Hi

I’ve read quite a few posts with strongly differing opinions on the importance (or not) of the type of passive components used.

I don’t wish to open a can of worms here, just to get some advice and/or suggestions.

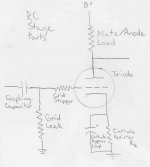

I’m up to replacing the resistors and caps in the dirty channel preamp section of my guitar tube amp – it has for stages of ECC83

I plan on using:

- 2W Metal Film resistors for cathode and gridleak in all four stages and for plate and grid stoppers in the first two stages

- 1/2W Carbon composition for plate and grid stoppers in the third and fourth stages and in tone stacks

- Silvered Mica caps for all cap values below 1n

I still am not sure what cap types to use for dc coupling and signal attenuation - Metallyzed Polyester, or Polypropylene

I also have a pile of 630V capacitors of unknown manufacturer or type. They look very much like Xicon Polypropylenes sold at hoffman’s site, but I cut one open and found that on the inside it has stacks or layers of what looks like metal film (at least it is shiny). I’m not sure if these are metal film or metallized paper (don’t know how to tell the difference). Are they any good for use in guitar tube amps?

What about the Evox Rifa paper caps from Farnell - has anybody tried them?

I’d appreciate any thoughts you have on my choice of resistor types as well as any suggestions for the capacitor types to use.

Thanks

PS: I forgot to specify that the amp is a fender tremolux clone and I've already modified (more like rebuilt to a new) the channel in question, so I will not be ruining anything precious.

Currently all resistors are 2W carbon film and caps are Wima polypropylene. By replacing these I'm aiming at less noise and more warmth.

I also wonder if I should replace the phase splitter resistors and caps too?

I’ve read quite a few posts with strongly differing opinions on the importance (or not) of the type of passive components used.

I don’t wish to open a can of worms here, just to get some advice and/or suggestions.

I’m up to replacing the resistors and caps in the dirty channel preamp section of my guitar tube amp – it has for stages of ECC83

I plan on using:

- 2W Metal Film resistors for cathode and gridleak in all four stages and for plate and grid stoppers in the first two stages

- 1/2W Carbon composition for plate and grid stoppers in the third and fourth stages and in tone stacks

- Silvered Mica caps for all cap values below 1n

I still am not sure what cap types to use for dc coupling and signal attenuation - Metallyzed Polyester, or Polypropylene

I also have a pile of 630V capacitors of unknown manufacturer or type. They look very much like Xicon Polypropylenes sold at hoffman’s site, but I cut one open and found that on the inside it has stacks or layers of what looks like metal film (at least it is shiny). I’m not sure if these are metal film or metallized paper (don’t know how to tell the difference). Are they any good for use in guitar tube amps?

What about the Evox Rifa paper caps from Farnell - has anybody tried them?

I’d appreciate any thoughts you have on my choice of resistor types as well as any suggestions for the capacitor types to use.

Thanks

PS: I forgot to specify that the amp is a fender tremolux clone and I've already modified (more like rebuilt to a new) the channel in question, so I will not be ruining anything precious.

Currently all resistors are 2W carbon film and caps are Wima polypropylene. By replacing these I'm aiming at less noise and more warmth.

I also wonder if I should replace the phase splitter resistors and caps too?

Use met. polypropylene caps over mylar (polyester), they are cheap enough.

Carbon comps are even noisier than carbon film. For lowest noise, replace the plate loads with wirewounds. For values between 10k-100k "NI" wirewounds are hard to beat in audio apps. Inductance is not an issue at these values, it becomes one as you go lower.

Metal film is a good choice in cathodes, carbon film may be "warmer".

Use carbon film or carbon comp for all grid stoppers.

Noise: carbon comp > carbon film > metal film > wirewound.

Metalized paper caps are for line apps and such, not signal. They are self healing and fail gracefully. Not to be confused with paper in oil (PIO) caps.

Carbon comps are even noisier than carbon film. For lowest noise, replace the plate loads with wirewounds. For values between 10k-100k "NI" wirewounds are hard to beat in audio apps. Inductance is not an issue at these values, it becomes one as you go lower.

Metal film is a good choice in cathodes, carbon film may be "warmer".

Use carbon film or carbon comp for all grid stoppers.

Noise: carbon comp > carbon film > metal film > wirewound.

Metalized paper caps are for line apps and such, not signal. They are self healing and fail gracefully. Not to be confused with paper in oil (PIO) caps.

If by plate stopper you mean a 47 ohm or so resistor paralleled by a 4-6 turn coil for the prevention of oscillations, these should be carbon film or carbon comp.

2W metal film resistors are unlikely to sound much quieter than 2W carbon films, and carbon films generally sound "warmer"- so you may get the opposite of what you want! Carbon comp resistors can be quite noisy, but if they're in the 3rd/4th stage you should be ok. Wirewound resistors are great if you can afford it, but hardly necessary for a guitar amp.

As for caps, any poly type will do, although film types are preferred over metallized types. Teflon or polystyrene is the best, although polypropylene is more common. In a guitar amp you probably won't notice the difference though. Some people also like to add a ceramic cap in parallel with coupling caps, to give some high-freq texture.

I agree with Tweeker about cathode bypass caps- avoid electrolytics if you possibly can, and use non-polarized ones if you have to. However, in a guitar amp you can safely reduce the cathode bypass caps to 1uF or 2uF, thus allowing you to use poly-type caps. The lower value will really tighten up and smooth out the bass tone too!

You don't "need" to replace the PI components- that part of the circuit already has excellent signal-noise ratio.

As for caps, any poly type will do, although film types are preferred over metallized types. Teflon or polystyrene is the best, although polypropylene is more common. In a guitar amp you probably won't notice the difference though. Some people also like to add a ceramic cap in parallel with coupling caps, to give some high-freq texture.

I agree with Tweeker about cathode bypass caps- avoid electrolytics if you possibly can, and use non-polarized ones if you have to. However, in a guitar amp you can safely reduce the cathode bypass caps to 1uF or 2uF, thus allowing you to use poly-type caps. The lower value will really tighten up and smooth out the bass tone too!

You don't "need" to replace the PI components- that part of the circuit already has excellent signal-noise ratio.

Higher wattage resistors are somewhat less noisy than lower, this one one reason you will sometimes see 2 watts where a half watt would do.

I agree with Tweeker about cathode bypass caps- avoid electrolytics if you possibly can, and use non-polarized ones if you have to.

Wath about tantalum electrolytic, are they better for cathode bypass then aluminium electrolytic?

No, they are really only suited for non signal roles. Besides, if you can use a tantalum here, you can use a poly.

No comments on the sound of one thing vs another, but regarding resistors in a tube amp, remember that resistors have a maximum voltage rating, regardless of value. Power rating isn't the only consideration. They also need to be derated in high temp applications. For metal films, I prefer the larger RN70 or equivalent types. Note that flameproof metal oxide resistors are very appealing until you find out how non-linear they can be with voltage. Though my favorite cap is polystyrene, remember the maximum temperature rating is very low for a tube amp- I'd stick with polypropylene or polyester.

How to differentiate between film/foil , metallized capacitor

As I saw in the first post above by voivodata, actually have opened the 630 volt capacitors, here some guidelines to determine the type of construction of the capacitor:

1. Determine the material used in the dielectric:

If you find paper between the layers , it's paper caps 🙂

if you find plastic, it's plastic, that simple.

2. Determine between Metallized or foil construction :

if you find foil of metal that can be separated from the dielectric

then it's paper/foil or plastic/foil construction

if instead you find sprayed metal that sticks to the dielectrics, and can not be separated from the dielectric, that's metallized construction.

paper type have many variations, as well plastic types.

plastic dielectric type can be determined but you must be familiar

with different plastic types. which is a bit hard if you don't work in plastic industry.

the simple way is to see the size of the capacitor:

metallized polypropylene is bigger than metallized polyester(cheaper) for the same size(uF) and (Volt)rating.

foil capacitor is bigger than metallized(usually cheaper) and heavier for the same capacity(uF) and (Volt)rating.

teflon is uncommon and extremely big for a given capacity.

polystyrene usually have clear body and mostly tiny leads to prevent soldering heat destroying it (polystyrene is rated at 85 degree Celcius)

about the sound of capacitors:

capacitors is not perfect, so they impart their characteristic to the signal. various type have their own measurable(mostly hard to measure) electrical parameter strength or weakness.

Dissipation factor, Equvalent Series Inductance (ESI), Dielectric Absorbtion, Equivalent Series Resistance (ESR)

Electrolytic capacitor have some more noticeable weakness: leakage, nonlinearity, terrible temperature stability (capacitance varies wildly with temperature change)

note for polarized (+/-) Electolytic capacitor : DO NOT put the wrong polarity,

it will misbehave, or even explode(often).

nonpolar electrolytic don't mind reverse polarity.

for guitar amp application, capacitor can be used to change the sound character of the amp, experimentation is necessary.

🙂

As I saw in the first post above by voivodata, actually have opened the 630 volt capacitors, here some guidelines to determine the type of construction of the capacitor:

1. Determine the material used in the dielectric:

If you find paper between the layers , it's paper caps 🙂

if you find plastic, it's plastic, that simple.

2. Determine between Metallized or foil construction :

if you find foil of metal that can be separated from the dielectric

then it's paper/foil or plastic/foil construction

if instead you find sprayed metal that sticks to the dielectrics, and can not be separated from the dielectric, that's metallized construction.

paper type have many variations, as well plastic types.

plastic dielectric type can be determined but you must be familiar

with different plastic types. which is a bit hard if you don't work in plastic industry.

the simple way is to see the size of the capacitor:

metallized polypropylene is bigger than metallized polyester(cheaper) for the same size(uF) and (Volt)rating.

foil capacitor is bigger than metallized(usually cheaper) and heavier for the same capacity(uF) and (Volt)rating.

teflon is uncommon and extremely big for a given capacity.

polystyrene usually have clear body and mostly tiny leads to prevent soldering heat destroying it (polystyrene is rated at 85 degree Celcius)

about the sound of capacitors:

capacitors is not perfect, so they impart their characteristic to the signal. various type have their own measurable(mostly hard to measure) electrical parameter strength or weakness.

Dissipation factor, Equvalent Series Inductance (ESI), Dielectric Absorbtion, Equivalent Series Resistance (ESR)

Electrolytic capacitor have some more noticeable weakness: leakage, nonlinearity, terrible temperature stability (capacitance varies wildly with temperature change)

note for polarized (+/-) Electolytic capacitor : DO NOT put the wrong polarity,

it will misbehave, or even explode(often).

nonpolar electrolytic don't mind reverse polarity.

for guitar amp application, capacitor can be used to change the sound character of the amp, experimentation is necessary.

🙂

THANK YOU ALL for the the valuable info and guidelines provided.

Now I have a better clue how to proceed.

Regards! V.

Now I have a better clue how to proceed.

Regards! V.

idea

I'm using a very stupid method of choosing capacitors: I just pass a guitar signal through a cap and listen to it through a hi-fi amplifier, comparing to bypass signal. No additional circuitry, just two clamps to connect the cap to the guitar cord.

The same goes to resistors.

Believe it or not, the caps all sound very different with many of them being noisy and ugly - for example, at some point I've bought "generic" axial yellow caps (mallory 150 style) and they were surprisingly noisy.

I'm not sure this is the way to test capacitors but it's pretty simple and if you're not sure what a certain cap is capable of you may simply plug in it.

I'm using a very stupid method of choosing capacitors: I just pass a guitar signal through a cap and listen to it through a hi-fi amplifier, comparing to bypass signal. No additional circuitry, just two clamps to connect the cap to the guitar cord.

The same goes to resistors.

Believe it or not, the caps all sound very different with many of them being noisy and ugly - for example, at some point I've bought "generic" axial yellow caps (mallory 150 style) and they were surprisingly noisy.

I'm not sure this is the way to test capacitors but it's pretty simple and if you're not sure what a certain cap is capable of you may simply plug in it.

- Status

- Not open for further replies.

- Home

- Live Sound

- Instruments and Amps

- Cap and resistor types in guitar tube amp