When I started this post today, there were 6 trays available. Now they are all sold out. Maybe I started a new trend.

djn,

One post said:

"... could be the first dishwasher-proof tube amp."

"A member here, W5JAG has run his SSE board through the dishwasher a few times to clean up the remains of failed experiments.

After spewing electrolytic goo all over one of mine several years ago, I tried it.....it did look nearly new despite several years of failed experiments. Now after 10 years of being used as a test mule, it's still kicking."

PCB board washing used to be done in Freon.

Washable Tube Amp

Washing PCBs

Yes, a bit of a stretch.

One post said:

"... could be the first dishwasher-proof tube amp."

"A member here, W5JAG has run his SSE board through the dishwasher a few times to clean up the remains of failed experiments.

After spewing electrolytic goo all over one of mine several years ago, I tried it.....it did look nearly new despite several years of failed experiments. Now after 10 years of being used as a test mule, it's still kicking."

PCB board washing used to be done in Freon.

Washable Tube Amp

Washing PCBs

Yes, a bit of a stretch.

Either six amp builds are underway or there's been a sudden nostalgic urge to eat C-Rations. 😛When I started this post today, there were 6 trays available. Now they are all sold out. Maybe I started a new trend.

All this dishwasher talk reminds me of a guy who was fixing game consoles, I think it was Play Stations? by putting them in the oven under low heat to re-melt the solder connections which were notorious for cracking and causing the unit to fail. He made a butt load of money.

I did something similar with automotive ECU's in the 80's and early 90's. I used a light coating of paste flux and a paint stripper type of heat gun. The area around the big connectors, where most of the cracks lived, often needed help with a soldering iron.

Some ECU's, notably those found in Mitsubishi cars needed wholesale replacement of all the electrolytic caps too. Right up there with Dell motherboards in the dead cap department.

Some ECU's, notably those found in Mitsubishi cars needed wholesale replacement of all the electrolytic caps too. Right up there with Dell motherboards in the dead cap department.

Dell has never fixed that dead cap issue, they insist on using cheap Chinese caps.

Dell is crap.

Dell is crap.

Cake pans are available in a wide variety of sizes. Just do a search for the size you want.That would be cool to find a cake pan with the same outside measurements.

They are also much more practical in that the divisions in the tray you pictured would make it very difficult to place parts and run wiring. A regular rectangular or square pan, like you would use to bake brownies, would work much better.

There have been at least a couple of builders who sold amps made with cake pans. One was Don Allen, who I believe has since passed. His amps developed somewhat of a cult following. Another builder, Lance Cochran, also sold at least a few amps built that way.

Some years back I found a very large, thick, heavy duty aluminum baking sheet at a flea market. I figured it must have come from an institutional kitchen like a school or prison. I built a PP 6B4G amp on it.

I seem to remember a Sound Practices article also. I'll look though my back issues CD when I get the chance.

I've been tempted to go the cake pan route myself. I think the main reason I haven't yet is because I tend to favor those thick die-cast jobs with rounded corners, and they ain't cheap. I've asked several of the local high-end cooking stores if they had any damaged ones they'd thrown out, but no luck so far. And since I'm too impatient to wait I almost always wind up just building a stinkin' box.

I really can't wait to see what the OP "cooks up" with this tray. I've never said this before, but his previous work has always inspired me to push the envelope on my own builds with regard to enclosures and presentation - and for that I'm truly grateful.

I've been tempted to go the cake pan route myself. I think the main reason I haven't yet is because I tend to favor those thick die-cast jobs with rounded corners, and they ain't cheap. I've asked several of the local high-end cooking stores if they had any damaged ones they'd thrown out, but no luck so far. And since I'm too impatient to wait I almost always wind up just building a stinkin' box.

I really can't wait to see what the OP "cooks up" with this tray. I've never said this before, but his previous work has always inspired me to push the envelope on my own builds with regard to enclosures and presentation - and for that I'm truly grateful.

the divisions in the tray you pictured would make it very difficult to place parts and run wiring. A regular rectangular or square pan, like you would use to bake brownies, would work much better.

I have used cake pans, street signs, Lexan, kitchen countertops, and other random pieces of free or cheap material for amp chassis and top plates. They work but just look traditional or boring. I have made too many amps like this in my life.

One of my favorite oddball amps was made on a piece cut from a mangled hurricane protection panel found in the street after the storm had passed. The tubes were sticking out at opposing angles, making it easy to call this amp the "V6." I didn't have it long before someone bought it on looks alone. A V8 was planned but the hurricane season was over so the Home Depot stores did not restock the panels.

I did buy one of the mess hall trays and will attempt to use it for a guitar amp featuring all metal tubes. The turning point for me will be in how easy it is to drill and punch holes in it. Stainless is notoriously finicky in this respect, and the reason I usually avoid it. It doesn't like paint either.

If it works out, it will be "different." Which is the reason for the metal tubes......Getting a big box full for free didn't hurt either. There were 8 nice metal 6V6's in that box and all have been tested to 30 WPC in a HiFi amp. This one will be lower powered, but stereo, with dissimilar channels, if I can make it all fit.

I almost never use metal chassis, I prefer to use Hard Wood or Marble / Tile, would like to try a Mirror or Agate slice. Metal is kinda blah. Although I do use it for Guitar amps, ... things that I expect will get rough treatment rather than just sitting on a shelf.

I really can't wait to see what the OP "cooks up" with this tray. I've never said this before, but his previous work has always inspired me to push the envelope on my own builds with regard to enclosures and presentation - and for that I'm truly grateful.

Thanks Mr. Z! I truly appreciate that. I have a couple projects on the bench so I have time to figure out the chassis for the dishwasher safe amp.

Here is the power supply I am working on now. I will start the assembly Friday after the clear coat dries.

Attachments

Last edited:

Here is the power supply I am working on now.

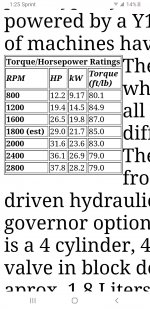

That little green power supply might put out a few hundred watts......that big yellow one is good for a bunch of kilowatts for sure.......1 HP = 746 watts.

90 HP for a 4 cyl flattie is pretty good. The universal Atomic Fours found in old sailboats made 30 HP with 4 cylinders ( I rebuilt a few many years ago), while my first car (also a flattie) needed 6 cylinders for 97 HP.

- Home

- Amplifiers

- Tubes / Valves

- Cool tube amp top plate