.......

It was this experiment that convinced me to invest in some tools and steel. I expect to make a few chassis' over the coming decade or two so the tools will pay themselves off pretty quickly. I think they already have.

Projects I have accumulated some, most or all of the parts for include:

Wolverine (monos of course)

Iron Pre

Miro 1862 Dac

Aikido Preamp

Tokin SITs (monos of course)

ACA Mini (probably monos)

The occasional commission for a friend.

probably some others I am forgetting

I probably have enough salvaged power transformers and heatsinks around to complete all of them for minimal cost on the heavy bits.

I can help if needed for the AD1862, have worked a little on them and published also free gerber for an i/V + buffer in smd op amps foot print if needing to drive difficult cans or low R input stages too. But there are a lot options in the thread and the first page towards the miro blog page that makes it short to read.

I wonder about the Tonkin SIT since the SIT 4. Any DIY iteration around that from Pass or the migthy @Zen Mod ? A 25W could be pleasant maybe ? (oh my dear my prefered loudspeaker is 85 db/2.83V with 2 ohms at 90 hz)😱

Thanks Patrick, pre anodized aluminum isn't available in Greece shops.https://bleche-nach-mass.de/kantteile/18-l-blech#001-0404

https://blechprofi24.de/blechkantteile/14/l-profil?c=5

(Have NOT used them before)

You need someone in Germany to order and re-ship to you.

But I think you should look for a local shop first.

Patrick

I can't find any.

Talking about expensive, guess how expensive ?

https://www.diyaudio.com/community/threads/headphone-amp-photo-gallery.366591/post-7801743

CNC milled from solid 6061aluminium.

Thinnest section 0.8mm.

Those who have machining experience would know how difficult.

Patrick

https://www.diyaudio.com/community/threads/headphone-amp-photo-gallery.366591/post-7801743

CNC milled from solid 6061aluminium.

Thinnest section 0.8mm.

Those who have machining experience would know how difficult.

Patrick

Talking about expensive, guess how expensive ?

Probably $300-400/each + setup/programming fees. That'd be my guess.

0.8 mm is thin. Very thin. Even thinner when approached by an end mill going 2500 RPM... 🙂

Tom

Here's some free casing.

My Ess9018 Arduino DAC in a Samsung's TV receiver box (I should remove the logo). The frame for the OLED screen is hand made.

And another DAC (Abraxalito's Abado II) in a ex WiFi router box. I have ordered a nice box for it from Ali but put this one together before it arrived.

My Ess9018 Arduino DAC in a Samsung's TV receiver box (I should remove the logo). The frame for the OLED screen is hand made.

And another DAC (Abraxalito's Abado II) in a ex WiFi router box. I have ordered a nice box for it from Ali but put this one together before it arrived.

Attachments

And another one (Whammy headphone amp). My father made it for me.

Wooden sides, top bottom, front, back 2mm flat aluminium. Just cut to size. I can't find the assembled photo, but these show the idea.

Wooden sides, top bottom, front, back 2mm flat aluminium. Just cut to size. I can't find the assembled photo, but these show the idea.

Attachments

I assume needs could be different relative to the device ?

Class A amps : needing metal casing for better cooling I surmise

Class A/b To D, certainly less ? Class D maybe more sensible to EMI pick ups needing more shielding ?

Dac ? But clock maybe (EMC?). Also wood can be good at dampig vibration with added mass (chipboard base) ?

Pre : ? : on one of the picture of my posts above, I showed a Douglas Self post (a goof thread here) about his last preamps. Of course it was woods rest ! (poplar for the front plate and bottom plus top and base chipboard. there is no LP stage.

Which I do not like in my casing whatever it is DACs mostly, is they need metal top cover for the heating, not wood isolation.... They alll have wood top with drilled holes or not, but I mostly use them w/o their top which could be so/so (think air vibration and EMC)

Class A amps : needing metal casing for better cooling I surmise

Class A/b To D, certainly less ? Class D maybe more sensible to EMI pick ups needing more shielding ?

Dac ? But clock maybe (EMC?). Also wood can be good at dampig vibration with added mass (chipboard base) ?

Pre : ? : on one of the picture of my posts above, I showed a Douglas Self post (a goof thread here) about his last preamps. Of course it was woods rest ! (poplar for the front plate and bottom plus top and base chipboard. there is no LP stage.

Which I do not like in my casing whatever it is DACs mostly, is they need metal top cover for the heating, not wood isolation.... They alll have wood top with drilled holes or not, but I mostly use them w/o their top which could be so/so (think air vibration and EMC)

Last edited:

Class A amps need large heatsinks. They're made of metal but the rest of the chassis could be wood.

Class AB needs heatsinks. They're made of metal but the rest of the chassis could be wood.

Class D sometimes needs a heatsink. That can usually be an aluminum sheet on the bottom. The rest of the chassis could be wood.

A preamp (even a phono stage), DAC, or whatnot could be in a wooden chassis. Unless we're talking a vacuum tube circuit, they tend to not develop much heat, so heat sinking is not much of an issue.

You can always line a wooden chassis with copper or brass mesh, foil, or thin sheet. Particle board is cheap. Many hifi chassis from the 70s and early 80s were made from veneered particle board.

The first amp I even built (at age 13-14) was in a chassis made of 12 mm particle board. It had a sheet of aluminum on the back that also served as the heat sink for the two 25 W Class AB channels within it. It had a sheet of aluminum on the front to hold the volume pot, tone controls, etc. It wasn't a looker but it worked just fine.

All you're trying to do is to build a box. There's nothing more to it than that so don't overthink it.

Tom

Class AB needs heatsinks. They're made of metal but the rest of the chassis could be wood.

Class D sometimes needs a heatsink. That can usually be an aluminum sheet on the bottom. The rest of the chassis could be wood.

A preamp (even a phono stage), DAC, or whatnot could be in a wooden chassis. Unless we're talking a vacuum tube circuit, they tend to not develop much heat, so heat sinking is not much of an issue.

You can always line a wooden chassis with copper or brass mesh, foil, or thin sheet. Particle board is cheap. Many hifi chassis from the 70s and early 80s were made from veneered particle board.

The first amp I even built (at age 13-14) was in a chassis made of 12 mm particle board. It had a sheet of aluminum on the back that also served as the heat sink for the two 25 W Class AB channels within it. It had a sheet of aluminum on the front to hold the volume pot, tone controls, etc. It wasn't a looker but it worked just fine.

All you're trying to do is to build a box. There's nothing more to it than that so don't overthink it.

Tom

The fact that you need heat sinks for power amp (except for Class D) does not mean you need an all metal chassis.

This has 2x 3886 in the upper case, with small heatsinks inside.

The lower case is only transformer and rectifiers.

If damping is important, Corian is better than wood.

Patrick

.

This has 2x 3886 in the upper case, with small heatsinks inside.

The lower case is only transformer and rectifiers.

If damping is important, Corian is better than wood.

Patrick

.

Attachments

I have to say the Ryobi as I have already the cells seems a good option (@Sadface post above) to cut some metal sheets on the ground if finding them before the recycling services take them at the early morning. Sorta of slow sport, it is okay as it is not if al was urgent here !

Here we have a monthly fixed day to put all the things that are not usually in the gardbadges like daily food or their containers, glass, paper made things or clothes (literally all different wastes box with their on color). It is usually bigger things: could be furniture, metal things, big things most of the time that do not enter in waste container with wheels. Surely the same everywhere. So if you can not find PCs or metal gears bowed at recycling center individuals have also the freedome to drop here, one day a month you can find related to the richness of your town fin good materials for our hobby ! I still have a B&W D14 in perfect condition working well, some CD players or integrated amps, all from the 70/80/90.

Here we have a monthly fixed day to put all the things that are not usually in the gardbadges like daily food or their containers, glass, paper made things or clothes (literally all different wastes box with their on color). It is usually bigger things: could be furniture, metal things, big things most of the time that do not enter in waste container with wheels. Surely the same everywhere. So if you can not find PCs or metal gears bowed at recycling center individuals have also the freedome to drop here, one day a month you can find related to the richness of your town fin good materials for our hobby ! I still have a B&W D14 in perfect condition working well, some CD players or integrated amps, all from the 70/80/90.

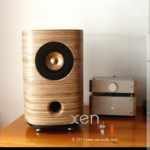

Is that Sister's series, Patrick? You have never posted any doc's on them?

BTW As always perfect!

I am also building small desktop speakers with similar drivers (MarkAudio?) but then again mine are nowhere close to what you have just posted.

BTW As always perfect!

I am also building small desktop speakers with similar drivers (MarkAudio?) but then again mine are nowhere close to what you have just posted.

Try heat sinks at 10,000 rpm. 🙁Even thinner when approached by an end mill going 2500 RPM...

jeff

Is that Sister's series ?

Yes, but you can consider building this, which is much easier and just as good looking :

https://www.diyaudio.com/community/threads/mini-2-way-with-peerless.415614/

The amp is standard BrianGT 3886.

You can build the case using 2 AL angle and 2 wooden panels as described earlier.

Just mount small, standard heatsinks inside on 5mm standoffs.

https://www.diyaudio.com/community/threads/casing-why-so-expensive.417998/post-7802304

I actually have the idea to build a Brother's Series but never get round to it.

The idea is to use 2x LM4780 or even LM4766 in bridge mode.

Music source can be a Pono Player in balanced mode.

Don't believe in people's comments about the Pono driving headphones.

It's best used to drive 10k load line level.

Else use any digital I2S source of your choice to drive ES9023 balanced.

Nothing else you need for a compact desktop system.

Patrick

I'd like a couple of stainless steel amplifier cases, no need for front panels, just keep it simple, but I haven't had much luck finding someone to make them yet. I think just a matter of cutting and folding, or maybe plates with corner posts to hold it together? Drilling and cutting for bolts, connectors and leds.

I had a look at various boxes online; they mostly seem to be for outdoor electrical installations so not very suitable. And I'm having trouble finding machine shops who might construct something from scratch. I suppose it might be simpler if they already made cases, but I haven't found those yet.

I'm in Thailand so Taobao etc are options. Any ideas? 🙂

I had a look at various boxes online; they mostly seem to be for outdoor electrical installations so not very suitable. And I'm having trouble finding machine shops who might construct something from scratch. I suppose it might be simpler if they already made cases, but I haven't found those yet.

I'm in Thailand so Taobao etc are options. Any ideas? 🙂

That's funny, why so much english people in Thailand more than anywhere else ? Do they speak english well enough ? Or is it just the beaches and the low cost way of life ?

Being near the retirment I ask cause some talk about many countries as drop third age coast but their owns' ?!

Being near the retirment I ask cause some talk about many countries as drop third age coast but their owns' ?!

My last kit build not named Neurochrome was a 3 channel ICEpower AS200 amp for my HT rig 4 years back. Found a great deal on a custom machined chassis with silkscreened rear panel from Ghent Audio in Shanghai* Landed cost something like $250 CDN, IIRC, which was about 60% of the cost of the amp modules.

* No apologies for the country of origin, and the quality of fabrication was at least the equal of the Galaxy chassis from Hi-fi 2000 I bought for my earlier Hypex UCD180 build.

Tom’s chassis for the original Modulus 286 kit was a perfect - if not spacious - enclosure for the design.

* No apologies for the country of origin, and the quality of fabrication was at least the equal of the Galaxy chassis from Hi-fi 2000 I bought for my earlier Hypex UCD180 build.

Tom’s chassis for the original Modulus 286 kit was a perfect - if not spacious - enclosure for the design.

- Home

- Member Areas

- The Lounge

- Casing, why so expensive?