They have arrived! Everything looks like it should. I can recommend the French shop.

Three stupid questions:

1. What is the plastic ring for? Just for the label "Alpair 10" or for custom grill with some mesh?

2. Where should I glue the rubber gasket - to the driver or to the baffle?

3. I'll use the gasket for a cutting template. Should I cut the baffle according to the RED or the GREEN line?

Three stupid questions:

1. What is the plastic ring for? Just for the label "Alpair 10" or for custom grill with some mesh?

2. Where should I glue the rubber gasket - to the driver or to the baffle?

3. I'll use the gasket for a cutting template. Should I cut the baffle according to the RED or the GREEN line?

Good questions. 🙂

- The plastic ring is mostly for cosmetic reasons. I recall mark mentioning that if glued on, the "bezel" adds additional damping to the frame. You can decide to glue it on on build without it.

- Ideally you should fix the gasket on the driver basket. If I am not wrong, the gasket comes with adhesive on one side?

- If you look at the Alpair 10P product brochure, the driver cut out needs to be a minimum of 139mm in diameter. It can be done with a circular router jig. No template required. I usually cut a slightly larger hole, so 141-142mm should be fine. Then you should chamfer the inner side of the driver cut out. Pictures attached for you reference.

- The plastic ring is mostly for cosmetic reasons. I recall mark mentioning that if glued on, the "bezel" adds additional damping to the frame. You can decide to glue it on on build without it.

- Ideally you should fix the gasket on the driver basket. If I am not wrong, the gasket comes with adhesive on one side?

- If you look at the Alpair 10P product brochure, the driver cut out needs to be a minimum of 139mm in diameter. It can be done with a circular router jig. No template required. I usually cut a slightly larger hole, so 141-142mm should be fine. Then you should chamfer the inner side of the driver cut out. Pictures attached for you reference.

Attachments

I've decided to take the easy way. I've bolted the A10p in the TL and excluded all existing drivers and passive components.

I've kept the original stuffing.

One down one to go

Initial impressions after just 1 hour - I like it.

Even though this enclosure was intended for different driver it now sounds better which was the goal.

It is louder in the whole spectrum. Especially below 300Hz.

It is a better woofer than the W130S. I can hear 40Hz at the same volume and I couldn't with the original speakers (at least in their current condition).

The vocals are hi-res. It has clearer midds than the FRS. But as I said in the begging they needed replacement.

I still can't hear a thing above 15K but this is due to my ears,

I'll keep the speakers like this for some time although they look ugly.

The future baffle will be plywood instead of MDF.

In the mean time can someone help with possible adjustments of the TL to the new driver (Length, area, driver position)?

I've kept the original stuffing.

One down one to go

Initial impressions after just 1 hour - I like it.

Even though this enclosure was intended for different driver it now sounds better which was the goal.

It is louder in the whole spectrum. Especially below 300Hz.

It is a better woofer than the W130S. I can hear 40Hz at the same volume and I couldn't with the original speakers (at least in their current condition).

The vocals are hi-res. It has clearer midds than the FRS. But as I said in the begging they needed replacement.

I still can't hear a thing above 15K but this is due to my ears,

I'll keep the speakers like this for some time although they look ugly.

The future baffle will be plywood instead of MDF.

In the mean time can someone help with possible adjustments of the TL to the new driver (Length, area, driver position)?

Initial impressions after just 1 hour - I like it.

Give them a good 100 hrs, but take it easy breaking them in.

dave

Last edited:

Report and impressions after 1 week. (~ 50 hrs) in the original TL enclosures.

There was too much rumble. I had to use "Equaliser APO" and apply -12db/oct HP filter at 63Hz.

I had trouble hearing speech especially male.

I was hearing a lot from the TL opening which may be initial flaw in the design, incompatibility with the new driver or my stuffing.

I've lowered my volume since the installation. PC master volume at 50%, Amp at 50%, and Media player between 30 and 60% depending on the content.

Last night I just removed the inside divider board and closed the rear port. It is now converted to sealed 28L with the driver in the corner.

The rumble is gone, I can hear speech better. With tone generator 63Hz are barely audible.

"Equaliser APO" HP filter at 80Hz does not affect the sound at all.

After this initial experience it looks like the A10p alone is enough for my needs in a proper enclosure.

Also TL design is beyond my DIY skills.

I'm on a crossroad what to do next:

There was too much rumble. I had to use "Equaliser APO" and apply -12db/oct HP filter at 63Hz.

I had trouble hearing speech especially male.

I was hearing a lot from the TL opening which may be initial flaw in the design, incompatibility with the new driver or my stuffing.

I've lowered my volume since the installation. PC master volume at 50%, Amp at 50%, and Media player between 30 and 60% depending on the content.

Last night I just removed the inside divider board and closed the rear port. It is now converted to sealed 28L with the driver in the corner.

The rumble is gone, I can hear speech better. With tone generator 63Hz are barely audible.

"Equaliser APO" HP filter at 80Hz does not affect the sound at all.

After this initial experience it looks like the A10p alone is enough for my needs in a proper enclosure.

Also TL design is beyond my DIY skills.

I'm on a crossroad what to do next:

- should I abort the woofer part and replicate some of the available floor standers for A10p

- should I stick to the initial plan to recycle the enclosures putting the FR in the existing 6.1L sealed but converting the TL to a side-firing box with 8" driver

apply -12db/oct HP filter at 63Hz

A room mode representing about a 2 and a bit metre distance most likely.

dave

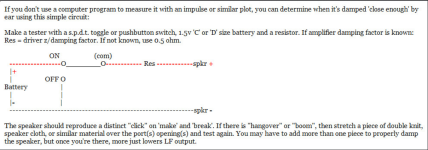

Regardless of room modes, 'critically' damping any port is ideally required to ensure it doesn't audibly impact the critical speech BW beginning around 100 Hz for men's 'fullness' and especially > ~240 Hz for females.

Attachments

Last night I just removed the inside divider board and closed the rear port. It is now converted to sealed 28L with the driver in the corner.

The rumble is gone, I can hear speech better. With tone generator 63Hz are barely audible.

"Equaliser APO" HP filter at 80Hz does not affect the sound at all.

After this initial experience it looks like the A10p alone is enough for my needs in a proper enclosure.

Also TL design is beyond my DIY skills.

I'm on a crossroad what to do next:

- should I abort the woofer part and replicate some of the available floor standers for A10p

- should I stick to the initial plan to recycle the enclosures putting the FR in the existing 6.1L sealed but converting the TL to a side-firing box with 8" driver

flatmo,

A few questions for you:

- Does your enclosure look like the attached with the "divider" removed?

- Do you have any stuffing material like poly-fill inside the enclosure?

- Would you be able to remove the panel between the chamber for the woofer and full-range drivers (red arrow pointing at it in the image)?

Attachments

Hi zman,

- yes now the enclosure is just like your drawing

- yes I have used one bag of this Visaton damping maetrial and some leftovers 10mm polyurethane foam like this

- yes i can remove the panel

flatmo,

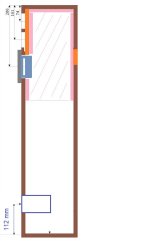

Please refer to the image below:

Please refer to the image below:

- The divider between the enclosures is removed, so now it is one enclosure only

- The part where there were cut-outs for the Visaton full-range drivers have been blocked

- At the lower part of the cabinet there is a port with an internal diameter of 50-51 mm, and length of 110 mm. The port center is 112 mm from the inside of the bottom

- The pink lines represent felt lining material of 10-12 mm thickness - advised to apply on the inside of the back of the cabinet, and also inside of the side walls. If possible inside of the front baffle too.

- There will be some requirement of poly-fill also; likely some loose poly-fill material for the upper 60% of the the cabinet. Image obtained from Google search of loose poly-fill material attached for your reference. "Dacron" hollow fiber fill is a good option.

Attachments

Last edited:

Thank you for your help!

I see where it is going and I think i can actually convert my enclosure to almost exact copy of the MLTL by Jim Griffin

What is "almost exact" is the driver position. It will be positioned 8.7" from the top (0.7" =18mm offset from the design)

I suppose I should stick to the original port size of 2.5x5" suggested for A10p from Jim in post #7 but since 63.5mm is not common port size I will convert it according to planet10 formula then it is either d=50/L=79 or d=70/L=154.

Should I also offset the port from the original place 4" from bottom?

This will be a temporary baffle just for testing.

I see where it is going and I think i can actually convert my enclosure to almost exact copy of the MLTL by Jim Griffin

What is "almost exact" is the driver position. It will be positioned 8.7" from the top (0.7" =18mm offset from the design)

I suppose I should stick to the original port size of 2.5x5" suggested for A10p from Jim in post #7 but since 63.5mm is not common port size I will convert it according to planet10 formula then it is either d=50/L=79 or d=70/L=154.

Should I also offset the port from the original place 4" from bottom?

This will be a temporary baffle just for testing.

Another weekend - another mod. I did what I sketched in the previous post. Like I wrote I aimed at almost exact copy of the MLTL.

The final result is: width = 150mm (5.9"), depth = 190mm (7.5"), driver is located at 8" from top, Port is located 32" from top, what is not as designed is the overall internal height 996mm (39.2") instead of 1016mm (40"). I've used 1 bag of the Visaton stuffing material for 1 enclosure to fill the upper part of the TL up to 2" bellow the driver. The port is on the front baffle because both speakers are located near a wall and maybe this was one of the reasons for the rumble from the original design with back firing TL terminus.

I couldn't find suitable speaker bass port with ID 2.5" so I went to the plumbing shop and find PVC high pressure water pipe external D = 63mm.

They had couplers for this pipe with internal D = 63mm and L = 79mm. I took 4 couplers and stick 2 of them then cut to the desired length of 5".

What is the result? I don't have measuring equipment so I'll just explain what I'm hearing at my normal listening level, which is most important for me as a user - it is linear from 80Hz above.

There is huge gain for the MLTL against the closed between 75 and 100Hz, after that they seem equal up to 200 where the MLTL continues to be linear and the closed is slightly muted up to 600Hz. From there on they seem equal.

The bass is way better but still at normal listening levels I can't hear sound below 60Hz. Both the closed and the MLTL are barely hearable at 60Hz. And below that it is silence.

According to the author the MLTL should be linear down to 40Hz when executed by design. I consider my result as way off the expected result.

What did I do wrong?

1. My TL is 0.8" shorter than the design

2. I have small leakages

3. I did't chamfer the inner side of the driver opening

4. Visaton damping material looks similar to zman01 picture but not exactly the same

My next step is to order new enclosures to a professional carpenter but now I'm not sure which "easy" project to execute - Griffin MLTL, Pensil, Poplar MLTL, Despina RTL or other...

The final result is: width = 150mm (5.9"), depth = 190mm (7.5"), driver is located at 8" from top, Port is located 32" from top, what is not as designed is the overall internal height 996mm (39.2") instead of 1016mm (40"). I've used 1 bag of the Visaton stuffing material for 1 enclosure to fill the upper part of the TL up to 2" bellow the driver. The port is on the front baffle because both speakers are located near a wall and maybe this was one of the reasons for the rumble from the original design with back firing TL terminus.

I couldn't find suitable speaker bass port with ID 2.5" so I went to the plumbing shop and find PVC high pressure water pipe external D = 63mm.

They had couplers for this pipe with internal D = 63mm and L = 79mm. I took 4 couplers and stick 2 of them then cut to the desired length of 5".

What is the result? I don't have measuring equipment so I'll just explain what I'm hearing at my normal listening level, which is most important for me as a user - it is linear from 80Hz above.

There is huge gain for the MLTL against the closed between 75 and 100Hz, after that they seem equal up to 200 where the MLTL continues to be linear and the closed is slightly muted up to 600Hz. From there on they seem equal.

The bass is way better but still at normal listening levels I can't hear sound below 60Hz. Both the closed and the MLTL are barely hearable at 60Hz. And below that it is silence.

According to the author the MLTL should be linear down to 40Hz when executed by design. I consider my result as way off the expected result.

What did I do wrong?

1. My TL is 0.8" shorter than the design

2. I have small leakages

3. I did't chamfer the inner side of the driver opening

4. Visaton damping material looks similar to zman01 picture but not exactly the same

My next step is to order new enclosures to a professional carpenter but now I'm not sure which "easy" project to execute - Griffin MLTL, Pensil, Poplar MLTL, Despina RTL or other...

Last edited:

Ops now i read what i wrote and I can't edit the post - the port is located not at 32" from top but as it should be at 36" from top.

Bottom line - A10p installed in almost exact copy of MLTL by Jim Griffin is good enough for my needs.

It is an upgrade to the old combo while maintaining the price of 2xFRS8 + W130S + passive components for XO.

I'm currently searching for local carpenter to make new plywood front baffles prepared for flush mount of the driver and chamfer on the inner side.

Case closed!

Thanks for the help!

It is an upgrade to the old combo while maintaining the price of 2xFRS8 + W130S + passive components for XO.

I'm currently searching for local carpenter to make new plywood front baffles prepared for flush mount of the driver and chamfer on the inner side.

Case closed!

Thanks for the help!

- Home

- Loudspeakers

- Full Range

- Choosing new FR driver for 6.1L closed part of a Floor-standing TL