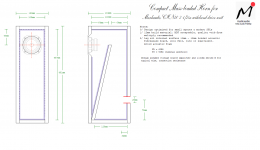

Thinking of making a pair of these but are confused by the plans. The driver and internal panel is shown 40mm down from top, the driver cannot be fitted that high. Also the port is 32mm long, is that including the box thickness. What value should these be, Thanks.

Attachments

Last edited:

Yes it can. The centre of the driver is 40mm down from the internal top of the enclosure. The CHN40 has an outside basket diameter of 78.4mm. 78.4/2 = 39.2mm, and the internal diameter is only 60mm.

Duct lengths unless otherwise stated are always total, which is inclusive of panel thickness.

Duct lengths unless otherwise stated are always total, which is inclusive of panel thickness.

Last edited:

Thanks for the reply, that would put the driver outside basket 13mm from the top of the box. can't recall seeing other speakers with a driver mounted so high, a similar box for the CHN50 puts the driver 76mm from top. Is there a reason for this like keeping the gap of the internal divider 40mm to the top of the box. Sorry for the idiot questions but can build from drawings but don't know the calculations of box design. Built some sealed boxes for this driver before and was thinking of trying them in something else.

Last edited:

Okay, thanks for the info. Should be interesting how this box sounds against the sealed box I already have and like.

Yes I see but with a slightly bigger gap. I do plan on making a Frugel-Horn Lite with a 3inch driver for a bedroom setup, lovely looking speaker 😀

Please excuse me if I am wrong but there does seem to be something wrong with that drawing. I have those drivers and I would also like to build that box. So I Printed out the plan and used Scott's measurements. If the driver cutout is 40mm from the internal top or 62mm from the external top then 62-39.2= 22.8mm. The edge of the driver would be 10mm from the inside top of the cabinet. It looks like it is lower than that. So i measured the 64mm marks on the top and got 18mm (on the Drawing), measuring the 40mm marks for the driver cutout I get 17mm ( on the drawing). Could the measurement for the driver cutout be 60mm instead of 40mm? that would make things look like the drawing 72-39.2 =32.8mm from the top of the cabinet to the edge of the driver and that would look more like the drawing

I expect this won't be possible, but could the box be made shorter and if so would the port size and length need to change. Sorry don't know the tech to work out if it's viable, hoping Dave or Scott could advise, thank you.

FYI etc., in my various 'careers' all my drawings for business use read NTS (not to scale) in 😉 regardless of (in) accuracy per corporate legal dictates since we had whole catalogs of universal sketches with/without model/pt. no. dimension tables, so considering the quantity of designs already done, will do or submitted by others, seems like ya'll would too.

Last edited by a moderator:

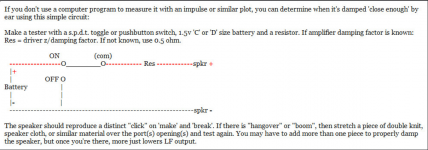

FYI, etc., IME maintaining the net Vb and tuning can/will in theory be a bit higher due to less 14 WL pipe action damping it; if so, then increasing stuffing or better still, critically damping the vent will smooth it back out and then some if doing the latter plus moves it closer to a sealed alignment's superior damping (Qt).I expect this won't be possible, but could the box be made shorter and if so would the port size and length need to change. Sorry don't know the tech to work out if it's viable, hoping Dave or Scott could advise, thank you.

Attachments

Last edited by a moderator:

Love your thinking. 😉FYI etc., in my various 'careers' all my drawings for business use read NTS(not to scale) in 😉 regardless of (in) accuracy per corporate legal dictates since we had whole catalogs of universal sketches with/without model/pt. no. dimension tables, so considering the quantity of designs already done, will do or submitted by others, seems like ya'll would too.

Humor aside, I'm taking that advice on board, as of the time of typing. I have actually included (albeit in probably over-small font!) some variation of that in a few, but not all / enough. 100% mea culpa on that front -it never really occured to me that people would not just work off the listed dimensions.

Last edited by a moderator:

GM means technically you can, providing you maintain the same overall internal volume (Vb). However, because it's a quarter-wave design, shortening the line length will raise the tuning frequency, which will put a peak at the new tuning frequency. This can be fixed by damping the vent: the easiest way of doing that is by using the old click test method he attached, which is still probably the most effective practical way of dialling in an acoustically efficient box load.Wow, could I have that in English please, only got some of that. 😵

- Home

- Loudspeakers

- Full Range

- CHN40 compact mass loaded horn box