I have not gotten them yet but once again they are not meant for us 'hi-fi' guys, which makes sense. We are not their market. Here is what Joseph Crow wrote to me. They are meant for Pro Sound applications which means they don't have any contour filters to flatten the frequency response. That is typically left to the DSP unit which is always part of a pro sound setup. The B&C crossover won't have the boost in the upper treble for example. Joseph however is very impressed with them when modified for home use. With that being said I am always in to tinkering around...so having a couple of horns and x-overs along with DSP it will be fun!

I still don't understand ... professional/oem definitely don't need an after market crossover made by B&C or whoever else, they design their own horns and crossovers, I mean how many crossovers you can find in B&C, RCF, Faital Pro, 18sound etc catalogs? you already know the answer... It could have been an interesting opportunity, but instead they came up with this "nonsense" ( I apologize for the harshness, it's just my ignorant and humble opinion but ...). At the beginning of this same thread the horn was only a prototype and it was said that it would hardly be produced precisely because the manufacturers make theirs own designs, so when I saw the horn become an actually and affordable product I (mistakenly, at this point) thought it was a little "wink" to the diyers, and when I read about the crossover the hype grew further and instead... "genuinely, genuinely disappointed" (quote)

Last edited:

This crossover is optimal for PA as DSP EQ presets are common anyway. Any EQ to flat in the crossover is not desirable as it wastes power and adds weight/cost. The essential crossover slopes and time alignment is there and nothing more.

Producing a large horn mold is expensive a probably out of reach of many smaller manufacturers so this horn may actually be (relatively) popular.

Producing a large horn mold is expensive a probably out of reach of many smaller manufacturers so this horn may actually be (relatively) popular.

Sure, agree 🙂, but as I already said, to my view (that could be wrong, of course) the manufacturers simply don't need of a "general pourpose" crossover made by a specific brand, they already know how do it and, mostly, how design a customized crossover suited for their specific products. But again, just my opinion 🙂

Last edited:

Hi guys, with the FB 464 crossover, three protective bulbs are connected in parallel. Do you know the parameters, please?

Hey Folks 🙂

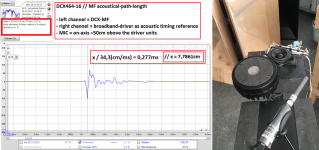

I don't know exactly if anyone has measured this in the meantime (I didn't find anything about it a while ago) . I have today made a measurement setup to measure the path lenght of the MF mebrane in the DCX.

. I have today made a measurement setup to measure the path lenght of the MF mebrane in the DCX.

What was already noted by others - I assume ideal room conditions - 20 degrees at normal humidity. I mean that in my workshop today it also felt like this. But of course I don't know exactly. In addition, the broadband membrane is not flat, of course, I have used a bit of judgment here to bring DCX-Throat and broadband driver in line with each other. Nevertheless, a good starting point for future simulations in Unity or Synergy. (HF shorted)

Kind regards, Christian 🙄

I don't know exactly if anyone has measured this in the meantime (I didn't find anything about it a while ago)

. I have today made a measurement setup to measure the path lenght of the MF mebrane in the DCX.

. I have today made a measurement setup to measure the path lenght of the MF mebrane in the DCX.What was already noted by others - I assume ideal room conditions - 20 degrees at normal humidity. I mean that in my workshop today it also felt like this. But of course I don't know exactly. In addition, the broadband membrane is not flat, of course, I have used a bit of judgment here to bring DCX-Throat and broadband driver in line with each other. Nevertheless, a good starting point for future simulations in Unity or Synergy. (HF shorted)

Kind regards, Christian 🙄

Attachments

Last edited:

464 crossover

Hello guys! I sent the 464 to Joseph Crow and he designed a crossover with his 300hz horns. I must say he did a great job! worth every penny. I did end up with a huge crossover compared to the 'OEM' FB464! To A/B them is not fair because the filters that Joseph put in flattened out the response so much so that my DSP (MiniDSP) had little work to do. Good job Joseph. I am now using some Mundorf Supremes and better in the FB464 configuration and see if the DSP can 'fix' the stock crossover. Then A/B it. Its all about 'fun'!!

Hello guys! I sent the 464 to Joseph Crow and he designed a crossover with his 300hz horns. I must say he did a great job! worth every penny. I did end up with a huge crossover compared to the 'OEM' FB464! To A/B them is not fair because the filters that Joseph put in flattened out the response so much so that my DSP (MiniDSP) had little work to do. Good job Joseph. I am now using some Mundorf Supremes and better in the FB464 configuration and see if the DSP can 'fix' the stock crossover. Then A/B it. Its all about 'fun'!!

Attachments

Does the B&C DCX464 use just one 2-pole RADIAL NdFeB magnet?

i.e. one pole on the magnet's outer ring surface and the other pole on the magnet's inner ring surface

i.e. one pole on the magnet's outer ring surface and the other pole on the magnet's inner ring surface

Last edited:

The B&C DCX464 spec sheet lists a Neodymium "ring" of 1.9T flux density for the mid unit, and Neodymium "inside slug" of 2.14T flux density for the HF unit, so sounds like separate magnet structures are used.

wekterstys ... I agree.... two separate magnets are necessary for the best coaxial performance. I'll keep searching for "radial magnets" being used with ring radiator tweeters. Large NdFeB radial magnets are too expensive for woof-mid speakers, but could reduce the distances in coaxial ring-radiator compression drivers, which might improve phase plug placement and shape.

Do you have a photo of the "Neodymium inside slug" of 2.14T flux density for the HF unit" B&C photos of "HF repair" does not show the tweeter motor.

Do you have a photo of the "Neodymium inside slug" of 2.14T flux density for the HF unit" B&C photos of "HF repair" does not show the tweeter motor.

Attachments

Last edited:

DCX464 MF Diaphragm Replacement - B&C Speakers

DCX464 HF Diaphragm Replacement - B&C Speakers

You can see quite a bit more here ...

DCX464 HF Diaphragm Replacement - B&C Speakers

You can see quite a bit more here ...

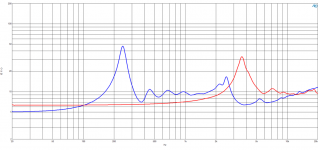

Hey LineSource, it wouldn't help much - and would take up space in the gap, reducing flux for the rest of the driver's bandwidth and adding cost. The part you have circled is not the magnetic gap, FYI, but where the MF energy leaves (and then passes through our MF filter, to avoid reflections from HF energy going down and returning back up the MF path). You can see in the LF impedance that inductance doesn't really start to raise the impedance until after 5 kHz, and the MF driver should be crossed over below that anyway. The frequency response falls off very quickly starting around 6kHz. The HF driver is useful down much further and the design expectation was for a crossover somewhere between 3-4kHz.DCX464

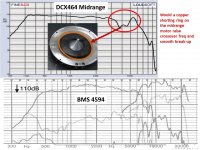

Would a copper shorting ring on the midrange motor raise the crossover freq and smooth break-up?

That same MF filter I mentioned is the reason that the energy falls off so quickly after 6kHz, and it keeps the HF energy smooth in that same frequency region by increasing the radiation impedance seen by the HF energy into the MF path. If you look at our DCM414 (the midrange only version of this driver), you'll see more typical smoothly rolling off HF response since that driver doesn't incorporate this filter.

For more details consider our paper here: http://www.aes.org/e-lib/browse.cfm?elib=21525

Attachments

Hi Bennett thanks for the info, is there a technical reason to select a 1.4" exit for the DCM414? or is it just to have commonality with the DCX464 as I understand that a larger exit diameter would have lower distortion due to less throat SPL for a given output. I guess the DCM420 is an adapter on the DCM414?

I have M200 compression drivers on hand but they won't last forever...

I have M200 compression drivers on hand but they won't last forever...

Hey Kipman, there's no need for a 2" throat at the levels and frequencies the DCM414 is capable of reproducing. We'd have to make the driver bigger to support it, and most users want it to be as compact and light weight as possible. The DCM420 is exactly as you surmise, a 1.4" -> 2" adapter bolted on the DCM414. Same with the DCX462.Hi Bennett thanks for the info, is there a technical reason to select a 1.4" exit for the DCM414? or is it just to have commonality with the DCX464 as I understand that a larger exit diameter would have lower distortion due to less throat SPL for a given output. I guess the DCM420 is an adapter on the DCM414?

Demodulation rings never "smooth" things out, only extend things, as well as lowering the distortion (sometimes quite drastically). Break-ups come from a different mechanical issue that doesn't have much to do with the inductance.DCX464

Would a copper shorting ring on the midrange motor raise the crossover freq and smooth break-up?

That being said, a demodulation ring in those things will always be beneficial.

Although seen from a sound-reinforcement perspective, that little less distortion isn't really a priority.

Plus there will be a slight penalty in sensitivity. (often resulting in a lower maxSPL)

Last edited:

- Home

- Loudspeakers

- Multi-Way

- B&C DCX464