Perfect, if you know how to work with shaping that. Most of these hexcels come with a veil on the surface. This is there to prevent the cells from filling up with epoxy, and to have something for the skins to attach too. When used as panel, it's fine. But when machined into a shape like a foil or blade, the cells get exposed and need to be filled with foam. So fine for PA type use, a bit more involved for shaped parts. If you are going to have to fill with foam, just use foamWhat about a non-metallic honeycomb core like Nidaplast?

I did up plans for a 20' sports cat in hexcel but shelved it in favour of HDPE skins over foam core and that turned out to perform better for the location. Hexcel will still be used for cabin walls when we get to that part, as a pallet from Alibaba can be cheaper than PVC. At the moment it's getting the hulls together, with more work on the bridge deck

Here is a hull that will be built in hexcel. This is a WIG bay runner concept. This one is being designed to run about 2' over the chop and the aim is to make zero contact with water

Alloy box beam/heat pipe added. The disc is 10mm alloy plate and a bridge from mag to pipe. The pipe on it own might just be enough but a pair of 30mm fans can fit either side if the temp sensor demands

Now to the dual propeller mounts 🙂

Hmmm, at a point of indecision. It looks like the CH2 in the FFA001 H/B modules is limiting the design of the complete system including the stereo speakers, with its PSU restricting things to 8R. Instead of two H/B boards, this would be a better place for a regular FFA001 to run the stereo and FFA002 to run the DVC on the subs. In this config, either of the two modules would be happy to provide equal power in 4 or 8R on any channel

The H/B modules would better suit active speakers with a 4 or 8R lows and 8R highs

Wagner Electronics in Sydney, Australia have proven to be extremely poor customer service. I ordered the PR units for this project on the 27th, it's the 9th today and still no communication from them regarding what's going on. They haven't replied to email and when I called, the person answering the phone sounded evasive and arrogant. Stay clear of this mob

Dayton looks like a company that has some in-house stuff and some generic rebadged items. I fear the PR units just might be the rebadged OEM type items, as there are identical no name offerings on Ali to a lot in their range. I'll locate some units and order them in. I am confident that should I order today, I'll receive them sooner than AU dispatchers like Wagner. Another case of voting with our wallets to those that provide a real service

The H/B modules would better suit active speakers with a 4 or 8R lows and 8R highs

Wagner Electronics in Sydney, Australia have proven to be extremely poor customer service. I ordered the PR units for this project on the 27th, it's the 9th today and still no communication from them regarding what's going on. They haven't replied to email and when I called, the person answering the phone sounded evasive and arrogant. Stay clear of this mob

Dayton looks like a company that has some in-house stuff and some generic rebadged items. I fear the PR units just might be the rebadged OEM type items, as there are identical no name offerings on Ali to a lot in their range. I'll locate some units and order them in. I am confident that should I order today, I'll receive them sooner than AU dispatchers like Wagner. Another case of voting with our wallets to those that provide a real service

Pulled out the amps from storage and all the different modules will fit inside the already drawn box beam so no more modifications needed

What will be the best connectors for sending speaker outs to the stereo pair from this cab. Speakons look massive and not interested in protruding type posts.

Does anyone know of a smaller heavy-duty system then Speakons?

What will be the best connectors for sending speaker outs to the stereo pair from this cab. Speakons look massive and not interested in protruding type posts.

Does anyone know of a smaller heavy-duty system then Speakons?

Will stick with Speakons, they are quite large but mostly on the male side. The chassis connectors are manageable

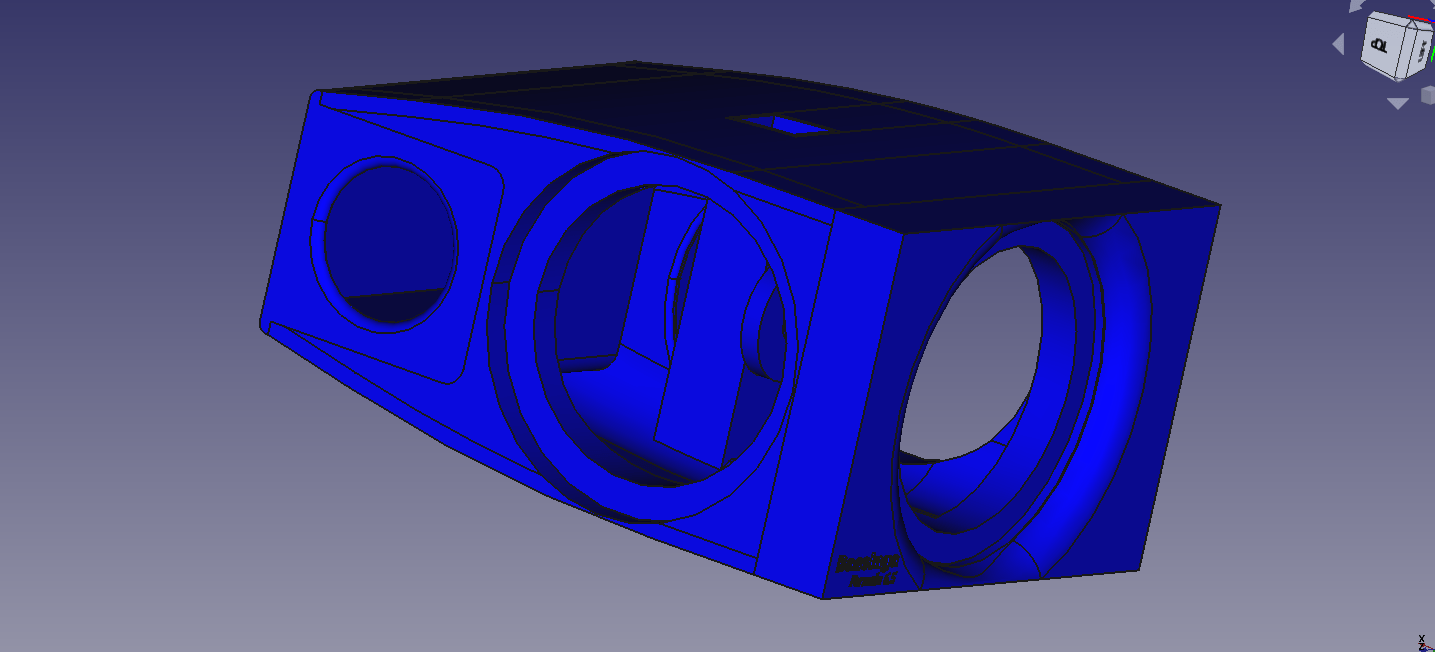

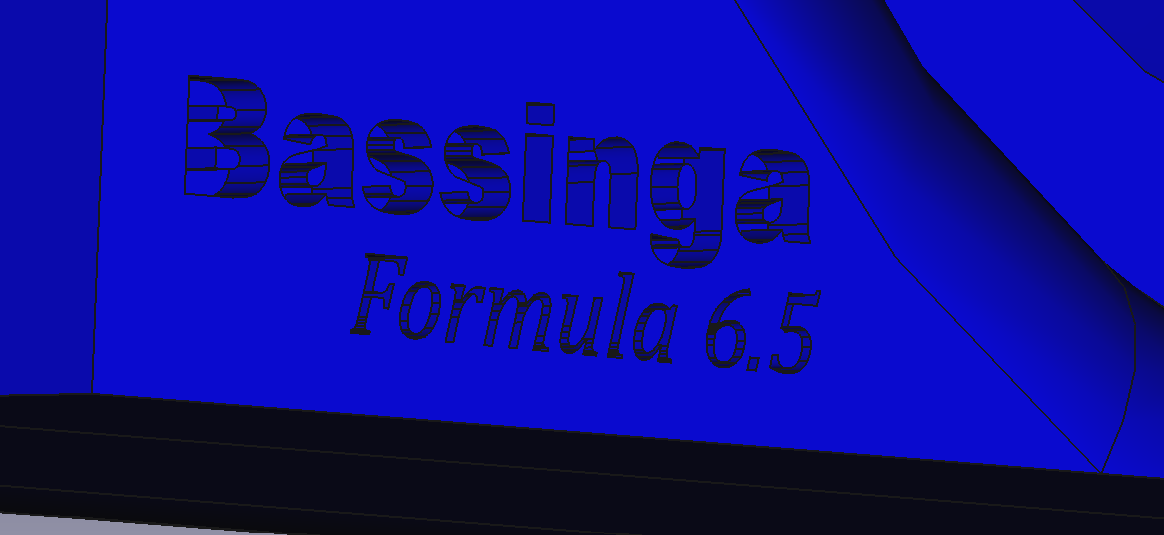

Ok, so all the design work of building up this virtual cab is complete. I managed to design in the badges today. It takes a couple of hours to learn how to do this the first time in FreeCAD

The text forms a 4mm pit into the surface designed to take a resin goop coloured with gold tint pigment. The baffle face trim is carbon fibre with structural cubic cell core

Next step is to pull off each part and either CNC or print followed by assembly which involves epoxying all the bits together and structural skins

The text forms a 4mm pit into the surface designed to take a resin goop coloured with gold tint pigment. The baffle face trim is carbon fibre with structural cubic cell core

Next step is to pull off each part and either CNC or print followed by assembly which involves epoxying all the bits together and structural skins

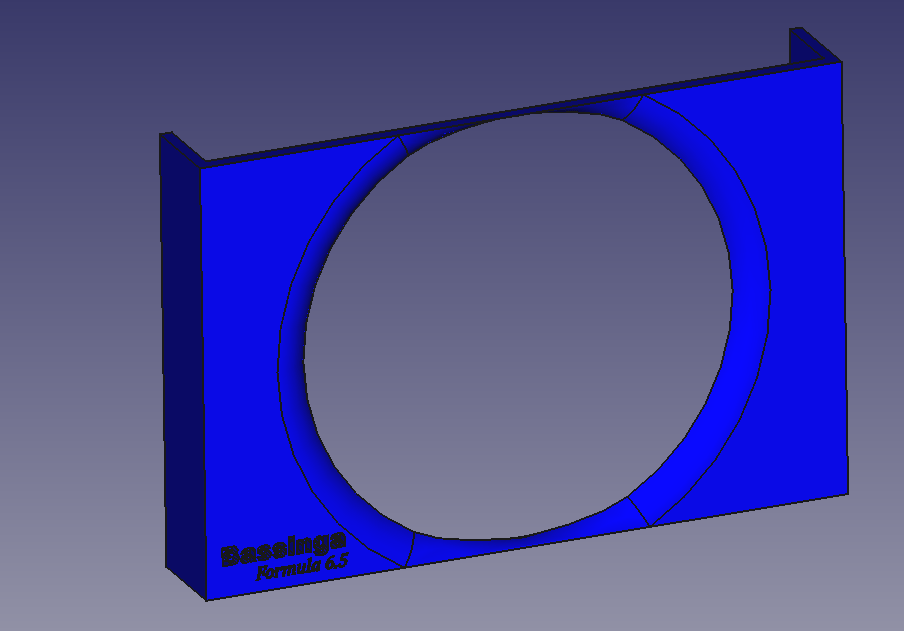

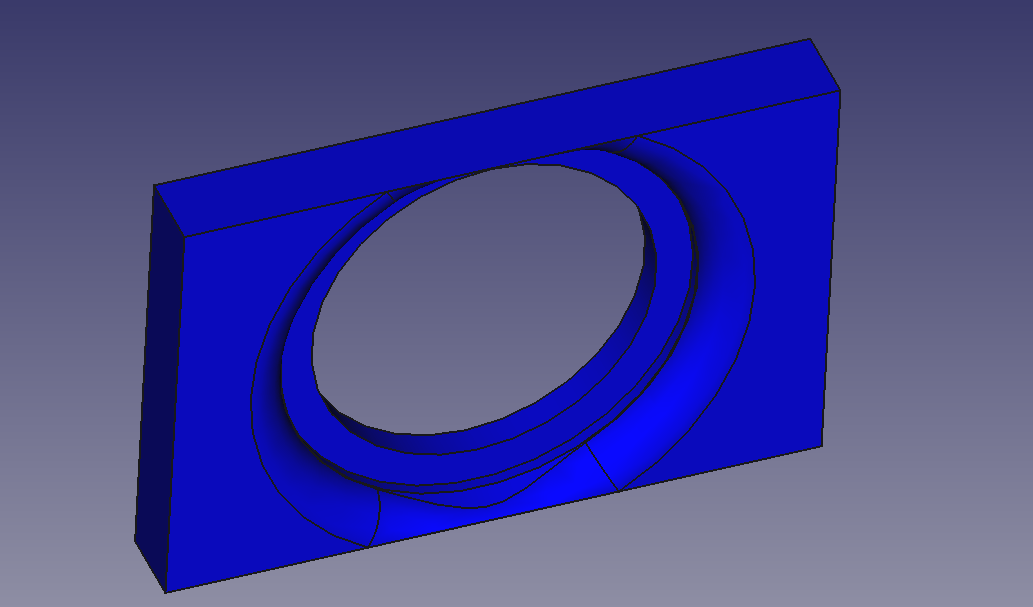

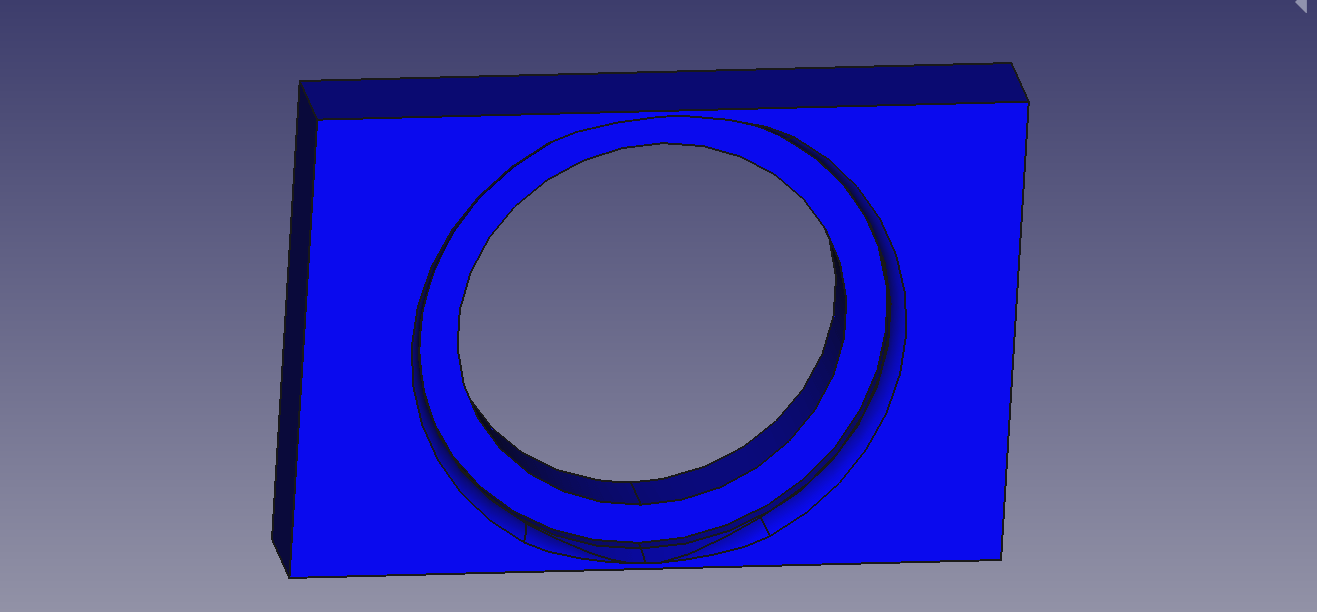

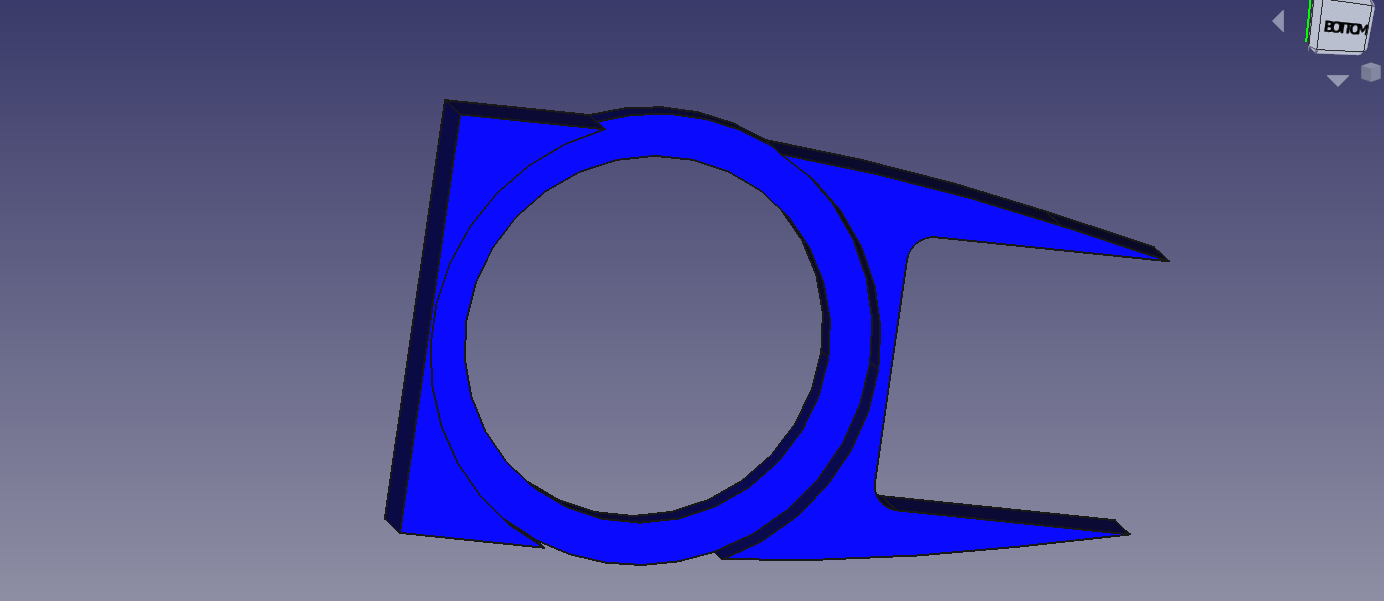

Starting at the main baffle, the first part to come off is the face trim. This can be 3D printed, CNC'ed or handcrafted. The file is currently available as a .stl and can be exported to other formats too

The specified colour is a carbon blackish grey, whatever is available in that shade. Can be made out of any preferred material, but a print will be easiest. Printed part is to be wet sanded with 400 wet/dry style paper and water can be used. Can be finished in clear poly with UV resistance

Alloy can be anodised, powder coated or painted

Wood should be done with my recommended water break free system and finished with UV resistant clear poly

Covering with a fabric finish will not need the prep work except for a lil bit of wet sanding with 240 paper

This part is fitted to the cab with epoxy

The specified colour is a carbon blackish grey, whatever is available in that shade. Can be made out of any preferred material, but a print will be easiest. Printed part is to be wet sanded with 400 wet/dry style paper and water can be used. Can be finished in clear poly with UV resistance

Alloy can be anodised, powder coated or painted

Wood should be done with my recommended water break free system and finished with UV resistant clear poly

Covering with a fabric finish will not need the prep work except for a lil bit of wet sanding with 240 paper

This part is fitted to the cab with epoxy

This is an alternative to using the baffle face trim. This is the full main baffle and should be CNC'ed out of bamboo board. This can be stained and a UV resistant clear poly should be used. Fabric or paint are alternative finishes. This is available in .step format. The badge can be lasered in from a separate file

Here is the CNC for the bamboo inlay for the face trim forms the face trim version of the main baffle. This part does not require finishing

Following is the side baffle, this part is repeated on the other side, so two pieces required. This is made of bamboo board and CNC is best, can be handcrafted. This one is 28mm thick. This can be finished with already mentioned systems for the main baffle face. The side baffle is exported to .step

Wagner Electronics in Sydney, Australia have proven to be extremely poor customer service. I ordered the PR units for this project on the 27th, it's the 9th today and still no communication from them regarding what's going on. They haven't replied to email and when I called, the person answering the phone sounded evasive and arrogant. Stay clear of this mob

Dayton looks like a company that has some in-house stuff and some generic rebadged items. I fear the PR units just might be the rebadged OEM type items, as there are identical no name offerings on Ali to a lot in their range. I'll locate some units and order them in. I am confident that should I order today, I'll receive them sooner than AU dispatchers like Wagner. Another case of voting with our wallets to those that provide a real service

I've been regularly buying stuff from Wagner since before they had online ordering and one had to fax orders to them, with my last order being an order of transistors a few months ago. They aren't at the forefront of technology website wise, but I've never had any issues whatsoever.

I lived within 10km of their shop for about 30yrs, I stopped going there after a while, preferring to use the 'old' multicultural Bankstown Jaycar instead. The Jaycar folks responded to ethnic youths better even back then. So far, these guys haven't replied to email, nor they have provided any updates. 13 days, man, what do you think about my experience?I've been regularly buying stuff from Wagner since before they had online ordering, with my last order being an order of transistors a few months ago. They aren't at the forefront of technology website wise, but I've never had any issues at all.

Anyway, moving past local annoyance, I'll prolly give them another few days and then write to the consumer affairs folks. The thing these local shops don't realise is that if they keep their end up, they will never have angry customers, and they need to lose this "doing you a favour by selling to you attitude"

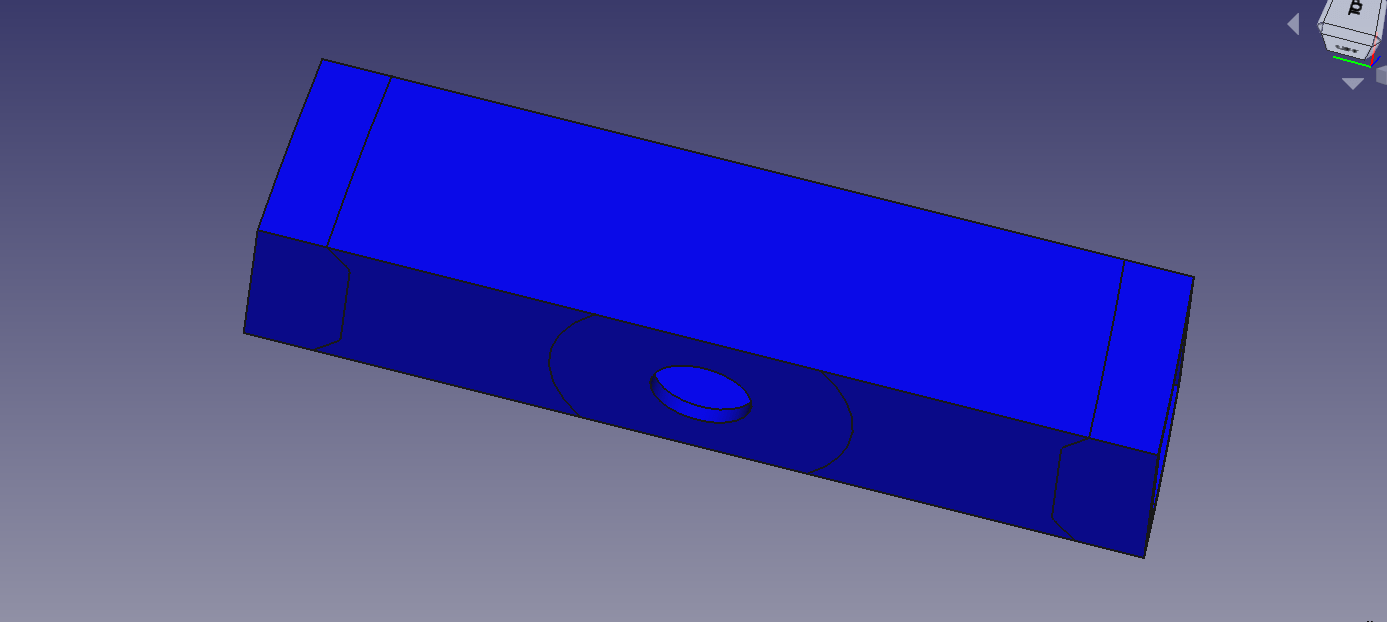

Next up will run off the box beam covers for the electronics section. I'll leave them undrilled for now, as those red jet fans do no specify hole sizes and such. Have to wait for them to arrive to measure

That leaves the heat pipe components in alloy and internal structurals. Eat now 😀

Next up will run off the box beam covers for the electronics section. I'll leave them undrilled for now, as those red jet fans do no specify hole sizes and such. Have to wait for them to arrive to measure

That leaves the heat pipe components in alloy and internal structurals. Eat now 😀

Wagner finally sent an email notifying that the items are shipped. No explanations, or apologies for the 16 days delay and zero updates. The best thing about this situation is that it's further incentive to rely less on difficult suppliers

Almost done with the individual parts. This is the heat pipe/box beam thingy. Now this build has, props, radiators, motor, ECU and an exhaust......built as a powered vessel seems apt. I need to pickup a bit of 40x40mm alloy box from local Steerite outlet, they will do by the metre price and I have an account there for my marine craft builds. The heat pipe can be formed with CNC or handcraft

I see it is time to learn new construction methods for me. Looking forward to seeing the rest.

The passive radiators for this project arrived today. These 6.5" Dayton DSA175s appear much cheaply built than the Ali 5" units for another project. The metal disc on the spider is way off-centre, the surround is foam. The basket is stamped steel. On the 5" Ali unit, the surround is rubber, all the gluing is more consistent and the basket just looks like a 5" version of the Dayton. The Dayton's cost AU $100 for the pair, with pathetic customer service and over two weeks shipping from the local dealer. The Ali units arrived a few days after ordering and cost AU $23 for the pair

I am finding it very difficult to support a local business and the Dayton brand. If this is the quality control, then I am lucky to not have ordered the Epique woofer for AU $265

I'll order the 6.5" version of the Ali PR units to test head to head with the Dayton's

Also need to draw in the mounts on the back panel for the I/O. Tossing up between the DSP board vs the analog 2.1 filter board, I have both on hand for this project. As well, really hating the bulk on the Speakons. There must be a nicer system

I am finding it very difficult to support a local business and the Dayton brand. If this is the quality control, then I am lucky to not have ordered the Epique woofer for AU $265

I'll order the 6.5" version of the Ali PR units to test head to head with the Dayton's

Also need to draw in the mounts on the back panel for the I/O. Tossing up between the DSP board vs the analog 2.1 filter board, I have both on hand for this project. As well, really hating the bulk on the Speakons. There must be a nicer system

- Home

- Loudspeakers

- Subwoofers

- Cub Sandwich