I know it's a long thread. Maybe it's time for you to detail what you want from a horn.. what range you want to cover, what properties you most value, what distortions you are most concerned about.i am familiar with the thread. are you suggesting it contains information on the reduction of audible distortion in horns?

The top end of the spectrum is not a bad place to start because of our sensitivity up there, the relative ease in building a higher frequency device and the return for the effort.

One viable option for the top end is a waveguide, and reading about these is IMO a good place to learn about some of the distortions that matter the most in a domestic situation.

Weltersys is very knowledgeable on horns BTW.

AllenB

the thread was started because someone kept threadjacking and saying that reducing distortion in horns was "not possible" and was "inaudible" and "irrelevant".

so far in this thread some good points have been made and some salient information has surfaced.

as far as divisions go i try not to do that as i think good audio is something for everyone.(whether it's home audio ,PA,a rave in the middle of the outback on stuff powered by batteries)

so at this point it's still open ended,any technique method or modification that has or may potentially reduce distortion in horns or is shown to provide a performance improvement is worthy of consideration.

the thread was started because someone kept threadjacking and saying that reducing distortion in horns was "not possible" and was "inaudible" and "irrelevant".

so far in this thread some good points have been made and some salient information has surfaced.

as far as divisions go i try not to do that as i think good audio is something for everyone.(whether it's home audio ,PA,a rave in the middle of the outback on stuff powered by batteries)

so at this point it's still open ended,any technique method or modification that has or may potentially reduce distortion in horns or is shown to provide a performance improvement is worthy of consideration.

AllenB

the thread was started because someone kept threadjacking and saying that reducing distortion in horns was "not possible" and was "inaudible" and "irrelevant"..

So you have all read this? 😛 Yes, that's 28 volts into a plane wave tube

The AES paper on subjective evaluations of compression drivers is available here. http://www.gedlee.com/downloads/AES_subjective.pdf

Last edited:

As far as compression drivers, other than the few relatively recent additions noted in #263, there have been no advances in reduction of distortion in decades, Art

Hi Art

Why do you think that is?

pooh

if you want to take a poke at Dr Geddes do so without quoting me. i respect his work and knowledge. i do take issue with the fact that he puts the audibility of distortion into question and appears to support his position with only his research and can not seem to provide corroboration from any other sources on the matter despite that, his knowledge of horns or should i say waveguides is work i hope to fully understand someday.

if you want to take a poke at Dr Geddes do so without quoting me. i respect his work and knowledge. i do take issue with the fact that he puts the audibility of distortion into question and appears to support his position with only his research and can not seem to provide corroboration from any other sources on the matter despite that, his knowledge of horns or should i say waveguides is work i hope to fully understand someday.

pooh

if you want to take a poke at Dr Geddes do so without quoting me. i respect his work and knowledge. i do take issue with the fact that he puts the audibility of distortion into question and appears to support his position with only his research and can not seem to provide corroboration from any other sources on the matter despite that, his knowledge of horns or should i say waveguides is work i hope to fully understand someday.

I wasn't taking a poke I was stating the paper compares driving a compression driver at 28 volts in a plane wave tube and it wasn't perceivable different in the test compared to 2.8 volts. That is what you should question not if I am poking at him since you decided to start a thread about it.

Turk, it's all here on this site if you want to learn. It's hard work to read it all and try it and find out for yourself. If you read enough you'll see that Earl knows the limitations of testing and has been honest about such. In my humble and limited experience I'll corroborate the conclusions as worthy of including in the goals of we members of the DIY community. I think it's your loss if you are unwilling to roll your sleeves up and give it a go.

AllenB

thanks for the good advise.

do you have anything you would like to contribute on the audibility of distortion in horns or something with respect to potential performance improvements of the latter.

thanks for the good advise.

do you have anything you would like to contribute on the audibility of distortion in horns or something with respect to potential performance improvements of the latter.

Sure. Myself, Earl and I'd hazard to guess the vast majority of DIYers and probably even the pros at some point all started out thinking that non-linear distortion was the issue behind all sound problems. Now we have some evidence to help put this into perspective. The work that has been done is probably what I would have liked to have done if I were in that position, but it's here and good results can be had.

Pavel,

Interesting device.

Looks like it would be well suited for line arrays, but I don't see it reducing distortion, and likely would be frightfully expensive to produce.

Electrostatics have very limited excursion, so the crossover frequency would have to be high for high output.

Any measured distortion vs. output level of an actual device?

Art

Art,

It was a differential, horn loaded electrostatic driver. Over damped membrane, heavily loaded with real part of impedance, ρCo. Frequency range was 1kHz – 19kHz, extremely flat frequency response. Non-oscillating, aperiodic impulse response (which is unique). Low distortion. High DC bias voltage.

There was no commercial success, production was very expensive and it was developed behind "iron curtain".

My notes are from mid of 1970's, and unfortunately I have no measurements left.

Pavel

ok i guess that the audibility of distortion(everyone seems to think i'm fixated on nonlinear for some reason) in horns and any discussion of it is beating a dead horse or old hat to some.i am somewhat dismayed by the fact that it appears nothing is possible or worth exploring with respect to reducing it's audibility and that it has been deemed unimportant to people who are in the position of consultants with the major companies,perhaps that is why the state of the art is what it is.

I said my piece and presented measurements to show that CLD on thin horn walls makes huge difference. People can keep an open mind and try it out or not believe it and call it bad data. Your choice. And true to the thread title - it is certainly most definitely, audible.

Just to keep to the thread title, here is the latex caulking being applied before the second layer is placed on for the CLD.

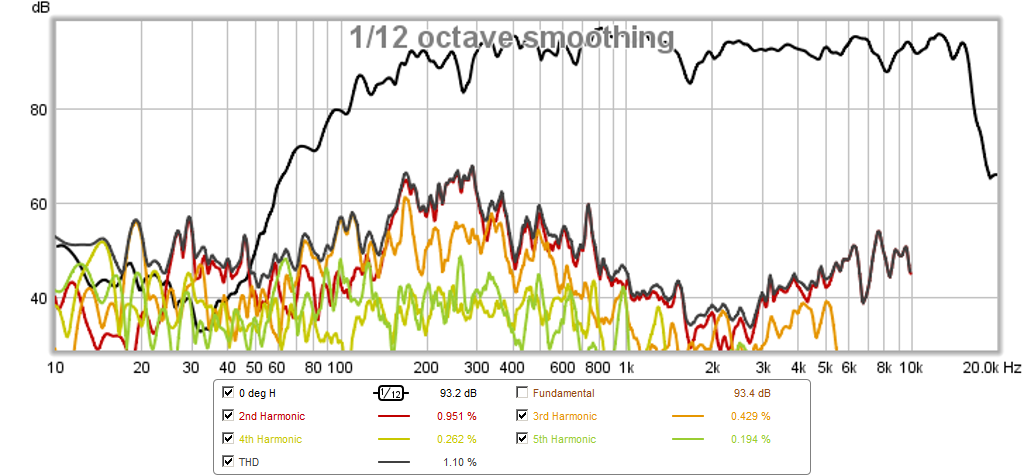

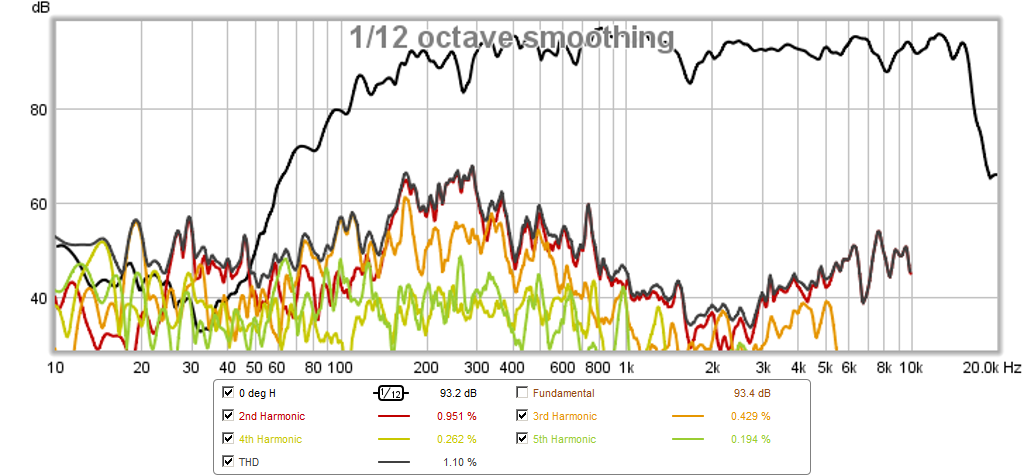

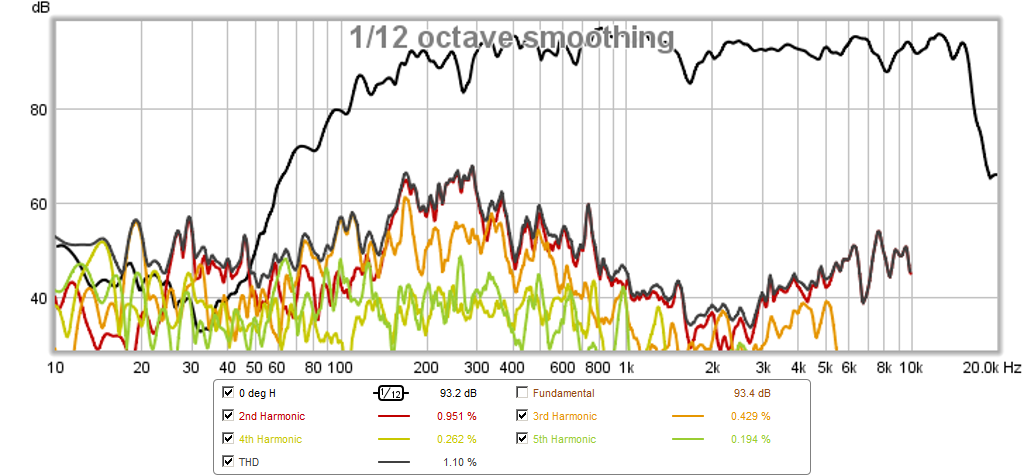

Here is the measurement before CLD:

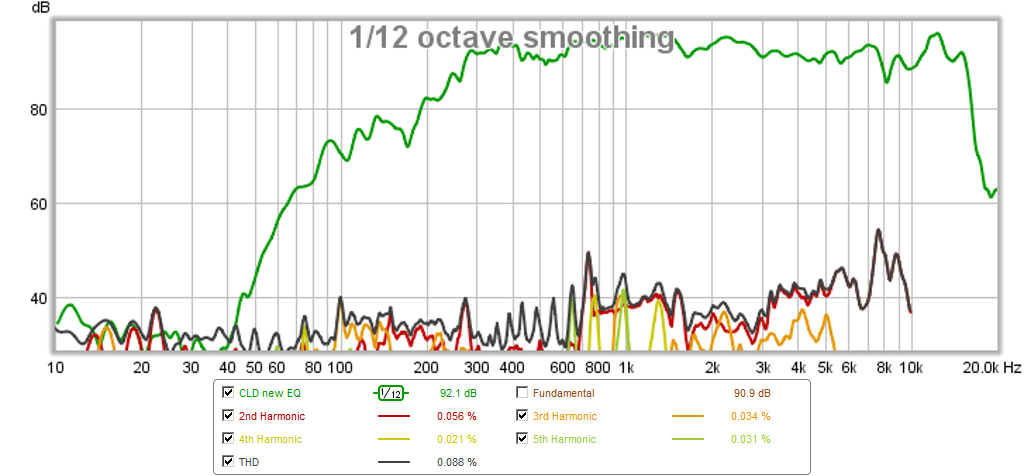

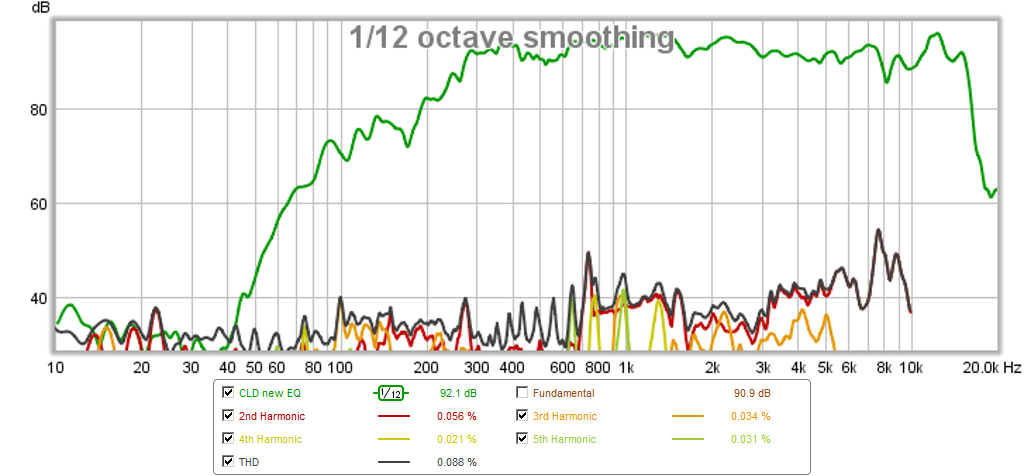

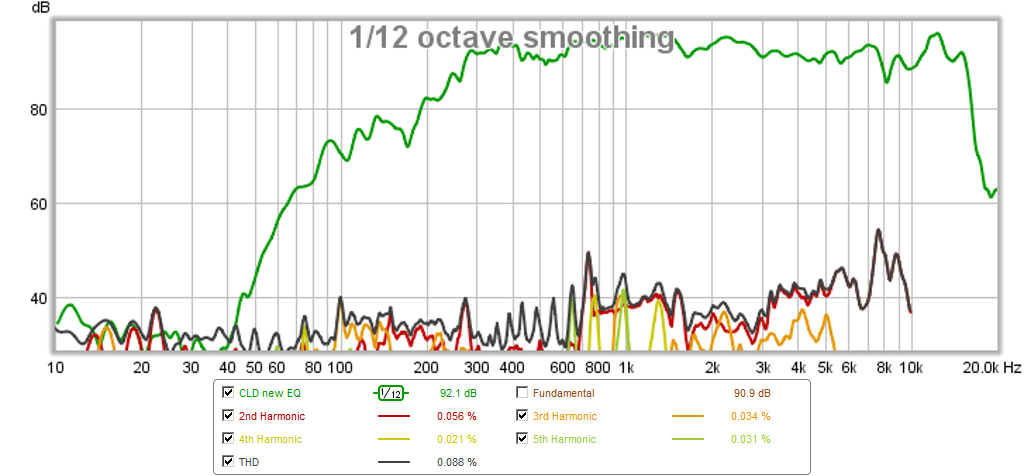

And here is after:

Let's not call it "harmonic" distortion but just plain distortion meaning sound generated by horn walls that was not in the source signal.

Just to keep to the thread title, here is the latex caulking being applied before the second layer is placed on for the CLD.

Here is the measurement before CLD:

And here is after:

Let's not call it "harmonic" distortion but just plain distortion meaning sound generated by horn walls that was not in the source signal.

Last edited:

this is a perfect example of things that can be done.

and from my experience this sort of thing can be applied to existing horns.i have seen this sort of thing in the past applied to large cast horns.

when this sort of thing is dismissed as "bad data" by people who profess they know better is it not cause to wonder if their opinion isn't tainted by the fact that audible improvements can be made without resorting to purchasing their product that has been touted as the the best solution (the emperor's new clothes).

and from my experience this sort of thing can be applied to existing horns.i have seen this sort of thing in the past applied to large cast horns.

when this sort of thing is dismissed as "bad data" by people who profess they know better is it not cause to wonder if their opinion isn't tainted by the fact that audible improvements can be made without resorting to purchasing their product that has been touted as the the best solution (the emperor's new clothes).

The above horn with CLD can play exceedingly loud without giving you a clue as to how loud it is until your ears ring. It is so clean sounding that I had to really be careful when testing it at 2.83v input. I wear ear plugs now 🙂

I have not made a horn out of thin wood, but I imagine a similar thing to happen there too so a good trick to keep handy. Certainly a very low cost way to improve SQ.

I think maybe adding sand as mass filler to the caulking may also help.

I have not made a horn out of thin wood, but I imagine a similar thing to happen there too so a good trick to keep handy. Certainly a very low cost way to improve SQ.

I think maybe adding sand as mass filler to the caulking may also help.

Originally Posted by weltersys

As far as compression drivers, other than the few relatively recent additions noted in #263, there have been no advances in reduction of distortion in decades

Bass drivers have made large advances, around an order of magnitude increase in output in the last 20 years, as they are not (as) constrained by excursion limitations, though are now starting to hit practical limitations.

As far as compression drivers, other than the few relatively recent additions noted in #263, there have been no advances in reduction of distortion in decades

The requirement of high compression ratios with very light, thin materials and less than 1mm distance from diaphragm to phase plug to get good output in the top octave has "boxed in" compression driver development.Hi Art

Why do you think that is?

Bass drivers have made large advances, around an order of magnitude increase in output in the last 20 years, as they are not (as) constrained by excursion limitations, though are now starting to hit practical limitations.

Originally Posted by weltersys

As far as compression drivers, other than the few relatively recent additions noted in #263, there have been no advances in reduction of distortion in decades

The requirement of high compression ratios with very light, thin materials and less than 1mm distance from diaphragm to phase plug to get good output in the top octave has "boxed in" compression driver development.

Bass drivers have made large advances, around an order of magnitude increase in output in the last 20 years, as they are not (as) constrained by excursion limitations, though are now starting to hit practical limitations.

I absolutely prefer the sound of a good cone compression driver like the JBL CMCD or the low compression Community M200 for midrange. They sound cleaner with a purer more natural sound while still retaining if not exceeding the high output and hair trigger transient sound we get with the high compression models people use by mistake in the midrange.

http://communitypro.com/sites/default/files/M200A.pdf

CMCD Cone Midrange Compression Driver

I said my piece and presented measurements to show that CLD on thin horn walls makes huge difference. People can keep an open mind and try it out or not believe it and call it bad data. Your choice. And true to the thread title - it is certainly most definitely, audible.

Just to keep to the thread title, here is the latex caulking being applied before the second layer is placed on for the CLD.

Here is the measurement before CLD:

And here is after:

Let's not call it "harmonic" distortion but just plain distortion meaning sound generated by horn walls that was not in the source signal.

That is crazy. How thin was the horn walls and what were they treated with?

From what I see here, the first suggestion that I would make is to make sure that the horn is as rigid as practicable. A flimsy device will act in highly unpredictable ways - none of which are likely to be good.

Then, given that, as Art says, there isn't much likely improvement in the drivers NLD, and that a rigid horn cannot add or subtract any significant NLD, then, logically, LD in the horn is the only thing that one has any control over.

The huge changes in horns over the last couple of decades testifies to the correctness of this conclusion. They have changed a lot and gotten better and better and it was all due to a lowering of the LD in them.

If this isn't a "practical" suggest, then I don't know what is.

Then, given that, as Art says, there isn't much likely improvement in the drivers NLD, and that a rigid horn cannot add or subtract any significant NLD, then, logically, LD in the horn is the only thing that one has any control over.

The huge changes in horns over the last couple of decades testifies to the correctness of this conclusion. They have changed a lot and gotten better and better and it was all due to a lowering of the LD in them.

If this isn't a "practical" suggest, then I don't know what is.

How thin was the horn walls and what were they treated with?

Horn built out of paper-faced foam core boards, as are most of my speakers. 3/16in thick panels - fairly stiff for their weight but flexible compared to wood. I treated it by applying latex caulking (home repair sealing compound) as shown and putting another layer of 3/16in thick foam core on top. The foam core I use comes in 2 grades: $1 store grade (Adams brand) is very thin and light, and Elmer's brand grade is $3 ea and use thick cardboard and is much stronger and stiffer. The foam core boards are the material of choice for building today's RC aircraft (it's the new balsa wood). More info on the differences here:

http://www.rcgroups.com/forums/showthread.php?t=952191

Adams brand FC:

http://www.goadams.com/

The above horn was built in this thread:

http://www.diyaudio.com/forums/full...450-ndy-fast-applications-10.html#post4033969

if you want to see other speakers that I have made of foam core check the Index on Post #1 of this thread:

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures.html

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Audibility of distortion in horns!