It seems like something's wrong with the Vcc to the 555 timer. It's about 3.4 volts from Vcc to ground and it's all 120Hz ripple. I'm trying to find out where it's sourcing that power from. It's not on the schematic. Tried removing the PCB today and some of the bias transistor wires broke off from the process. I've replaced every electrolytic cap on the board. It seems like it's getting power from the filament circuit as Vcc pin 8 traces to one of the big capacitors on the board.

The other thing that's troubling is that the amplifier is drawing 175W from the line with no MOSFETs installed and the transformer heats up rather quickly. As in warm to the touch after 2 minutes running. I'm starting to be concerned that the winding for the filament circuit may be damaged from the event that lead up to the caps exploding when the customer last used it.

The physical layout, lack of plug in connectors and no access to solder side of PCB make troubleshooting very tedious and slow.

The other thing that's troubling is that the amplifier is drawing 175W from the line with no MOSFETs installed and the transformer heats up rather quickly. As in warm to the touch after 2 minutes running. I'm starting to be concerned that the winding for the filament circuit may be damaged from the event that lead up to the caps exploding when the customer last used it.

The physical layout, lack of plug in connectors and no access to solder side of PCB make troubleshooting very tedious and slow.

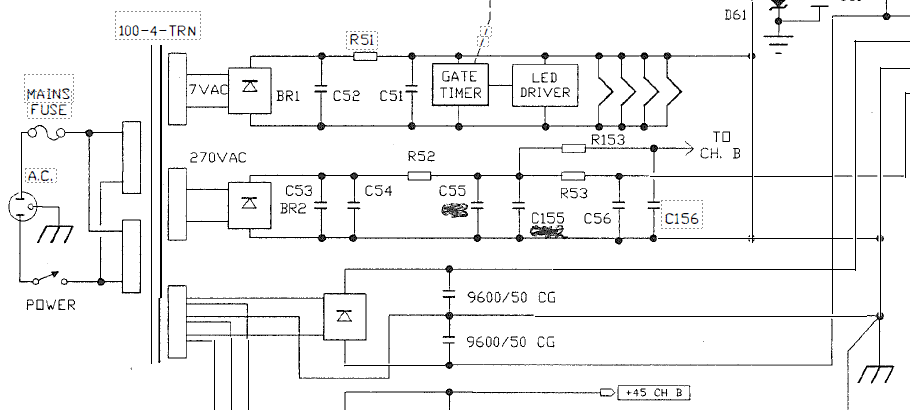

The gate timer is powered from the unregulated heater supply. The wrinkle is that the positive side is connected to ground to it is a nominal -6V supply. Here is snippet from the schematic to explain.

If you are lucky, the bridge rectifier BR1 has died. If so, replace it with a chassis mount part bolted to the chassis floor in front of the PCB and then wire it to the plated-though holes that the original rectifier was fitted to.

If you are unlucky, then you have a dead transformer...

If you are lucky, the bridge rectifier BR1 has died. If so, replace it with a chassis mount part bolted to the chassis floor in front of the PCB and then wire it to the plated-though holes that the original rectifier was fitted to.

If you are unlucky, then you have a dead transformer...

Attachments

Well it turns out that the 270VAC winding is only putting out 1.4 VAC and measures 2.3 ohms.

Looks like it needs a new power transformer.

Looks like it needs a new power transformer.

The original FETs are ALL bad. I got new lateral MOSFETs for it, did the bias mods, but came to discover this new wrinkle. Probably the customer didn't shut off the amp when the capacitors failed and it damaged the HV winding.

This is a pretty hard to find transformer. Any leads on a replacement?

This is a pretty hard to find transformer. Any leads on a replacement?

You could rewind the transformer which is unlikely to be economic if either you or a commercial transformer winder does the job. It is a custom transformer as it is effectively a valve preamp + solid state power amp transformer built on one core. Easiest solution (and it might even fit in the box) would be to get two toroidal transformers - the first with heater and plate windings and the second with suitable power windings and then mount #1 on top of #2

PacTran is telling me that they are having trouble meeting the specs for this transformer based on physical dimensions and winding voltage. They said when they run the simulation, it runs too hot. I have not been able to get them to follow up. I suggested de-rating a bit for music crest factor, but it's been a month and they have not responded. So I am still looking for someone to rewind the original transformer.

They asked for the dimensions, winding voltages and DCR of each winding. I also sent a photo of the diagram that is pasted on top of the transformer, showing winding diagram with winding voltages.What spec did you give to PacTran?

I recommend that you measure the available space rather than the actual transformer. Allow a 5mm gap front/back/sides and 5mm clearance to the top plate. But otherwise, fill the space. That should allow TranspAc to use a larger core. Also the B+ voltage has more headroom than is sensible - you do not have to cope with different mains input voltages. If you like I can drag out my files and advise on a lower B+ secondary voltage that should make that winding smaller

Sorry, forgot to mention that a larger transformer means that you will need to drill four new holes in the steel case floor. So be prepared for that. And don't forget to vacuum out ALL the steel filings - they do not play nicely with electrical bits

I did mention to PacTran that we can increase dimensions in all axis by about 12mm and still fit, but with drilling needed. Despite that, this was the response:Sorry, forgot to mention that a larger transformer means that you will need to drill four new holes in the steel case floor. So be prepared for that. And don't forget to vacuum out ALL the steel filings - they do not play nicely with electrical bits

"I tried simulating this with the information given and the transformer is still running really hot"

The 270VAC and 7VAC windings will be loaded at 100% (Class A circuitry) but the winding for the MOSFET output stage will be loaded at 10% for 95% of the time - unless you are into EDM, a bit deaf and have very inefficient speakers - in which case you bought the wrong amplifier 😉

That might help the PacTran dude that he/she can do something.

It is worth noting that the original ran hot.

That might help the PacTran dude that he/she can do something.

It is worth noting that the original ran hot.

I suspected it would run hot. What I didn't expect is that PacTran would lose interest in this job, even with oversizing the transformer a bit.

So I have an amplifier that I've already spent many hours cleaning up the damaged PCB from capacitor failure, recapped the board, bought replacement MOSFETs from another tech on this board after many weeks of searching for the unobtainium parts, all taking place since it was shipped in here in mid August from out of state. The packing material is taking up precious space in my 80 sq ft shop and I'm frustrated that there is no end in sight to this fiasco. (sigh)

So I have an amplifier that I've already spent many hours cleaning up the damaged PCB from capacitor failure, recapped the board, bought replacement MOSFETs from another tech on this board after many weeks of searching for the unobtainium parts, all taking place since it was shipped in here in mid August from out of state. The packing material is taking up precious space in my 80 sq ft shop and I'm frustrated that there is no end in sight to this fiasco. (sigh)

God bless you Konst. I collect and repair counterpoints as a hobby and I second your Vishay / Infineon IRFP240 subst.

One person went as far as saying I will set owners houses on fire with this mosfet replacement!

K1 has ALWAYS given me a lot of trouble with old SA12 and SA100s.

If there's no 5V going to trigger it wont pop.

ALso NEW relays have the plus and minus REVERSED and wont trigger evenif the voltage rises to 5 from the 555 timer.

So the way to TEST is to pull a pair of wires and use a 3 cell batterypacke to trigger it yourself as you are testing the bringup.

Do nit bypass the relay otherwise startup in rush and DC from the 1uF couplers can kill things.

One person went as far as saying I will set owners houses on fire with this mosfet replacement!

K1 has ALWAYS given me a lot of trouble with old SA12 and SA100s.

If there's no 5V going to trigger it wont pop.

ALso NEW relays have the plus and minus REVERSED and wont trigger evenif the voltage rises to 5 from the 555 timer.

So the way to TEST is to pull a pair of wires and use a 3 cell batterypacke to trigger it yourself as you are testing the bringup.

Do nit bypass the relay otherwise startup in rush and DC from the 1uF couplers can kill things.

AmpExpert you can convert the amp into an SA12-like stereo PS vs a dual mono-at-output-rails like the SA100.

That way you use 2 x 20,000 63V caps, 1 bridge, 1 30V+30V Antek Toroid and a cheap Hammond that can output 270V and filament V.

They will fit into the front of the amp.

That way you use 2 x 20,000 63V caps, 1 bridge, 1 30V+30V Antek Toroid and a cheap Hammond that can output 270V and filament V.

They will fit into the front of the amp.

If the customer had an unlimited budget for re-engineering the power supply, I would try something like that. In the meantime, I'm keeping an eye out for a parts unit, or someone parting out a unit.AmpExpert you can convert the amp into an SA12-like stereo PS vs a dual mono-at-output-rails like the SA100.

That way you use 2 x 20,000 63V caps, 1 bridge, 1 30V+30V Antek Toroid and a cheap Hammond that can output 270V and filament V.

They will fit into the front of the amp.

Mercury Magnetics quoted me $870 to build a new power transformer for this. Out of the question entirely.

If you are willing to buy via Aliexpress, then you can build a 'replacement transformer' for USD120 + shipping. I would expect that would go to ~USD250 for DHL to the US. By replacement transformer, I mean one for the SS output stage and another one for the valve plate and heater.

- Home

- Amplifiers

- Solid State

- Counterpoint SA-100 MOSFETs Source?