Hi,

Does anyone have the idea to make a tonearm head shell to match the DIY Schroeder Tonearm ?

Regards,

Bins.

Does anyone have the idea to make a tonearm head shell to match the DIY Schroeder Tonearm ?

Regards,

Bins.

I'm making mine using these guys.... just have to get a little creative with their software. They are a little bit expensive tho..

http://www.emachineshop.com

JD

http://www.emachineshop.com

JD

Why a head shell

Just make the end flat, and mount the pickup

Small piece of alu, or may better brass, across on top

A couple of screws

Nothing special needed

Just make the end flat, and mount the pickup

Small piece of alu, or may better brass, across on top

A couple of screws

Nothing special needed

Hi,

I would like to do it like in the Schroeder reference arm. But, I am not sure on the dimensions. 🙁

Regards,

Bins.

I would like to do it like in the Schroeder reference arm. But, I am not sure on the dimensions. 🙁

Regards,

Bins.

dimensions?

As long as you have the mounting holes for the cartridge spaced at 12.7 mm all should be easy after that. The overall width should be 25.4 mm (an inch) and about 18 mm (about 3/4") long. The plate can be 2 or 3 mm thick. After that, it's easy.

As long as you have the mounting holes for the cartridge spaced at 12.7 mm all should be easy after that. The overall width should be 25.4 mm (an inch) and about 18 mm (about 3/4") long. The plate can be 2 or 3 mm thick. After that, it's easy.

Hello Stew,

1. What is the ideal material for the plate: Aluminium/Brass/Steel/Others ? (Can we use Acrylic ?)

2. What should be the width and thickness for the head section of the arm ?

3. What is the angle at which the plate is mounted on the arm wand ?

Regards,

Bins.

1. What is the ideal material for the plate: Aluminium/Brass/Steel/Others ? (Can we use Acrylic ?)

2. What should be the width and thickness for the head section of the arm ?

3. What is the angle at which the plate is mounted on the arm wand ?

Regards,

Bins.

Attachments

dimensions con't

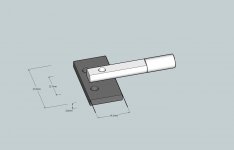

1) I think wood or non-ferrous metals are the best choice, acrylic can flex

2) see the attachment for some rough dimensions, but the "plate" can be 1" X 3/4" X 1/8" or so.

3) if a similar "headshell" is adopted the angle is adjustable and usable for arms of essentially any length.

1) I think wood or non-ferrous metals are the best choice, acrylic can flex

2) see the attachment for some rough dimensions, but the "plate" can be 1" X 3/4" X 1/8" or so.

3) if a similar "headshell" is adopted the angle is adjustable and usable for arms of essentially any length.

Attachments

Firstly you need to think about the cartridge which you

a) already own, and

b) the cartridge which you yearn for!

If you intend using low compliance MCs you will need a very stiff head to control the energy produced, whereas if you use a high compliance MM you can get away with a more flimsy affair.

For MC low compliance I would undoubtedly use pure, fine grain, carbon. It is easy to work - even by hand, but DO use a breathing mask. It is certain that carbon dust will not improve your lungs!

For high compliance anything which is rigid will do, but keep it light and skeletal. THis will reduce the mass. Again I would use carbon but in much reduced quantity.

If your arm is to be straight find the cartridge + headshell centre of gravity and ensure that the centreline through the arm-beam and cartridge head assembly intersect at the correct overall length for the arm + overhang to the stylus tip. This will at least decrease the amount of 'yaw' which you will get if you are out of balance in these planes.

Good luck!

Search on Google for "tone arm geometry". You will get results which will answer any questions re off set etc.

a) already own, and

b) the cartridge which you yearn for!

If you intend using low compliance MCs you will need a very stiff head to control the energy produced, whereas if you use a high compliance MM you can get away with a more flimsy affair.

For MC low compliance I would undoubtedly use pure, fine grain, carbon. It is easy to work - even by hand, but DO use a breathing mask. It is certain that carbon dust will not improve your lungs!

For high compliance anything which is rigid will do, but keep it light and skeletal. THis will reduce the mass. Again I would use carbon but in much reduced quantity.

If your arm is to be straight find the cartridge + headshell centre of gravity and ensure that the centreline through the arm-beam and cartridge head assembly intersect at the correct overall length for the arm + overhang to the stylus tip. This will at least decrease the amount of 'yaw' which you will get if you are out of balance in these planes.

Good luck!

Search on Google for "tone arm geometry". You will get results which will answer any questions re off set etc.

the trouble with this headshell is that it is meant for an "S" shaped arm. The "S" gives the cartridge the "offset angle" that is appropriate for it's given arm length (i.e. effective length, pivot to spindle distance, overhang, etc..) according to a formula to decrease or limit tracking error hence percentage of distortion (Baerwald, Lofgren etc...)

The Schroeder arm is a straight arm and once the length is determined, the headshell is "tilted" or rotated to get the correct offset angle.

The Schroeder arm consists of two pieces... the arm hand ( with an integrated headshell, and a "cartridge carrier that has the ability to be rotated to the correct angle, then screwed/locjed/tightened in place.

Have you ever seen or used an alignment gauge? It is used to check for correct geometry, BUT it is calculated from arm data for a specific set of demension for a specific tonearm using a specif alignmewnt formula. If you use a fixed headshell designed for an "S" arm in a straigh arm, you will never have correct cartridge alignment..... just won't work. If you look close at the Schroeder, you'll see an attachement piece between the cartridge and arm tube. On the Scroeder it allows rotation of the cartridge to get correct alignment. The Jelco headshell is fixed and no rotation is possible (except mayby for azimuth i.e. side to side vertical tilt).

The material of the carrier depends on the compliance of the carteidge you wand to use. Do a google search to find and understanding of this or search this forum... lots and lots of info here. If you look at the suspension of the cartrdge like a spring, you'll see that ther are softer springs (higher compliance) and harder springs (lower compliance). a higher complance spring usually requires less mass weight on it to work properly so aluminum would work well, and a lower complance cartridge would need more mass so a brass carrier would work well. Effective mass is not the same as tracking force so don't confuse the two.

It's a good idea to research and understand how an arm works before you start to build one using another design visually copied as if the measurements / distances / angles etc are not correct FOR THE ARM YOU BUILT, your results will be less than satisfactory and you will be greatly disappointed with the sound and all you efforts, time, money, will have been wasted. You need to understand all these 'terms" and understand how they are applied to the design and construction of the tonearm. They are very easy to understand and it's not rocket science or neuro-surgery.

There's a saying.... measure twice, cut once... in this case. understand what your measuring, understand what the measurements are, do this over and over a few times to really "get it" then build the arm. you'll be much happier with the end result.

JD

The Schroeder arm is a straight arm and once the length is determined, the headshell is "tilted" or rotated to get the correct offset angle.

The Schroeder arm consists of two pieces... the arm hand ( with an integrated headshell, and a "cartridge carrier that has the ability to be rotated to the correct angle, then screwed/locjed/tightened in place.

Have you ever seen or used an alignment gauge? It is used to check for correct geometry, BUT it is calculated from arm data for a specific set of demension for a specific tonearm using a specif alignmewnt formula. If you use a fixed headshell designed for an "S" arm in a straigh arm, you will never have correct cartridge alignment..... just won't work. If you look close at the Schroeder, you'll see an attachement piece between the cartridge and arm tube. On the Scroeder it allows rotation of the cartridge to get correct alignment. The Jelco headshell is fixed and no rotation is possible (except mayby for azimuth i.e. side to side vertical tilt).

The material of the carrier depends on the compliance of the carteidge you wand to use. Do a google search to find and understanding of this or search this forum... lots and lots of info here. If you look at the suspension of the cartrdge like a spring, you'll see that ther are softer springs (higher compliance) and harder springs (lower compliance). a higher complance spring usually requires less mass weight on it to work properly so aluminum would work well, and a lower complance cartridge would need more mass so a brass carrier would work well. Effective mass is not the same as tracking force so don't confuse the two.

It's a good idea to research and understand how an arm works before you start to build one using another design visually copied as if the measurements / distances / angles etc are not correct FOR THE ARM YOU BUILT, your results will be less than satisfactory and you will be greatly disappointed with the sound and all you efforts, time, money, will have been wasted. You need to understand all these 'terms" and understand how they are applied to the design and construction of the tonearm. They are very easy to understand and it's not rocket science or neuro-surgery.

There's a saying.... measure twice, cut once... in this case. understand what your measuring, understand what the measurements are, do this over and over a few times to really "get it" then build the arm. you'll be much happier with the end result.

JD

Hello Stew,

Excellent work. Thanks a lot. I got a head shell diagram from Jelco (Might be helpful for others too)

Best regards,

Bins.

Last edited:

I agree with Mr Davidson.

Nanook's idea for an cartridge carrier is far better than anything like the Jelco.

In fact I would suggest that you make for yourself a good unipivot arm before seriously tackling the Schroder. That arm is far far more complicated than any other as a first project. A design engineer with top manual skills may well be the type of person you would need to tackle making a Schroder clone as a first project. Also you do need to understand how to properly apply arm geometry whatever arm you build.

Good luck.

Nanook's idea for an cartridge carrier is far better than anything like the Jelco.

In fact I would suggest that you make for yourself a good unipivot arm before seriously tackling the Schroder. That arm is far far more complicated than any other as a first project. A design engineer with top manual skills may well be the type of person you would need to tackle making a Schroder clone as a first project. Also you do need to understand how to properly apply arm geometry whatever arm you build.

Good luck.

Stew,

I was planning to implement the design you gave earlier. While browsing the net, I came across the JELCO head shell and I put that one across, thats all.

What is the arm wand head section width and length appropriate for a Clear Audio/ Schroeder arm ? What should be the thickness ?

Regards,

Bins.

I was planning to implement the design you gave earlier. While browsing the net, I came across the JELCO head shell and I put that one across, thats all.

What is the arm wand head section width and length appropriate for a Clear Audio/ Schroeder arm ? What should be the thickness ?

Regards,

Bins.

arm wand section...

dimensions are dependent on the arm wand you use. I have used 6mm diameter aluminium, and measured the inside of the wand, and adjusted accordingly. For length, perhaps an inch or so would do (or less, just make sure you support the "headshell" within the tube an adequate amount.

dimensions are dependent on the arm wand you use. I have used 6mm diameter aluminium, and measured the inside of the wand, and adjusted accordingly. For length, perhaps an inch or so would do (or less, just make sure you support the "headshell" within the tube an adequate amount.

Hi Nanook,

Just to get the facts straight. The headshell design/critical dimensions found in pivoted arms by Clearaudio( and Musical life too) was copied from my No. 2 arms. After supplying Mr. Suchy with a drawing to get a quote for having this part produced by Clearaudio(in 2001) he just took it over. "You can't patent a headshell, can you?"... where his words. That terminated my relationship with this "innovative" company right then.

As they say, imitation is the sincerest form of flattery, but if I had a buck for each arm Clearaudio(not to mention ML) sold since, my son's college education would be easier to finance.

The first such headshell type was used by Bill Firebaugh in the original Well Tempered arm, albeit with completely different dimensions. My hat off to him!

Cheers,

Frank

Just to get the facts straight. The headshell design/critical dimensions found in pivoted arms by Clearaudio( and Musical life too) was copied from my No. 2 arms. After supplying Mr. Suchy with a drawing to get a quote for having this part produced by Clearaudio(in 2001) he just took it over. "You can't patent a headshell, can you?"... where his words. That terminated my relationship with this "innovative" company right then.

As they say, imitation is the sincerest form of flattery, but if I had a buck for each arm Clearaudio(not to mention ML) sold since, my son's college education would be easier to finance.

The first such headshell type was used by Bill Firebaugh in the original Well Tempered arm, albeit with completely different dimensions. My hat off to him!

Cheers,

Frank

Frank...about straight facts...

I was completely unaware that this was the situation. I only suggested that design as that is where I had recalled seeing it in the past. There is no intention to "throwing salt on an open wound". Please accept my apology.

I was completely unaware that this was the situation. I only suggested that design as that is where I had recalled seeing it in the past. There is no intention to "throwing salt on an open wound". Please accept my apology.

Hi

I've tried my hand at making a headshell a while back. I found it's easier said than done but I suppose with practise things will go a bit quicker. The biggest fiddle was to remove the connector from a donor headshell without damage. The one shown below was milled from red ivory hardwood and is adjustable for azimuth with a 1.6mm capscrew and locknut.

bulgin

I've tried my hand at making a headshell a while back. I found it's easier said than done but I suppose with practise things will go a bit quicker. The biggest fiddle was to remove the connector from a donor headshell without damage. The one shown below was milled from red ivory hardwood and is adjustable for azimuth with a 1.6mm capscrew and locknut.

bulgin

Attachments

Last edited:

Hi

The biggest fiddle was to remove the connector from a donor headshell without damage.

bulgin

H Bulgin,

Thank for your idea and nice construction.

I (tray) to do it with a (reserve) EMT headshell for easy mounting cell and easy adjustable "AZIMUTH" (in Alu)

Allez, salukes.

Karel

Hi Carolus

Yours look better😀 and geometry will be easier to adjust. I've got a few pieces of titanium here which is tempting to use for one of those 'shells with the bars and clamp (can't think of the name right now!). The only problem with titanium is, it kills my milling cutters.

bulgin

Yours look better😀 and geometry will be easier to adjust. I've got a few pieces of titanium here which is tempting to use for one of those 'shells with the bars and clamp (can't think of the name right now!). The only problem with titanium is, it kills my milling cutters.

bulgin

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Build your own tonearm headshell