I'm building a very high efficiency 3 way with some B&C 18PZB100 drivers. The woofer LP will be about 350 Hz in its own ported enclosure, so it will be critical to control all the lower midrange junk being radiating backwards into the cab. I'm used to building sealed enclosires. Based on my previous experiences with ported cabs, it will be tricky to make this planned design sound clean enough to satisfy hifi standards with the higher than usual LP with this big of a driver.

Basically, I wanted some advice on a vented alignment with optimized enclosure and port dimensions that will result in minimal resonances, play low enough despite the LF driver's low Qts and enclosure dampening strategy for best practical SQ. I also was hoping to bump up the Qts a little with the series resistance of the LP inductor, but not to the point of losing too much efficiency.

Any takers?

Basically, I wanted some advice on a vented alignment with optimized enclosure and port dimensions that will result in minimal resonances, play low enough despite the LF driver's low Qts and enclosure dampening strategy for best practical SQ. I also was hoping to bump up the Qts a little with the series resistance of the LP inductor, but not to the point of losing too much efficiency.

Any takers?

Attachments

Find inspiration on Troels Gravesen's pages, e.g. http://www.troelsgravesen.dk/The-Loudspeaker-2.htm

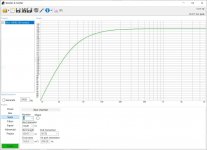

Use WinISD for sim of vented box.

Be especially careful of Group Delay ... not really sure where the limit is, but with higher GD in the sub bass you start to hear the sound of the "beat" "lacking behind".

I would really consider going active for the bass at least, with DSP to get the sound right.

350 Hz Xover wrt directivity should not be a problem ... beaming: https://www.audiosciencereview.com/...eaker-driver-beaming-frequency-formula.23816/

B&C 18PZB100 is a super nice driver, but as with all pro units, they are not designed to go really deep.

WinISD suggest 80 liter tuned at 30 Hz, and wit ca 800W you'll get +112 db at 30 Hz which i really nice for such a relatively small cab.

You should try to fit 2 x Ø10cm ports (flared if possible) to reduce port noise .... at 2 x 10 cm they need to be +60 cm long, so in a 80 l box probably need to be bended

Use WinISD for sim of vented box.

Be especially careful of Group Delay ... not really sure where the limit is, but with higher GD in the sub bass you start to hear the sound of the "beat" "lacking behind".

I would really consider going active for the bass at least, with DSP to get the sound right.

350 Hz Xover wrt directivity should not be a problem ... beaming: https://www.audiosciencereview.com/...eaker-driver-beaming-frequency-formula.23816/

B&C 18PZB100 is a super nice driver, but as with all pro units, they are not designed to go really deep.

WinISD suggest 80 liter tuned at 30 Hz, and wit ca 800W you'll get +112 db at 30 Hz which i really nice for such a relatively small cab.

You should try to fit 2 x Ø10cm ports (flared if possible) to reduce port noise .... at 2 x 10 cm they need to be +60 cm long, so in a 80 l box probably need to be bended

Attachments

Appreciate the info. GD is a concern with ported stuff, which is why i usually shy away from it, but I need the extra low end efficiency. I've heard some alignments are ok if the driver is optimized for it, which is why I chose this B&C driver with a lower Fs and parameters that allow it to play higher with a not so heavy curve linear cone design that is rigid enough. Most 18s have either very heavy cones for subwoofer duty and sound awful going into the few hundred Hz range.

I hear you on the active vs passive argument. I want to try passive first depending on complexity of network. I suspect an LCR is needed to shape the lower mids and that is expensive to do passively. I was hoping that being open with the cab dimensioms would help alot here.

I hear you on the active vs passive argument. I want to try passive first depending on complexity of network. I suspect an LCR is needed to shape the lower mids and that is expensive to do passively. I was hoping that being open with the cab dimensioms would help alot here.

Bracing the cab correctly was another concern with that high of an XO and large of panels. I tend to use a grid pattern with progressively spaced ribs to break up the distances between them for scattered separate resonances (rather than the same spacing, resulting in similar individual resonances creating a higher specific peak resonance).

Usually baltic birch is my go to material for this sort of thing. I like the sound of BB plywood and its lower weight than any other suitable wood. I hate the sound of MDF, but HDF in layers isn't too bad (but too heavy). As a bassist, I prefer BB anyways and was inspired to get some of that fullrange bass warmth in this new 18" build.

Most people woild do a separate sub with this sort of thing, but i don't like how detached and inorganic a separate sub usually sounds like crossing under 100 Hz to a larger midbass. I just don't like crossovers between bass drivers playing lower than 400 Hz, especially not steeper than 1st order. The phase shift is too audible especially if the midbass cab is ported. I'd rather have less low end extension than the traditional mis-timed bass typically the case with a big heavy coned sub crossing low to a midbass.

Usually baltic birch is my go to material for this sort of thing. I like the sound of BB plywood and its lower weight than any other suitable wood. I hate the sound of MDF, but HDF in layers isn't too bad (but too heavy). As a bassist, I prefer BB anyways and was inspired to get some of that fullrange bass warmth in this new 18" build.

Most people woild do a separate sub with this sort of thing, but i don't like how detached and inorganic a separate sub usually sounds like crossing under 100 Hz to a larger midbass. I just don't like crossovers between bass drivers playing lower than 400 Hz, especially not steeper than 1st order. The phase shift is too audible especially if the midbass cab is ported. I'd rather have less low end extension than the traditional mis-timed bass typically the case with a big heavy coned sub crossing low to a midbass.

Check out what Bareface does with their bass cabs ... might be something that you'd consider.

https://barefacedbass.com/technical-information/generation-three-enclosures.htm

https://barefacedbass.com/technical-information/generation-three-enclosures.htm

If you increasing the Qts (Qes) by inserting series resistance, you will lose efficiency, that's how it works. But if you want higher Qts with about the same (or even higher) efficiency as the B&C 18PZB100, check the Faital Pro 18FX600 or for larger "optimum" box (and lower cutoff), the 18FH500 or 510.Basically, I wanted some advice on a vented alignment with optimized enclosure and port dimensions that will result in minimal resonances, play low enough despite the LF driver's low Qts and enclosure dampening strategy for best practical SQ. I also was hoping to bump up the Qts a little with the series resistance of the LP inductor, but not to the point of losing too much efficiency.

https://faitalpro.com/en/products/LF_Loudspeakers/product_details/index.php?id=151070160

https://faitalpro.com/en/products/LF_Loudspeakers/product_details/index.php?id=151070150

The best way I found to control the midrange faff the driver radiates into the cab are acoustic foam tiles.

Here are the test results from 10cm (4 inch) thick wedge tiles: afw100-NRC-scaled.webp (WEBP Image, 1809 × 2560 pixels) – Scaled (36%)

You'll see that they have an NRC (Noise Reduction Coefficient) of 0.62 at 250Hz meaning they absorb 62% at that frequency, less at lower and more at higher ones. Probably as good as it gets. I'd line every interior surface with them.

My preferred method of fixing them is this stuff: EVERBUILD® BLACK JACK® 908 D.P.M. | Bitumen & Roofing Products

It is a water-based (no fumes!) rubber-bitumen solution so you are basically coating the entire inside with a layer of heavy rubber which can't be bad.

Here are the test results from 10cm (4 inch) thick wedge tiles: afw100-NRC-scaled.webp (WEBP Image, 1809 × 2560 pixels) – Scaled (36%)

You'll see that they have an NRC (Noise Reduction Coefficient) of 0.62 at 250Hz meaning they absorb 62% at that frequency, less at lower and more at higher ones. Probably as good as it gets. I'd line every interior surface with them.

My preferred method of fixing them is this stuff: EVERBUILD® BLACK JACK® 908 D.P.M. | Bitumen & Roofing Products

It is a water-based (no fumes!) rubber-bitumen solution so you are basically coating the entire inside with a layer of heavy rubber which can't be bad.

I appreciate all the great input guys. Please feel free to think out loud with this.

@ puppet - Thats what I've done before to some extent and it appears to be affective. I would likely alternate spacing to break up the resonance frequencies of each section.

@ YSDR - I was looking at the 510 Faital. Its promising but the B&C has the inside/outside VC winding, which to me is a big benefit in regards to mid band distortion performance. This dampens the VCs radial resoance modes at the unterminated end. Also, my track record with Faital drivers isn't that good.

@ Charles Darwin - The V - arrangement with foam works well. I tried it with smaller mid drivers and it appears to cut down on rear mid wash if the foam is thick enough to work into the low 100 Hz area. The trick with larger drivers is not impeding air flow and even dynamic symmetrical load across the entire cone. Its easy to provoke weird resonances based on my previous experiences.

@ puppet - Thats what I've done before to some extent and it appears to be affective. I would likely alternate spacing to break up the resonance frequencies of each section.

@ YSDR - I was looking at the 510 Faital. Its promising but the B&C has the inside/outside VC winding, which to me is a big benefit in regards to mid band distortion performance. This dampens the VCs radial resoance modes at the unterminated end. Also, my track record with Faital drivers isn't that good.

@ Charles Darwin - The V - arrangement with foam works well. I tried it with smaller mid drivers and it appears to cut down on rear mid wash if the foam is thick enough to work into the low 100 Hz area. The trick with larger drivers is not impeding air flow and even dynamic symmetrical load across the entire cone. Its easy to provoke weird resonances based on my previous experiences.

One thing I have to admit is that I sometimes listen at PA levels. Tight and pristine lower mids are important to me at all listening levels. It improves other areas of performance as well, especially when asking an 18" driver to play hifi clean up to 300+ Hz in a huge box.

It's basically a pioneer's prosound driver, so historically works best overall in the their Vb = Vas/1.44, Fb = Fs classic BR and Vb = Vas/1.44, Fb = 1.56x Fs classic prosound BR with critically damping the vent curing any peaking at Fb/excessive group delay and of course use a sufficiently large vent to keep its mach low at peak power.

FYI/FWIW, GD was debated extensively on the late Basslist.

FYI/FWIW, GD was debated extensively on the late Basslist.

Hornresponse will help with visualising the effects of the Duct and rear reflection from the box, my approximate HR model showed a clear resemblance to the Production partner test of the L Acoustics K28, also here are a couple of papers re vent design:

https://www.comsol.com/paper/download/679311/bezzola_paper.pdf

https://www.pearl-hifi.com/06_Lit_A...ions/Maximizing_Performance_from_LS_Ports.pdf

If you have access to the AES there is more info there.

https://www.comsol.com/paper/download/679311/bezzola_paper.pdf

https://www.pearl-hifi.com/06_Lit_A...ions/Maximizing_Performance_from_LS_Ports.pdf

If you have access to the AES there is more info there.

@ GM - I've never been able to make a driver with a higher Qts sound decent in a ported cab, especially when the tuning frequency is lower than driver Fs. One conclusion is that no driver will do a decent job reproducing frequencies under its own Fs and the other is insufficient drive capability with lower BL. This is one of the reasons why I usually favor drivers with a Qts of .36 to .38 for BR enclosures, so Fb lands about the same as driver Fs. I believe that's a QB3 alignment... not sure, but it appears to sound better to my ears than most other alignments. This all mainly applies to subwoofer duty enclosures, not so much with designs having the LF driver doing midbass as well. Thats when I prefer lower Qts and Fs drivers, which tend to keep the lower midrange unaffected by means of better dampening and a motor design optimized for lower midrange performance ie. more of s traditional midrange/ midbass driver.

@ SubSoniks - That is a fantastic and very specific paper on the whole subject. I've always been frustrated with port design. To get a BR design sounding clean and tight at higher drive levels isn't easy. I've always tried keeping the porr length as short as possible (as with many pro audio 2 way designs), but that makes midrange bleed a big problem.

Longer ports tend to fall apart sonically at higher SPL around Fb, where port velocity is high. The inevitable compression and distortion ruin it for me. This is why I'm a big fan of sealed boxes despite their inefficiency and tendency for VC heating at continuous higher drive levels. The alternative is horn loading, which i tend to favor over anything else for PA applications. A good horn loaded, well designed and implemented sub can sound effortless and musical. Most ported subs can't match that kind of performance.

@ SubSoniks - That is a fantastic and very specific paper on the whole subject. I've always been frustrated with port design. To get a BR design sounding clean and tight at higher drive levels isn't easy. I've always tried keeping the porr length as short as possible (as with many pro audio 2 way designs), but that makes midrange bleed a big problem.

Longer ports tend to fall apart sonically at higher SPL around Fb, where port velocity is high. The inevitable compression and distortion ruin it for me. This is why I'm a big fan of sealed boxes despite their inefficiency and tendency for VC heating at continuous higher drive levels. The alternative is horn loading, which i tend to favor over anything else for PA applications. A good horn loaded, well designed and implemented sub can sound effortless and musical. Most ported subs can't match that kind of performance.

??? Your point? This driver has the specs for the alignment I posted, which meets your stated performance requirements, i.e. best practical efficiency, power handling. For HIFI, the pioneers did a fine job just critically damping the vent, which for this driver @ 700 W @ < ~18 m/s vent mach is a 12" i.d. pipe (cardboard concrete former works well when braced at 2/3 back) x ~9.25" long. Damp cab to 'taste'.

If series resistance is used, which I don't recommend for this type of alignment, then calculate new Qts (Qts') and again damp to 'taste' or increase cab size, redo the vent.

If series resistance is used, which I don't recommend for this type of alignment, then calculate new Qts (Qts') and again damp to 'taste' or increase cab size, redo the vent.

Attachments

Thats a slick and simole test circuit. I built something similar to test overhang in a rear loaded horn and later discovered it could b used for more situations, like you describe. I agree with you regarding suggested alignment you made and I'm actaulyl a big fan of them.

No, unfortunately not. I may still use the 18s for another large 3 way, but my health has gotten alot worse the past year and forced me to re-prioritize my projects.

I'm wondering why you often bring up this formula and with its explanation (like optimal extension/highest efficiency/smallest box size with best transient response)? This formula requires a specific Qts value (I think it is approx 0.39) to work as intended, otherwise some aspects deteriorates. And the 18PZB100 have a very low Qts so it will not produce the best F3 alignment, and gives high GD (so it "overhangs") around Fb and all this in a relative large box with this formula.It's basically a pioneer's prosound driver, so historically works best overall in the their Vb = Vas/1.44, Fb = Fs classic BR

Or there is a "magical" thing happening with any drivers (regardless of their T/S parameters) in a BR box, when the Vb=Vas/1.44 and Fb=Fs?

Last edited:

What can I say? It works well with every Qt driver I've used from my 515B's 0.2 to the 421's up to nearly 0.4 Qt and please note I try to remember to only suggest it when wanting a vintage performance, which typically includes some variable impedance in series to 'taste' and normally some fine tuning by either internal damping and/or 'critically' damping the vent that was normally done with decorative grill cloth.

As for the 18PZB100, in HR it doesn't calc a high GD and minimal vent damping rolls it off further, though of course it doesn't sim an optimum flat response unless 3.5 ohms series resistance is used.

As for the 18PZB100, in HR it doesn't calc a high GD and minimal vent damping rolls it off further, though of course it doesn't sim an optimum flat response unless 3.5 ohms series resistance is used.

Okay, seems there is no magical power in the formula, just a few numbers and mathematical operations wich gives some results.

Probably the driver with a Qts = 0.2 gives very different result than a driver with a Qts = 0.4, so probably a Vb=Vas/1.5 or Vas/1.3 would work too as it gives just a slightly different result.

I'm still wondering where the Vb=Vas/1.44 comes from.

3.5 Ohms in series with a bass driver Jeeez! 😂

Probably the driver with a Qts = 0.2 gives very different result than a driver with a Qts = 0.4, so probably a Vb=Vas/1.5 or Vas/1.3 would work too as it gives just a slightly different result.

I'm still wondering where the Vb=Vas/1.44 comes from.

3.5 Ohms in series with a bass driver Jeeez! 😂

Pg. 76: https://archive.org/details/HowToBuildSpeakerEnclosuresByAlexixBadmaieffDonDavis/page/n75/mode/2up

“A nagging question in the design stage of any enclosure of this type is "How large shall it be?” It was pointed out earlier that the enclosure can be too large or too small for proper bass-reflex action. This implies that an optimum volume exists and indeed it does. This optimum volume does not depend upon the size of the speaker nor its resonant frequency per se but rather on the ratio of enclosure air stiffness to the speaker cone suspension stiffness. This optimum ratio is 1.44 or, looking at it another way, the speaker resonant frequency in the enclosure before porting should be 1.56 times the free-air resonance of the speaker. This size enclosure, when properly tuned, yields at the same time the most extended low-frequency response and a transient response with subjectively unnoticeable hangover, assuming sufficient damping exists. Compared to the entirely closed cabinet, the half-power point (3 db down) occurs at 0.7 times the closed cabinet speaker resonance for an extension of one-half octave."

Actually, historically many of the folks used matching impedance amps, so while not the same electrically as a simple resistor, still significant.

“A nagging question in the design stage of any enclosure of this type is "How large shall it be?” It was pointed out earlier that the enclosure can be too large or too small for proper bass-reflex action. This implies that an optimum volume exists and indeed it does. This optimum volume does not depend upon the size of the speaker nor its resonant frequency per se but rather on the ratio of enclosure air stiffness to the speaker cone suspension stiffness. This optimum ratio is 1.44 or, looking at it another way, the speaker resonant frequency in the enclosure before porting should be 1.56 times the free-air resonance of the speaker. This size enclosure, when properly tuned, yields at the same time the most extended low-frequency response and a transient response with subjectively unnoticeable hangover, assuming sufficient damping exists. Compared to the entirely closed cabinet, the half-power point (3 db down) occurs at 0.7 times the closed cabinet speaker resonance for an extension of one-half octave."

Actually, historically many of the folks used matching impedance amps, so while not the same electrically as a simple resistor, still significant.

- Home

- Loudspeakers

- Multi-Way

- B&C 18PZB100 ported enclosure design advice