This album, Hound Dog Taylor: A Tribute - Various Artists | Songs, Reviews, Credits, Awards | AllMusic, is as good as any for seeing whether a system has "balls". Very well recorded, this has energy to burn - it's 'house-rocking' music - and ideally you should be able to turn it up until you can feel the walls bouncing on their foundations, 😀, and the sound should still remain pristinely clear ...

The good news is that there is also an emergence of simple recording with the excellent (digital) results which even comes over on high quality radio FM or Web.

True! Do you have any examples you can point to that I can download?

True! Do you have any examples you can point to that I can download?

You may be able to download:

For FM radio try BBC Radio 3 from their website or ? satellite if you can receive that. Uncompressed AAC +. They do live concerts at various venues. The country venues ones are often the best due to simple mic layouts etc. Often lunchtime broadcasts of chamber music from Wigmore Hall live FM wow. Good system 'you are there' sound. Plenty of other stuff.

Try Linn Audio, who are based in Scotland who allow snippets of various genre with excellent quality in FLAC studio quality downloads grading down to CD 16/44.1 to MP3.

Thanks, those are good links. I listen a lot to online radio through Audiles or Songbird. I can get like 60 thousand channels now - been introduced to all kinds of stuff - try the flac downlod here for something different and great sound 😎

https://archive.org/details/Complex_Silence_40

https://archive.org/details/Complex_Silence_40

Its great that you can use it all over there. MindblowingThanks, those are good links. I listen a lot to online radio through Audiles or Songbird. I can get like 60 thousand channels now - been introduced to all kinds of stuff - try the flac downlod here for something different and great sound 😎

https://archive.org/details/Complex_Silence_40

Lynn,

I like to ask why you chose to make a custom LeCleac'h horn instead of, say, a 340Hz "off-the-shelf" horn. I surmise that you wanted to get the acoustic centers of the drivers closer together, but would like to hear your rationale.

I like to ask why you chose to make a custom LeCleac'h horn instead of, say, a 340Hz "off-the-shelf" horn. I surmise that you wanted to get the acoustic centers of the drivers closer together, but would like to hear your rationale.

The AH425 had to: use a T ratio optimized for the most uniform diaphragm loading (based on sims, this turned out to be 0.707 or thereabouts), an entrance angle matched to the Altec 288 (or Radian 745), and fit in an Australian post box for shipping to the USA. FedEx or DHL from Oz to Denver is around $500 to $700, way too much for shipping.

The costs of wood horns made in the USA was astronomical, several times what Martin was quoting. Most of the US builders only wanted to build conicals or Tractrix; neither profile interests me. Since nobody in the USA would build what I wanted, at a price I would pay, I commissioned Martin to build the first pair of AH425's for me.

A 340 Hz off-the-shelf LeCleac'h would be an excellent choice provided it had a T=0.707 (T=0.8 would be fine) and an entrance angle that matched the Altec 288 or Radian 745. Again, no interest in a conical or Tractrix, no matter whether the horn is made of wood, fiberglass, or carbon-fiber. The selection of horn profile, combined with accuracy in matching the exit of the compression driver, is more important than the construction material.

My attitude towards spending moola on hifi might puzzle some: I splash around $3000 to $5000 for the parts for the Karna, an equal amount for the drivers for the new speaker, yet balk at $500 for shipping from Australia.

I see the shipping money as wasted. I feel the same way about a DAC or linestage that's all solid-state and costs $9000 or more. I know what solid-state parts cost: not much, from a few cents to a few dollars. Even something as complex as an iPhone only costs Apple about $190 in parts cost ... audiophile solid-state manufacturing costs are less than an iPhone, and the cost-to-sales-price ratio is far higher than Apple's 1:3.5 ratio. I'll pay Apple's prices because I like their software; how much software is in a DAC, linestage, or power amplifier?

Vacuum tubes, transformers, and Alnico-magnet drivers cost a lot because they are small production runs and are labor-intensive. When Bud Purvine of O-Netics charges $600 for an output transformer, it takes him about 4 to 6 hours to build it. That's an entirely fair price for his time and experience, and Bud's a professional in the industry that I want to support.

I am less sympathetic to products made on production lines with inexpensive parts that also have 4-color ads in magazines. I'm paying for that ad, and possibly bribing a corrupt reviewer (it happens, you know). No thanks, that's a part of the industry I do not want to support.

The costs of wood horns made in the USA was astronomical, several times what Martin was quoting. Most of the US builders only wanted to build conicals or Tractrix; neither profile interests me. Since nobody in the USA would build what I wanted, at a price I would pay, I commissioned Martin to build the first pair of AH425's for me.

A 340 Hz off-the-shelf LeCleac'h would be an excellent choice provided it had a T=0.707 (T=0.8 would be fine) and an entrance angle that matched the Altec 288 or Radian 745. Again, no interest in a conical or Tractrix, no matter whether the horn is made of wood, fiberglass, or carbon-fiber. The selection of horn profile, combined with accuracy in matching the exit of the compression driver, is more important than the construction material.

My attitude towards spending moola on hifi might puzzle some: I splash around $3000 to $5000 for the parts for the Karna, an equal amount for the drivers for the new speaker, yet balk at $500 for shipping from Australia.

I see the shipping money as wasted. I feel the same way about a DAC or linestage that's all solid-state and costs $9000 or more. I know what solid-state parts cost: not much, from a few cents to a few dollars. Even something as complex as an iPhone only costs Apple about $190 in parts cost ... audiophile solid-state manufacturing costs are less than an iPhone, and the cost-to-sales-price ratio is far higher than Apple's 1:3.5 ratio. I'll pay Apple's prices because I like their software; how much software is in a DAC, linestage, or power amplifier?

Vacuum tubes, transformers, and Alnico-magnet drivers cost a lot because they are small production runs and are labor-intensive. When Bud Purvine of O-Netics charges $600 for an output transformer, it takes him about 4 to 6 hours to build it. That's an entirely fair price for his time and experience, and Bud's a professional in the industry that I want to support.

I am less sympathetic to products made on production lines with inexpensive parts that also have 4-color ads in magazines. I'm paying for that ad, and possibly bribing a corrupt reviewer (it happens, you know). No thanks, that's a part of the industry I do not want to support.

Last edited:

Its great that you can use it all over there. Mindblowing

I know, I've been streaming for a couple of years now either through my horns or through my STAX headphones.

Here's one that has excellent bass detail at 320 KBS - WARNING don't try this on your direct radiator boxes you'll miss half the music! 😱

https://archive.org/details/ClaudioNunez_NadaEsParaTodos

Nice collection http://www.acustronica.com/artists.html

Last edited:

The AH425 had to: use a T ratio optimized for the most uniform diaphragm loading (based on sims, this turned out to be 0.707 or thereabouts), an entrance angle matched to the Altec 288 (or Radian 745), and fit in an Australian post box for shipping to the USA. FedEx or DHL from Oz to Denver is around $500 to $700, way too much for shipping.

The costs of wood horns made in the USA was astronomical, several times what Martin was quoting. Most of the US builders only wanted to build conicals or Tractrix; neither profile interests me. Since nobody in the USA would build what I wanted, at a price I would pay, I commissioned Martin to build the first pair of AH425's for me.

A 340 Hz off-the-shelf LeCleac'h would be an excellent choice provided it had a T=0.707 (T=0.8 would be fine) and an entrance angle that matched the Altec 288 or Radian 745. Again, no interest in a conical or Tractrix, no matter whether the horn is made of wood, fiberglass, or carbon-fiber. The selection of horn profile, combined with accuracy in matching the exit of the compression driver, is more important than the construction material.

My attitude towards spending moola on hifi might puzzle some: I splash around $3000 to $5000 for the parts for the Karna, an equal amount for the drivers for the new speaker, yet balk at $500 for shipping from Australia.

I see the shipping money as wasted. I feel the same way about a DAC or linestage that's all solid-state and costs $9000 or more. I know what solid-state parts cost: not much, from a few cents to a few dollars. Even something as complex as an iPhone only costs Apple about $190 in parts cost ... audiophile solid-state manufacturing costs are less than an iPhone, and the cost-to-sales-price ratio is far higher than Apple's 1:3.5 ratio. I'll pay Apple's prices because I like their software; how much software is in a DAC, linestage, or power amplifier?

Vacuum tubes, transformers, and Alnico-magnet drivers cost a lot because they are small production runs and are labor-intensive. When Bud Purvine of O-Netics charges $600 for an output transformer, it takes him about 4 to 6 hours to build it. That's an entirely fair price for his time and experience, and Bud's a professional in the industry that I want to support.

I am less sympathetic to products made on production lines with inexpensive parts that also have 4-color ads in magazines. I'm paying for that ad, and possibly bribing a corrupt reviewer (it happens, you know). No thanks, that's a part of the industry I do not want to support.

I see. It was about practical availabilty.

I understand the desired T=.7 spec. And I understand the need to match the exit angle of a desired driver. However, if a pancake driver like the jbl2451 was used, it has no throat having an exit angle to match.

That being said, while a T=.7 is desirable for the low end near Fc, the nature of that parameter pinches the throat and, I believe, narrows the high frequency spread. There must be an entrance angle as a desired parameter that benefits high frequency dispersion that provides good imaging in a desirably wide sweet spot. I guess if the multiple parameters of Fc, T, and throat radius don't jive for good entrance angle that provides for good dispersion at high frequencies, you just have to xover to a tweeter at the necessary frequency to match the polar of the mid horn.

Last edited:

A 340 Hz off-the-shelf LeCleac'h would be an excellent choice provided it had a T=0.707 (T=0.8 would be fine) and an entrance angle that matched the Altec 288 or Radian 745.

The 340Hz Le Cleac'h horn that I make (and I chose 340 as a good number based on a 600mm mouth with full roll back - the commission was for a Vitavox S2 driver) has a wall angle (one side to axis) of 6 degrees with 1.4" throat. T=0.8. Unfortunately it can't be posted by Auspost either with the full roll back or 510mm mouth diameter. However well worth checking out online courier services - something that has come on a lot.

I pay half to the fibreglass shop to do the layup, and take half for myself, to do throats, flanges and finishing. Not sure how many hours I put into it, best not to think, but I still enjoy it - satisfying to make a product from raw materials in this day and age, and happy if I have done something to help bring Jean-Michel's expansion into the mainstream. Not to mention a self funding hobby 🙂.

Probably this looks like self promotion, but I never set out to make horns (except a pair for myself) - it was from the beginning always the result of commissions. I think now that there is a good Polish manufacturing facilty - autotech - an 'off the shelf' horn' is a real choice. I always expected a Chinese JMLC horn to appear but the market must be too small. I guess there will not be a JMLC pro horn because pro-sound wants constant directionality - though I think this is a mistake as a small venue might greatly benefit in the same way as a listening room. The horrible sound of the ubiquitous box on a pole could be so easily improved.

martin

Hello Lynn, and others, I'm interested in building a horn for frequencies 1500 hz upward out of marble.

Can you point me in a direction where I can have someone draw me up some plans. I think around 12 inches or so but not sure. I don't mind paying for the service.

Can you point me in a direction where I can have someone draw me up some plans. I think around 12 inches or so but not sure. I don't mind paying for the service.

Hello Lynn, and others, I'm interested in building a horn for frequencies 1500 hz upward out of marble.

Can you point me in a direction where I can have someone draw me up some plans. I think around 12 inches or so but not sure. I don't mind paying for the service.

Hornresp is all you need

The AH425 had to: use a T ratio optimized for the most uniform diaphragm loading (based on sims, this turned out to be 0.707 or thereabouts), an entrance angle matched to the Altec 288 (or Radian 745)

What is the flare of the internal throat of these drivers?

Exit angle is only a derivate of this, and it could be argued that the best possible horn for a given driver is the one that matches its integrated flare (which of course also implies a matched exit/entrance angle).

I don't know how important this is (full flare/loading continuity vs profile/angle only continuity), but this is for example the case for the TD4003/TH4003 couple: hypex T=0.6 F=350Hz right from the phasing plug exit to the mouth of the horn.

Of course all this can be ignored with throatless drivers...

Thanks for that. The bass rhythm was deft and deep. Great, and it lead me of course on to other genre. Excellent new addition for me.I know, I've been streaming for a couple of years now either through my horns or through my STAX headphones.

Here's one that has excellent bass detail at 320 KBS - WARNING don't try this on your direct radiator boxes you'll miss half the music! 😱

https://archive.org/details/ClaudioNunez_NadaEsParaTodos

Nice collection Artists

Not on horns for me, yet but still very close performances - who needs to buy recordings - well some maybe.

What is the flare of the internal throat of these drivers?

Exit angle is only a derivate of this, and it could be argued that the best possible horn for a given driver is the one that matches its integrated flare (which of course also implies a matched exit/entrance angle).

I would think so, too.

I don't know how important this is (full flare/loading continuity vs profile/angle only continuity), but this is for example the case for the TD4003/TH4003 couple: hypex T=0.6 F=350Hz right from the phasing plug exit to the mouth of the horn.

Well, I would tend to think that it should be pretty important to avoid any major flare/loading discontinuity in the first section of the horn at least, where pressure is higher. As sound moves further towards the horn mouth, it will probably be less critical.

Interesting about the TD4003/TH4003 couple, by the way. Where did you get that information from?

From what I know, 'traditional' 2" throat drivers such as the JBL 375/2440 have an internal flare rate corresponding to a cut-off frequency Fc = 160 Hz (this was inherited from the old WE drivers that had originally been designed to drive very large 'full range' theatre horns).

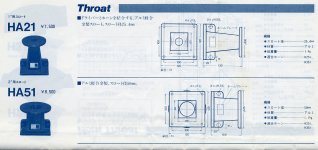

Incidentally, back-calculating the flare rate of the old Fostex HA51 throat adapter for 2" drivers, and assuming an exponential expansion law, it too comes out as being exactly 160Hz (probably designed so as not to create a discontinuity with the internal flare of the drivers it was designed to be used with).

Given that the TAD TD4001 was developed starting from the JBL 375, I would assume that it would share the same internal geometry too.

The TD4003 being a much newer driver re-designed from scratch, it comes as no surprise that the geometry of the internal throat was redesigned too.

I wouldn't be so sure there. The phase plug design itself sets the first flare rate. The recent JBL drivers are named 'rapid flare' for that reason, and according to JBL's own technical literature they were designed so as to have an internal flare rate "double or quadruple" the 'classical' 160Hz. This design choice was reportedly made to reduce high frequency 'beaming' in the top octave:Of course all this can be ignored with throatless drivers...

http://www.jblpro.com/pub/technote/tn_v1n21.pdf

These 'new' drivers are primarily meant to be used with equally rapid flare (i.e. highish Fc) horns in two-way sound reinforcement applications, crossed over with a steep electrical high-pass to a direct radiator woofer at Fx > 800Hz. BUT, there's no such thing as a free lunch, and there is reason for legitimate doubt about their suitability to be used with lower-Fc horns.

In my personal opinion, a more 'traditional' (i.e. lower internal Fc) driver used in a horn with matching initial flare rate and, if needed or desired, crossed over to a real (compression or ring radiator) Tweeter to form a proper 3-way system, is still the preferable way to go for home hi-fi applications.

Marco

Attachments

Last edited:

Marco,

My understanding fully lines up with your analysis.

That being said, does anyone know the flare rate of the Coherent Phasing Plug of the modern JBL drivers?

My understanding fully lines up with your analysis.

That being said, does anyone know the flare rate of the Coherent Phasing Plug of the modern JBL drivers?

Marco,

My understanding fully lines up with your analysis.

That being said, does anyone know the flare rate of the Coherent Phasing Plug of the modern JBL drivers?

According to this document: Jim Lansing

The "Coherent Wave" phaseplug of JBL's 435Be driver (which was used in the then-flagship K2 S9800 loudspeaker system) has an expansion rate corresponding to an interal Fc = 550Hz (which BTW is too high for my personal liking...)

I do not know if all modern "Coherent Wave" drivers share the exact same Fc, though. In fact, they probably do not. The "Coherent Wave" phrase was introduced with the 2450H/J compression driver, which does have an internal throat similar to the 'old school' drivers a-la 375/2440 (and therefore probably also has a conventionally low internal Fc).

So I think the crucial difference in so far as internal flare rate is concerned is between 'conventional' drivers with a deep throat and "rapid flare" drivers that are virtually 'throatless', not between "coherent" or "non coherent" phase plugs.

Marco

Last edited:

The 435 has a 3" diaphragm, while the 2451 has a 4", so perhaps the 2451 does have a lower Fc.

If the expansion is exponential, then I would presume it would be best to use T=1 for the LeCleac'h horn, too. (Also, according to the document you linked, the driver's power response is such that an on-axis FR response is maintained at high frequencies when loaded by an exponential horn.)

If the expansion is exponential, then I would presume it would be best to use T=1 for the LeCleac'h horn, too. (Also, according to the document you linked, the driver's power response is such that an on-axis FR response is maintained at high frequencies when loaded by an exponential horn.)

Last edited:

There is nothing wrong with tractrix profiles. I have not heard a JMLC but they seem very similar to a tractrix.

There is nothing wrong with tractrix profiles. I have not heard a JMLC but they seem very similar to a tractrix.

Sorry, but in fact the two are rather different.

While there is certainly nothing "wrong" with either in principle, they are derived under different sets of assumptions, and they are targeted at optimizing different parameters.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel