Clay sounds fine to me (with appropriate dampening). Is it too late in the project to put some figural motifs on the outside?

another update!

My first attempt refused to remove itself from the mold, so I scraped it.

Second attempt worked, got it off the mold, got it ready to dry. Went to pick it up after it had dried and it shattered in my hands 🙁 I probably made the clay much too thin.

Third attempt, worked well until I left it to dry over the weekend. The clay shifted and gravity made a mess of it. The two pictures of the whole unit were taken dead on. As you can tell, its pretty lopsided...so I scraped it as well.

I'm likely to explore these properly over the summer when I have much more time to make proper molds. The biggest reason for these unsuccessful attempts was the fact I was using a male mold. Had I made a large female mold, the clay would be supported through the entire drying process and I wouldn't have it sagging like I did.

Unfortunately, I've run out of time to make these. Instead I will be building some simple sealed or ported boxes over the weekend (out of clay). If only to have a working product ready for class.

So now, my question is, for the drivers I have (the tangband w3's I linked in the first post) what would be a good volume for the enclosure and ported or sealed?

My first attempt refused to remove itself from the mold, so I scraped it.

Second attempt worked, got it off the mold, got it ready to dry. Went to pick it up after it had dried and it shattered in my hands 🙁 I probably made the clay much too thin.

Third attempt, worked well until I left it to dry over the weekend. The clay shifted and gravity made a mess of it. The two pictures of the whole unit were taken dead on. As you can tell, its pretty lopsided...so I scraped it as well.

I'm likely to explore these properly over the summer when I have much more time to make proper molds. The biggest reason for these unsuccessful attempts was the fact I was using a male mold. Had I made a large female mold, the clay would be supported through the entire drying process and I wouldn't have it sagging like I did.

Unfortunately, I've run out of time to make these. Instead I will be building some simple sealed or ported boxes over the weekend (out of clay). If only to have a working product ready for class.

So now, my question is, for the drivers I have (the tangband w3's I linked in the first post) what would be a good volume for the enclosure and ported or sealed?

Attachments

If you make a driver mounting ring from plywood to surround with clay, would it survive the oven? (Then you wouldn't need to worry so much about it warping or settling.)

I have considered slip casting, but as this is for a school project. But this, along with all the other end of term schoolwork, means that I simply didn't have time for anything more involved.

I was planing on using a piece of wood to mount the driver, but it needs to be mounted after the fact. The kilns get quite hot, hot enough to melt most metals.

I was planing on using a piece of wood to mount the driver, but it needs to be mounted after the fact. The kilns get quite hot, hot enough to melt most metals.

Ivan,

sorry to see your set backs. It's an ambitious project for sure! Slip casting does sound like a solid option, though a LOT of work getting the mold together. Keep at it though and I'm sure you will get a good system figured out.

Joe

sorry to see your set backs. It's an ambitious project for sure! Slip casting does sound like a solid option, though a LOT of work getting the mold together. Keep at it though and I'm sure you will get a good system figured out.

Joe

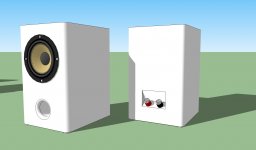

Progress has been made! Unfortunately I forgot to take "making of" pics, but I do have pics of the mostly finished product.

Currently these sound awful, but they arent 100% done yet. Drivers have only been used a few minutes so far and I still need to make a small panel on the back to plug a space I made for the binding posts. This being left open kills all the bass and even just plugging it with my hand makes a difference.

Currently I have about 1" of dampening along the interior walls. What would be better, lined walls or stuffed?

I've also thought of some more interesting designs and techniques, some of which I will definitely explore over the summer as time allows. I'll share some of those ideas here later.

Currently these sound awful, but they arent 100% done yet. Drivers have only been used a few minutes so far and I still need to make a small panel on the back to plug a space I made for the binding posts. This being left open kills all the bass and even just plugging it with my hand makes a difference.

Currently I have about 1" of dampening along the interior walls. What would be better, lined walls or stuffed?

I've also thought of some more interesting designs and techniques, some of which I will definitely explore over the summer as time allows. I'll share some of those ideas here later.

Attachments

100% done!

Got an A in ceramics and project accomplished.

Now I get to build the little matching amp to go with them.

I'd like to be able to sell these since I haven't much use for them.

Plugging that hole on the back for the posts made a world of difference. Night & Day really. They still have no real bass but I didn't expect much else. They definitely would make decent desktop/kitchen/etc... speakers. Very clean sound and certainly quite a bit better than most budget speakers you can get commercially.

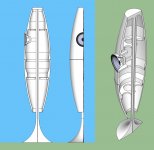

The sketchup file is my summer project. I'll take my time on this one since I want it to turn out right, and I'm thinking it would be an interesting small scale business venture if I got the process right. ( to feed my hobbies mostly' cars, computers, and speakers)

No dimensions as of yet, but it would probably be designed around the CHR-70's I have with the intention of substituting them later for something better. The bottom would be open but the top would be closed. The stand would be made of fiberglass most likely and would run down the entire center and house the wires to the drivers.

I have some other ideas, but this is something I can build without spending a whole lot.

Got an A in ceramics and project accomplished.

Now I get to build the little matching amp to go with them.

I'd like to be able to sell these since I haven't much use for them.

Plugging that hole on the back for the posts made a world of difference. Night & Day really. They still have no real bass but I didn't expect much else. They definitely would make decent desktop/kitchen/etc... speakers. Very clean sound and certainly quite a bit better than most budget speakers you can get commercially.

The sketchup file is my summer project. I'll take my time on this one since I want it to turn out right, and I'm thinking it would be an interesting small scale business venture if I got the process right. ( to feed my hobbies mostly' cars, computers, and speakers)

No dimensions as of yet, but it would probably be designed around the CHR-70's I have with the intention of substituting them later for something better. The bottom would be open but the top would be closed. The stand would be made of fiberglass most likely and would run down the entire center and house the wires to the drivers.

I have some other ideas, but this is something I can build without spending a whole lot.

Attachments

For the floor standers, could you not use the simple method of coiling? Either that or do it in two sections, with either lengthways or front and back and build a former out of ply for perfect finish.

Then weight for the clay to go quite dry so it didn't flop and support with ceramic stands to be on the safe side when out of the mould, take out of mould and then fire it.

Would work well for batch production if you sold them as would speed up construction times. You could also make sure there were little holes for dowel after wards so the two pieces aligned up while glueing and attaching together. Just a thought.

Then weight for the clay to go quite dry so it didn't flop and support with ceramic stands to be on the safe side when out of the mould, take out of mould and then fire it.

Would work well for batch production if you sold them as would speed up construction times. You could also make sure there were little holes for dowel after wards so the two pieces aligned up while glueing and attaching together. Just a thought.

For the first one, Im planing on making to primary molds, one for the top half, and one for the bottom. One of the two pieces would have a lip on it so that they fit perfectly onto each other.

for the stand, I would let my initial piece dry, get fired, glazed and then measure things out for mounting it inside. The reason I want fiberglass (or metal I suppose) is that it is easier to modify when dry. I can still build it off a mold and IMO would be alot easier,quicker, and consistent than coil building. Another advantage of the fiberglass stand would be the ability to cut into it to run wires and attach the posts.

Once I build my first one, I would have all the measurements and molds for both the stand and body. After that, making more would be incredibly straight forward ergo for the stand.

I'll draw up something later to explain what I mean for the stand

for the stand, I would let my initial piece dry, get fired, glazed and then measure things out for mounting it inside. The reason I want fiberglass (or metal I suppose) is that it is easier to modify when dry. I can still build it off a mold and IMO would be alot easier,quicker, and consistent than coil building. Another advantage of the fiberglass stand would be the ability to cut into it to run wires and attach the posts.

Once I build my first one, I would have all the measurements and molds for both the stand and body. After that, making more would be incredibly straight forward ergo for the stand.

I'll draw up something later to explain what I mean for the stand

Yes I was thinking of a lip, but suggested the dowels instead.

What you could do to quite easily is for strength and making things fit together nicely anyway as you say with the pipe; is have a piece of PVC plumbing pipe to run from the floor through the stand and up to the top of the clay roof in essence.

At the top could be a piece of mdf attached to the PVC to support the clay and same at the bottom on the inside of the clay to seal the bottom where the hole in the clay would be. If the clay was done in halves this would be easy.

Then they would slot together in the middle with a T piece with a piece of pipe coming off it with yet another piece of mdf at the end for the speaker to screw into to keep a clean minimalist look. Plus could house the wires. And along the whole length of the pipe could be more mdf bracing.

I may have overcomplicated this a little, but its just what I would do. I can do a quick sketch if necessary.

What you could do to quite easily is for strength and making things fit together nicely anyway as you say with the pipe; is have a piece of PVC plumbing pipe to run from the floor through the stand and up to the top of the clay roof in essence.

At the top could be a piece of mdf attached to the PVC to support the clay and same at the bottom on the inside of the clay to seal the bottom where the hole in the clay would be. If the clay was done in halves this would be easy.

Then they would slot together in the middle with a T piece with a piece of pipe coming off it with yet another piece of mdf at the end for the speaker to screw into to keep a clean minimalist look. Plus could house the wires. And along the whole length of the pipe could be more mdf bracing.

I may have overcomplicated this a little, but its just what I would do. I can do a quick sketch if necessary.

that's essentially what I was thinking, but rather than bonding a variety of materials together i'd likely make it one solid piece of fiberglass.

When Ivan says that these speakers don't have much bass he omitted to put that statement into context.

These speakers are small, maybe 10" tall, and 4" x 5" depth and width, and the driver is just a wee little Tang Band.

When he writes, "They still have no real bass" They don't have much bass when compared to his Saburos or the CHR70 Pensils, or his Paradigm Atoms. And the drivers were virgin, not played in at all. They do have bass, just not room shaking bass. Listened to alone, they really do sound quite good! Not bad for winging the design!

Now we both are flooded with new ideas. Stay tuned.

These speakers are small, maybe 10" tall, and 4" x 5" depth and width, and the driver is just a wee little Tang Band.

When he writes, "They still have no real bass" They don't have much bass when compared to his Saburos or the CHR70 Pensils, or his Paradigm Atoms. And the drivers were virgin, not played in at all. They do have bass, just not room shaking bass. Listened to alone, they really do sound quite good! Not bad for winging the design!

Now we both are flooded with new ideas. Stay tuned.

I've knocked together a reasonably detailed sketchup model of what I was thinking.

To start with I would use the CHR-70's, when finished, or for small scale production I would likely switch to more expensive drivers (alpair 10.2 perhaps?)

What software would be good for optimizing things before I start? There will be a fair ammount of planning on this and I want to cover my bases.

To start with I would use the CHR-70's, when finished, or for small scale production I would likely switch to more expensive drivers (alpair 10.2 perhaps?)

What software would be good for optimizing things before I start? There will be a fair ammount of planning on this and I want to cover my bases.

Attachments

Books !!What software would be good for optimizing things before I start?

I think you're doing a 'shell design' ,the study of backwaves is more sophisticated ...

Programs are just equations based on data , so a quick look at driver's Cms by pressing it with a finger 🙄 and its Sd ,having in mind cabinet internal volume ,may be worth instead of hours of simulations .

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Clay as speaker enclosure?