Hello,

I am looking for some theoretical help on an infra sound subwoofer idea I am thinking about trying out.

I am software engineer and an inveterate stuff builder, but I don't have a ton of knowledge with the finer points of loudspeaker design theory. I was hoping maybe someone would be up for answering some quick questions before I start screwing things together.

So you may have heard of this thing: Eminent Technology TRW-17 Rotary Subwoofer | Home Theater

It is very cool, a functionally infinite excursion woofer. And very expensive. And somewhat difficult to build. Judging by the forums, there have been several attempts by more capable tinkerers than myself. My background in software and hardware control systems has me thinking of taking a different tack to aim for the same result.

I am thinking of taking a higher pressure blower, something like this: Residential Inflatable Blower by Blast Zone - Bounce Houses Now

And running it constantly (outdoors or in the garage or the next room or something) while I am watching movies or whatever. Then valving it with a servo and something like this: D690A1002 - Honeywell D690A1002 - 6" Single Blade Round Damper Maybe a diversion instead of a flat valve could keep the required servo torque down and make it more responsive.

I could easily make a cheap micro controller convert an analog sound signal amplitude to a valve openness percentage, and a cheap stepper motor aught to be able to drive the valve up to maybe 20 or 30 hz.

So far so good.

Here are my concerns, that maybe someone (or a few someones) could take a whack at:

- This would only be a half wave. Unless I used two blowers, one sucking. I wonder if it would matter at all at such low frequencies. If the positive side of the wave were doubled in amplitude compared to the signal, I am not sure there would be any meaningful difference at all.

- I am afraid the wavefront would be too defused to really do anything. A coil can slam a speaker cone out pretty hard and fast with a thousand watts behind it and produce some good compression. I wonder how high the static pressure stopped up behind the valve would have to be to be able to get meaningful sound pressure when the valve was opened. I worry the air would only just be starting to bother to get moving through the newly opened duct when the valve closed again.

- I am worried about fan noise and hissing and such. I thought about putting a batting stuffed folded horn or something like that on the output side of this thing to tame some of that. Which may prove how little I know about this stuff 🙂

It is encouraging to me that the rotary woofer is able to set up enough pressure to be meaningful, since its just a fan.

The other approach I have considered is just skipping to compressed air and something like a tiny ball valve controlled by a servo motor. No question of possible sound pressure there, is there a good way to deal with the hiss caused by high velocities at the nozzle? And what is the difference between a horn and a whistle here? I imagine an infrasonic whistle would have to be very big, and a remarkably bad idea. I would probably filter anything under maybe 10 or 12 hz completely anyway.

The whole point here would be to avoid a 30kw system with a dozen 18" woofers. I dont want huge pressure levels, just enough to feel it in my chest a little. I don't know what kind of pressure level that takes. I cant help wondering if cone speakers just aren't really the tools for the job. At such low frequencies, we are getting well within the range of other more powerful and efficient, if much less delicate, computerized mechanical approaches.

I am looking for some theoretical help on an infra sound subwoofer idea I am thinking about trying out.

I am software engineer and an inveterate stuff builder, but I don't have a ton of knowledge with the finer points of loudspeaker design theory. I was hoping maybe someone would be up for answering some quick questions before I start screwing things together.

So you may have heard of this thing: Eminent Technology TRW-17 Rotary Subwoofer | Home Theater

It is very cool, a functionally infinite excursion woofer. And very expensive. And somewhat difficult to build. Judging by the forums, there have been several attempts by more capable tinkerers than myself. My background in software and hardware control systems has me thinking of taking a different tack to aim for the same result.

I am thinking of taking a higher pressure blower, something like this: Residential Inflatable Blower by Blast Zone - Bounce Houses Now

And running it constantly (outdoors or in the garage or the next room or something) while I am watching movies or whatever. Then valving it with a servo and something like this: D690A1002 - Honeywell D690A1002 - 6" Single Blade Round Damper Maybe a diversion instead of a flat valve could keep the required servo torque down and make it more responsive.

I could easily make a cheap micro controller convert an analog sound signal amplitude to a valve openness percentage, and a cheap stepper motor aught to be able to drive the valve up to maybe 20 or 30 hz.

So far so good.

Here are my concerns, that maybe someone (or a few someones) could take a whack at:

- This would only be a half wave. Unless I used two blowers, one sucking. I wonder if it would matter at all at such low frequencies. If the positive side of the wave were doubled in amplitude compared to the signal, I am not sure there would be any meaningful difference at all.

- I am afraid the wavefront would be too defused to really do anything. A coil can slam a speaker cone out pretty hard and fast with a thousand watts behind it and produce some good compression. I wonder how high the static pressure stopped up behind the valve would have to be to be able to get meaningful sound pressure when the valve was opened. I worry the air would only just be starting to bother to get moving through the newly opened duct when the valve closed again.

- I am worried about fan noise and hissing and such. I thought about putting a batting stuffed folded horn or something like that on the output side of this thing to tame some of that. Which may prove how little I know about this stuff 🙂

It is encouraging to me that the rotary woofer is able to set up enough pressure to be meaningful, since its just a fan.

The other approach I have considered is just skipping to compressed air and something like a tiny ball valve controlled by a servo motor. No question of possible sound pressure there, is there a good way to deal with the hiss caused by high velocities at the nozzle? And what is the difference between a horn and a whistle here? I imagine an infrasonic whistle would have to be very big, and a remarkably bad idea. I would probably filter anything under maybe 10 or 12 hz completely anyway.

The whole point here would be to avoid a 30kw system with a dozen 18" woofers. I dont want huge pressure levels, just enough to feel it in my chest a little. I don't know what kind of pressure level that takes. I cant help wondering if cone speakers just aren't really the tools for the job. At such low frequencies, we are getting well within the range of other more powerful and efficient, if much less delicate, computerized mechanical approaches.

Can you feel the fan blower on your chest?

If you are only modulating that then that will be the best peak SPL the system can generate.

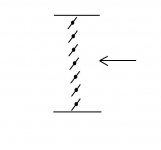

You could try the multi-vane approach (see jpg) but you might be listening to the vane movement and not the air flow modulation.

Have fun.

🙂

If you are only modulating that then that will be the best peak SPL the system can generate.

You could try the multi-vane approach (see jpg) but you might be listening to the vane movement and not the air flow modulation.

Have fun.

🙂

Attachments

- I am worried about fan noise and hissing and such...

... is there a good way to deal with the hiss caused by high velocities at the nozzle?

Velocity is the problem and I haven't thought of a solution yet. (I also haven't put much time into it or researched existing devices yet either though.)

I did try this idea several years ago with a large shopvac and the proof of concept failed miserably. The shopvac can suck and blow simultaneously, so I used a hose on both the suck and blow ends, put the shopvac outside the listening room and cut holes in the wall to insert the hose ends into the listening room. Then I used a valve (actually a small piece of flat sheet wood and my arm) to intermittently cover the holes, giving intmittent positive pressure, then negative pressure, and so on. My arm can't go too fast but I think I was able to achieve somewhere around 3 - 5 hz or so.

I didn't feel anything at all and the only thing I could hear was massive velocity induced turbulence through the hoses. Even with the hoses wide open the velocity is way too fast to be quiet, and then as the holes close the velocity becomes ridiculously high as it nears an almost fully closed state.

The only thing I could think of to stop this was making the hoses exponentially larger to slow the velocity. But at the same time, since I didn't feel anything, I'd need to move a LOT more air. I couldn't think of a reasonable compromise.

Maybe I should look through Danley's patent, although I doubt his invention was aimed at quiet, distortion free home theater operation.

Tom Danley did it with his sonic boom generator.

Patent: 5140641

A quick look at the patent suggests Danley used massive ducts to keep velocity down and used a flow through system so there's never an almost closed position and therefore never a position where velocity gets out of control. He's a smart guy. It would take some serious fabrication skills to make that thing though, it's a bit more complex than my shopvac fail.

BUT... since he has this in his toolbox and still uses conventional cone drivers for his commercial products leads me to believe there's probably a good reason for that.

Last edited:

I think Fiat just announced a concept car that uses compressed air.

Trafficking in air sound like a bad idea when we strive for the best S/N. Likewise, even for woofers, we want tiny distortion figures: do you have a means of controlling air with less than 1% "distortion"?

But... who knows?

Remember, one watt of sound power will destroy your ears (although that means hundreds of watts of amp power into conventional systems). So maybe tiny amounts of air, well-controlled is the route to go

Ben

Trafficking in air sound like a bad idea when we strive for the best S/N. Likewise, even for woofers, we want tiny distortion figures: do you have a means of controlling air with less than 1% "distortion"?

But... who knows?

Remember, one watt of sound power will destroy your ears (although that means hundreds of watts of amp power into conventional systems). So maybe tiny amounts of air, well-controlled is the route to go

Ben

Hey all, thanks for the thoughts.

I actually have one of these blowers, and it is pretty intimidating to stand in front of it. Multi vane would be great for getting the port open quickly, but like with an iris valve, I worry about maintenance, lag, and inertia in linkages and stuff.

For the shop vac approach, were both hoses in the same room at the same time? Seems like you might just get a little air current between them, not a pressurization.

At these frequencies, I would think it makes more sense to think in terms of rapidly pressurizing and depressurizing the room than to think in terms of sound waves, since a 10hz sound wave is probably something like 100 feet long.

I wonder if you feel distortion at 15hz like you can hear it at 30, or if it becomes less important. Either way, I can at least say that I am confident I could control air flow with less than a few percent accuracy. I don't know if that translates to low distortion in the 'sound'.

I actually have one of these blowers, and it is pretty intimidating to stand in front of it. Multi vane would be great for getting the port open quickly, but like with an iris valve, I worry about maintenance, lag, and inertia in linkages and stuff.

For the shop vac approach, were both hoses in the same room at the same time? Seems like you might just get a little air current between them, not a pressurization.

At these frequencies, I would think it makes more sense to think in terms of rapidly pressurizing and depressurizing the room than to think in terms of sound waves, since a 10hz sound wave is probably something like 100 feet long.

I wonder if you feel distortion at 15hz like you can hear it at 30, or if it becomes less important. Either way, I can at least say that I am confident I could control air flow with less than a few percent accuracy. I don't know if that translates to low distortion in the 'sound'.

For the shop vac approach, were both hoses in the same room at the same time? Seems like you might just get a little air current between them, not a pressurization.

Yes, both hose ends in the room. When there's no bass (both ends open) there is neutral (or no) pressure, just constant flow. With the "blow" end closed there's negative pressure and with the "suck" end closed there's positive pressure. Alternate between closing one and then the other and theoretically you get bass.

But without large ducts and an overflow (flow through) duct there's always turbulence noise.

Last edited:

The TRW is pretty bad when it comes to noise. It requires a front lowpass chamber to eliminate fan noise.

Most ventilation systems have mufflers to remove air noise. It works by leaving flow unaltered but absorbing pressure changes. Works great. And at these low frequencies one can use fairly long dampers without it acting as a pipe.

Although a bunch of TH down to 11Hz would probably be both easier to build and louder especially as the size of the fan thinge is going to be huge.

Most ventilation systems have mufflers to remove air noise. It works by leaving flow unaltered but absorbing pressure changes. Works great. And at these low frequencies one can use fairly long dampers without it acting as a pipe.

Although a bunch of TH down to 11Hz would probably be both easier to build and louder especially as the size of the fan thinge is going to be huge.

Yes, both hose ends in the room. When there's no bass (both ends open) there is neutral (or no) pressure, just constant flow. With the "blow" end closed there's negative pressure and with the "suck" end closed there's positive pressure. Alternate between closing one and then the other and theoretically you get bass. ... .

Actually, you didn't get bass. 🙂

For example, when you blocked the "suck" hose, you also blocked airflow from the "blow" hose. What you should have done was have two vacs, one with the "suck" hose in the room, the other with the "blow" hose in the room.

I recall from Tom Danly's patent that the "no signal" condition was a closed recirculating duct - "suck" connected to "blow". The diverter vanes progressively connected either the "suck" or "blow" path to the room, and the other path to "outside the room".

Actually, you didn't get bass. 🙂

That much is true.

For example, when you blocked the "suck" hose, you also blocked airflow from the "blow" hose. What you should have done was have two vacs, one with the "suck" hose in the room, the other with the "blow" hose in the room.

I didn't realize the shopvac was a closed system, I thought it could still suck if you closed the blow hole (through the vents in the top). I guess I should have taken it apart to see how it works before basing an experiment on the device.

I also didn't do the math to find out if there was enough airflow to pressurize the room to any extent (even if it did work as planned).

The whole thing lasted about 1/2 an hour from initial brainstorm to failed proof of concept so I guess I didn't put in the time required to think it through properly. And I haven't spent any time thinking about it since. (IIRC this was back around 2006 or so.)

I recall from Tom Danly's patent that the "no signal" condition was a closed recirculating duct - "suck" connected to "blow". The diverter vanes progressively connected either the "suck" or "blow" path to the room, and the other path to "outside the room".

Clever device. Clearly he put more thought, work and parts into his than I did. There's no suck in this one though, it's blowing through one horn or the other or just recirculating in the no signal condition. I didn't read the patent (just looked at the pics) but if only one of these was used in a room, only one horn would connect to the inside of the room and it would only produce the positive half of the wave.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Most of the "chest feel" is in the 60- 120 Hz range at 100 dB +, and can be easily accomplished with relatively little cost, 30KW for a domestic use system is over the top.I would probably filter anything under maybe 10 or 12 hz completely anyway.

The whole point here would be to avoid a 30kw system with a dozen 18" woofers. I dont want huge pressure levels, just enough to feel it in my chest a little. I don't know what kind of pressure level that takes. I cant help wondering if cone speakers just aren't really the tools for the job.

If you want to go much, much, louder than a little feel in the chest, Josh Ricci’s single 18" Gjallerhorn at 2 meter, ground plane, outdoors measures:

10hz 90.2db

12.5hz 105.2db

16hz 118.3db

20hz 122db

25hz 124.9db

31.5hz 125.8db

40hz 128.4db

50hz 127.2db

63hz 130.2db

80hz 130.9db

100hz 131.1db

125hz 123.6db

Add 6 dB to those figures for a one meter equivalency, and perhaps another 6 to 12 dB for indoor corner loading, and other than in the single digit frequencies you plan to filter out, it has far more output capability, and costs far less than a Thigpen, and even though large, takes up less real estate than a blower system..

Although Tom Danley's sickmaker had enough level to deflect wall panels several inches, it goes far beyond "just enough to feel it in my chest a little", air driven speakers are simply far more complicated and not needed.

Art

There's no suck in this one though, it's blowing through one horn or the other or just recirculating in the no signal condition. I didn't read the patent (just looked at the pics) but if only one of these was used in a room, only one horn would connect to the inside of the room and it would only produce the positive half of the wave.

After a bit more studying I can see that this statement is not true. With one horn mouth inside the room and the other outside it will suck and blow and produce the full positive and negative halves of the wave. I really wish I could just edit instead of adding another post to correct this silly error.

It requires a front lowpass chamber to eliminate fan noise.... a bunch of TH...

Yeah, bingo, a low pass chamber, that's like a big muffler right? what does that look like? A foot square horn 10 feet long stuffed with batting? A folded horn? Sneezing in to a pillow quiets things significantly right? So how do I make that happen selectively for high frequencies? (over 30 or 40 hz or something)

Also, I don't think I know what TH means 😱

Chest feel at 60-100hz: That is very good to know. I have been eying a tapped horn design I like, maybe I'll start there and see if it does what I am looking for before I start chasing magical infrasonic experiences.

30kw: Definitely overkill, I might have been exaggerating 🙂

Blowing and sucking: Yeah, I was thinking the same for the vacuum, its a mostly closed system and probably wouldn't do what we need.

At this frequency and room size, I am pretty sure the effect we are looking for is basically to slightly inflate and deflate the room at 10hz (or whatever). So we either need a VERY powerful woofer (or a set of them) in a sealed box, that can punch out in to the room, fighting against the vacuum they are creating in the sealed box, and then pull back in fighting the pressure they create inside the box. They need to be able to appreciably compress and rarefy the entire air volume of the room very quickly (hence huge woofers with huge throw)... Or we need to pump air in and out of our mostly sealed room from an outside space, and the bigger that outside space is, the less it will fight the woofer or fan. I think they call that an infinite baffle.

At wavelengths this long, I don't think you get to pull stunts like tuned ports or setting up a wave on one side of the cone, sending it around a maze, and reenforcing it with the other pull of the cone before exiting the box. Unless you make the maze 75 feet long and the woofer is huge and/or has an excursion of a foot. And the volume of the maze and displacement of the cone will need to be a significant percentage of the volume of the room to get any real pressure.

I am pretty sure this blower I have will be able to set up the static pressure to inflate the room a bit, since it inflates bouncy houses in its day job. I think the question will be how quickly it can get the pressure in the room up. Which is has to do through a 3 inch port, which brings us back to velocity and noise.

Since our best contributed 'try it and see' so far seems like it might have been missing something important, I think I am just going to set up something quick and dirty and try it 🙂.

Last edited:

Yeah, bingo, a low pass chamber, that's like a big muffler right? what does that look like? A foot square horn 10 feet long stuffed with batting? A folded horn? Sneezing in to a pillow quiets things significantly right? So how do I make that happen selectively for high frequencies? (over 30 or 40 hz or something)

The fan makes a large amount of noise at higher frequencies. Here's a couple of quick video that gives an idea of how much extra high frequency noise the thing makes.

Rotary Subwoofer - Worlds Lowest Freq Subwoofer - YouTube

http://www.youtube.com/watch?v=Q5CRteX5hfQ

So a large amount of absorbtion is required. This usually takes the shape of a very large box between the fan and the listening room, lined with insulation and containing at least one bend to bleed off the higher frequency noise. Here's a couple of pics of front chambers that people have created for these systems. In the first pic, the guys are standing in the back room, not the listening room. (Note the size of the chamber.)

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Also, I don't think I know what TH means 😱

Tapped horn.

At this frequency and room size, I am pretty sure the effect we are looking for is basically to slightly inflate and deflate the room at 10hz (or whatever). So we either need a VERY powerful woofer (or a set of them) in a sealed box, that can punch out in to the room, fighting against the vacuum they are creating in the sealed box, and then pull back in fighting the pressure they create inside the box. They need to be able to appreciably compress and rarefy the entire air volume of the room very quickly (hence huge woofers with huge throw)... Or we need to pump air in and out of our mostly sealed room from an outside space, and the bigger that outside space is, the less it will fight the woofer or fan. I think they call that an infinite baffle.

The goal is your choice, it can be 10 hz or higher or lower. The definition of infinite baffle is a sealed box with a volume of ideally at least 10x the driver(s) Vas.

At wavelengths this long, I don't think you get to pull stunts like tuned ports or setting up a wave on one side of the cone, sending it around a maze, and reenforcing it with the other pull of the cone before exiting the box. Unless you make the maze 75 feet long and the woofer is huge and/or has an excursion of a foot. And the volume of the maze and displacement of the cone will need to be a significant percentage of the volume of the room to get any real pressure.

Ported boxes and even horns can be made to produce 10 hz at adequate spl in a size as small or smaller than the front chamber a rotary woofer requires (see pics above). 75 feet is a bit of an exaggeration but yes, ports and/or horn flares need to be quite long to tune to 10 hz. If you need to get lower than 10 hz, infinite baffle or sealed start to make a lot more sense.

I am pretty sure this blower I have will be able to set up the static pressure to inflate the room a bit, since it inflates bouncy houses in its day job. I think the question will be how quickly it can get the pressure in the room up. Which is has to do through a 3 inch port, which brings us back to velocity and noise.

This is fairly simple math. Just compare the blower's cfm rating to a woofer's volume displacement per time at any given frequency. And don't forget that you need to suck too, you can't just blow.

A 3 inch port isn't going to be adequate. You will need something a lot bigger than that if you expect to get any decent spl without a huge amount of turbulence noise.

Since our best contributed 'try it and see' so far seems like it might have been missing something important, I think I am just going to set up something quick and dirty and try it 🙂.

A "can do" attitude, a bunch of motivation and inspiration can go a long way but a bit of simple math will save you a bunch of time by highlighting things that won't work. Calculating spl and velocity, blower cfm vs woofer displacement are all relatively easy and quick. Trial and error isn't so quick but both methods are valid.

Last edited:

This is fantastic, thanks for distilling all that for me.

That is a big box.

I found a displacement calculator. Looks like an 18" might have something like .3ish cfm of displacement. I assume that means from one extreme to the other? So then at, say 18hz, thats about 5.4cfs. At 10hz, 3cfs.

The blower I have is rated at 700cfm. Probably wide open, so lets say we have 500 to work with behind ducts and valves and baffle and whatnot. WAG. I have NO idea what this thing's static pressure curve looks like. I know it pushes quite a lot harder than a squirrel cage, speaking strictly of flow at higher static pressure. So that's 8.3cfs, regardless of frequency.

So by 20hz, I am not doing anything a single 18 couldn't, and spending a lot of trouble doing it. But down at 10hz, I am in the fight with 3 18s... to make noise I cant hear... great. 🙂

By 5hz, we would need 6 18s to keep up.

Definitely start to see why the woofer loses oomph fast as the frequency drops... And why the rotary woofer can maintain such a pretty flat response curve.

I cant help feeling I am missing too many important variables for this to be very meaningful, but it doesn't seem completely crazy yet. Especially if the goal is a strictly infrasonic emitter.

But velocity. The thing absolutely roars air. It is powerful and intimidating. Big box outside the valve and I need a huge valve... no can flutter at 10hz without huge servos and rapidly wearing parts.... Big box inside the valve and I use up my theater with a hush box that might as well be a speaker box with a couple of 18s and an eq weighted heavily on infrasonics. Probably not a huge cost diff either way really, bit one way ends up with a Frankenstein bunch of ducts and wires and blowers. The other is an off the shelf speaker in a wood box.

That is a big box.

I found a displacement calculator. Looks like an 18" might have something like .3ish cfm of displacement. I assume that means from one extreme to the other? So then at, say 18hz, thats about 5.4cfs. At 10hz, 3cfs.

The blower I have is rated at 700cfm. Probably wide open, so lets say we have 500 to work with behind ducts and valves and baffle and whatnot. WAG. I have NO idea what this thing's static pressure curve looks like. I know it pushes quite a lot harder than a squirrel cage, speaking strictly of flow at higher static pressure. So that's 8.3cfs, regardless of frequency.

So by 20hz, I am not doing anything a single 18 couldn't, and spending a lot of trouble doing it. But down at 10hz, I am in the fight with 3 18s... to make noise I cant hear... great. 🙂

By 5hz, we would need 6 18s to keep up.

Definitely start to see why the woofer loses oomph fast as the frequency drops... And why the rotary woofer can maintain such a pretty flat response curve.

I cant help feeling I am missing too many important variables for this to be very meaningful, but it doesn't seem completely crazy yet. Especially if the goal is a strictly infrasonic emitter.

But velocity. The thing absolutely roars air. It is powerful and intimidating. Big box outside the valve and I need a huge valve... no can flutter at 10hz without huge servos and rapidly wearing parts.... Big box inside the valve and I use up my theater with a hush box that might as well be a speaker box with a couple of 18s and an eq weighted heavily on infrasonics. Probably not a huge cost diff either way really, bit one way ends up with a Frankenstein bunch of ducts and wires and blowers. The other is an off the shelf speaker in a wood box.

If you truly want an infrasonic emitter the Danley device seems like the way to go. I imagine you could build most of the recirculating loop using PVC plumbing parts of suitable size. What is the diameter of the output on your blower? The housing for the flutter valve could be a PVC "+" fitting.

Whilst looking for something else in my comp, i Rediscovered this 😱

Their overall characteristics were quite simple to determine, a math*ematical formula being devised for the purpose. The whistle's resonant pitch was found by dividing its diameter into a numerical constant of 51. Increas*ing the depth of the whistle effectively increased its amplitude. A whistle 1.3 meters in diameter produced an infrasonic pitch of 37 cycles per second. This form violently shook the walls of the entire laboratory complex, though its intensity was less than 2 watts infrasonic power

Deadly Sounds - Dr. Vladimir Gavreau

"Deadly sounds" my yass.Whilst looking for something else in my comp, i Rediscovered this 😱

Their overall characteristics were quite simple to determine, a mathematical formula being devised for the purpose. The whistle's resonant pitch was found by dividing its diameter into a numerical constant of 51. Increasing the depth of the whistle effectively increased its amplitude.

A whistle 1.3 meters in diameter produced an infrasonic pitch of 37 cycles per second. This form violently shook the walls of the entire laboratory complex, though its intensity was less than 2 watts infrasonic power

Deadly Sounds - Dr. Vladimir Gavreau

2 acoustic watts is 123 dB SPL.

37 Hz is not considered "infrasonic" this century.

Josh Ricci's Gjallerhorn can do an order of magnitude louder than that indoors an octave lower.

My Keystone sub, half the size of the Gjallerhorn, can do well over 133 dB (more than an order of magnitude louder than Vlad's "deadly sounds") at 37 Hz in a small room.

We don't need room sized whistles and blowers or 30 KW to produce wall shaking "infrasonic" sound .

Art

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Blower or compressed air powered infra sub?