I have used liquid dish and hand wash solutions on computer SMPS, with a tooth brush to remove dirt. this also softens up the really sticky dirt.

I wash off excess dirt, using a tooth brush to clean under running water, then use soap solution with a tooth brush to clean really dirty parts.

It removes the dirt quite well, and then I rinse it thoroughly and use compressed air to blow off moisture, then sun dry for at least a day. Alternately, my tray drier for plastics, set at 70 Centigrade for at least 2 hours.

After that, I power up after checking for obvious faults like bad caps...

Then I put insulating varnish on the track side to prevent dust and moisture induced flash over problems.

The problem with alcohol is also that it tends to remove the markings on the boards and components, adding to service hassles later, also it is quite expensive compared to soapy water, apart from being a fire hazard.

And the smell in a closed room makes my head spin...

I wash off excess dirt, using a tooth brush to clean under running water, then use soap solution with a tooth brush to clean really dirty parts.

It removes the dirt quite well, and then I rinse it thoroughly and use compressed air to blow off moisture, then sun dry for at least a day. Alternately, my tray drier for plastics, set at 70 Centigrade for at least 2 hours.

After that, I power up after checking for obvious faults like bad caps...

Then I put insulating varnish on the track side to prevent dust and moisture induced flash over problems.

The problem with alcohol is also that it tends to remove the markings on the boards and components, adding to service hassles later, also it is quite expensive compared to soapy water, apart from being a fire hazard.

And the smell in a closed room makes my head spin...

Electronics are routinely cleaned with water and a surfactant in production. You just want to be careful around parts that are not sealed, such as pots, switches, and relays. And be careful with the solvents if your circuit contains polystyrene caps.

I've even heard of dishwashers being used for flux cleaning of circuit boards in low-volume production. Just don't wash your dishes in it after. 🙂

I use solder with water soluble flux for my prototype builds. I was the board in the kitchen sink with a bit of dish soap. I then shake the water off the board and blow any remaining water off with a can of compressed air and leave the board in the oven for 10-15 minutes at 60ºC.

That approach would likely work for you, though given the amount of plastic in an amp, I would probably aim for 40ºC.

Tom

I've even heard of dishwashers being used for flux cleaning of circuit boards in low-volume production. Just don't wash your dishes in it after. 🙂

I use solder with water soluble flux for my prototype builds. I was the board in the kitchen sink with a bit of dish soap. I then shake the water off the board and blow any remaining water off with a can of compressed air and leave the board in the oven for 10-15 minutes at 60ºC.

That approach would likely work for you, though given the amount of plastic in an amp, I would probably aim for 40ºC.

Tom

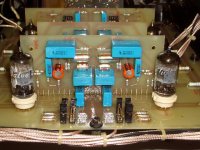

It looks like the amp in post 1 can be cleaned by mechanical means only,

strong compressed air beam and brush.

For severe cases and smokers gear in particular let me recommend a

radical approach, by means of baking oven cleaner spray.

In instruments where smoke and dirt have developed a sticky layer it

is very helpful. I use it for a long time now with only minor caveats.

Yes, it can damage some paints, especially on old surfaces. This of course

depends on the time of exposure mainly - check it out on the bottom or

somewhere else appropriate. It will not destroy imprints, colour codes etc.

most of the time.

Outside surfaces can be cleaned in a nice way applying some of the substance

and using it with moist cloth.

Buy the cheapest no-name can of cleaner, the brand names contain nasty

perfumes. Take off cover and bottom plate for a good access to the innards.

Best place for application is in the bath tube.

After spraying leave the cleaner do its work for about half an hour or more,

but not too long, foam must still be present. Clean with the shower head and

strong water beam, temperature set to maximum, then let dry in hot sun or

on the oven.

I tried this first with a cheap old stereo receiver just to be sure. It looked like

new inside after application.

The sample pictures show a tube preamp which has no air vents at all.

Somehow smoke came in through minor tolerance slots and all the particles

remained inside the case. You see I applied it to the open ALPS pot even.

strong compressed air beam and brush.

For severe cases and smokers gear in particular let me recommend a

radical approach, by means of baking oven cleaner spray.

In instruments where smoke and dirt have developed a sticky layer it

is very helpful. I use it for a long time now with only minor caveats.

Yes, it can damage some paints, especially on old surfaces. This of course

depends on the time of exposure mainly - check it out on the bottom or

somewhere else appropriate. It will not destroy imprints, colour codes etc.

most of the time.

Outside surfaces can be cleaned in a nice way applying some of the substance

and using it with moist cloth.

Buy the cheapest no-name can of cleaner, the brand names contain nasty

perfumes. Take off cover and bottom plate for a good access to the innards.

Best place for application is in the bath tube.

After spraying leave the cleaner do its work for about half an hour or more,

but not too long, foam must still be present. Clean with the shower head and

strong water beam, temperature set to maximum, then let dry in hot sun or

on the oven.

I tried this first with a cheap old stereo receiver just to be sure. It looked like

new inside after application.

The sample pictures show a tube preamp which has no air vents at all.

Somehow smoke came in through minor tolerance slots and all the particles

remained inside the case. You see I applied it to the open ALPS pot even.

Attachments

I've tried similar cleaning methods on a 1960 era tube kitchen radio that still worked, albeit not perfectly. Bought for $10 at a yard sale. After cleaning, it sold for $2.50 on Ebay. That is why I no longer buy stuff to clean and re-sell 😀

Guys buying old tube radios want them in original condition and if the capacitors are gone you fit smaller new ones inside the shells of the old ones to keep the authentic look.

Small American old tube radios made out of plastic are worth money especially if they are brightly colored.

Small American old tube radios made out of plastic are worth money especially if they are brightly colored.

I've tried similar cleaning methods on a 1960 era tube kitchen radio that still worked, albeit not perfectly. Bought for $10 at a yard sale. After cleaning, it sold for $2.50 on Ebay. That is why I no longer buy stuff to clean and re-sell 😀

Great story. 😀

I have a little more into this amp than you. It was $16.99, sold as-is with no returns. The cashier gave me the "senior discount", so it was $12.50, plus tax and this does not count the 1/4 bottle of isopropyl alcohol and a handful of Q-tips that I have used so far.

The shop-vac and air compressor were already on the scene. 😀

Yes, agree, I found a gold mine in the area and brushed it up for a lot of money,

but later had to sell it for pennies.

but later had to sell it for pennies.

Guys buying old tube radios want them in original condition and if the capacitors are gone you fit smaller new ones inside the shells of the old ones to keep the authentic look.

Coincidentally this is also how you make a hand grenade... Authentic look or not, that's not exactly safe. If the electrolytic cap decides to vent, you'll be in a world of hurt.

Tom

I am afraid no UK "handgrenades " have gone off in peoples in UK citizens homes due antique valve radio restorers like myself trying to keep the original condition as that's what UK buyers want .

If sales in the USA depend on how "shiny " something is well its just a cultural difference .

"Hand-grenades " ?--- I suppose that comes from watching too many US war movies .

Spend some time on very well established UK antique radio renovation forums or should I say wireless as that is the original definition and you will find its common practice .

No report in the press in my lifetime Tom has appeared as a news item of a renovated wireless exploding ---but maybe you can dig one up with a link ?

If sales in the USA depend on how "shiny " something is well its just a cultural difference .

"Hand-grenades " ?--- I suppose that comes from watching too many US war movies .

Spend some time on very well established UK antique radio renovation forums or should I say wireless as that is the original definition and you will find its common practice .

No report in the press in my lifetime Tom has appeared as a news item of a renovated wireless exploding ---but maybe you can dig one up with a link ?

If you use the old can over the new one and it is not sealed up you have a shield not a grenade if the ecap decides to spill its guts. The only time I have seen ecap's explode is when they are installed backwards or you insert them into the AC line plug ( power off) and then turn on the breaker on. Yes we liked to blow things up when we were young and foolish.

I have seen tants in boards installed backwards, blow holes thru the pcb. Sometimes it is quickly and in other times it was a ticking time bomb. When I was designing boards at HP, we could only use Kemet fused tantalums, because of these safety concerns.

I have seen tants in boards installed backwards, blow holes thru the pcb. Sometimes it is quickly and in other times it was a ticking time bomb. When I was designing boards at HP, we could only use Kemet fused tantalums, because of these safety concerns.

Last edited:

If sales in the USA depend on how "shiny " something is well its just a cultural difference .

Very true. Content matters not to most.

I counter that trend. Not a believer in the "cover of the book".

Fluc the Facade.

OS

No. My experience with hand grenades is from my four years of military service. Maybe your experience is different."Hand-grenades " ?--- I suppose that comes from watching too many US war movies .

Tom

I saw the results of war when UK veterans came home after WW2 --without body parts -minds affected etc .

I have in the past also been in contact with the USA Veterans Association and it a case of cheers as they go to fight and being ignored on their return.

But you made out I was making "hand-grenades" that's something I will not let go unanswered.

I have in the past also been in contact with the USA Veterans Association and it a case of cheers as they go to fight and being ignored on their return.

But you made out I was making "hand-grenades" that's something I will not let go unanswered.

I was exaggerating for effect. Should I have added a smiley face? 🙂

Exploding capacitors is a thing. The old ones - as I'm sure you know - can explode and throw shrapnel at you. While they may not kill you, I'm sure they can remove a finger and certainly poke an eye out. I recall seeing a video on YouTube where someone one was repairing a tube amp and an electrolytic cap let go. He found shrapnel embedded in the walls of his workshop.

Unless you can guarantee that the smaller cap inside the larger can can safely vent its innards without causing the outer can to become a projectile, I would hesitate to use that method. But that's me.

Anyway... About cleaning of amplifiers...

Tom

Exploding capacitors is a thing. The old ones - as I'm sure you know - can explode and throw shrapnel at you. While they may not kill you, I'm sure they can remove a finger and certainly poke an eye out. I recall seeing a video on YouTube where someone one was repairing a tube amp and an electrolytic cap let go. He found shrapnel embedded in the walls of his workshop.

Unless you can guarantee that the smaller cap inside the larger can can safely vent its innards without causing the outer can to become a projectile, I would hesitate to use that method. But that's me.

Anyway... About cleaning of amplifiers...

Tom

I think the new ones have a rubber vent, and are generally safer unless wrongly selected or installed.

But I defer to the experienced restorers for their experience.

And if they do fail in tube radios, it will be 30 odd years for new ones, we are unlikely to be using them as broadcasts on those frequencies stop.

And most of us will be dead,

Enjoy and savor each moment...it won't come back.

But I defer to the experienced restorers for their experience.

And if they do fail in tube radios, it will be 30 odd years for new ones, we are unlikely to be using them as broadcasts on those frequencies stop.

And most of us will be dead,

Enjoy and savor each moment...it won't come back.

Clean amp, vacuum, blow air, scrub, elbow grease polish did I miss anything chemicals detergents solvents I am done

- Home

- Amplifiers

- Solid State

- Cleaning an Extremely Dirty Amp