vary the voltage to reduce vibration. AC motors tend vibrate by nature because of the modulating field in the stator. What you need to do is replace the motor mounts with the right rubber. I make my own, but the rubber stock may not be available to you. There are precision changer motors from the 50s and 60s. Telefunken motors are excellent. It is hard to tell whether they are turning or stopped.

You can’t get rid of all the rumble. But it can be greatly minimized. If the changer is too cheap then the motor will not be balanced. Then you can’t get much done with vibration.

Some of the better changers of the console era such as the Magnavox/Collaro have fairly well balanced motors. The better Garrards have good silent motors. I have a Garrard RC98 from the 1950s. It has a speed control knob for the AC motor, but there is an extra coil on the motor for this. Very low rumble.

The idler doesn’t transmit vibration so much as it comes up through the deck, to the platter, and then to the stylus.

Put a plastic bottle top on the deck under the headshell. Put the stylus on the bottle top with the motor running. If the platter is in neutral (with the motor turning) the idler will not be involved. With the idler engaged (if the rubber is still pliant) you will probably hear little or no increase in rumble.

With rare exception you can’t vary the rpm of the motor with phase controls etc. The motors are designed to take wide variations in voltage. I saw two ceramic caps in a picture. These may be across the switch contacts.

As pertains to motor RPM (thought I would mention this in case someone was curious), the only speed control I have ever seen for a common shaded pole “squirrel cage” motor was on a Sears console. It worked very well. It was a 2W 50-ohm wire potentiometer in series with one of the motor leads. There was a common 1N4007 rectifier strapped across the potentiometer. I can’t recall exactly how the rectifier was connected to the pot. I tried this on other changers and it had minimal effect. I don’t know what was different about this Sears motor. It looked like all the others.

I put the information about the RPM in so you would have a better idea of what you are dealing with. You may find that it runs a little fast or slow. Dual used the variable pulley to set the speed. Good Luck, Mark

hailteflon said:

It isn’t really synchronous because the shaded pole allows it to slip under load.

Good Luck, Mark

Hi,

There are shaded pole induction motors and shaded pole synchronous motors.

The former has a squirrel cage rotor, the latter a magnetised rotor.

The variety common in fixed speed turntables does not "slip".

There is a further variety, used e.g. in the Garrard 401, that does

slip and this allows the drag based variable speed (+/- ~ 4%).

The difference is one has a slip angle, the other a slip frequency.

The former is synchronous, the latter asynchronous.

With a slip angle rotation is locked to the incoming frequency.

I cannot remember the details of the 401 type motor.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=25865&perpage=25&pagenumber=1

🙂/sreten.

Hi Sreten,

Yes, motor technology can go far beyond what is in a common record player.

AFAIK the shaded pole induction motor would be synchronous if it did not have the shaded pole. It is synchronous with line frequency when not under load.

The fixed speed turntables with AC motor do slip. When they go into the change cycle the RPM will usually drop considerably. Without the shaded pole the motor would lock up when placed under load.

A common ailment in record players is when the platter runs a little slow no matter what is done to bearings, lubricants, etc. This is due to the quality control and materials used in the motor. It has too much slip.

The 50s motors generally are OK, but in the 60s they seem to be using recycled aluminum in the rotors and no telling what other inferior materials that do not age will. The varnish between the rotor laminations may deteriorate, not sure.

The rotor pins can be swaged and this may bring it up to speed. Rust on the rotor can affect RPM as can the lubricant. They slip too much. Sometimes this can be cured by replacing the rotor with one from another motor.

I read about these little motors until I finally found all that I could about bringing them up to speed. There are many tutorials, but almost none of them discuss the rotor laminations. As I recall an induction motor is synchrous by classification. It would have no torque without the shaded pole that

allows it to slip ( drop below synchronous RPM) when under load. Mark

Yes, motor technology can go far beyond what is in a common record player.

AFAIK the shaded pole induction motor would be synchronous if it did not have the shaded pole. It is synchronous with line frequency when not under load.

The fixed speed turntables with AC motor do slip. When they go into the change cycle the RPM will usually drop considerably. Without the shaded pole the motor would lock up when placed under load.

A common ailment in record players is when the platter runs a little slow no matter what is done to bearings, lubricants, etc. This is due to the quality control and materials used in the motor. It has too much slip.

The 50s motors generally are OK, but in the 60s they seem to be using recycled aluminum in the rotors and no telling what other inferior materials that do not age will. The varnish between the rotor laminations may deteriorate, not sure.

The rotor pins can be swaged and this may bring it up to speed. Rust on the rotor can affect RPM as can the lubricant. They slip too much. Sometimes this can be cured by replacing the rotor with one from another motor.

I read about these little motors until I finally found all that I could about bringing them up to speed. There are many tutorials, but almost none of them discuss the rotor laminations. As I recall an induction motor is synchrous by classification. It would have no torque without the shaded pole that

allows it to slip ( drop below synchronous RPM) when under load. Mark

You may have some sort of point from a technical terminology standpoint.

Shaded pole induction motors do slip and they are used extensively in changers before the DC motor era began. The nominal RPM is synchronized with line frequency.

My intent here is to help someone who is working on a Garrard motor.

These forums will be archived for decades. I have derived many good pieces of info from forums in general.

I have worked on hundreds of these motors and regardless of some techical flaw in my terminology I am not wrong. I have fixed many of them. Excessive slip is usualy due to excessive rotor resistance. The squirrel cage (rotor pins) has a flaw in it. I said this for those who may benefit from this, not as a target for your ego war.

People usually want changers to play 78s. They are being destroyed due to lack of understanding about how to repair them. When properly overhauled they are not the junk that they appear to be beforehand. The predominant problem with all old turntables and changers is dried lubricant and rotten rubber parts.

You seem to be on a quest to increase the mass of your ego.

I don't want to argue with you. I don't want you to teach me about your delusions of grandeur.

Many competent and potential posters do not participate in forums because of punks like you. A very knowledgable audio engineer told me that he doesn't post because of "flame-o-grams."

This is a well moderated forum. Even so, you have learned to drag an issue into conflict.

Shaded pole induction motors do slip and they are used extensively in changers before the DC motor era began. The nominal RPM is synchronized with line frequency.

My intent here is to help someone who is working on a Garrard motor.

These forums will be archived for decades. I have derived many good pieces of info from forums in general.

I have worked on hundreds of these motors and regardless of some techical flaw in my terminology I am not wrong. I have fixed many of them. Excessive slip is usualy due to excessive rotor resistance. The squirrel cage (rotor pins) has a flaw in it. I said this for those who may benefit from this, not as a target for your ego war.

People usually want changers to play 78s. They are being destroyed due to lack of understanding about how to repair them. When properly overhauled they are not the junk that they appear to be beforehand. The predominant problem with all old turntables and changers is dried lubricant and rotten rubber parts.

You seem to be on a quest to increase the mass of your ego.

I don't want to argue with you. I don't want you to teach me about your delusions of grandeur.

Many competent and potential posters do not participate in forums because of punks like you. A very knowledgable audio engineer told me that he doesn't post because of "flame-o-grams."

This is a well moderated forum. Even so, you have learned to drag an issue into conflict.

Hi,

You misunderstand my post.

The guy is interested in performance. He has a Garrard Zero 100S.

My post was somewhat brusque, I apologise about that.

Seems I do have to argue the point.

It may be true that a synchronous motor in an autochanger slips

during the change cycle but this is not relevant to the question.

What is relevant is the typical "not under load" performance.

To me you are just confusing the issues to someone who is unlikely

to become an expert on the all and sundry of turntable motors.

Under the circumstances of interest this is not relevant, and

from my perspective very misleading. The shaded pole creates

the rotating field at the cost of extra power drawn and heat.

The sort of slip you are referring to applies to all synchronous

motor types under "load", not just shaded pole.

The point of his Garrards Synchrolab motor and the near ubiquitous

4 pole shaded pole motors in far eastern belt drive turntables is they

operate with a slip angle and are synchronously locked to the incoming

AC frequency when playing records, effectively near "no load" behaviour.

(also applies to shaded pole clocks and tape recorder capstan motors)

😎 /sreten.

You misunderstand my post.

The guy is interested in performance. He has a Garrard Zero 100S.

My post was somewhat brusque, I apologise about that.

Seems I do have to argue the point.

It may be true that a synchronous motor in an autochanger slips

during the change cycle but this is not relevant to the question.

What is relevant is the typical "not under load" performance.

To me you are just confusing the issues to someone who is unlikely

to become an expert on the all and sundry of turntable motors.

It isn’t really synchronous because the shaded pole allows it to slip under load.

Under the circumstances of interest this is not relevant, and

from my perspective very misleading. The shaded pole creates

the rotating field at the cost of extra power drawn and heat.

The sort of slip you are referring to applies to all synchronous

motor types under "load", not just shaded pole.

The point of his Garrards Synchrolab motor and the near ubiquitous

4 pole shaded pole motors in far eastern belt drive turntables is they

operate with a slip angle and are synchronously locked to the incoming

AC frequency when playing records, effectively near "no load" behaviour.

(also applies to shaded pole clocks and tape recorder capstan motors)

😎 /sreten.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Cutting vibrations from a (Garrard) synchronous motor.