Do you mean finished speakers, or drivers? I seem to remember distortion graphs for drivers.

I have never seen it measured or published as spec.

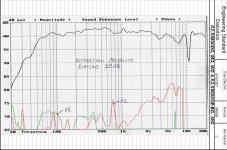

If you are talking drivers some do. Just have to know where to look. For some JBL's you can see them here.

Rob🙂

Transducer Information

Last edited:

I just took a quick look at one compression driver. Tested using a tube? Does this tell you distortion from the motor? How does the tube contribute to the distortion? How does improper loading contribute to distortion?

The proper way is to design a compression driver with a horn and measure it that way.

The proper way is to design a compression driver with a horn and measure it that way.

I just took a quick look at one compression driver. Tested using a tube? Does this tell you distortion from the motor? How does the tube contribute to the distortion? How does improper loading contribute to distortion?

You are testing into a plane wave tube. That's SOP for testing compression drivers. That's the driver distortion no horn. Why are you assuming the tube is an issue it's just a measurement technique that you are not familiar with. That is a completely valid way to test and compare compression drivers. Do a search.

The proper way is to design a compression driver with a horn and measure it that way.

Well no because the horn and system voltage drives can influence the measurement so if you want to see a measurement on a horn look at the complete system plots. An example is the 9800 system plot that gives you the 435Be on the 9800 Bi-radial horn. Crossovers at 800Hz and 10K to the 045Be driver. Or better yet make your own measurements using the horns and drivers you want to use.

The distortion levels are up 20db in the plots.

System Information

Attachments

Last edited:

Do you mean finished speakers, or drivers? I seem to remember distortion graphs for drivers.

Finished speaker. Driver distortion spec is less important as it is predictable and easily audible. Driver distortion should be part of the driver spec for designers to use the driver (to buy or to decide an acceptable Fc).

Tweeter distortion is more important than woofer/midrange distortion, because for woofers, "after-crossover" distortion is the weak point. With tweeters, the distortion remain more or less as is, whatever trick is done in the crossover.

And of course, high frequency distortion is more critical to the ears.

I believe in the future speaker distortion will have a standard to judge how well speakers have been designed. That's the only logical consequence of what I know about speaker quality.

A compression driver plus horn makes up the equivalent of a normal driver.You are testing into a plane wave tube. That's SOP for testing compression drivers. That's the driver distortion no horn. Why are you assuming the tube is an issue it's just a measurement technique that you are not familiar with. That is a completely valid way to test and compare compression drivers. Do a search.

Well no because the horn and system voltage drives can influence the measurement so if you want to see a measurement on a horn look at the complete system plots. An example is the 9800 system plot that gives you the 435Be on the 9800 Bi-radial horn. Crossovers at 800Hz and 10K to the 045Be driver. Or better yet make your own measurements using the horns and drivers you want to use.

The distortion levels are up 20db in the plots.

System Information

You can believe in SOP, but a doctor could legally kill a patient using SOP. When one applies SOP, you really need to know how it benefits the decision making.

As Earl had mentioned, study done showed no correlation with perceived sound quality. One reason could be the distortion level is always above a,threshold such that change in distortion level is not enough to create such correlation, or the test conditions have not use for design application.

A compression driver plus horn makes up the equivalent of a normal driver. You can believe in SOP, but a doctor could legally kill a patient using SOP. When one applies SOP, you really need to know how it benefits the decision making.

Hello soongsc

What does that comment have to do with testing compression drivers?? If you want raw driver distortion plots measured that's how it's done plain and simple. If you want to measure the raw driver frequency response that how it's done. Been measuring compression drivers like this forever. So instead of looking it up you immediately try to find fault with the measurement technique because you are not familiar with it.

The point of measuring this way is to see how the compression drivers looks by itself. Once you add a horn the voltage drives can effect the distortion measurement by driving up the percentages in the higher octaves due to the frequency response tailoring, attenuation curve, in the network. This does not include and distortion contributed by the horn.

How are you going to be able to measure distortion added by the horn if you don't know what the driver numbers are? How are you going to measure driver improvements without a baseline?

Rob🙂

http://www.jblpro.com/BackOffice/ProductAttachments/tn_v1n08.pdf

Last edited:

We have tried that exact method to measure microphones.

That method is fine when you want to find certain design fault in the compression driver, but it in no way provides the necessary information necessary to match a proper horn. Nothing wrong running that test as long as you know the limitations.

That method is fine when you want to find certain design fault in the compression driver, but it in no way provides the necessary information necessary to match a proper horn. Nothing wrong running that test as long as you know the limitations.

Hello soongsc

So what's missing??

What exact measurements are needed to provide that information??

How are they measured without using a plane wave tube??

Why don't you post some you have taken as an example.

Rob🙂

That method is fine when you want to find certain design fault in the compression driver, but it in no way provides the necessary information necessary to match a proper horn.

So what's missing??

What exact measurements are needed to provide that information??

How are they measured without using a plane wave tube??

Why don't you post some you have taken as an example.

Rob🙂

Well, this what happened. Since it is a mystery solved for me. I just share this experience for people to consider if they wish. The choice is yours.

The supper tweeter comes in at some 10KJz, if there were connection problems, it would be too obvious in measurements and listening, not just occurring when you have lots of bass in the music.

If it is length of wire, then it should be easy for you to duplicate.

Soongsc

You need to listen here because you have it wrong. A plane wave tube is the ideal measurement situation. I wish that I had one.

And distortion in an amp is entirely different than it is in a speaker. That is why one can be audible at .01% and the other inaudible at 20%. THD is simply useless at discriminating between the two. All of this is explained in our papers on our website.

You need to listen here because you have it wrong. A plane wave tube is the ideal measurement situation. I wish that I had one.

And distortion in an amp is entirely different than it is in a speaker. That is why one can be audible at .01% and the other inaudible at 20%. THD is simply useless at discriminating between the two. All of this is explained in our papers on our website.

OMG... Audio needs geniuses... Next 10 years, why not?H

And distortion in an amp is entirely different than it is in a speaker. That is why one can be audible at .01% and the other inaudible at 20%. THD is simply useless at discriminating between the two. All of this is explained in our papers on our website.

A plane wave tube is the ideal measurement situation. I wish that I had one.

Hello Earl

I know someone who made one. You might find this thread of interest.

Rob🙂

Plane Wave Tube Construction

There are not hard to make, I know many who have. But they take up an incredible amount of room for something used very seldom.

Too bad a spiral wouldn't work.

Hello Pano

Or

The mouth of the vertical portion of the PWT where the compression driver is bolted on is at about waist height and the PWT curves where is meets the floor and extends out for a few feet where it ends.

That's the description on one at JBL. My friend has one in his shop so no length issues there.

Rob🙂

I was talking about crossover distortion in amps.

It doesn't matter too much below 60 cycles or so with my system/horns but class A up to around 10 watts for 60 up works for me. Anything above 10 watts or so (multiamping) I am so overwhelmed with the music anyhow to care if there is a notch

First of all, what we call a plane wave tube, is it really a plane wave that has been verified by testing? What is the velocity profile at the mouth which really varies with different design configurations? Now, even if the wave has a wave front of a planer wave right at the exit of the compression driver, it is most likely to change when you change the loading conditions, and thus not match the assumptions of horn design. It is more likely that one should design the driver such that it is not a plane wave at the with the tube, but becomes a plane wave when the horn it is designed for is attached.Hello soongsc

So what's missing??

What exact measurements are needed to provide that information??

How are they measured without using a plane wave tube??

Why don't you post some you have taken as an example.

Rob🙂

I am sorry that I just have more questions. This is after I did some analysis and tests posted in other horn and waveguide threads. I think there is no way I currently know of that provides a set of data to show how well a driver will match a horn design. The best way I can think of is to design the driver and horn together. Sure, I hope the people more experienced in this area can do somthing like this in the future. But let us not forget that the compression driver was originally designed for horns more closer to a plane wave tube format so that you can focus the sound energy and deliver it further. As the horn gradually moves to a wider dispersion profile, this changes the loading condition further away from the intent of the standard test method. Maybe someone will publish some studies using different profiles other than the tube but still locate the mic at the throught exit of the driver to see how the measurements will change. Will I ever get into that kind of testing? Not until I am prepared to design a compression driver, which may not happen unless I see potential for wide bandwidth application.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel