Hmmm?

Do they make a hole saw version of this machine?

Ralf

A stamper punch is the solution. You can centre and punch the disc with this device.

Record Products of America

SPSLT Punching Machine | Sibert-Online

Do they make a hole saw version of this machine?

Ralf

@ALL

When you look to the drawing below, you see a laserpen upon an old tonearm (without counterweight). Now imagine it is your own tonearm and the laserpen isn’t fasten to the tonearm.

You cut a little piece out of the inner circle of an old CD (some mm2) and stick this small mirror on top of your headshell, just above the stylus. Take a record, put the stylus in the groove and start the turntable. When you shine with the laserpen upon the small mirror, the beam will be projected somewhere on the wall (angle mirror – centreline headshell about 45 degrees).

When the eccentricity of the record is less than the distance between 2 adjacent grooves, the red laser dot will move slowly in one direction. Not with a constant speed, because there is still eccentricity. So it slows down, accelerates, slows down, etc. every 1,8 second (12 inch LP).

When the eccentricity of the records is more than the distance between 2 adjacent grooves, the red dot of the laserpen stops, moves slowly back, stops, moves fast forwards, stops, etc.

The red dot of the laserpen just shows us the left diagram below (a difference of 4 Hz because it is a self centering recordplayer; other diagrams of high end turntables show a variance of 20 Hz and more). The RIAA standard permits an extreme eccentricity of 1,27 mm. That’s 1% deviation from every frequency from 20Hz – 20.000 Hz.

When the stylus has to move back on its way to the inner groove, the tonearm will continue its motion in the forward direction because of the mass (inert mass). Therefore, the pivot of the cantilever will be forced out of the centreline of the groove. As a result the balance of the volume of the right and left channel will shift a bit (every 0,9 second).

Conclusion: the drawback of eccentric records is not only the instability of all the frequencies, the stereo image is involved too.

I have described a practical solution to centre records. It is easy and “low tech”. Unfortunately, I haven't found a tool everywhere available (shops, internet) that can be used to “drill” someone’s record collection (about 40 mm holes). Smaller centre holes don’t work – to few physical bandwidth to achieve the desired tolerance of 0,1 mm – and expensive punching machines will not be bought by the users of vinyl records....

So there is a solution for the eccentricity of vinyl records, but there is - at this moment - no solution for a simple modification of the records to use these non-concentric rings.

When you look to the drawing below, you see a laserpen upon an old tonearm (without counterweight). Now imagine it is your own tonearm and the laserpen isn’t fasten to the tonearm.

You cut a little piece out of the inner circle of an old CD (some mm2) and stick this small mirror on top of your headshell, just above the stylus. Take a record, put the stylus in the groove and start the turntable. When you shine with the laserpen upon the small mirror, the beam will be projected somewhere on the wall (angle mirror – centreline headshell about 45 degrees).

An externally hosted image should be here but it was not working when we last tested it.

When the eccentricity of the record is less than the distance between 2 adjacent grooves, the red laser dot will move slowly in one direction. Not with a constant speed, because there is still eccentricity. So it slows down, accelerates, slows down, etc. every 1,8 second (12 inch LP).

When the eccentricity of the records is more than the distance between 2 adjacent grooves, the red dot of the laserpen stops, moves slowly back, stops, moves fast forwards, stops, etc.

The red dot of the laserpen just shows us the left diagram below (a difference of 4 Hz because it is a self centering recordplayer; other diagrams of high end turntables show a variance of 20 Hz and more). The RIAA standard permits an extreme eccentricity of 1,27 mm. That’s 1% deviation from every frequency from 20Hz – 20.000 Hz.

An externally hosted image should be here but it was not working when we last tested it.

When the stylus has to move back on its way to the inner groove, the tonearm will continue its motion in the forward direction because of the mass (inert mass). Therefore, the pivot of the cantilever will be forced out of the centreline of the groove. As a result the balance of the volume of the right and left channel will shift a bit (every 0,9 second).

Conclusion: the drawback of eccentric records is not only the instability of all the frequencies, the stereo image is involved too.

I have described a practical solution to centre records. It is easy and “low tech”. Unfortunately, I haven't found a tool everywhere available (shops, internet) that can be used to “drill” someone’s record collection (about 40 mm holes). Smaller centre holes don’t work – to few physical bandwidth to achieve the desired tolerance of 0,1 mm – and expensive punching machines will not be bought by the users of vinyl records....

So there is a solution for the eccentricity of vinyl records, but there is - at this moment - no solution for a simple modification of the records to use these non-concentric rings.

Last edited:

What about using a reamer of, say 7.5 mm. The nominal diameter of the spindle is 7.15 mm. The reamer would enlarge it to 7.5 mm. Same would be achieved as with the removable spindle - the record could be positioned so that the stylus would move forward evenly, instead of moving forward and backward 1.8 times per second. Proper positioning would need a trial and error within the 0.225 mm tolerance that this method permits.

@oshifis,

There is only one way to centre an eccentric record and that’s with the help of 2 non-concentric rings. Because the spiral groove at both sides of the record are not identical aligned in relation of the spindle. So every side of the record has its own eccentricity. Moreover, both eccentric grooves are not lined up too (the same centre line).

Nevertheless, your idea about using a reamer is really a very nice idea! I think you have the solution...

Look to the image above. When I stick a thick ring around the reamer with a diameter of 8 mm, every centre hole of the collection vinyl records will get exactly the same width. Now I can use a specialized drill – I have one to make cylinders in wood with a diameter of 20 mm – to make the new centre hole.

These two steps can be done without importing a lot of tolerance. And... without damaging the grooves of the records because of the slow pace. So now I have to search for a 40 mm (or 42 mm) specialized drill... (or someone has a better idea.)

There is only one way to centre an eccentric record and that’s with the help of 2 non-concentric rings. Because the spiral groove at both sides of the record are not identical aligned in relation of the spindle. So every side of the record has its own eccentricity. Moreover, both eccentric grooves are not lined up too (the same centre line).

Nevertheless, your idea about using a reamer is really a very nice idea! I think you have the solution...

An externally hosted image should be here but it was not working when we last tested it.

Look to the image above. When I stick a thick ring around the reamer with a diameter of 8 mm, every centre hole of the collection vinyl records will get exactly the same width. Now I can use a specialized drill – I have one to make cylinders in wood with a diameter of 20 mm – to make the new centre hole.

These two steps can be done without importing a lot of tolerance. And... without damaging the grooves of the records because of the slow pace. So now I have to search for a 40 mm (or 42 mm) specialized drill... (or someone has a better idea.)

Last edited:

Tom, I understand your idea with the excentric centering disks. My only remark is that if you have a new center hole of 8 mm (or 7.5 mm, does not matter), you can position the disc carefully off center right away to eliminate any excentricity. The new hole will not touch the spindle, and the disc will be positioned a bit off axis. How to position the disc? By observing the movement of the stylus in the horizontal plane, using your laser pen method, whatever.

Jan sent pictures the .55Hz FM is real, I have seen folks fiddle and eliminate it solely by re-centering.

I saw Jan's data and your interpretation. It doesn't really look like it's a large effect compared to the other inaccuracies, but it's not zero. Now I have a vision of a major centering ritual added to playback of the records with reamed out center holes.

I was wondering exactly How one would quantify the eccentricity.

The laser bit looks as Clever.

Still remains the issue of Repositioning the hole (easy as a stick on piece with a hole) ACCURATELY as in less so than the bungled original 🙂

Me I'd either live with it or throw away the damaged LP.

Life too short for some things 🙂

The laser bit looks as Clever.

Still remains the issue of Repositioning the hole (easy as a stick on piece with a hole) ACCURATELY as in less so than the bungled original 🙂

Me I'd either live with it or throw away the damaged LP.

Life too short for some things 🙂

@oshifis,

It is a terrible job to centre a record without 2 non-concentre rings. The record has a weight that’s far too much to displace the record by e.g. 0,2 mm. It is terrible frustrating and you probably will spend hours to centre one record.

@SY,

You are right, the lower the frequency, the less instability of the frequency by eccentricity. Nevertheless, we buy silver interconnect cables – instead of copper ones – because we think it will increase the quality of the reproduced sound. We buy expensive tube amplifiers because it sounds a bit “warmer”. Actually, this all has nothing to do with specs but it is a matter of taste (and unproven magic).

The eccentricity of a record has nothing to do with “taste”, it is a measurable flaw. Moreover, new vinyl records are more eccentric in relation to the records I bought 35 years ago. See this one, bought in 2013 (the quality of the recording is perfect, but the centre hole...).

When people can buy turntables that cost $100,000.—and more, they must have the opportunity to buy centric records too. Otherwise they better can buy a $1000.—CD player (better quality of reproduced sound in relation to distortion, etc.).

It is simple: high end phono equipment needs high end vinyl records. The manufacturer of new vinyl records won’t do it, so I try to find a “practical” solution for everyone.

@Bare,

I don’t like centring records. But when I have bought a bad eccentric record, I cannot go back to the shop and buy a second one that’s much better. That’s the problem.

It is a terrible job to centre a record without 2 non-concentre rings. The record has a weight that’s far too much to displace the record by e.g. 0,2 mm. It is terrible frustrating and you probably will spend hours to centre one record.

@SY,

You are right, the lower the frequency, the less instability of the frequency by eccentricity. Nevertheless, we buy silver interconnect cables – instead of copper ones – because we think it will increase the quality of the reproduced sound. We buy expensive tube amplifiers because it sounds a bit “warmer”. Actually, this all has nothing to do with specs but it is a matter of taste (and unproven magic).

The eccentricity of a record has nothing to do with “taste”, it is a measurable flaw. Moreover, new vinyl records are more eccentric in relation to the records I bought 35 years ago. See this one, bought in 2013 (the quality of the recording is perfect, but the centre hole...).

When people can buy turntables that cost $100,000.—and more, they must have the opportunity to buy centric records too. Otherwise they better can buy a $1000.—CD player (better quality of reproduced sound in relation to distortion, etc.).

It is simple: high end phono equipment needs high end vinyl records. The manufacturer of new vinyl records won’t do it, so I try to find a “practical” solution for everyone.

@Bare,

I don’t like centring records. But when I have bought a bad eccentric record, I cannot go back to the shop and buy a second one that’s much better. That’s the problem.

I can measure many flaws that I can't hear. I can, however, readily detect the ten or fifteen minutes of fiddling to get a record aligned. 😀

Slightly OT but Tom, I have always admired your solution-oriented thinking, and have followed your other threads closely. I haven't watched the video all the way through before, and this time i noticed a less wanted behavior between 9:15 and 9:20. It looks as if the pivot end suddenly rushes 15-20 millimeter to "catch up" with the stylus? If this happens regularly, you need to make some improvements😀The eccentricity of a record has nothing to do with “taste”, it is a measurable flaw. Moreover, new vinyl records are more eccentric in relation to the records I bought 35 years ago. See this one, bought in 2013 (the quality of the recording is perfect, but the centre hole...).

Steen

@jan.didden,

The diagrams show the variation of the rpm. But I am not concerned about the stability of the rpm, I am concerned about the instability of the frequencies by the eccentricity of the vinyl record. I am fully aware of the fact we don’t recognize these instabilities when we listen to a lot of frequencies at the same time. But when I listen to a single test tone I can hear a “wow” every rotation of the platter (it is a very eccentric test record). This frequency variance is easy to calculate too.

The distortion of the stereo image by the inert mass of the tonearm – because the volume of both channels will vary every 0,9 second by the eccentricity of the record – is a drawback too. Especially for the owners of a heavy cartridge and fixed pivot tonearm (heavy counterweight). So don't buy Ortofon's most expensive and heaviest cartridge: the 16 gram MC Anna! ;-)

@Dyolf,

It is right, in the video the tonearm corrects 3 x a misalignment. I have done this to show “the principle” of the linear tonearm. The horizontal bar isn’t positioned tangential to a radial of the spindle, so people may assume that the angle of the horizontal bar is responsible for the movement and right position of the tonearm. Just because the rotating record pulls the tonearm towards the horizontal bar.

So I have misaligned the bowl/horizontal bar a bit. Now you can see the tonearm corrects itself by a force that keeps the tonearm at right angles to the spindle. This video shows the flawless movement of the tonearm all along the trajectory when I align the horizontal bar/bowl in the right way.

The diagrams show the variation of the rpm. But I am not concerned about the stability of the rpm, I am concerned about the instability of the frequencies by the eccentricity of the vinyl record. I am fully aware of the fact we don’t recognize these instabilities when we listen to a lot of frequencies at the same time. But when I listen to a single test tone I can hear a “wow” every rotation of the platter (it is a very eccentric test record). This frequency variance is easy to calculate too.

The distortion of the stereo image by the inert mass of the tonearm – because the volume of both channels will vary every 0,9 second by the eccentricity of the record – is a drawback too. Especially for the owners of a heavy cartridge and fixed pivot tonearm (heavy counterweight). So don't buy Ortofon's most expensive and heaviest cartridge: the 16 gram MC Anna! ;-)

@Dyolf,

It is right, in the video the tonearm corrects 3 x a misalignment. I have done this to show “the principle” of the linear tonearm. The horizontal bar isn’t positioned tangential to a radial of the spindle, so people may assume that the angle of the horizontal bar is responsible for the movement and right position of the tonearm. Just because the rotating record pulls the tonearm towards the horizontal bar.

So I have misaligned the bowl/horizontal bar a bit. Now you can see the tonearm corrects itself by a force that keeps the tonearm at right angles to the spindle. This video shows the flawless movement of the tonearm all along the trajectory when I align the horizontal bar/bowl in the right way.

Just to pour more gasoline to the fire: what about the eccentricity between A and B sides? Do we take for granted that they are aligned to each other?

@Willi Studer,

Sorry when I was not clear enough! Both spiral grooves are not alligned to each other. So the eccentricity changes when you turn the record upside down and drop it around the spindle. That's the big problem! Both sides of the recorde have their own eccentricity.

Otherwise you only have to centre the record and glue a thin metal ring upon the label with a hole that fits exactly the spindle. But that's not reality.

Sorry when I was not clear enough! Both spiral grooves are not alligned to each other. So the eccentricity changes when you turn the record upside down and drop it around the spindle. That's the big problem! Both sides of the recorde have their own eccentricity.

Otherwise you only have to centre the record and glue a thin metal ring upon the label with a hole that fits exactly the spindle. But that's not reality.

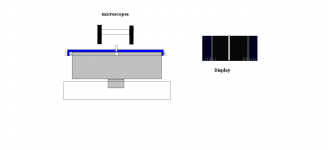

What about using USB microscopes placed above the player to help with the positioning of the record.

Last edited:

@Mark Witney,

It can be done, but probably is is not easy to do (I have an USB microscoop).

A laserpen is very cheap (about 15 euro), that's why I preferred the solution.

It can be done, but probably is is not easy to do (I have an USB microscoop).

A laserpen is very cheap (about 15 euro), that's why I preferred the solution.

The advantage of using microscopes is that you can adjust the position of the record without it rotating. Add a method of adjustment at the OD of the record and remove the centre pin. No need to drill holes in the records.

@Mark Witney,

The only "point of reference" - in relation to the eccentricity of one side of the record - is the outrun groove (a real circle). The outer side of a vinyl record isn't a real circle at all. So you have to move your USB microscope right above the outrun groove and correct the position of your records "by hand". That's quite annoying.

Drilling a hole into a record isn't the problem. The problem is to get the same excentricity as the old centre hole and the tool cannot be too expensive (otherwise no one will centre his/her records).

The only "point of reference" - in relation to the eccentricity of one side of the record - is the outrun groove (a real circle). The outer side of a vinyl record isn't a real circle at all. So you have to move your USB microscope right above the outrun groove and correct the position of your records "by hand". That's quite annoying.

Drilling a hole into a record isn't the problem. The problem is to get the same excentricity as the old centre hole and the tool cannot be too expensive (otherwise no one will centre his/her records).

I did not explain the design very well.

I can't see many people wanting to drill into their records or modifying their players ether.

I can't see many people wanting to drill into their records or modifying their players ether.

Attachments

Last edited:

@Mark Witney,

Sorry, I didn’t realize you want to use a new “deck” upon the platter. Well, your idea will centre the record in a perfect way, but it is necessary to calibrate every record over and over again. I am afraid it is a bit time consuming because you have to turn the record when the centre line of the eccentricity is just between two screws. So you have to mark your records at the brim.

Back again: suppose you buy a new turntable and cartridge for about 500 euro. Do you think it is important for you to centre your records? Of course not, the eccentricity of your records is one of a lot of imperfections. But there are people who pay 25.000,-- euro and more for a turntable because they want “the ultimate sound”. Spending so much money for high quality and after all just listening to the same eccentric records as the owner of a 500 euro turntable is quite amusing.

The industry don’t make any attempt to increase the quality of vinyl records. Therefore, we have to do it ourselves when we have high end phono equipment. Personally, I don’t like it, centring my records. Nevertheless, it is a bit stupid trying to increase the quality of turntables and cartridges when the source of the recorded music – the vinyl record – has so much mechanical imperfections.

Two non-concentric rings can centre every record in a perfect way and there are no modifications needed of the platter. Of course, there is a drawback too: the inner ring is pinched around the spindle (there is no other way when we don’t want to modify the platter). Therefore, we cannot shift between vinyl records with the original centre hole and modified records.

It is really easy to change “the design” to make this exchange possible: for example, just a square groove (about 3 mm) around the spindle where the inner ring can be pinched in. That’s all. We can buy an acrylic turntable mat (e.g. 6 mm) and ask the manufacturer to lathe the 3 mm square groove. Unfortunately, your platter will become heavier, perhaps the rpm becomes a bit more unstable, etc.

And... you still have to drill a lot of new centre holes. Subsequently you get used to high centred records and after some time you make the decision to modify some more records, may be even all your records...

It is important to keep it simple and cheap. No one will buy 2 conic drills for 165 euro to drill new centre holes (it needed 2 steps to increase the diameter from ~7 mm to 40 mm). Punching new holes (post #9 by Straight Tracker) is really a very good idea, but the bolt of these punches is about 10 mm. So we still have to drill a perfect hole that has exactly the same eccentricity as the original ~7,2 mm centre hole. I don’t like expensive modifications! ;-))

Sorry, I didn’t realize you want to use a new “deck” upon the platter. Well, your idea will centre the record in a perfect way, but it is necessary to calibrate every record over and over again. I am afraid it is a bit time consuming because you have to turn the record when the centre line of the eccentricity is just between two screws. So you have to mark your records at the brim.

Back again: suppose you buy a new turntable and cartridge for about 500 euro. Do you think it is important for you to centre your records? Of course not, the eccentricity of your records is one of a lot of imperfections. But there are people who pay 25.000,-- euro and more for a turntable because they want “the ultimate sound”. Spending so much money for high quality and after all just listening to the same eccentric records as the owner of a 500 euro turntable is quite amusing.

The industry don’t make any attempt to increase the quality of vinyl records. Therefore, we have to do it ourselves when we have high end phono equipment. Personally, I don’t like it, centring my records. Nevertheless, it is a bit stupid trying to increase the quality of turntables and cartridges when the source of the recorded music – the vinyl record – has so much mechanical imperfections.

Two non-concentric rings can centre every record in a perfect way and there are no modifications needed of the platter. Of course, there is a drawback too: the inner ring is pinched around the spindle (there is no other way when we don’t want to modify the platter). Therefore, we cannot shift between vinyl records with the original centre hole and modified records.

It is really easy to change “the design” to make this exchange possible: for example, just a square groove (about 3 mm) around the spindle where the inner ring can be pinched in. That’s all. We can buy an acrylic turntable mat (e.g. 6 mm) and ask the manufacturer to lathe the 3 mm square groove. Unfortunately, your platter will become heavier, perhaps the rpm becomes a bit more unstable, etc.

And... you still have to drill a lot of new centre holes. Subsequently you get used to high centred records and after some time you make the decision to modify some more records, may be even all your records...

It is important to keep it simple and cheap. No one will buy 2 conic drills for 165 euro to drill new centre holes (it needed 2 steps to increase the diameter from ~7 mm to 40 mm). Punching new holes (post #9 by Straight Tracker) is really a very good idea, but the bolt of these punches is about 10 mm. So we still have to drill a perfect hole that has exactly the same eccentricity as the original ~7,2 mm centre hole. I don’t like expensive modifications! ;-))

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Centering eccentric vinyl records