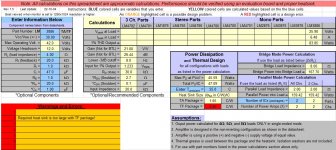

With the most expensive part of the Gainclone/basic chip amps coming from PSU, I'm investigating whether there is a cheaper way of getting the required power (2x25-30VAC for a regulated supply). I've managed to secure a bunch of adjustable 8A regulator boards for $16/rail, which I can rig up for +/- supplies (and have even successfully implemented a switching arrangement for varying rail voltages based upon speaker impedance).

Now, in the US you guys have Antek which is very cheap - the issue is getting these transformers overseas. Antek are wanting $73.50-$214USD postage per toroid, meaning the cheapest I can get these for is +$150AUD. Looking locally, I've managed to find some cheaper toroids for $110AUD + postage, or eBay specials for ~$90AUD (with no warranty or guarantee they will work).

Has anybody found a 'novel' way of getting the required current and voltage for less money? We have 4 or 5 amps to build which will be driving full-range speakers, so having ~300VA on tap would be nice.

Now, in the US you guys have Antek which is very cheap - the issue is getting these transformers overseas. Antek are wanting $73.50-$214USD postage per toroid, meaning the cheapest I can get these for is +$150AUD. Looking locally, I've managed to find some cheaper toroids for $110AUD + postage, or eBay specials for ~$90AUD (with no warranty or guarantee they will work).

Has anybody found a 'novel' way of getting the required current and voltage for less money? We have 4 or 5 amps to build which will be driving full-range speakers, so having ~300VA on tap would be nice.

Possible approach - 2x160VA 15/0/15 transformers with a capped off CT. $75 for both. Secondary voltage is

Can you stack toroids vertically with isolation washers?

Can you stack toroids vertically with isolation washers?

You will have a hard time regulating after 30VAC.

How much current do you need and what rail voltages?

Gainclones usually don't use regulated supply, just caps.

How much current do you need and what rail voltages?

Gainclones usually don't use regulated supply, just caps.

You will have a hard time regulating after 30VAC.

How much current do you need and what rail voltages?

Gainclones usually don't use regulated supply, just caps.

Because voltage is too high? I can drop 10v over the regs I'm using with enough heat sinking - probably a pinch high but gives me headroom.

28-30v@3A-5A is ideal. Plenty of Gainclone are using regulated supplies with great success - it's only a slight increase in cost for gaining a whole heap of bottom end and lowering cap requirements (offsetting the cost).

Ok, ghetto option - rewinding MOT's. Obviously this isn't ideal, but it is cheap. They would be in a separate enclosure with plenty of shielding, so shouldn't be much noisier in this situation.

Is there any -feasible- way to decrease continual current draw and heat build-up for long periods of usage? I'm guessing you could make some sort of ballast

Is there any -feasible- way to decrease continual current draw and heat build-up for long periods of usage? I'm guessing you could make some sort of ballast

I think your best bet is to salvage a transformer out of an old, broken receiver or amplifier. For instance, for one project I managed to pull a quite nice transformer with 35-0-35v AND 15-0-15v secondaries out of a broken Harmon Kardon AVR-55.

Another approach would be to use these inexpensive switching supplies:

Qualtek QPDF-320-36 Switching Power Supply 36 VDC 8.8A 320W Single Output

I don't know what shipping costs to AUS would be, but they only weigh 2.2 lbs. each, so it probably wouldn't be too bad.

Qualtek QPDF-320-36 Switching Power Supply 36 VDC 8.8A 320W Single Output

I don't know what shipping costs to AUS would be, but they only weigh 2.2 lbs. each, so it probably wouldn't be too bad.

I think your best bet is to salvage a transformer out of an old, broken receiver or amplifier. For instance, for one project I managed to pull a quite nice transformer with 35-0-35v AND 15-0-15v secondaries out of a broken Harmon Kardon AVR-55.

I've been on the look out and managed to grab a 2x40+2x15 toroid at 300VA the other day - a good score. Unfortunately this is just too high for the voltage I need; dropping 25v across my reg drops output current to 1A. I've also got a heap of 225VA toroids but unfortunately they're 40v too. I guess I can keep scrounging!

Another approach would be to use these inexpensive switching supplies:

Qualtek QPDF-320-36 Switching Power Supply 36 VDC 8.8A 320W Single Output

I don't know what shipping costs to AUS would be, but they only weigh 2.2 lbs. each, so it probably wouldn't be too bad.

You can't create dual voltages from them though as each negative is tied to ground though, right? Is it possible to drop output voltage to 28-30v?

Great ideas though, I appreciate it guys!

"You can't create dual voltages from them though as each negative is tied to ground though, right? Is it possible to drop output voltage to 28-30v?

I believe the outputs are floating and you CAN use them as a +/- pair. Check with Parts Express. The listing says "The Qualtek QPDF-320-36 regulated power supply has the ability to adjust its output from 33.2 VDC to 38.4 VDC. It can deliver up to 8.8A output for those high power amplifier boards"

Why would you want to drop the voltage any farther than this? The gainclone amps using the LM3866/4780 chips will easily take this voltage, and you'll have more headroom.

I believe the outputs are floating and you CAN use them as a +/- pair. Check with Parts Express. The listing says "The Qualtek QPDF-320-36 regulated power supply has the ability to adjust its output from 33.2 VDC to 38.4 VDC. It can deliver up to 8.8A output for those high power amplifier boards"

Why would you want to drop the voltage any farther than this? The gainclone amps using the LM3866/4780 chips will easily take this voltage, and you'll have more headroom.

They are floating, there is a separate post for ground. I haven't tried making a dual switching supply but there are others on the forum that have done it. Look on ebay you can find a switching power supply much closer. Two of these would do the trick.

120W 36V 3 3A Single Output Switching Power Supply for LED Strip Light AC to DC | eBay

120W 36V 3 3A Single Output Switching Power Supply for LED Strip Light AC to DC | eBay

"You can't create dual voltages from them though as each negative is tied to ground though, right? Is it possible to drop output voltage to 28-30v?

I believe the outputs are floating and you CAN use them as a +/- pair. Check with Parts Express. The listing says "The Qualtek QPDF-320-36 regulated power supply has the ability to adjust its output from 33.2 VDC to 38.4 VDC. It can deliver up to 8.8A output for those high power amplifier boards"

Why would you want to drop the voltage any farther than this? The gainclone amps using the LM3866/4780 chips will easily take this voltage, and you'll have more headroom.

3886's exceed thermal capacity of the chip with more than 28v into 4 ohms, or 30v into 8 ohms. I want something to last, so I'd rather run them slightly cooler.

I do not see that on the datasheet---it lists the chip power dissipation as 125W MAX, and the power dissipation at +/-35v, 60 watts to be about 65 watts. I still think an adequate heatsink is necessary to be safe.3886's exceed thermal capacity of the chip with more than 28v into 4 ohms, or 30v into 8 ohms. I want something to last, so I'd rather run them slightly cooler.

Being in Argentina, I share your problems of distance and excessive freight.Now, in the US you guys have Antek which is very cheap - the issue is getting these transformers overseas. Antek are wanting $73.50-$214USD postage per toroid, meaning the cheapest I can get these for is +$150AUD. Looking locally, I've managed to find some cheaper toroids for $110AUD + postage, or eBay specials for ~$90AUD (with no warranty or guarantee they will work).

Has anybody found a 'novel' way of getting the required current and voltage for less money? We have 4 or 5 amps to build which will be driving full-range speakers, so having ~300VA on tap would be nice.

For 4/5 amplifiers (and maybe more in the future) consider handwinding your own.

Quite easy and feasible on SS amps, because lower voltages mean way less turns of beefier wire, now tube amps require thousands turns of fine wire.

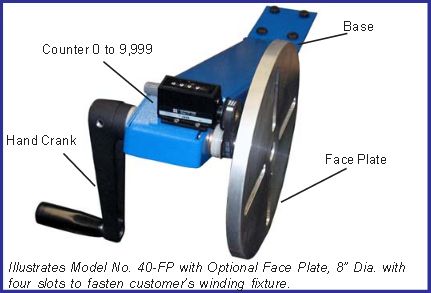

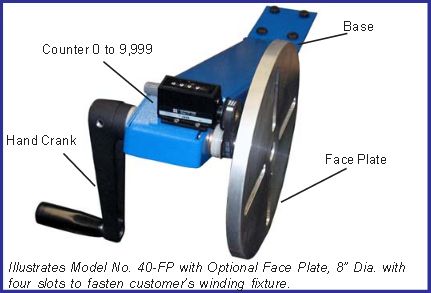

You can invest *once* on a proper hand winder, ready made including a turns counter and a pulley for later motor addition (think sewing machine motor):

or you can kludge one :

a pedometer or cheap calculator can be adapted as a turns counter:

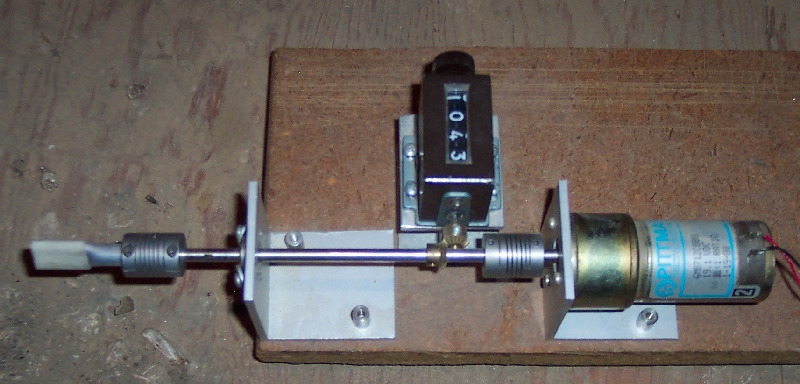

this is the deluxe homemade version, a friend of mine commercially makes and sells tube guitar amplifiers (a couple a Month) and is happy with a similar one, in his case driven by a cordless screwdriver, which is both low, controllable speed and has high torque:

An externally hosted image should be here but it was not working when we last tested it.

I am NOT recommending this popular solution, its feeble torque can't pull any reasonable wire, except very fine such as used in guitar pickups, I mention it only because it's often suggested ... forget it:

if you want just to test the concept, you might sink as low as 😉 :

I have a proper, industrial type one, because I use some 30 transformers a Month, but still keep my old hand cranked one for emergencies or prototypes, go figure.

Being in Argentina, I share your problems of distance and excessive freight.

For 4/5 amplifiers (and maybe more in the future) consider handwinding your own.

Quite easy and feasible on SS amps, because lower voltages mean way less turns of beefier wire, now tube amps require thousands turns of fine wire.

You can invest *once* on a proper hand winder, ready made including a turns counter and a pulley for later motor addition (think sewing machine motor):

or you can kludge one :

a pedometer or cheap calculator can be adapted as a turns counter:

An externally hosted image should be here but it was not working when we last tested it.

this is the deluxe homemade version, a friend of mine commercially makes and sells tube guitar amplifiers (a couple a Month) and is happy with a similar one, in his case driven by a cordless screwdriver, which is both low, controllable speed and has high torque:

I am NOT recommending this popular solution, its feeble torque can't pull any reasonable wire, except very fine such as used in guitar pickups, I mention it only because it's often suggested ... forget it:

if you want just to test the concept, you might sink as low as 😉 :

I have a proper, industrial type one, because I use some 30 transformers a Month, but still keep my old hand cranked one for emergencies or prototypes, go figure.

Brilliant idea! I have access to a full machine shop so I'm sure I could build something if I do decide to go down this route.

Do you just rewind existing transformers?

No, I commercially make and sell Guitar amplifiers since 1969, some 14000 delivered so far and obviously all transformers are designed and wound in-house, only way to keep a price competitive with the Chinese.

Also own made chassis / panels / cabinets / PCBs / speakers / silkscreening / etc. , plus own die sets for corner protectors / strap handles / knobs / rubber feet / horn drivers / etc. , again forn the same reason.

Think Australia in the 70's where local brands fully supplied the local market, like those featured in: Classic ANZ Valve Guitar Amplifiers

Also own made chassis / panels / cabinets / PCBs / speakers / silkscreening / etc. , plus own die sets for corner protectors / strap handles / knobs / rubber feet / horn drivers / etc. , again forn the same reason.

Think Australia in the 70's where local brands fully supplied the local market, like those featured in: Classic ANZ Valve Guitar Amplifiers

No, I commercially make and sell Guitar amplifiers since 1969, some 14000 delivered so far and obviously all transformers are designed and wound in-house, only way to keep a price competitive with the Chinese.

Also own made chassis / panels / cabinets / PCBs / speakers / silkscreening / etc. , plus own die sets for corner protectors / strap handles / knobs / rubber feet / horn drivers / etc. , again forn the same reason.

Think Australia in the 70's where local brands fully supplied the local market, like those featured in: Classic ANZ Valve Guitar Amplifiers

The only reason I asked was I'm not sure how to go about designing/making cores. Rewinding the coils themselves seems 'easy enough' with some trial and error on my behalf.

I've seen a few bits and pieces that were locally made floating around (the toroid I pinched was actually manufactured in Australia, along with the broken amplifier), however it definitely seems to be dropping off. Most of the stores that supported smaller volume DIY stuff are closed or dropped all stock that is useful for this sort of stuff 🙁

±25V 200W ±15V 5W Digital Amplifier Switching Switch Power Supply Board | eBay

I've one of these powering a stereo fetzilla and it seems pretty happy so far. I intend one day to use a pair to drive some F4's as well, so I would imagine they'd be fine for a couple of gainclones.

Dunno if that hits the spot for you in terms of price/performance!

I've one of these powering a stereo fetzilla and it seems pretty happy so far. I intend one day to use a pair to drive some F4's as well, so I would imagine they'd be fine for a couple of gainclones.

Dunno if that hits the spot for you in terms of price/performance!

Oh, no NASA Science involved, basic well known technology.The only reason I asked was I'm not sure how to go about designing/making cores. Rewinding the coils themselves seems 'easy enough' with some trial and error on my behalf.

I'm certain there's online design stuff; main problem might be to get a lamination/wire/bobbins supplier, but check around.

Or ask motor rewinders, they use at least same wire, and may have leads for iron suppliers or ask their copper suppliers.

Same here and most everywhere else, thank globalization.I've seen a few bits and pieces that were locally made floating around (the toroid I pinched was actually manufactured in Australia, along with the broken amplifier), however it definitely seems to be dropping off. Most of the stores that supported smaller volume DIY stuff are closed or dropped all stock that is useful for this sort of stuff 🙁

Looks like China will be the world factory and everybody else their suppliers.

We sell them soybeans , I guess Australia sells them minerals.

Industry? ... a mythical thing of the past to tell our grandchildren at bedtime.

So use the TA package with Thermalloy paste and a mica or Kapton washer. It'll be better all around anyway!

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Cheaper Gainclone PSU