Panel resonances not only vary with panel thickness but also with panel size and more specifically with the ratio of panel dimensions. So very generally, smaller panels have higher resonance frequencies than bigger ones and more specifically, longer, narrow rectangular panels also have higher resonances than square panels (depending on actual dimensions of course). Also, adding mass without adding stiffness (ie. damping) not only reduces the amplitude of the resonances but lowers the resonance frequency as well.

So you should take note of the size of your panels vs the size of BBC's because I suspect that the BBC was using larger side panels than 33cm x 13cm. I'm not that versed in the BBC's methodology but it might be good to know what their target panel resonance frequency was. Was it 300Hz? 400Hz? The attached chart suggests that the resonance needs to be down 30dB for frequencies that are above about 400Hz to be inaudible and that it can be progressively louder than that as you go lower in frequency and still be ok as well.

Using Steinberg's formula for panel resonances that diyAudio lists here, I calculate that your 7mm x 13cm x 33cm side panels if made with Baltic Birch plywood will have a resonance frequency of about 750Hz. (Would a poorer quality plywood have a higher resonance frequency?) That frequency will be lowered with 8mm of damping but it still doesn't look that good to me. It still looks like you'll end up with audible resonances somewhere in the 400Hz to 600Hz range.

Now if you just changed your cabinet depth from 13cm to about 20cm, you'll be starting with a panel resonance with BB closer to about 350Hz and now that would be looking a lot better. Theoretically anyways.

So you should take note of the size of your panels vs the size of BBC's because I suspect that the BBC was using larger side panels than 33cm x 13cm. I'm not that versed in the BBC's methodology but it might be good to know what their target panel resonance frequency was. Was it 300Hz? 400Hz? The attached chart suggests that the resonance needs to be down 30dB for frequencies that are above about 400Hz to be inaudible and that it can be progressively louder than that as you go lower in frequency and still be ok as well.

Using Steinberg's formula for panel resonances that diyAudio lists here, I calculate that your 7mm x 13cm x 33cm side panels if made with Baltic Birch plywood will have a resonance frequency of about 750Hz. (Would a poorer quality plywood have a higher resonance frequency?) That frequency will be lowered with 8mm of damping but it still doesn't look that good to me. It still looks like you'll end up with audible resonances somewhere in the 400Hz to 600Hz range.

Now if you just changed your cabinet depth from 13cm to about 20cm, you'll be starting with a panel resonance with BB closer to about 350Hz and now that would be looking a lot better. Theoretically anyways.

Attachments

Stiff heavy things ( like church bells ) ring.

And church bells are made of what?

jeff

If extra bracing and damping doesn't come cheaper than thicker walls we are left with weight savings for mobile applications.

Braced boxes with thinner walls work better than just using thicker panels. Finesse vrs brute-force.

dave

How would be build a 2 way speaker to cover the range above 100hz?

Other than that i would build a 1-way speaker and lose the XO, but i have designed many, and we have built many. I use the same thinnish wall, well braced, very stiff enclosures and they work very well.

I have listened to a large number of BBC designs (and descendeants) and they all have a warmish, inviting colouration i associate with the box construction.

dave

Harpeth, Spendor and Stirling. And people are still copying the BBC Ls35a. How thick can you get mass loaded vinyl? 1/2" and you wouldn't need a frame ( possibly ).

A bit of rare data NoiseBlok, Mass Loaded Vinyl (MLV), Noise Barrier Roll Toronto Canada

...I can only presume heaver...

While it does play a role in keeping the box from “rocking” an increasing amount of mass, as Allen alludes, quickly gets to the point where it takes much more to make a difference.

Mass (or density) by itself is not an asset unless it is a side effect of a much stiffer material (ie stranded/fossilized bamboo plywood). Light & stiff will push resonances higher than heavy & stiff.

dave

Panel resonances not only vary with panel thickness but also with panel size and more specifically with the ratio of panel dimensions. So very generally, smaller panels have higher resonance frequencies than bigger ones and more specifically, longer, narrow rectangular panels also have higher resonances than square panels (depending on actual dimensions of course). Also, adding mass without adding stiffness (ie. damping) not only reduces the amplitude of the resonances but lowers the resonance frequency as well.

The general guidline i use is that the aspect ratio of the subpanel created by a brace should be higher than that of the panel being braced (and different than the other panel created by the brace).

but it might be good to know what their target panel resonance frequency was. Was it 300Hz? 400Hz?

Lower. Less than 100 Hz was the target.

My approach is opposite. I try to push the (potential) panel resonances up above about 500 Hz where they are much less likely to be excited.

dave

Life is way too short to re-assemble ill fated speaker designs, that nobody seem glorious, expect five companies.

Thus far, you have actually received eight examples (which were meant as such, not to be a comprehensive list) of companies which either produce, or have produced, loudspeakers of this type since the 1970s. Many of these have been highly successful and are very highly regarded, with excellent technical performance to their design remits. All of which is simply a matter of fact.

I'm not wasting time on those, just doing the best whats possible.

And on those famous designs, nobody did it that way.

These 'famous designs' being, and 'best' in specifically what ways? Since as we all know, there is no such thing as 'best', just a collection of compromises from which you select according to your objectives.

Thats enough of an argument that the whole thing is a bad idea.

What argument?

Even when it was developed by BBC. But who are they in the world of speaker designs? Problem is, most people have no clue what was developed in audio history and what makes a good design count.

Including yourself it would appear. I respectfully suggest you read the technical papers produced by the BBC R&D engineering department from the 1950s onwards (such as the one I provided you a link to) before announcing that they didn't know what they were doing. Because that is also completely untrue, and in direct contradiction to historical fact. You may not like the approach they took, which is fine. It isn't, as noted, the way I do things either. But it was, and remains, a perfectly valid engineering approach which had extensive research and development behind it. That is fact. Not opinion: fact.

Last edited:

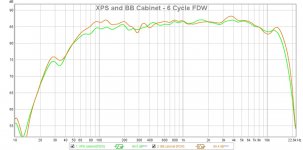

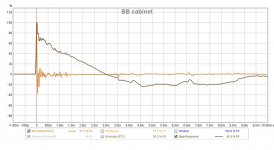

Heavy “dead” panels are not necessary for a good sounding speaker. You can have a box that is about as light as air using XPS foam, and if well-braced and has a thin wood veneer to allow drivers to be mounted via screws, the measured frequency response and harmonic distortion are very similar to a good Baltic birch plywood box.

10F/8424 & RS225-8 FAST / WAW Ref Monitor

Here is the internal construction of the XPS box (no butyl mass loaded sheets, no eggcrate foam, just polyfill or fiberglass stuffing):

XPS: Distortion and frequency response measurements...

18mm BB plywood (with mass loaded butyl sheets on the inside and full eggcrate foam on inside with polyfill stuffing):

I always prototype in foamcore or XPS and build in wood later. However, the foam speakers often end up sounding just as good after I make the wooden ones. The wood looks better and is more durable. But I have seen that light foam panels that are braced can make excellent speakers. Even larger synergy or tractrix horn type speakers or large TLs. If you are interested, here are dozens and dozens of speakers made of foamcore or XPS:

Foam Core Board Speaker Enclosures?

10F/8424 & RS225-8 FAST / WAW Ref Monitor

Here is the internal construction of the XPS box (no butyl mass loaded sheets, no eggcrate foam, just polyfill or fiberglass stuffing):

XPS: Distortion and frequency response measurements...

18mm BB plywood (with mass loaded butyl sheets on the inside and full eggcrate foam on inside with polyfill stuffing):

I always prototype in foamcore or XPS and build in wood later. However, the foam speakers often end up sounding just as good after I make the wooden ones. The wood looks better and is more durable. But I have seen that light foam panels that are braced can make excellent speakers. Even larger synergy or tractrix horn type speakers or large TLs. If you are interested, here are dozens and dozens of speakers made of foamcore or XPS:

Foam Core Board Speaker Enclosures?

Last edited:

Transmission loss spec of what and how do you measure that? You mean relative efficiency between foam and wood?

About 1.5dB to 2dB loss in SPL sensitivity at 100Hz between the foam and BB ply box.

About 1.5dB to 2dB loss in SPL sensitivity at 100Hz between the foam and BB ply box.

Attachments

Last edited:

This is not a fair comparison, given that the enclosure will have timing and directionality aspects that a response plot can neatly sweep under the rug.using XPS foam, and if well-braced and has a thin wood veneer to allow drivers to be mounted via screws, the measured frequency response and harmonic distortion are very similar to a good Baltic birch plywood box.

Thanks for posting this! I checked the LS3/5A dimensions and its 11.9" (30,4 cm) high by 7,4" (19 cm) wide by 6,4" (16,5 cm) deep. So even though side panels are somewhat deeper, its not a night and day difference, its somewhere between my 750 Hz and 350hz of a 20 cm deep panel.

I checked the 1977 BBC paper and it looks like LS3/5a panels didnt have much resonance between 100 and 200 hz. Resonance bahaviour of side panels was pretty smooth without distinct peaks and dips (thanks to damping) but it was elevated between some 450 Hz and 1500 Hz.

So I should either brace for the hope of pushing the resonance closer to 2kHz territory where tweeter takes over or use a different or thinner material.

BBC approach doesn't seem valid for such small boxes, though panel damping is always a good thing (unless its a sub). Thats a huge surprise.

I checked the 1977 BBC paper and it looks like LS3/5a panels didnt have much resonance between 100 and 200 hz. Resonance bahaviour of side panels was pretty smooth without distinct peaks and dips (thanks to damping) but it was elevated between some 450 Hz and 1500 Hz.

So I should either brace for the hope of pushing the resonance closer to 2kHz territory where tweeter takes over or use a different or thinner material.

BBC approach doesn't seem valid for such small boxes, though panel damping is always a good thing (unless its a sub). Thats a huge surprise.

Panel resonances not only vary with panel thickness but also with panel size and more specifically with the ratio of panel dimensions. So very generally, smaller panels have higher resonance frequencies than bigger ones and more specifically, longer, narrow rectangular panels also have higher resonances than square panels (depending on actual dimensions of course). Also, adding mass without adding stiffness (ie. damping) not only reduces the amplitude of the resonances but lowers the resonance frequency as well.

So you should take note of the size of your panels vs the size of BBC's because I suspect that the BBC was using larger side panels than 33cm x 13cm. I'm not that versed in the BBC's methodology but it might be good to know what their target panel resonance frequency was. Was it 300Hz? 400Hz? The attached chart suggests that the resonance needs to be down 30dB for frequencies that are above about 400Hz to be inaudible and that it can be progressively louder than that as you go lower in frequency and still be ok as well.

Using Steinberg's formula for panel resonances that diyAudio lists here, I calculate that your 7mm x 13cm x 33cm side panels if made with Baltic Birch plywood will have a resonance frequency of about 750Hz. (Would a poorer quality plywood have a higher resonance frequency?) That frequency will be lowered with 8mm of damping but it still doesn't look that good to me. It still looks like you'll end up with audible resonances somewhere in the 400Hz to 600Hz range.

Now if you just changed your cabinet depth from 13cm to about 20cm, you'll be starting with a panel resonance with BB closer to about 350Hz and now that would be looking a lot better. Theoretically anyways.

This is not a fair comparison, given that the enclosure will have timing and directionality aspects that a response plot can neatly sweep under the rug.

Timing wise, the step responses are nearly identical. Polar plots also don’t have much of a difference. I lost that data in a hard disk crash but remember it was not notable. About the same. So not sure what else is “swept under the rug”. I’m not hiding anything - if there is data you want to see please ask for it.

When removing my inline figures in a previous post where comparison data was shown makes it hard for people to appreciate the data without actually reading the other thread.

Here is step response in XPS:

And here is step response in BB plywood:

Attachments

Last edited:

You're being clever with your words.

Showing step response timing is as misleading as the frequency response plot, and adds nothing technical but pretty pictures.

Showing step response timing is as misleading as the frequency response plot, and adds nothing technical but pretty pictures.

If step response isn’t about timing, please tell us what you would like to see - if it is measurable? I have a mic, REW software, sound interface, amps, oscilloscope, Fluke DMM’s, and a DATS.

Perhaps waterfall? CSD?

Btw, other members are also starting to use XPS to build speakers. Here is a nice one by hifijim:

Image borrowed from this thread:

Unexplained low frequency measurement mystery

Perhaps waterfall? CSD?

Btw, other members are also starting to use XPS to build speakers. Here is a nice one by hifijim:

Image borrowed from this thread:

Unexplained low frequency measurement mystery

Attachments

Last edited:

I am about to order plywood for my speaker project, a subwoofer assisted two way speaker, with BBC-style thin wall enclosure. When researching the subject I found that as far as panel thickness goes Harbeth/Spendor/Rogers (so BBC contractors) used from 8mm in two way monitors to 12 mm plywood for larger boxes.

Now, from my local supply I can order only 7 mm plywood, even though its just 1 mm thinner than BBC spec, its as much as 12,5% difference from 8 mm panels used in commercial designs.

Overall, I think your ideas are pretty good, but it is easy to get frozen with too many choices 🙂

Just build it.

IMO the easiest "fix" to get into the 8-12mm range would be to simply go with 7mm ply, and then glue the offcuts to the inside of the box, so that parts of it end up as 14mm.

Or use a single layer + a veneer. Something like this would take your wall thickness to 7.6mm:

Wide Leaf Veneer | Plyco

Or do both of the above.

Please let me remind you all, that thin wall construction was chosen simply to minimize weight of these small monitors for speech. Nothing to do with hifi.

LS3/5A - Wikipedia

LS3/5A - Wikipedia

Please let me remind you all, that thin wall construction was chosen simply to minimize weight of these small monitors for speech. Nothing to do with hifi.

LS3/5A - Wikipedia

Wrong: as it's stated in that link you post:

The LS3/5A is a commercially produced loudspeaker driven by the need of the BBC to monitor and assess broadcast programme quality. It was derived from the LS3/5, which was conceived and developed by the BBC Engineering Department in the early 1970s, when it was under the stewardship of Dudley Harwood.[2] Having found no commercially produced small loudspeaker that met the requirement for naturalness and sonic neutrality,[2][3] the BBC specifically set out to design a speaker to achieve natural overall sound quality and good dynamic range for monitoring broadcasts in tightly confined spaces.[2][4]

So they did develop this, because the speakers available were not good on sound quality enough to meet their high standards on sound neutrality and dynamics. And in the BBC studies mentioned and linked earlier you also see they were searching to reduce cabinet resonance, and came to this mass damped lossy thin wall cabinet as engineered solution. You may not like it, and it's certainly not the only way to go, but it's a working principle that is based on scientific research, not just a gig or a way to save money or space.

- Home

- Loudspeakers

- Multi-Way

- BBC style thin wall enclosure - how thin can one go?