Thanks Mooly

There seems to be some contrversey on weather to trap both the hot and neutral sides of the supply.

What is your opinion on this?

There seems to be some contrversey on weather to trap both the hot and neutral sides of the supply.

What is your opinion on this?

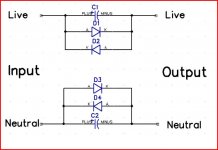

Never tried this so can't say if it will fix problem or not. As to whether to use in both lines, just remember that that the primary side is a series circuit. It should'nt matter (from an operating point of view) if it's in live or neutral. Using two networks I guess allows for more D.C. to be removed (0.7v + 0.7v). If you allowed for a higher reverse voltage across the caps then two diodes in series (still two sets in inverse parallel mind) and one cap would achieve the same, as would the two original networks in series. I am just rambling now 🙂 what about two networks in series, with a single diode across each cap for reverse polarity protection and a string of say 4 diodes to limit the foward volt drop and connect the two networks so they form a bi-polar cap. Have to think about that one

Regards Karl

Regards Karl

rtate said:Thanks Mooly

There seems to be some contrversey on weather to trap both the hot and neutral sides of the supply.

What is your opinion on this?

2a+b = c

a + b +a = c

I think this is common knowledge in mathematics

In Sweden and in many countries we make no difference between neutral and live.

I tryed this version of DC trap.

http://sjostromaudio.com/joomla/index.php?option=com_content&task=view&id=62&Itemid=27

The results was too poor for my big problem.

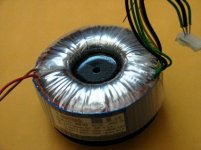

The stray effect was too high (1kW toroid).I tryed also to potted with 3mm double steel shield....rounded and H style.

The best choice is to replace the transformer with a dedicated toroid special made FOR AUDIO and not to try to make from an industrial tranny "something" good for audio.

Plitron-special design for audio- is one of the manufactures in audio transformers with very low stray effect and noise..

The type of winding and shielding of the bobin in such tranny is quite different from an industrial one.

Also R-core have low stray efect and noiseless tranny.Be careful with chineze manufactures.

http://sjostromaudio.com/joomla/index.php?option=com_content&task=view&id=62&Itemid=27

The results was too poor for my big problem.

The stray effect was too high (1kW toroid).I tryed also to potted with 3mm double steel shield....rounded and H style.

The best choice is to replace the transformer with a dedicated toroid special made FOR AUDIO and not to try to make from an industrial tranny "something" good for audio.

Plitron-special design for audio- is one of the manufactures in audio transformers with very low stray effect and noise..

The type of winding and shielding of the bobin in such tranny is quite different from an industrial one.

Also R-core have low stray efect and noiseless tranny.Be careful with chineze manufactures.

A DC trap will only catch the DC problem. If the transformer hums anyway, you might have a problem with not so hard wounded winding and a lose core. This is a quality problem I should guess. Some manufactures are better than others.

Could someone recommend a good DIY product for coating the windings so they cannot vibrate? Is there some sort of varnish or epoxy specially suited to this?

An audio transformer from Noratel (former Toroid Transformer AB).

http://www.elfa.se/elfa-bin/dyndok.pl?lang=se&vat=0&dok=2021854.htm

The transformer seems to come from an amp project, was it Advantage or Bladelius?

http://www.bladelius.com/

http://www.bladelius.com/s250new.html

http://www.elfa.se/elfa-bin/dyndok.pl?lang=se&vat=0&dok=2021854.htm

The transformer seems to come from an amp project, was it Advantage or Bladelius?

http://www.bladelius.com/

http://www.bladelius.com/s250new.html

Hi all , RyanW I have never found any product that works, we used to remove transformers, not large toroids admittedly, and heat them and then dip/soak them in varnish, no good  There is so much energy (magnetic field) involved that if the laminations are "loose" your never going to cure it this way. If the mains is spiky with harmonics present the transformer does a pretty good job of audibly reproducing these. I am also not a big fan of oversized power supply capacitors as the charging currents are huge, made even worse by the small conduction angle of the bridge rectifier in "topping up" these caps every half cycle. Where do all the negative half cycles go that we dont use 😀 😀 😀 ?

There is so much energy (magnetic field) involved that if the laminations are "loose" your never going to cure it this way. If the mains is spiky with harmonics present the transformer does a pretty good job of audibly reproducing these. I am also not a big fan of oversized power supply capacitors as the charging currents are huge, made even worse by the small conduction angle of the bridge rectifier in "topping up" these caps every half cycle. Where do all the negative half cycles go that we dont use 😀 😀 😀 ?

Hello Peranders, regarding live and neutral, we have the neutral bonded to earth at the consumer unit, there is no potential difference between them. From a safety point of view any network is better inserted in the neutral side as there is less chance of getting a shock if it is accidently touched.

Regards Karl

There is so much energy (magnetic field) involved that if the laminations are "loose" your never going to cure it this way. If the mains is spiky with harmonics present the transformer does a pretty good job of audibly reproducing these. I am also not a big fan of oversized power supply capacitors as the charging currents are huge, made even worse by the small conduction angle of the bridge rectifier in "topping up" these caps every half cycle. Where do all the negative half cycles go that we dont use 😀 😀 😀 ?

There is so much energy (magnetic field) involved that if the laminations are "loose" your never going to cure it this way. If the mains is spiky with harmonics present the transformer does a pretty good job of audibly reproducing these. I am also not a big fan of oversized power supply capacitors as the charging currents are huge, made even worse by the small conduction angle of the bridge rectifier in "topping up" these caps every half cycle. Where do all the negative half cycles go that we dont use 😀 😀 😀 ?Hello Peranders, regarding live and neutral, we have the neutral bonded to earth at the consumer unit, there is no potential difference between them. From a safety point of view any network is better inserted in the neutral side as there is less chance of getting a shock if it is accidently touched.

Regards Karl

I know and you are alone about this as I understand. Our mains outlets has a ground wire connected to a central grounding point and we don't mix neutral (which carries current) and protective earth. We can also turn our connectors 180 degrees because they are symmetrical and we also have a different fuse arrangement (or the brittish fuse arrangements is different from the rest of the worldMooly said:Hello Peranders, regarding live and neutral, we have the neutral bonded to earth at the consumer unit, there is no potential difference between them. From a safety point of view any network is better inserted in the neutral side as there is less chance of getting a shock if it is accidently touched.

Regards Karl

)

)RyanW said:Could someone recommend a good DIY product for coating the windings so they cannot vibrate? Is there some sort of varnish or epoxy specially suited to this?

Read post #10 for the method you ask.

Fotios

Hi,

Fotios post 10 is good, but even better is to buy from a manufacturer that uses vacuum impregnation of the core and then of the windings to ensure no air spaces are left.

The lack of air in the core and windings also helps the transformer to run cooler than one that is not impregnated.

Fotios post 10 is good, but even better is to buy from a manufacturer that uses vacuum impregnation of the core and then of the windings to ensure no air spaces are left.

The lack of air in the core and windings also helps the transformer to run cooler than one that is not impregnated.

Hi,

Neutral and earth in Britain are tapped from the star point of a three phase transformer (think of the Mitsubishi logo). If the earth is not as part of the supply companies' incoming cables then an earth rod is used.

Edit : Our fuses/MCB's are in the phase conductor, where are they in Sweden (and the rest of the world) then ?

Thanks

Gareth

Neutral and earth in Britain are tapped from the star point of a three phase transformer (think of the Mitsubishi logo). If the earth is not as part of the supply companies' incoming cables then an earth rod is used.

Edit : Our fuses/MCB's are in the phase conductor, where are they in Sweden (and the rest of the world) then ?

Thanks

Gareth

Thanks fotios. Can a person simply use standard 2-part epoxy from the hardware store? Is there a particular type of varnish? Polyurethane, etc...?

The fuses are at the phase wires but we have them on the wall to more than one outlet, usually 10 A to an amount of outlets that seems to be reasonable.

peranders said:The fuses are at the phase wires but we have them on the wall to more than one outlet, usually 10 A to an amount of outlets that seems to be reasonable.

Hi,

Sorry to everyone for going a little off topic but, in Sweden are your outlets on a radial then ? How many outlets to a 10 amp ?

Thanks

Gareth

RyanW said:Thanks fotios. Can a person simply use standard 2-part epoxy from the hardware store? Is there a particular type of varnish? Polyurethane, etc...?

The most common used varnish for insulating copper wires it is the enamel varnish and indeed it is based on polyurethane. I think that it is very difficult and expensive to find and by someone the varnish, because it is offered in seperate cans for the base insulating liquid, for the appropriate hardener and for the appropriate solvent. Usually these cans are from 10 lt and above.

The easiest way, it is to find a workshop of manufacturing transformers or to repair electric motors. From the same workshops many times we get few meters of enameled wire to make the chokes for the outputs of our amplifiers. The same workshops have also the appropriate varnish and if the owner it is a good man maybe he give you a little amount of the varnish to make your job.

Fotios

AndrewT said:The lack of air in the core and windings also helps the transformer to run cooler than one that is not impregnated.

Thanks Andrew for this information that i forgot to reffer for the heating caused (except the crackling noise of core) from the not well tightening of windings. Also the proccess in the vacuum it is indeed the final solution for the best results.

Regards

Fotios

rtate said:I have 8 leach super amp mono blocks all built with toroid transformers, 10 amp with 80,000uf supplies

Some of the trannies have developed a hum or buzz that is audible during quiet passages.

Is there any solution to this problem??

Voila a sample of a custom maden toroid according to my references in post #10. Its power it is 200VA

Fotios

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- buzzing transformers....