I haven't found anything specifically addressing this on here, so apologies if I've missed something.

I'm intrigued by the BBC technique of mounting their bass-mid drive units on the back of the baffle, rather than on the front as is more usual. It may be a hangover from the 1960s when most speakers had removable baffles and a seal on the front of the drive unit. However even more recent iterations - such as Harbeth and Stirling Broadcast - continue the tradition.

Can anyone point to an advantage in doing it this way? Smoother transition between drive unit and baffle?

I'm intrigued by the BBC technique of mounting their bass-mid drive units on the back of the baffle, rather than on the front as is more usual. It may be a hangover from the 1960s when most speakers had removable baffles and a seal on the front of the drive unit. However even more recent iterations - such as Harbeth and Stirling Broadcast - continue the tradition.

Can anyone point to an advantage in doing it this way? Smoother transition between drive unit and baffle?

Usually (as I recall) to help time-alignment with the acoustic crossover slopes employed. I speak under correction though.

I refer you to my previous answer:

Neat, eh? 🙂

You will find this interesting I think, DrBoar. 🙂

It was always the BBC tradition to NOT time align drivers, but do flat baffle.

In fact the woofer was often recessed, as in this Harbeth model:

An externally hosted image should be here but it was not working when we last tested it.

If you know your filters, you will know that 4th order acoustic Linkwitz-Riley should be time-aligned on the drivers' acoustic centres and WIRED IN PHASE for good lobing and phase alignment. So this arrangement really looks hopeless. But it isn't.

Interestingly, with real world filters (like second order electrical bass and third order electrical tweeter), if you move the tweeter half a wavelength forward, which is about 5cms at 3kHz, and WIRE OUT OF PHASE, you can get some very good phase alignment too. My PREDICTION would therefore be that your own splendid Dorspen speaker is wired out of phase. Along with the BBC LS3/5A and the Rogers LS5/9. And they ARE! 😎

Neat, eh? 🙂

If your Swedish is less than perfect, pretty much the same thing is in English at

http://www.diyaudio.com/forums/multi-way/228670-one-bc-homage-classic-vintage-design.html

I am currently sidetracked by the Decca Corner horn and an other Voigt pipe, but I intend to get back to the Dorspen design. I dropped the box on the garage floor and that dislodged one of the soft fiber board sheets from the speaker wall! So do not use latex sealer as a glue use silicone or some other real adhesive.

http://www.diyaudio.com/forums/multi-way/228670-one-bc-homage-classic-vintage-design.html

I am currently sidetracked by the Decca Corner horn and an other Voigt pipe, but I intend to get back to the Dorspen design. I dropped the box on the garage floor and that dislodged one of the soft fiber board sheets from the speaker wall! So do not use latex sealer as a glue use silicone or some other real adhesive.

Noted this with the Spendor BCIII & SA3 designs I own presumably a technique used to improve diffraction hence frequency dispersion?

Hi Colin re; original post I have often wondered the same thing. My only thought so far was perhaps they wanted to avoid restrictions or obstructions at the rear of the driver frame/basket that might cause reflections of sound waves. If you mount a B110 recessed into a19mm baffle you still have quite a lot of material around the four gaps in the driver frame.

There was a paper by Fryer (maybe) or another guy in the UK (HFN-RR?) press from the 70's who showed that there were audible reflections from the basket............

Btw on a similar theme I was always a little puzzled that designers of transmission lines would go to great lengths to calculate the cross sectional area of the tapered pipes to the third decimal place and then find that the open area of the speaker frame was a little as 50% of the cone area.............

Cheers, Jonathan

There was a paper by Fryer (maybe) or another guy in the UK (HFN-RR?) press from the 70's who showed that there were audible reflections from the basket............

Btw on a similar theme I was always a little puzzled that designers of transmission lines would go to great lengths to calculate the cross sectional area of the tapered pipes to the third decimal place and then find that the open area of the speaker frame was a little as 50% of the cone area.............

Cheers, Jonathan

It also alows closer C-C distance by rear mounting the woofer and in some applications I would imagine it makes it easier to decouple the driver using the rubber grommets?

Thanks for replies. I think protection and not restricting airflow at the back are probably the answer. I haven't rear mounted the driver but having a removable baffle if so much nicer to work with than footling around with captive nuts and poking about through a driver hole.

Of course the OB boys knew that all along 🙂

Of course the OB boys knew that all along 🙂

I don't think there was any particularly good reason for rear mounting. In the 50s more cabinets were screw on backs and it was easy to rear mount. Old drivers had gaskets on the front to aid in driver manufacturing. It also gave some distance for excursion between cone and a thin grille.

Acoustically there is no up side. Response will tend to mound in the midrange. I have worked on the LS3 5a and the step/bump in the mids is significant and crossover complexity is required to compensate.

One aspect of BBC design that I wouldn't copy.

Acoustically there is no up side. Response will tend to mound in the midrange. I have worked on the LS3 5a and the step/bump in the mids is significant and crossover complexity is required to compensate.

One aspect of BBC design that I wouldn't copy.

I remember a famous tweeker of hi fi in the 70s/80s called Jimmy Hughes who opined that the 1-2cm baffle thickness had an acoustic effect that could be considered beneficial. He advised trying the effect of replicating this by having a 1-2cm wide strip of cardboard around the cone and surround. He said it focused the sound but reduced "space". As he pointed out, it costs nothing to try it out.

That's really just adding a mild amount of midrange cavity resonance. You may occasionally like the effect, but it isn't likely to be an improvement for every speaker you come across.

Generally woofers will measure a little flatter and smoother when front mounted. Rear mounting creates a little more directivity and the cavity resonance mentioned. If the baffle board is thin it may not be a problem at all, but as the baffle gets thicker it will always end up as degraded response.

For example, cup your hands into a short megaphone around your mouth.

David

Generally woofers will measure a little flatter and smoother when front mounted. Rear mounting creates a little more directivity and the cavity resonance mentioned. If the baffle board is thin it may not be a problem at all, but as the baffle gets thicker it will always end up as degraded response.

For example, cup your hands into a short megaphone around your mouth.

David

Well, I have tried this tweek out, and was unconvinced by it. But how is it that the LS3/5a is considered by many to have the best midrange reproduction of any speaker, if it is beset with cavity resonances? Or the BC1?

One of the reasons speaker boxes have front mounted drivers, is that it is much easier and cheaper to make. A removable baffle or back is needed for rear mounting.

One of the reasons speaker boxes have front mounted drivers, is that it is much easier and cheaper to make. A removable baffle or back is needed for rear mounting.

Well, I have tried this tweek out, and was unconvinced by it. But how is it that the LS3/5a is considered by many to have the best midrange reproduction of any speaker, if it is beset with cavity resonances? Or the BC1?

One of the reasons speaker boxes have front mounted drivers, is that it is much easier and cheaper to make. A removable baffle or back is needed for rear mounting.

Not cavity resonances (plural) but a clearly elevated midrange from 1000Hz and below. Extra crossover complexity was required and it isn't fully compensated for. This can be seen in any measurements of the 3/5a.

As to "best midrange of any speaker" its legend is a bit overblown. I was asked to redesign the unit in the early 80s as the response had drifted badly. The BBC came up with some reference units to emulate and I created the 11 Ohm version built since that time. I did a network that matched their units, but also a second network with flatter midrange. The Beeb agreed that the flatter network sounded better but felt that the prudent course was to match the average unit in the field from prior to the big drift (this is all in Ken Kantors KEF book if you want corroboration).

The LS 5/8 and 5/9 have much better midrange.

As to cost of construction, drivers used to be rear mounted because it was cheaper to make the drivers. I'm talking 1930s through 1950s radios and radiograms. The practical approach was to mount the driver on the back side with the chassis. For the driver this was easier as you glued the cone assembly in, added a fiberboard gasket (needed for cabinet seal) and plunked it face down until the glue dried. For front mounted drivers you need to create a large number of clamping fixtures to hold down surrounds as they dry, considerably more expensive.

Screw on cabinet backs lost favor at the end of the 50s as air seal, bracing and general solidity were hard to achieve. With acoustic suspension systems it made more sense to create a solid one piece cabinet.

Harry Olson documented the problems of the mounting cavity in the 50s

David

As to cost of construction, drivers used to be rear mounted because it was cheaper to make the drivers. I'm talking 1930s through 1950s radios and radiograms. The practical approach was to mount the driver on the back side with the chassis. For the driver this was easier as you glued the cone assembly in, added a fiberboard gasket (needed for cabinet seal) and plunked it face down until the glue dried. For front mounted drivers you need to create a large number of clamping fixtures to hold down surrounds as they dry, considerably more expensive.

David

Que??

I've not seen Any diversion from this construction method on Any drivers I've ever seen. Admittedly not an all encompassing list.. but still.

Despite many/most being front mounted.

Quote:

Originally Posted by speaker dave View Post

As to cost of construction, drivers used to be rear mounted because it was cheaper to make the drivers. I'm talking 1930s through 1950s radios and radiograms. The practical approach was to mount the driver on the back side with the chassis. For the driver this was easier as you glued the cone assembly in, added a fiberboard gasket (needed for cabinet seal) and plunked it face down until the glue dried. For front mounted drivers you need to create a large number of clamping fixtures to hold down surrounds as they dry, considerably more expensive.

David

Que??

I've not seen Any diversion from this construction method on Any drivers I've ever seen. Admittedly not an all encompassing list.. but still.

Despite many/most being front mounted.

Please don't confuse 2 separate issues 🙂

1) speakers are still made "the old way" because ... well .... it's easier, faster and cheaper that way. 😀

I should know, 😉 , I make speakers for a living.

You should see squares of 4 speakers face down on a piece of plywood, with another 4 on top, yet another square plywood ... and so on, drying up overnight .

Afterwards (not my case) you can apply a back sealing gasket.

2) Difference with 40's and 50's is that in the old day most adhesives were solvent based, in fact "speaker cement" was thick Nitrocellulose lacquer so you had to press parts together while drying up, while later contact cements were used.

In fact, some speakers (notably Celestion) come with a spare self adhesive gasket for optional front mounting, go figure.

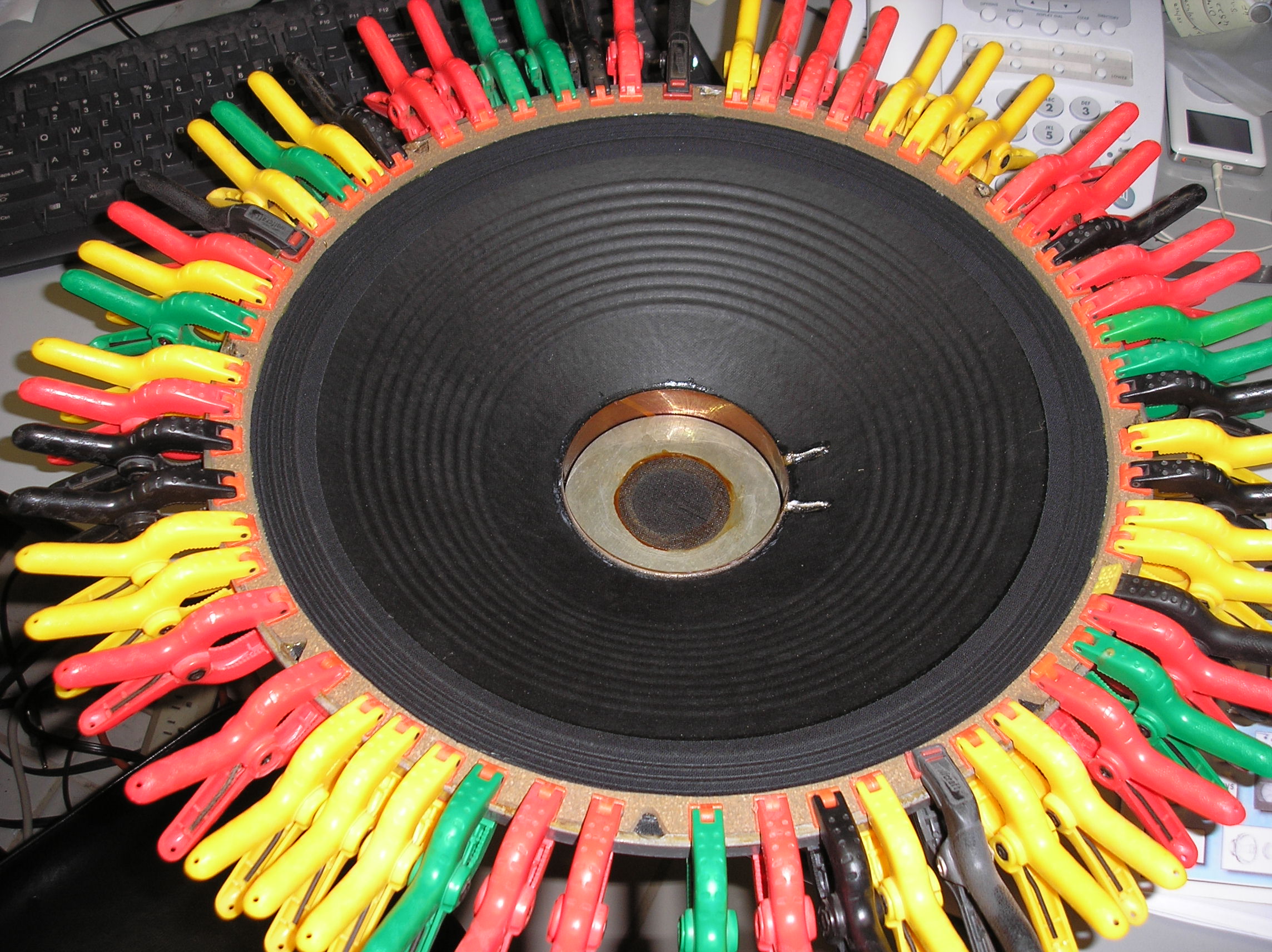

Just for fun, here's an extremely anal guy reconing his vintage JBL with old adhesives but who for some obscure reason did not want to let it peacefully dry face down on the table.

So he had to add "a couple clamps" 🙄

Last edited:

I always imagined that the reason that the B110 was mounted from the back was for much the same reason that Felt Strip Squares are used around the T27 in the BBC LS3/5a, to focus the output and control diffraction in a near field monitor to be used in a confined space?

As to "best midrange of any speaker" its legend is a bit overblown.

+1

dave

What is the significance of the change from a 15 Ohm version to an 11 Ohm version and why do some 15 Ohm versions have transformers on the crossover and others don't?<snip> I created the 11 Ohm version built since that time. <snip>

Also, why have some people (e.g. Keith Snook) placed the crossover outside the cabinet and doesn't this change in internal volume affect the sound?

Please don't confuse 2 separate issues 🙂

1) speakers are still made "the old way" because ... well .... it's easier, faster and cheaper that way. 😀

I should know, 😉 , I make speakers for a living.

Jim,

Tell me that the order of the clamp colors has an impact on the sound....

There is a lot of fashion involved in these changes as well. Gaskets on the front and mounting on the back became "old fashioned" after a while and nobody wanted to see thick front gaskets. Classy woofers were front mounted and had a styled basket or frame with the surround glued neatly and exposed, or perhaps under a rubber trim piece (like the 60s and 70s JBL LE series). Cardboard pad rings were considered the province of cheap TV replacement speakers or automotive OEM.

There really is performance difference though. Read Harry Olson's account of the LC1a and how it was given a special chassis design to let it sink into the mounting baffle to improve the sonics.

(see attached picture for details, Mercy, what's with them bumps!)

David

Attachments

- Home

- Loudspeakers

- Multi-Way

- BBC rear-mounting drive units on baffles