it's really time for an update!

........yep, I was thinking that as well😀

Its coming guys.

Hi ShinOBIWAN

Did you finish the website? I used to use a combination of Dreamweaver, fireworks and Photoshop and mash up a bit of CSS, then Wordpress I now use Muse, got my site up in about a day 8ballaudio.com

Happy to help out if you need it.

Hi ShinOBIWAN

Did you finish the website? I used to use a combination of Dreamweaver, fireworks and Photoshop and mash up a bit of CSS, then Wordpress I now use Muse, got my site up in about a day 8ballaudio.com

Happy to help out if you need it.

I love the look of your "Tall" with the walnut cab and fabric baffle. Nice choices.

Greg

I love the look of your "Tall" with the walnut cab and fabric baffle. Nice choices.

Greg

Thank you, wife friendly 🙂 not something I've seen so wanted to produce a cabinet to blend more easily with our changing decor.

Hi ShinOBIWAN

Did you finish the website? I used to use a combination of Dreamweaver, fireworks and Photoshop and mash up a bit of CSS, then Wordpress I now use Muse, got my site up in about a day 8ballaudio.com

Happy to help out if you need it.

Thanks Adam,

I've got a basic functional shell of a website. The content is lagging behind though so its not particularly interesting right now.

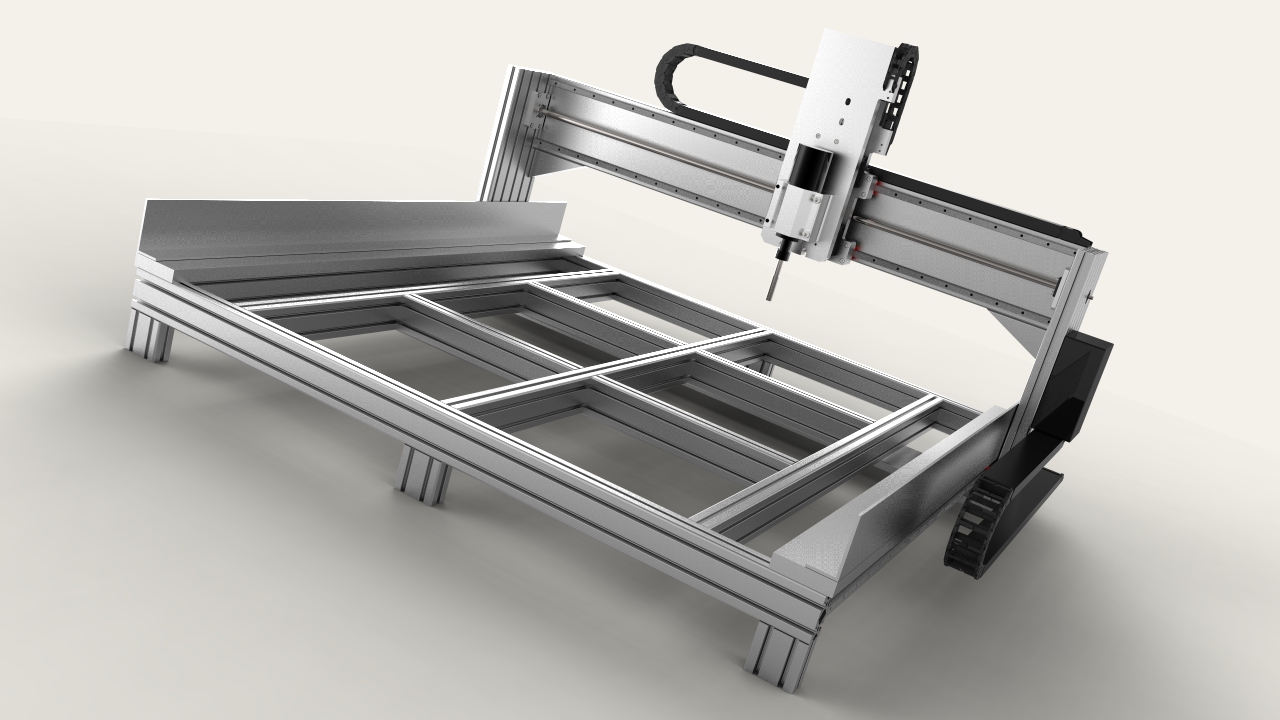

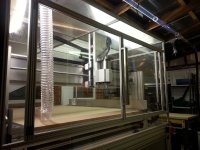

OK this thread is long overdue an update and its not for lack of trying either!

Believe me when I say CNC is a dirty word in this house now. I've been wrestling with it for about a year now and its cost roughly double the original price tag of the cnc to put right all the problem the cowboy manufacturer introduced when he spewed this abomination into being. There is some small justice in that they are now out of business - oh no there goes my warranty!

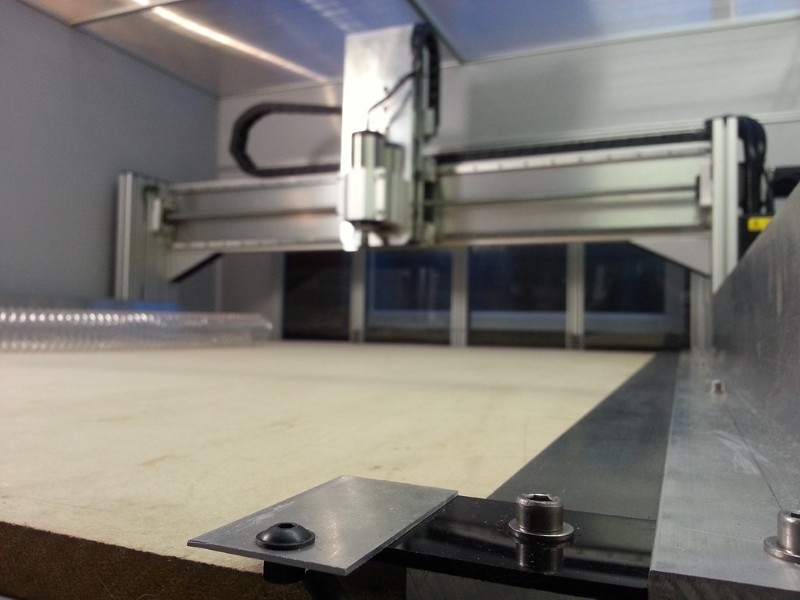

Its been completely rebuilt and there's a huge number of fixes and upgrades along the way. Too many to list but suffice to say its now a competent machine able make absolute mince meat of wood and quite good with harder materials such as steel and alloys.

For the CNC boffins out there. It happily cuts MDF at 6m/min, rapids at upto 12m/min although I prefer to knock it back to 10m/min to leave some margin. Has repeatable accuracy to 0.03mm and acceleration is in the region of 1-1.5m/s^2 depending. Profile rails all around, inductive proximity switches, huge reinforcement throughout the whole machine compared to before and lots of other stuff that cost an arm and a leg! lol Ah well you only live once and if your going to do something then do it right etc.

The machine is with a company near me who specialises in machinery of all kinds but will be back here within a couple of weeks. I'll be posting some vids of it in action shortly after.

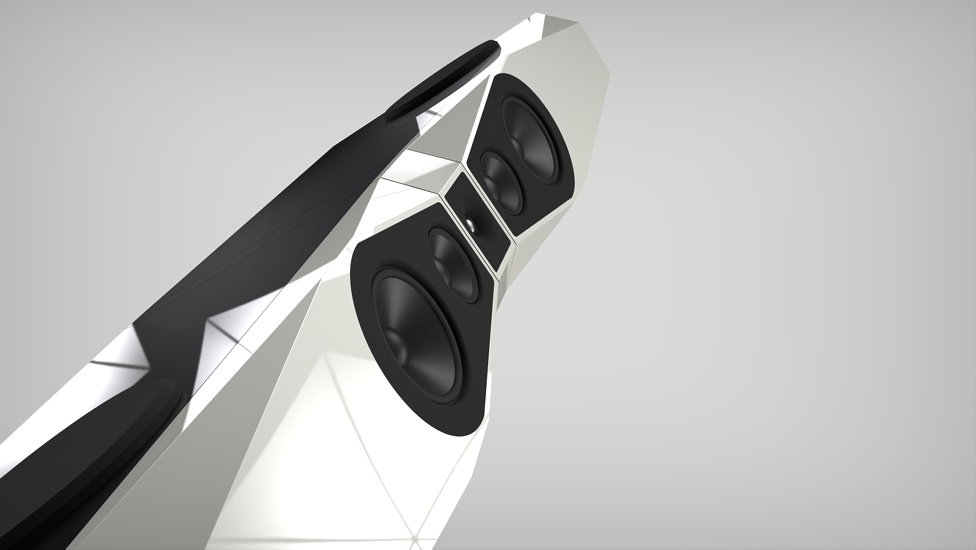

In the meantime here's the obligatory model for the cnc along with a couple more of the Apollo for good measure. I've switched over to using a material called Valchromat instead of MDF and look forward to working with this, its a hybrid of solid surface and fibre based boards such as MDF.

Believe me when I say CNC is a dirty word in this house now. I've been wrestling with it for about a year now and its cost roughly double the original price tag of the cnc to put right all the problem the cowboy manufacturer introduced when he spewed this abomination into being. There is some small justice in that they are now out of business - oh no there goes my warranty!

Its been completely rebuilt and there's a huge number of fixes and upgrades along the way. Too many to list but suffice to say its now a competent machine able make absolute mince meat of wood and quite good with harder materials such as steel and alloys.

For the CNC boffins out there. It happily cuts MDF at 6m/min, rapids at upto 12m/min although I prefer to knock it back to 10m/min to leave some margin. Has repeatable accuracy to 0.03mm and acceleration is in the region of 1-1.5m/s^2 depending. Profile rails all around, inductive proximity switches, huge reinforcement throughout the whole machine compared to before and lots of other stuff that cost an arm and a leg! lol Ah well you only live once and if your going to do something then do it right etc.

The machine is with a company near me who specialises in machinery of all kinds but will be back here within a couple of weeks. I'll be posting some vids of it in action shortly after.

In the meantime here's the obligatory model for the cnc along with a couple more of the Apollo for good measure. I've switched over to using a material called Valchromat instead of MDF and look forward to working with this, its a hybrid of solid surface and fibre based boards such as MDF.

Attachments

Last edited:

Valchromat

Nice. I can't wait to get my hands on some. Doesn't seem to be anywhere in Australia yet.

Following with much interest.

Thanks Adam,

I've got a basic functional shell of a website. The content is lagging behind though so its not particularly interesting right now.

Let me know if you want a hand.

Out of interest what renderer does Solidworks use (I make the assumption your using Solidworks) It looks like V-ray but I could be mistaken.

Let me know if you want a hand.

Out of interest what renderer does Solidworks use (I make the assumption your using Solidworks) It looks like V-ray but I could be mistaken.

Thanks again Adam, I might just take you up on that once I get back to looking at it. Right now I'm itching to build stuff so it could be some time.

The Photoworks render packaged within Solidworks isn't great. Its ok for use to help you visualise a model whilst your working away in solidworks. Its very good for maintaining a smooth workflow like that, just hit the render preview and within seconds you've got an overview. But I can't get on with it when trying to produce good quality images. Its definitely my ineptitude with the software because I've seen some stunning images produced by it.

I get along much better with a package called keyshot and that's what I've used whenever I post images here.

Ah OK.

I haven't really touched Solidworks, I mainly use Sketchup then into Maya and use MentalRay which has a nice library of architectural materials set up that you can tweak.

The materials you use are excellent, very realistic, do you tweak the settings at all?

Keep up the render porn! 😉

I haven't really touched Solidworks, I mainly use Sketchup then into Maya and use MentalRay which has a nice library of architectural materials set up that you can tweak.

The materials you use are excellent, very realistic, do you tweak the settings at all?

Keep up the render porn! 😉

I mostly use the base materials included with the package with some small tweak here and there but do sometimes create new one's if there's nothing in the library that suits the purpose. Mostly your good to go though as there's often something in the same category that can be tweaked to get the desired look.

...

I've switched over to using a material called Valchromat instead of MDF and look forward to working with this, its a hybrid of solid surface and fibre based boards such as MDF.

Shin - nice to see your progress. 😀

Thanks for the info on Valchromat - this is great stuff. 😉

Cheers!

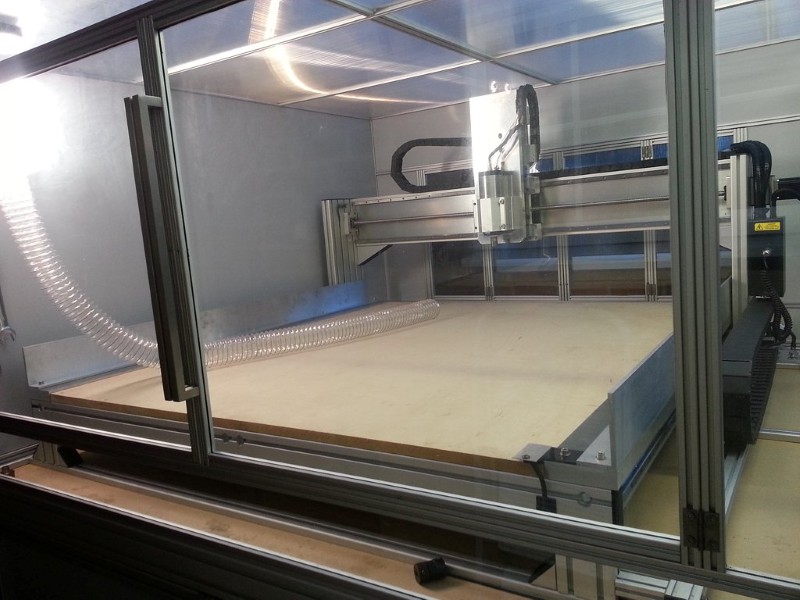

Big update on the CNC. Its now working. Yep hard to believe I know!

Here's a bunch of images showing the highlights of the changes needed to get it in shape.

Workshop:

http://www.diyaudio.com/forums/attachment.php?attachmentid=326727&stc=1&d=1359324618[img]

Couple of cnc images:

[IMG]https://www.diyaudio.com/forums/attachment.php?attachmentid=326718&stc=1&d=1359323333

Bed Reinforcements:

Dust extraction:

Here's a bunch of images showing the highlights of the changes needed to get it in shape.

Workshop:

http://www.diyaudio.com/forums/attachment.php?attachmentid=326727&stc=1&d=1359324618[img]

Couple of cnc images:

[IMG]https://www.diyaudio.com/forums/attachment.php?attachmentid=326718&stc=1&d=1359323333

Bed Reinforcements:

Dust extraction:

Attachments

-

Overview1.jpg146.9 KB · Views: 682

Overview1.jpg146.9 KB · Views: 682 -

extraction2.jpg130.1 KB · Views: 672

extraction2.jpg130.1 KB · Views: 672 -

Extraction1.jpg156.4 KB · Views: 671

Extraction1.jpg156.4 KB · Views: 671 -

Completedcnc3.jpg115.4 KB · Views: 676

Completedcnc3.jpg115.4 KB · Views: 676 -

Completedcnc2.jpg138.6 KB · Views: 684

Completedcnc2.jpg138.6 KB · Views: 684 -

Completedcnc1.jpg133.5 KB · Views: 68

Completedcnc1.jpg133.5 KB · Views: 68 -

Bed Reinforce2.jpg93.4 KB · Views: 680

Bed Reinforce2.jpg93.4 KB · Views: 680 -

Bed reinforce1.jpg95.5 KB · Views: 693

Bed reinforce1.jpg95.5 KB · Views: 693 -

Overview2.jpg132.2 KB · Views: 92

Overview2.jpg132.2 KB · Views: 92

Touch probe for setting work piece height:

Fixed probe plate for semi automatic tool changes:

One of the proximity switches used for homing/limits:

Shuttle jog pad:

Bottom of the cnc base was kinda wasted space so a couple of doors and a floor were added to allow storage of sheets.

Fixed probe plate for semi automatic tool changes:

One of the proximity switches used for homing/limits:

Shuttle jog pad:

Bottom of the cnc base was kinda wasted space so a couple of doors and a floor were added to allow storage of sheets.

Attachments

I made a video for Arthur whom the Apollo are destined for. I'm sure he won't mind me posting it here though. Apologies for sounding confused and bunged up. Its my first time talking to just a camera (felt really weird!) and I hadn't really thought about anything before hitting record so its random to say the least!

Rambling about CNC - YouTube

Rambling about CNC - YouTube

Nice. I can't wait to get my hands on some. Doesn't seem to be anywhere in Australia yet.

Following with much interest.

Hmm. i wonder.

Wish I'd found all this sooner.

Been trying to find hd mdf for the last few months to use in my current speaker project.

Ended up with 32mm mr mdf sent to my cabinet maker.

From this link it suggests its been here since 2006.........

Valchromat solid through colour MDF panels

more here

Valchromat - Investwood - Concept

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Apollo Construction Diary