For the horn, you need to first create a guide. As it appears to be mostly rectangular, you might get away with screwing together a bigger rectangle from MDF stripes.

Thanks,i mean if horn mounting hole need to be router processed or horn must be screwed to the wood without a groove?

Last edited:

The horn provides VHF output and here, any small edge will introduce diffraction. As with tweeters, flat baffle mounting (recessed, with a groove) is advantageous.

Or this.

What is better?

Please not to take into account the polymerization of the ovary in the future.

I have the option for the pure wool too(washed and dried) but I can't find the way for fixing into the speaker wall.

What is better?

Please not to take into account the polymerization of the ovary in the future.

I have the option for the pure wool too(washed and dried) but I can't find the way for fixing into the speaker wall.

Attachments

Last edited:

I've had foam as in post 426 discintegrate into dust after 30 years. A camera case liner my Mother bought for me. Another disadvantage, if there is a fire foam produces poison gases.

Wool & jute bats, you can use hot melt glue or a number of screws inserted into holes of a limited depth drilled with a drill stop collar. https://www.mcmaster.com/drill-stop-collars/

Wool & jute bats, you can use hot melt glue or a number of screws inserted into holes of a limited depth drilled with a drill stop collar. https://www.mcmaster.com/drill-stop-collars/

How to treat a speaker in the inside is a confusing theme, near to a religion.

This is caused by people with different interest. Those that sell special materials want you to spent a lot of money. Then, different principles like closed, vented, horn or transmission line need different material at different places. So a place for a lot of Voodoo and confusion.

I stick to the final word of physics in this discussion. If you have a closed bass cabinet, anything fiber or light foam at the walls is not really helping the bass. The most effective thing is to completely fill the volume and brace the walls, period.

As you do not want anything to block sensitive parts of the driver, loose material is not suited. If you insist on it, you have to screen the driver with some cloth, but loose material will concentrate at the bottom over time.

If you want to do the best for sound, increasing the acoustic volume and removing any reflection, you should fill the whole box with rock wool. If for some reason, you don't want it, the second best and more expensive solution, is acrylic wool in sheet form. People often look what they find in the basement and can use for free. Please accept this may not be the best material, even when they later rave about it.

While extending the bass a little and removing any echo inside, this filling does nothing to the walls resonances. You need mass to damp this out or stronger walls. Both will make the bass more "dry" sounding, as you prevent the walls from storing energy and releasing it later. Compare it to an ill tuned vent in the box messing up the bass response.

Best is to do both, complete fill with fibers plus braces at the walls. What you loose in volume by the braces, is over compensated by the 5-10% virtual volume increase of the filling. You get rock wool at any home depot or Baumarkt. Cheap and effective, easy to cut, no risk for your health, even as people who want to sell you 5 times as expensive “natural” products, impregnated with tons of fire retardant chemicals, tell you the opposite. Do not compress it, just fill the whole volume.

The simplest and most effective braces are simple slices of MDF or plywood, glued to the walls to form a “T”. Usualy about 5-7cm high, same strength as the wall. I prefer ply to MDF.

If your cabinet has a large driver opening, you can even fit them later. A good construction glue is best if you can not clamp them and do not want to use screws from the outside.

After drying, knocking at the treated wall will give you an impressive idea how dead they sound compared to the bare wall. You will find a lot of information how to set braces and how to dimension them. I use this simple finger test to find the last resonating parts of a cabinet.

Last there is self adhesive heavy foil, sometimes backed with aluminum, as used for damping car doors. The problem is to make it stick permanently, so you should prime the wood. So the best realistic and price sensitive option is to use rock wool, braces and heavy, viscous elastic foil in a combination. You find this in very high priced commercial products only.

You find all three measures in you daily live, everywhere, simply because they work best. So cheap is the best way to go.

For wool, it is a good material to absorb sound energy, but as you realised, not so easy to handle in large cabinets. Second, in a closed cabinets, depending on how it was treated, it can accumulate moisture, which leads to rust on sensitive speaker parts. Sheep are no loudspeakers.

This is caused by people with different interest. Those that sell special materials want you to spent a lot of money. Then, different principles like closed, vented, horn or transmission line need different material at different places. So a place for a lot of Voodoo and confusion.

I stick to the final word of physics in this discussion. If you have a closed bass cabinet, anything fiber or light foam at the walls is not really helping the bass. The most effective thing is to completely fill the volume and brace the walls, period.

As you do not want anything to block sensitive parts of the driver, loose material is not suited. If you insist on it, you have to screen the driver with some cloth, but loose material will concentrate at the bottom over time.

If you want to do the best for sound, increasing the acoustic volume and removing any reflection, you should fill the whole box with rock wool. If for some reason, you don't want it, the second best and more expensive solution, is acrylic wool in sheet form. People often look what they find in the basement and can use for free. Please accept this may not be the best material, even when they later rave about it.

While extending the bass a little and removing any echo inside, this filling does nothing to the walls resonances. You need mass to damp this out or stronger walls. Both will make the bass more "dry" sounding, as you prevent the walls from storing energy and releasing it later. Compare it to an ill tuned vent in the box messing up the bass response.

Best is to do both, complete fill with fibers plus braces at the walls. What you loose in volume by the braces, is over compensated by the 5-10% virtual volume increase of the filling. You get rock wool at any home depot or Baumarkt. Cheap and effective, easy to cut, no risk for your health, even as people who want to sell you 5 times as expensive “natural” products, impregnated with tons of fire retardant chemicals, tell you the opposite. Do not compress it, just fill the whole volume.

The simplest and most effective braces are simple slices of MDF or plywood, glued to the walls to form a “T”. Usualy about 5-7cm high, same strength as the wall. I prefer ply to MDF.

If your cabinet has a large driver opening, you can even fit them later. A good construction glue is best if you can not clamp them and do not want to use screws from the outside.

After drying, knocking at the treated wall will give you an impressive idea how dead they sound compared to the bare wall. You will find a lot of information how to set braces and how to dimension them. I use this simple finger test to find the last resonating parts of a cabinet.

Last there is self adhesive heavy foil, sometimes backed with aluminum, as used for damping car doors. The problem is to make it stick permanently, so you should prime the wood. So the best realistic and price sensitive option is to use rock wool, braces and heavy, viscous elastic foil in a combination. You find this in very high priced commercial products only.

You find all three measures in you daily live, everywhere, simply because they work best. So cheap is the best way to go.

For wool, it is a good material to absorb sound energy, but as you realised, not so easy to handle in large cabinets. Second, in a closed cabinets, depending on how it was treated, it can accumulate moisture, which leads to rust on sensitive speaker parts. Sheep are no loudspeakers.

Last edited:

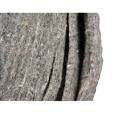

The one you show is a form of compressed rock wool which gives some kind of board. I (and the loudspeaker industry) prefer the looser, softer, more fluffy version. It often comes on rolls. I attached a picture. Do not stuff it, best seems to loosen it up a bit. To much filling reduces the virtual volume instead of increasing it.

Wear a mask and hand protection, even if it does not have long therm effects, it itches and inhaled fibres do not feel good. If you smoke you may not care.

Rock or mineral wool are better than glas wool, that is also around.

Wear a mask and hand protection, even if it does not have long therm effects, it itches and inhaled fibres do not feel good. If you smoke you may not care.

Rock or mineral wool are better than glas wool, that is also around.

Attachments

Looks better. Just cut to pieces that fit well into the whole cabinet. This will prevent any resonance, as the box is large and you run the driver quite high.

No need to glue it to the walls. If you look at the speed of sound in such a cabinet, it is highest in the middle, while it is zero at the wall. Instead at the wall the pressure is high, that is what the braces deal with.

Moving through the wool slows down the speed of sound and moving the particles converts energy into heat.

If you have a vented cabinet and measure the impedance, while putting just a very little fiber material in the port, you will see how much that changes resonances.

A very nice project, I still have a pair of large aluminum horns in storage I want to reactivate some day. A well equalized horn speaker is hard to beat with dynamic music. You hardly get that from passive, conventional speakers.

PS found this https://www.leonmaterials.gr/product-category/%ce%bc%ce%bf%ce%bd%cf%89%cf%84%ce%b9%ce%ba%ce%ac/%ce%bf%cf%81%cf%85%ce%ba%cf%84%ce%bf%ce%b2%ce%ac%ce%bc%ce%b2%ce%b1%ce%ba%ce%b1%cf%82/

No need to glue it to the walls. If you look at the speed of sound in such a cabinet, it is highest in the middle, while it is zero at the wall. Instead at the wall the pressure is high, that is what the braces deal with.

Moving through the wool slows down the speed of sound and moving the particles converts energy into heat.

If you have a vented cabinet and measure the impedance, while putting just a very little fiber material in the port, you will see how much that changes resonances.

A very nice project, I still have a pair of large aluminum horns in storage I want to reactivate some day. A well equalized horn speaker is hard to beat with dynamic music. You hardly get that from passive, conventional speakers.

PS found this https://www.leonmaterials.gr/product-category/%ce%bc%ce%bf%ce%bd%cf%89%cf%84%ce%b9%ce%ba%ce%ac/%ce%bf%cf%81%cf%85%ce%ba%cf%84%ce%bf%ce%b2%ce%ac%ce%bc%ce%b2%ce%b1%ce%ba%ce%b1%cf%82/

Last edited:

These types of rigid plates are typically used to soundproof rooms. I'd be curious to see if they offer the same performance as a batt type would inside of a loudspeaker enclosure. There will be a difference in density between the two types. I believe a lower density batt type damping infill would be preferred to break up a wider range of frequencies. IME higher densities tend to be more reflective in nature.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Asathor - a JBL 4367 Clone