"Go over and check out LM4780 thread. Take a flack jacket and some brass knuckles."

Right behind you, C... 😀

Thanks. It didn't really take that long to build the amp... I was building a comp-ready sub for a kid (35hz... +6dB -0dB...1100W), with the promise that if he woke me up with it, I'd take it back out with an axe...

Still debating the vent scheme on the mini. You wouldn't believe how "dead" it is.

E

Right behind you, C... 😀

Thanks. It didn't really take that long to build the amp... I was building a comp-ready sub for a kid (35hz... +6dB -0dB...1100W), with the promise that if he woke me up with it, I'd take it back out with an axe...

Still debating the vent scheme on the mini. You wouldn't believe how "dead" it is.

E

I might do that 🙂.chipco3434 said:... I think before I started cutting that nice big aluminum plate, I might make the case components in cardboard as a prototype.

...

Oh btw, I didn't drill out the holes, I tried another transistor and it didn't short to the case, so everything seems OK.

Well, all I've got is a Dremel, but let's see what my friend's got:Magura said:What sort of machinery do you have available?

lathe, saw "table" (I still don't know what this is called), drill press, drills, jig saw, router, lot's of other stuff you need to build your own house 🙂. He hasn't got an aluminium blade for his saw table however and he says it costs way to much to buy it for one occasion (as much as €500 according to him).

Devil_H@ck said:Well, all I've got is a Dremel, but let's see what my friend's got:

lathe, saw "table" (I still don't know what this is called), drill press, drills, jig saw, router, lot's of other stuff you need to build your own house 🙂. He hasn't got an aluminium blade for his saw table however and he says it costs way to much to buy it for one occasion (as much as €500 according to him).

Is that a wood lathe or metal? A mill would be pretty handy doing that case design you want too, or a vertical slide for the lathe (if it is a metal one). I have a few ideas how you could do that button fairly easily if you have access or you know someone with those things.

Steve

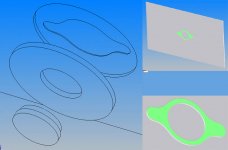

Hi, I'm bored this morning, so heres an idea of how to implement that button idea. Takes away the need to accurately match the profile of the plastic to that of the ally. The shape in the ally could be roughed out with a mill (or chain drilled) and the filed to the shape you want. That just leaves the recess in the back, which could be milled out, it doesn't have to be accurate either.

Hope this helps,

Steve

Hope this helps,

Steve

Attachments

It's a metal lathe. I don't know what you mean by a mill or a vertical slide though. (*See bottom of post*)baggystevo82 said:Is that a wood lathe or metal? A mill would be pretty handy doing that case design you want too, or a vertical slide for the lathe (if it is a metal one). I have a few ideas how you could do that button fairly easily if you have access or you know someone with those things.

Steve

Thanks for the nice graphic 🙂.baggystevo82 said:Hi, I'm bored this morning, so heres an idea of how to implement that button idea. Takes away the need to accurately match the profile of the plastic to that of the ally. The shape in the ally could be roughed out with a mill (or chain drilled) and the filed to the shape you want. That just leaves the recess in the back, which could be milled out, it doesn't have to be accurate either.

Hope this helps,

Steve

I see how you would do it, but if done that way, the plexi won't be flush with the front plate, although that maybe isn't a drama. I have no idea though how I could make the recess, but that probably because I don't know what a mill is 😉.

* Ok, I searched on Yahoo and found out what a mill is. I believe my friend's lathe is actally both a lathe and a mill in one piece. I don't think a 50cm * 15cm panel would fit under it however.

How to choose drill press?

Man, I am tire of asking for tools. I should have finished my chassis in spring break if I was not waiting for someone to let me use the place. After that I have been waitting to go to someone's place to drill my stuffs for another four weeks from now. I think I need to buy a drill press now. Since I am a noob, and a cheap *** student (no job), can anyone point me to some drill press that will suit my need? Budget: $50, Bit to stand distance: at least 7-8 in, chuck size: 1/2 at least. I will need it to drill alummium plate, and the thickest one is 1 in & the height is 7 1/8" .

Man, I am tire of asking for tools. I should have finished my chassis in spring break if I was not waiting for someone to let me use the place. After that I have been waitting to go to someone's place to drill my stuffs for another four weeks from now. I think I need to buy a drill press now. Since I am a noob, and a cheap *** student (no job), can anyone point me to some drill press that will suit my need? Budget: $50, Bit to stand distance: at least 7-8 in, chuck size: 1/2 at least. I will need it to drill alummium plate, and the thickest one is 1 in & the height is 7 1/8" .

Does your college have a physics department? We had a nice little tool room in the physics department and a mean old German toolmaker. That was the best.

I don't think that fifty bucks buys much of a drill press...

but here ya go. Buyer beware.

http://www.harborfreight.com/cpi/ctaf/Displayitem.taf?itemnumber=44506

At that price you could throw it away when your done.

I don't think that fifty bucks buys much of a drill press...

but here ya go. Buyer beware.

http://www.harborfreight.com/cpi/ctaf/Displayitem.taf?itemnumber=44506

At that price you could throw it away when your done.

My community college have CNC tech.... class + machine, but I don't think they will let me use their stuff by just asking. Department Link

If you have limited access to a shop, the first thing I would do is use that time to build drill guides.

No?

E

No?

E

after owning a nice drill press, i personally wouldnt recommend getting a really cheap one. its almost not worth it. using a good one just makes projects SO much easier, quicker, and look better. you will end up just frustrating yourself i imagine.

Hmmm... That's mean I have to do more saving + wish I'm lucky next week that I can go to my uncle working place.

cowanrg said:after owning a nice drill press, i personally wouldnt recommend getting a really cheap one. its almost not worth it. using a good one just makes projects SO much easier, quicker, and look better. you will end up just frustrating yourself i imagine.

Well, honestly I can't imagine how can you buy a bad drill press. Look at my projects posted so far. All of them were done with a cheapest Skills drill press I bought almost 10 years ago.

I just bought a good one last month, but my projects didn't really change. Don't spend more than $100, if you are on tight budget. It will work the same way as the "not cheap one".😉

That's exactly the type I was using untill recently. It's as good as anything else out there. After all, this thing just rotates yout drill bit😉

Later you might need more choices reagarding the speed (especially on the slow side) but for casual work, it's fine and you don't have to look for anything else.

Later you might need more choices reagarding the speed (especially on the slow side) but for casual work, it's fine and you don't have to look for anything else.

yeah, i use the variable speed feature quite a bit on mine. plus, its nice to have the power. i can go through very thick metal without a problem.

but, i guess you are right, it all does the same thing really. until i got the drill press, i was using a cordless drill i bought on sale for $19.95. it was a special at a local hardware store, and its an 18v pack too! i couldnt pass it up for that price. its worked perfectly considering the price.

but, i guess you are right, it all does the same thing really. until i got the drill press, i was using a cordless drill i bought on sale for $19.95. it was a special at a local hardware store, and its an 18v pack too! i couldnt pass it up for that price. its worked perfectly considering the price.

and keep it at a friends place to use.

Other alternatives...

1. Den

2. Bedroom

3. Kitchen

4. Bathroom

The cheapest way to get a good drillpress is to look for machine auction in your neighbourhood. Plenty of pro drill presses are to be found in the 100 to 200USD range at liquidation auctions. Those pro machines are gonna last forever for a DIY'er and offers a lot more than a crap hobby drillpress for pretty much the same price. What to look for is the speed range and the power. You would want to be able to get at least 10 speeds from 50rpm to 2000rpm, preferably more than 10. Besides that you dont want less than 1hp.

Magura🙂

EDIT: And stay clear of belt drives, they cause nothing but trouble if low quality, and its almost sure to be low quality on a cheap drillpress.

Magura🙂

EDIT: And stay clear of belt drives, they cause nothing but trouble if low quality, and its almost sure to be low quality on a cheap drillpress.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- Cutting, drilling, mounting etc. for the absolute beginner