Gorgeous sailboat! I don't recognize the make or designer though. My secret dream is to build a copy of Ian Oughtred's "Wee Seal", for which I purchased the plans.

Gaff-rigged, of course.

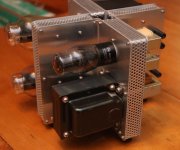

And for the purposes of staying on-topic, I'm trying to figure out how to lay out my next amp using 1/4" to 3/8" aluminum. I have a friend with a milling machine who's willing to let me have a go at fabricating a top plate (I'm a pretty fair amateur machinist), but I need to get the particulars worked out first. It's not easy planning for a multitude of countersunk/counterbored bolts, patterned cooling holes and strategic thinning around the tube sockets. Heck, I might just even go stainless for that matter.

Any fool can grind metal, but it takes a bit of extra effort to pull off something that looks decent.

Gaff-rigged, of course.

And for the purposes of staying on-topic, I'm trying to figure out how to lay out my next amp using 1/4" to 3/8" aluminum. I have a friend with a milling machine who's willing to let me have a go at fabricating a top plate (I'm a pretty fair amateur machinist), but I need to get the particulars worked out first. It's not easy planning for a multitude of countersunk/counterbored bolts, patterned cooling holes and strategic thinning around the tube sockets. Heck, I might just even go stainless for that matter.

Any fool can grind metal, but it takes a bit of extra effort to pull off something that looks decent.

Attachments

Last edited:

I've always used 3/8" aluminum. For the size we build that is plenty thick and ridged. Your friend should be able to walk you through the process.

Last edited:

Is that a vertically-mounted Antek toroidal transformer? I did the same thing on a pair of monoblocks two or three years ago. Worked great!

I ordered one of these trays from an Ebay seller on July 15. A tray matching my Ebay order arrived today from the local Amazon fulfilment center in Pittsburgh in an Amazon box. The Ebay seller took my order, then ordered one from Amazon on July 17, and had it drop shipped to me as a "gift."

The tray is a new production unit "made in India" and is a bit lighter in weight than the Navy mess hall units found on Ebay. It is entirely suitable for a small guitar amp since I'm not going to put 50 pounds worth of iron on it. It's nice and shiny too.

The brand mane is Winco and their part number is SMT-2. They can be found on Amazon for $10.34 with free Prime shipping.

Amazon.com | Winco 6-Compartment Mess Tray, Style B: Divided Serving Trays: Divided Trays & Platters

The tray is a new production unit "made in India" and is a bit lighter in weight than the Navy mess hall units found on Ebay. It is entirely suitable for a small guitar amp since I'm not going to put 50 pounds worth of iron on it. It's nice and shiny too.

The brand mane is Winco and their part number is SMT-2. They can be found on Amazon for $10.34 with free Prime shipping.

Amazon.com | Winco 6-Compartment Mess Tray, Style B: Divided Serving Trays: Divided Trays & Platters

What are you going to use for a chassis Tube?

Not sure yet. My current thinking is to make or recycle an aluminum box for the base, and build something that sits into a speaker cabinet like one of those old flip top Ampeg guitar amps. Maybe just some spacers / standoffs holding the tray an inch or so above a flat metal sheet. I'll make it up as I go along.

I have no need for a 1.21 Jiggowatt guitar amp, so this will be something that makes 10 watts or so and I can carry with one hand.

Now that I have the mess hall tray, I can start figuring out how much stuff I can cram into it, and where to put it all. Then I need to figure out how to wire it up.

This will be something that could have been built before I was born (1952) so no PC boards or silicon will be used. I have exactly one metal rectifier tube, so I hope it's good.

Stan at ESRC recently passed away, and the business is closed, so the days of "yo, send me some tubes (cheap)" is gone forever.

Might look cool to use 1" stand offs 1" apart all around the perimeter. solid and cool and safe all at the same time.

Might look cool to use 1" stand offs 1" apart all around the perimeter.

That does sound neat.

I spent some time last night gathering up a pile of parts for the "dream amp" I want to build. Before I had fully populated the pile of parts on the floor it became obvious that the stereo, channel switching, high gain amp with a reverb tank that I want to build is NOT going to happen in this chassis. There is too much wasted space, and my 60 year old Stancor power transformer is not going to fit where I wanted to put it. Neither are the two OPT's that I ripped out of 50's vintage Baldwin organ.

Time to reconsider. The full on MetallicAmp 2 will happen, with those parts, but probably in a standard Bud or Hammond chassis at a later date. I have collected a lot of those chassis cheap at hamfests over the 50+ years that I have been going to them.

Today's task is to figure out what I can make with this mess hall tray and the parts I have on hand. Expenditures for things like spacers are OK, but my history dictates that if momentum stops while I wait for parts......it could be a long time until I get back to it.

I have a smaller power transformer that will do fine feeding a pair of metal 6V6's, and up to 8 other tubes. ONE of the Baldwin OPT's will fit just fine. The task is now, how to mount the pots / knobs, and how many do I want / need. The large reverb tank that I wanted to use is over an inch longer than this tray is wide, so it gets saved for MetallicAmp 2. I have a smaller tank that was removed from a dead guitar amp I got at a hamfest. If It works, it may get used.

Decisions......decisions.......

you could use 2 of them.

My first thought was that it would be a rather large amp. Then after dreaming on it last night, I thought that it might be cool to place the two "chassis" vertically with the "eating sides" together with the tubes and transformers sticking out in a horizontally opposed arrangement, like a BMW motorcycle or Subaru car engine.

Signal one one and power on the other.

The next part of the dream has me building two similar looking but different complete amps, one on each chassis. Each fed by the same guitar, and meeting in the middle where the "preamp" meets the "power amp" where blend and balance controls would be.

One "preamp" would do the "clean" guitar sound with its own tone controls, while the other does the "cranked" sounds. The blend / balance part routes a different mix of each sound to two power amps, and to two separate speakers.

I'm leaning toward this plan, which makes life a bit easier since each amp can be built individually, then joined.

...Maybe just some spacers / standoffs holding the tray an inch or so above a flat metal sheet. I'll make it up as I go along.

...Stan at ESRC recently passed away, and the business is closed, so the days of "yo, send me some tubes (cheap)" is gone forever.

For safety you could "wrap the gap" created by the spacers with a strip of perforated aluminum (like the fi-X amp pictured below in a file stolen shamelessly off of the web). Just a thought, since you've mentioned in previous posts that you might have some curious youngsters about.

Stan's passing was a blow on many levels. My wife and I became acquainted with him over the years during visits to the larger hamfests; I got to know him even better later on whenever I'd phone in an order while on travel to some far-flung section of the country (explaining that would take another thread). Stan was a true gentleman, one of the good guys in the business. He'll be sorely missed.

Returning to the topic at hand, I'm reading this thread with intense interest. My amp-building has been put on semi-hiatus for a few weeks while I perform some major upgrades to the house, so in the meantime I'll just have to satisfy myself with seeing what you guys whip up. It's gotta' be good.

Attachments

Stan was a true gentleman, one of the good guys in the business.

I met Stan at the Miami hamfest back when his father still ran ESRC, then known as the Electron Supply Replacement Corporation. He operated out of a small warehouse in Palm Beach county not far from the off campus "think tank" that I worked at in the early 90's. I often went there for tubes on my lunch break. He moved the operation to Orlando when his father passed, and expanded it a lot over the years.

you could "wrap the gap" created by the spacers with a strip of perforated aluminum

That was my thought. The strip in the front would be solid, and used to mount the pots and switches. Ditto the rear for power, speaker, and pedal board jacks.

I think I still have some of the aluminum channel and diamond plate left over from building the metal SSE, which was glued together with JB Weld, and came a bit "unglued" when it got dropped during a house move. I'll put it back right some day, but even its current (out of) shape, it still works.

like the fi-X amp pictured below in a file stolen shamelessly off of the web

I saw one of those a long time ago at a house next door to my brother. This guy had several expensive amps, and a few years later he would buy two TSE's from me, back when I built completed amps for sale.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Cool tube amp top plate