I guess I and many other experienced EEs have been doing it all wrong. I have an AVO160 (which can actually test most tubes under realistic operating conditions), a Utracer, and I occasionally build test jigs for testing and matching specific types. I had no idea that was ridiculous, thank you for setting me straight. 🤣🤣No joke. Building a tester for a tube is ridiculous. Buy a tube tester.

Talking about a DIY tester for a power tube in real world operation. I use to measure the operating temperature of tubes in my amp and match by operating temperature. I had 27 NOS tubes for one amp thus could get same temperature with tubes within one degree. Unusual, but works.

hello jcalverez:

A few thoughts to consider

firstly, ignore the polluters, they are often quite uninformed!

secondly, check out the sticky thread on those magnificent TV tubes. Very good and a huge amount of very valuable ideas and information.

thirdly, search for DIY tube testers here and elsewhere, lots of good work has been done to guide your pursuits

fourth, real world conditions is the best way to test and match tubes. Most testers except the fancy expensive ones are emission testers and end up with a good/bad type result, that does not tell you very much useful info. In circuit testing makes a lot of sense.

fifth, most of the so called audio tubes started life as a TV tube and were "discovered" to be good at audio.

have fun and explore

I hope this helps

A few thoughts to consider

firstly, ignore the polluters, they are often quite uninformed!

secondly, check out the sticky thread on those magnificent TV tubes. Very good and a huge amount of very valuable ideas and information.

thirdly, search for DIY tube testers here and elsewhere, lots of good work has been done to guide your pursuits

fourth, real world conditions is the best way to test and match tubes. Most testers except the fancy expensive ones are emission testers and end up with a good/bad type result, that does not tell you very much useful info. In circuit testing makes a lot of sense.

fifth, most of the so called audio tubes started life as a TV tube and were "discovered" to be good at audio.

have fun and explore

I hope this helps

Most TV tubes have odd filament voltages that cannot be used in common audio amps. Only tubes of value are sweep tubes.

Well I guess not everybody has the ability to solve problems or design a power supply. Just a hint, there are other transformers voltages available than 6.3 or 12 volts.

Have a nice day, ............ if you can

Have a nice day, ............ if you can

There are scores of projects on these pages using tubes with oddball filament voltages, in the age of cheap monolithic voltage regulators it's not much of a problem.

Original starving student headphone amp is just one example that came to mind.

Original starving student headphone amp is just one example that came to mind.

Are you in the wrong place? Most of us design and build our own amps or repair/modify existing ones.I never seen a manufactured amp use other than 6.3 or 12.6 volt filament tubes.

DHT based amps using 1.5V, 2.5V, 4.0V, 5.0, 7.5V, 10V and 20V filament supplies are common both in DIY and commercial amps.

Neither .would you test then with an output transformer, like a real SE circuit? or just best keep it simple, using a resistor as a load?

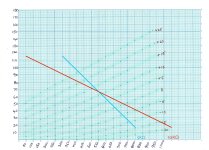

For a tube with unknown DC operating curves.

With variable voltage supply for the grid(s) and using a simple variac controlled B+ power supply, test with no plate load .

Current measurement resistors in series with relevant electrodes, run the tube through the voltage range of interest , and plot V / I points on graph paper .

Once the physical set-up is ready to go, the left hand goes in pocket and the only thing I touch with the right hand is the variac knob and the pen to mark the point on the paper. Then B+ to zero, shut it down, change the grid voltage , power up and sweep the next set of of points.

Connect the dots after to show the curves.

The curves get used to decide on the load impedance for the circuit I intend to build.

Attachments

"worthless TV tubes"Building a tube tester for one power tube at real world conditions is valid, but building multiple jigs to test worthless TV tubes is not practicable.

Obviously, this guy does not know me.

Many of the tubes that audiophiles use were designed for TV use. The good old 6SN7GTB is "especially useful as a blocking oscillator, multivibrator, or vertical deflection amplifier in television receivers." The 12AT7 was intended for "mixer oscillator use up to 300 Megacycles", again for VHF TV tuners. The 12AU7 and the 6V6GT have a separate set of ratings for "vertical deflection" amplifiers. These all have 6 volt heaters.

Isn't this a DIY forum. I have three guitar amps. All have series heater strings, and the tubes were designed for TV sets with the exception of the UL84 / 45B5's. 17DQ6 tubes and several others work fine running from a generic 19 volt laptop power brick and most of us have several of those. 24 volt transformers are pretty common and there are lots of 24, 25, and 26 volt tubes available for low $$$$.I never seen a manufactured amp use other than 6.3 or 12.6 volt filament tubes.

The best way to "test" a tube is in the circuit in which it will be used. If not the exact circuit, use something that runs the tubes as close to the final use conditions as possible. A generic tube tester can not do that. Want to build an audio amp of some sort, HiFi, guitar, or other, set the tubes up to measure the THD and maybe power output if that's where the tubes are going. Many years ago I bought a big box full of 6U8 (another TV tube) tubes from Stan at ESRC for use in a guitar amp circuit (input amp and phase inverter). I used the exact circuit that would be found in the target amp and ran THD tests. About 5% of the tubes had THD much higher than the others. All of them tested fine in several tube testers. Stan swapped them for low THD tubes and I went on my way.

Anyone who actually designs tube circuits from scratch as opposed to building from a known schematic should spend some time with a box full of TV tubes (or other cheap tubes), a couple of adjustable power supplies some cheap OPT's and an audio capable test setup. This can be a sig gen and a scope, a THD analyzer, or a PC and a sound card...... or all of these. Often tubes don't always match the published data and even when they do, sometimes happy accidents fall somewhere outside the published data.Current measurement resistors in relevant electrodes, run the tube through the voltage range of interest , and plot V / I points on graph paper .

Once the physical set-up is ready to go, the left hand goes in pocket and the only thing I touch with the right hand is the variac knob and the pen to mark the point on the paper. Then B+ to zero, shut it down, change the grid voltage , power up and sweep the next set of of points.

Connect the dots after to show the curves.

The curves get used to decide on the load impedance for the circuit I intend to build.

If someone wants to make a test jig to characterize tubes, good for him, I have built several. Sometimes it's just a hacked up version of one of my amp boards.

Here a Tubelab SSE board gets used to "characterize" a box full of 6LU8 and 6LR8 TV tubes. This led to the SPUD board which never made it into production for reasons beyond my control.

Also, a board that would eventually become the original TSE with 300B tubes got to test a bunch of different TV tubes.

Attachments

Yes this is a good way to evaluate tubes. Here is the jig I built to test dual triodes because I do it so much. Dual Triode Test StationWhen I say characterise is to test them and find out whether the tube parameters are still within datasheet specifications.

And here is a discussion comparing two different dual triodes. A Tale of Two Tubes

I find that comparing tubes in a simple circuit is still the best way to evaluate their performance.

I agree, having a uTracer would be good. I've been thinking about buying one for a while, maybe I should treat myself for my 60th birthday 🙂The data sheets gives some operating conditions but far from all possible.

For example pentode/beam tetrode data sheets only provide anode curves for a very few screen voltages.

Sometimes only one screen voltage is provide on the data sheet.

Parameters can be traded off against each other and the data sheet normally only gives you a small subset of what is possible.

Tubes were in the past often designed to solve a particular application.

However there is often a opportunity to use a tube in novel applications if the tube is operated with values that are not provided for on the data sheet.

I use a uTracer3+ to acquire Ia curves verses Va - Vg2 - Vg1.

Often tubes designed for one application can be repurposed for other applications. I find the quest for using tubes in novel ways enjoyable.

By the way the uTracer3+ is a kit so you built it your self.

I said manufactured not DIY.Are you in the wrong place? Most of us design and build our own amps or repair/modify existing ones.

DHT based amps using 1.5V, 2.5V, 4.0V, 5.0, 7.5V, 10V and 20V filament supplies are common both in DIY and commercial amps.

TdP from EAR used PL519 / 509 and transformer in late version can use separate filament for EL519 / 509.

That is bonafide manufacturer.

That is bonafide manufacturer.

Yes, you did, and that was not what was being discussed. Don't know how to be any clearer than that.I said manufactured not DIY.

Perhaps figure out how you can contribute positively to the conversation and if you can't best to not say anything at all. Or ask questions to build your own understanding of what is being discussed. Your comments to the OP were borderline insulting and also demonstrate a lack of understanding of standard design methodologies.

Last edited:

Perhaps figure out how you can contribute positively to the conversation and if you can't best to not say anything at all. Or ask questions to build your own understanding of what is being discussed. Your comments to the OP were borderline insulting and also demonstrate a lack of understanding of standard design methodologies.

This member looks like a "troll" - Welcome to my ignore list, Tubesaregreat !

T

- Home

- Amplifiers

- Tubes / Valves

- Characterising a tube