...bamboo is certainly something special...

Neopolitan. I wish it was available in 15mm.

With a 10-ton press or a big enuff vacuum bag, one should be able to make an evern stiffer board by laminating 5 of the stranded outer veneers (available separately) into a piece of plywood.

And, i figure making the same kind of veneer/plywood using hemp fibres instead of bamboo could be even stonger (longer fibres), and it grows almost anywhere.

Imagine driving Hiway 1 thru Saslatchewan and having 20 foot rtall stands of hemp on either side destined to be harvested and turned into boards you can make your speaker out of.

Bamboo has thousands of uses. Hemp probably 10x as much potential. Even guitars.

Hemp Wood Guitar | JOI Guitars

BTW: Hemp is a grass (like bamboo) not wood.

The World's First Hemp Wood Acoustic Guitar - YouTube

dave

"If your goal is to make high priced speakers then that’s another thing."

To fill you in, the goal is lightweight and portable. Tasked with constructing a cabinet that would normally weigh 40lbs but it now has to weigh 4lbs, what would you do? Will poly make a 4lb box that won't flap around like a loose snare drum?

If I wanted to go full on extreme it'd be made of a durabar ingot and weigh 4000lbs. Now that would be expensive.

To fill you in, the goal is lightweight and portable. Tasked with constructing a cabinet that would normally weigh 40lbs but it now has to weigh 4lbs, what would you do? Will poly make a 4lb box that won't flap around like a loose snare drum?

If I wanted to go full on extreme it'd be made of a durabar ingot and weigh 4000lbs. Now that would be expensive.

Last edited:

Why not use what NASA uses?

https://www.mscdirect.com/product/details/01926062

Light. Won't flop. Won't burn. Bugs won't eat it.

Also this from a guide on damping:

"Nevertheless, it is common practice to mount sound absorptive

layers directly against a wall, because it is very convenient to do so.

We must, however, realize that, in such cases, only the outer one-third of the thickness of the layer is effective in absorbing sound.

The rest of the material is simply acting as a convenient support!

Therefore, the values of R/rc for the 1/2" layer of material

given in Table 4, and the corresponding values of amax, assume that

this 1/2" layer is mounted near the perforated metal screen with, say,

an inch of empty airspace behind it. so that the entite 1/2" layer is

effective.

If the layer were mounted directly against a hard wall, the

tabulated values of R/rc would have to be multiplied by 1/3, and the

corresponding values of maximum absorption recalculated."

https://www.mscdirect.com/product/details/01926062

Light. Won't flop. Won't burn. Bugs won't eat it.

Also this from a guide on damping:

"Nevertheless, it is common practice to mount sound absorptive

layers directly against a wall, because it is very convenient to do so.

We must, however, realize that, in such cases, only the outer one-third of the thickness of the layer is effective in absorbing sound.

The rest of the material is simply acting as a convenient support!

Therefore, the values of R/rc for the 1/2" layer of material

given in Table 4, and the corresponding values of amax, assume that

this 1/2" layer is mounted near the perforated metal screen with, say,

an inch of empty airspace behind it. so that the entite 1/2" layer is

effective.

If the layer were mounted directly against a hard wall, the

tabulated values of R/rc would have to be multiplied by 1/3, and the

corresponding values of maximum absorption recalculated."

Last edited:

I used this stuff to get a 44mm edge radius. Costs $50 out the door for 12 feet to my local hardware store.

Moulding | Fypon Decorative Millwork

I've done listening tests and measurements w/ and w/o the edge. If I mess with the tweeter timing to make it come way sooner than anything it makes it easier to hear a difference. IMO a large edge makes high-frequency things harder to localize.

Don't forget you can simulate an edge radius in virtuixcad's baffle sim.

My speaker is still a WIP.

You mean it was harder to hear unwanted sound with the large radius, right?

Maybe this would be useful?

Natural, Black and Gray UHMW Sheets In Stock & Cut-to-Size from ePlastics

For a light cabinet the foam core might work well.

WRT the large round over... was that with one speaker or a stereo pair?

Natural, Black and Gray UHMW Sheets In Stock & Cut-to-Size from ePlastics

For a light cabinet the foam core might work well.

WRT the large round over... was that with one speaker or a stereo pair?

Why not use what NASA uses?

https://www.mscdirect.com/product/details/01926062

Light. Won't flop. Won't burn. Bugs won't eat it.

Also this from a guide on damping:

"Nevertheless, it is common practice to mount sound absorptive

layers directly against a wall, because it is very convenient to do so.

We must, however, realize that, in such cases, only the outer one-third of the thickness of the layer is effective in absorbing sound.

The rest of the material is simply acting as a convenient support!

Therefore, the values of R/rc for the 1/2" layer of material

given in Table 4, and the corresponding values of amax, assume that

this 1/2" layer is mounted near the perforated metal screen with, say,

an inch of empty airspace behind it. so that the entite 1/2" layer is

effective.

If the layer were mounted directly against a hard wall, the

tabulated values of R/rc would have to be multiplied by 1/3, and the

corresponding values of maximum absorption recalculated."

Very interesting

Neopolitan. I wish it was available in 15mm.

With a 10-ton press or a big enuff vacuum bag, one should be able to make an evern stiffer board by laminating 5 of the stranded outer veneers (available separately) into a piece of plywood.

And, i figure making the same kind of veneer/plywood using hemp fibres instead of bamboo could be even stonger (longer fibres), and it grows almost anywhere.

Imagine driving Hiway 1 thru Saslatchewan and having 20 foot rtall stands of hemp on either side destined to be harvested and turned into boards you can make your speaker out of.

Bamboo has thousands of uses. Hemp probably 10x as much potential. Even guitars.

Hemp Wood Guitar | JOI Guitars

BTW: Hemp is a grass (like bamboo) not wood.

The World's First Hemp Wood Acoustic Guitar - YouTube

dave

I think hemp has a few more advantages, easier to work with and locally sourced. Dinosaur grass vs stoner tech.

Tasked with constructing a cabinet that would normally weigh 40lbs but it now has to weigh 4lbs, what would you do? Will poly make a 4lb box that won't flap around like a loose snare drum?

.

Maybe look more at a driver that will not require the traditional cabinet, but just more of a plain baffle. Then using the uber lightweight material, laminated together with some urethane foam. The glue used could be an elastomer, contributing to damping.

Keep in mind there are physical limits though, and the amount of energy involved will be a factor.

I had a designer ask me once to find a way to make light go around a form, (ie a corner) seriously…

Mainly I'm just excited about the Purifi driver, so that part is already baked in.

You mentioned that you prefer hd poly, what is special about that material in comparison with other materials?

You mentioned that you prefer hd poly, what is special about that material in comparison with other materials?

Maybe this would be useful?

Natural, Black and Gray UHMW Sheets In Stock & Cut-to-Size from ePlastics

For a light cabinet the foam core might work well.

WRT the large round over... was that with one speaker or a stereo pair?

WRT which one? Not sure if you mean one of the baffle designs being entertained.

Foam core is a great go to btw. But if it's to stiffen the panel there are several ways to get that. If it's to do with damping, I'm seeing that as a whole other can of worms.

My point may have been slightly missed. If there were no higher frequency diffraction (regardless of the baffle size) then there would be no mention of the difference between baffle widths - except for the lower cutoff which is plenty important on its own, but has nothing to do with the old narrow baffle is better for imaging argument.In that case is it safe to assume you favor the larger and more smoothly transitioned geometries?

What's your understanding?My understanding is that the timing and the distance are more important.

My point may have been slightly missed. If there were no higher frequency diffraction (regardless of the baffle size) then there would be no mention of the difference between baffle widths - except for the lower cutoff which is plenty important on its own, but has nothing to do with the old narrow baffle is better for imaging argument.

Ok, gotcha. One interesting thing I noticed in terms of material costs is that the wide version has about 25% more surface area then the more cube shaped one. That should also translate into more bracing thanks to longer span.

First, I'm a newb at making speakers. I guess another way of putting it is with the edge there is a greater spaciousness with the high frequencies. So much so that they sound like they are coming from a space bigger than the room. This makes it harder to locate the speaker. I assume this is because the off-axis is as smooth as the on-axis.You mean it was harder to hear unwanted sound with the large radius, right?

My sighted test comparing w/ and w/o a radius was in mono with the speaker in the center of the room. I was sitting about 3m away and 20 degrees off-axis from the speaker so I would be listening to the room more than the direct sound.

I used these tracks and a few more with a 0 delay on the tweeter to compare the spaciousness.

E1sbar - Vapour [Audio] - YouTube

Utai IV: Reawakening - YouTube

Bobby Darin - Beyond the sea - YouTube

They all have something that pops out on the tweeter. With the edge, I get a wall of sound with the vocals, horns, high pitch things, etc..

I hope to repeat the test with instant and random switches between the speakers w/&w/o edges once my final baffle is done. I also think listening to smaller loops would be better too.

A pair. My first speaker for my desk. I am still working on it and waiting for the next round of parts. Been listening in mono for months. 😛Maybe this would be useful?

Natural, Black and Gray UHMW Sheets In Stock & Cut-to-Size from ePlastics

For a light cabinet the foam core might work well.

WRT the large round over... was that with one speaker or a stereo pair?

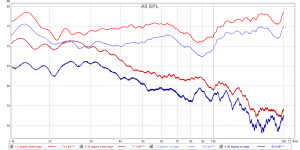

I attached early measurements from a temporary foam baffle when things were not flush-mounted and the eq not cleaned up. The speaker and mic positions are the same. The measurements were taken with different system volumes so the curves would be stacked. The dip on-axis at 8-10khz is prob from the way the tweeter was mounted at the time.

Attachments

This is great! I keep getting tripped up with your definition of edge though lol. "No edge" could mean no sharp edge or no rounded edge. When you attached the large radius, is that what gave the opened up (read good) sound stage? They all have an edge, to my thinking, just some are chamfered, some are straight, some are curved. Forgive me if I'm being daft with edge semantics😀

What is your measurement setup like? I'd like to be able to do that, on a tight budget if possible.

What is your measurement setup like? I'd like to be able to do that, on a tight budget if possible.

Yeah, "no edge" is w/o the white molding. The photos in my prev. post show w/ and w/o.

" is that what gave the opened up (read good) sound stage?"

Yes.

"They all have an edge, to my thinking, just some are chamfered, some are straight, some are curved. Forgive me if I'm being daft with edge semantics"

Yeah, somewhere on this site someone shared of sim of round vs straight edge radii. Not much difference if I recall.

" is that what gave the opened up (read good) sound stage?"

Yes.

"They all have an edge, to my thinking, just some are chamfered, some are straight, some are curved. Forgive me if I'm being daft with edge semantics"

Yeah, somewhere on this site someone shared of sim of round vs straight edge radii. Not much difference if I recall.

What is the material like, soft, textured, etc.? I'm wondering if a hard, smooth profile similar to yours would do the same thing.

"Been listening in mono for months. 😛"

Been there. Don't even have mono currently 🙄

"Been listening in mono for months. 😛"

Been there. Don't even have mono currently 🙄

Ok, gotcha. One interesting thing I noticed in terms of material costs is that the wide version has about 25% more surface area then the more cube shaped one. That should also translate into more bracing thanks to longer span.

Geometery say sthat as the shape approaches a sphere, the surface are decreases relative to the contained volume. A sphere is naturally self-bracing, but really bad for internal standing waves.

But with almost any box enclosing a speaker driver, we try to avoid dimensions of box dimensions that fall on interger multiles. A cube is 1:1:1, for a strong single internal resonance/standing wave.

dave

- Home

- Loudspeakers

- Multi-Way

- Baffle Design....Diffraction and Crammed Tweeter?