Hi,

Well, silicone treatment remain as the first option.

Last week, I moved x-o point between subs and Stages woofer panel, from 80 to 125Hz. The problem with buzzing is improved, of course, the sound changed on some way, but this is kind of compromise for now.

The other idea come on my mind. Everyone from this part of forum knows JAMESBOSS and his planar speakers. Let’s suppose that Stages woofer panel is dead (unusable), but we still have perforated metal plate with glued magnets. I believe that it would not be so difficult for average diy person, to make the appropriate frame, stretch plastic foil and fix the aluminum security foil on it, like JAMESBOSS is doing.

What do you think, any suggestions whether this could be closer substitute for original woofer and better option than go to the conventional cone driver (drivers)?

I wonder about sound of that kind of planar, freq. range etc.

Thanks in advance

Well, silicone treatment remain as the first option.

Last week, I moved x-o point between subs and Stages woofer panel, from 80 to 125Hz. The problem with buzzing is improved, of course, the sound changed on some way, but this is kind of compromise for now.

The other idea come on my mind. Everyone from this part of forum knows JAMESBOSS and his planar speakers. Let’s suppose that Stages woofer panel is dead (unusable), but we still have perforated metal plate with glued magnets. I believe that it would not be so difficult for average diy person, to make the appropriate frame, stretch plastic foil and fix the aluminum security foil on it, like JAMESBOSS is doing.

What do you think, any suggestions whether this could be closer substitute for original woofer and better option than go to the conventional cone driver (drivers)?

I wonder about sound of that kind of planar, freq. range etc.

Thanks in advance

As for this Diy silicone fix..........I would never do the hole speaker...only the small spot that buzzed............an add if I needed....

any one that thinks this oily fix is not adding mass to the foil....is dreaming.......I would think there are over tones above a 1000hz come from these foil Bass drivers...

This fix will drop it...say only 100hz... that drop may be to much...but thay still work...hehe

As for making new mylar-foil type driver for the Stage..........yes James setup look good to me..

It works for him....

any one that thinks this oily fix is not adding mass to the foil....is dreaming.......I would think there are over tones above a 1000hz come from these foil Bass drivers...

This fix will drop it...say only 100hz... that drop may be to much...but thay still work...hehe

As for making new mylar-foil type driver for the Stage..........yes James setup look good to me..

It works for him....

Last edited:

tyu, explain to me why the silicone would add mass to the foil? You only put it around the corners, to replace the rotten foam. Spring rate of the suspension may change slightly compared to original with good foam, but I think it's inessential. With rotten foam it's essential, as nothing is controlling the movement of the foil.

Before the silicone, bass was sloppy and weak on my Stages.

DAMIC, what you suggest is a complete new woofer ribbon. It will take alot of work to get good sound, and something nearly as good as the original. The Stage foil was, and still is very advanced and difficult to DIY. Still, I would consider a new ribbon woofer instead of cones. In the end, it might be a very rewarding job even if sound would not be as good as the original. Just keep the original Stage so you can reverse the job if needed.

Dave, do keep us updated how the work proceeds 🙂

Before the silicone, bass was sloppy and weak on my Stages.

DAMIC, what you suggest is a complete new woofer ribbon. It will take alot of work to get good sound, and something nearly as good as the original. The Stage foil was, and still is very advanced and difficult to DIY. Still, I would consider a new ribbon woofer instead of cones. In the end, it might be a very rewarding job even if sound would not be as good as the original. Just keep the original Stage so you can reverse the job if needed.

Dave, do keep us updated how the work proceeds 🙂

The foam in not on the foil..... the oily silicone fix is...........or are you saying you can put the silicone just on the wood part of the frame?........I don't see how this is done....so if as I say an the silicone is on the foil.....an now your saying you have better bass.....well more mass more roll off....but this is not the point...you can not get new foil for the Stages............do what you like... to make them work....great....

Other Apogees..........new foil driver can be had.....

look ...if you have had a pr of Duettas seting around for years not working.....an the frams are not worpet....

you do this silicone fix....................Wow thay work...Wow the buzz stopet....this is all good..........so thay sound diff.....most well not care..or even know..thayll be maken sound...after years......got be a good thing!

I just fell these old Apogee that new foil drivers can be had.. are well worth the cost.... an people should not be put down for thinking this....an well sound better than this fix .................others do what ever..have fun

Other Apogees..........new foil driver can be had.....

look ...if you have had a pr of Duettas seting around for years not working.....an the frams are not worpet....

you do this silicone fix....................Wow thay work...Wow the buzz stopet....this is all good..........so thay sound diff.....most well not care..or even know..thayll be maken sound...after years......got be a good thing!

I just fell these old Apogee that new foil drivers can be had.. are well worth the cost.... an people should not be put down for thinking this....an well sound better than this fix .................others do what ever..have fun

Last edited:

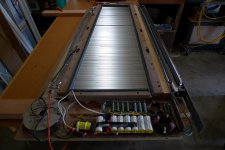

On the Stages an the Centaur .... ....the wire is 16g soild...with these crimp on ends.. that I have found can give the same buzzing sound... as if it was the panels..these ends an the wire can get lose.....an the soiled wire make it look like all is well.....but thay buzz to the beat...........

these plated ends... give the sound a unneeded peak....not just my ears hear this...I have always pull these out of my Apogees.....from my frist pr...

Also the caps are glue or were... with the coils an there zip ties

All this can become buzzzzzzers...........

You may ck this befor moving on to other fixs.....

these plated ends... give the sound a unneeded peak....not just my ears hear this...I have always pull these out of my Apogees.....from my frist pr...

Also the caps are glue or were... with the coils an there zip ties

All this can become buzzzzzzers...........

You may ck this befor moving on to other fixs.....

Attachments

Last edited:

I am the author of the external foam mod contributed to the old Apogee forum some 12 years or so ago. I would like to report since that mod I have not heard one buzz out of my Duettas used in my home theater as the front channels.

If I had my old Duetta Sig today .....I would do this fix in a min....an well do my Stages if I ever need

I could always get the new Graz replaces bass foils. on the Duettas..thanks for your work on this fix.............

but 12 years with the same speaker...for me that would be a feet..........but these old Apogees are just that good.............

I could always get the new Graz replaces bass foils. on the Duettas..thanks for your work on this fix.............

but 12 years with the same speaker...for me that would be a feet..........but these old Apogees are just that good.............

Last edited:

tyu, explain to me why the silicone would add mass to the foil? You only put it around the corners, to replace the rotten foam. Spring rate of the suspension may change slightly compared to original with good foam, but I think it's inessential. With rotten foam it's essential, as nothing is controlling the movement of the foil.

Dave, do keep us updated how the work proceeds 🙂

It doesn't add mass to the foil. It doesn't change the tension or the tuning or any other aspect of the transducer.....unless you deliberately modify those during the process. It simply restores edge damping to an acceptable level......which reduces/eliminates the buzz.

Dave.

As We all know ...............if anyone on earth knows,....how it all works......It you!

So you say......

After all........ in your world.......you did

traded the Caddy for a microphone..... I cant see that....good luck

So you say......

After all........ in your world.......you did

traded the Caddy for a microphone..... I cant see that....good luck

Also, another mis-characterization that was forwarded a few years back was that the silicone fix would harm the speakers in a way that would prevent future full refurbishment with new bass transducers. That discussion was total nonsense also.

Any silicone residue can easily be removed and it will not penetrate the MDF strips that remain. Those strips are rabbeted to create the spot for the original foam and the top (denser) surface of the MDF removed. The underlying MDF surface would sponge effectively certain low viscosity liquids, but not this silicone mixture, if of proper consistency. The whole repair is 100% removable should you eventually decide to go that direction.

Cheers,

Dave.

Any silicone residue can easily be removed and it will not penetrate the MDF strips that remain. Those strips are rabbeted to create the spot for the original foam and the top (denser) surface of the MDF removed. The underlying MDF surface would sponge effectively certain low viscosity liquids, but not this silicone mixture, if of proper consistency. The whole repair is 100% removable should you eventually decide to go that direction.

Cheers,

Dave.

Last edited:

Yes, that's absolutely true.

The silicone oil gets perfectly into the molecular structure of the silicone; the mixture is neither oily nor greasy (like butter or fat). But the 2 components have to be stirred very thoroughly.

This story was told, to prevent DIYers to do the fix (financial reasons of course).

About added mass, for me it's insignificant. Resonance frequency only changed marginal with my duettas, a sign for very small mass changes.

Damping now is perfect. Silicon mixture is extrem soft. Of cource it influences the frequency response, but only in the very high regions where the ribbon already has taken over.

@TYU

You seem very experienced concerning the silicon changes!

The silicone oil gets perfectly into the molecular structure of the silicone; the mixture is neither oily nor greasy (like butter or fat). But the 2 components have to be stirred very thoroughly.

This story was told, to prevent DIYers to do the fix (financial reasons of course).

About added mass, for me it's insignificant. Resonance frequency only changed marginal with my duettas, a sign for very small mass changes.

Damping now is perfect. Silicon mixture is extrem soft. Of cource it influences the frequency response, but only in the very high regions where the ribbon already has taken over.

@TYU

You seem very experienced concerning the silicon changes!

Last edited:

This story was told, to prevend DIYers to do the fix (financial reasons of course).

Really? Is this something in the past as I have seen nothing on this thread to back this up. It would be nice if we could not dig up some old fight from 5 years ago and stay in the present.

About added mass, for me it's insignificant. Resonance frequency only changed marginal with my duettas, a sign for very small mass changes.

Has anyone compared factory fresh foam with silicon? I guess not (and never will) so there is no way of telling how significant it is. It would be very interesting to find this out.

Damping now is perfect. Silicon mixture is extrem soft. Of cource it influences the frequency response, but only in the very high regions where the ribbon already has taken over.

Measurements?

Also, another mis-characterization that was forwarded a few years back was that the silicone fix would harm the speakers in a way that would prevent future full refurbishment with new bass transducers. That discussion was total nonsense also.

Ok, past again. In the present I have not seen that. It will increase the cost of a refurb as the installer will have to remove it, but unless I misread Groove T he didn't say he would refuse to do a foil replacement in this case ( for the odd Swiss Apogee owner that would try it).

Can we agree that there ARE people who might not understand the instruction and mess things up royally as well? For every craftsman there are a few who would just wield a caulking gun. And I think its that variation in abilities that causes the friction not anything else. At least here in the present. I wasn't there for the great Apogee forum wars!

Just to repeat: I love it that people are willing to get hot under the collar over a speaker from a company that died 20 years ago!

It will increase the cost of a refurb as the installer will have to remove it....

No, it won't. In fact, I think it would make the removable process easier by (sort of) coagulating the old foam.

This removal process is a bit tedious and time-consuming in any case since the original glue and remnants of the ribbon pieces that are underneath the clamps need to be scraped/pulled/ground/etc away to yield a clean surface for a new woofer installation. Relatively speaking, a foam repair will not yield any extra work at all.

Cheers,

Dave.

@TYU

You seem very experienced concerning the silicon changes!

No I have not had to use the Fix.......What you say is not proof to me....I pulled the Bars off my Minors MT ribbon.... one of the best thing Sound wise I have ever done to any speaker.....But where the proof for you are others.....

.But I have done a lot of mods on my Stages unbuzzzing bass panels...an just putting new foam on the top an bottem Mdf runs....changed the tone...So for ME the fixs Added mass... at my house ...well change the sound.....

still I would do the Fix if there no were to go with Stages..............hehe...glad it works for you....

You seem very experienced concerning the silicon changes!

No I have not had to use the Fix.......What you say is not proof to me....I pulled the Bars off my Minors MT ribbon.... one of the best thing Sound wise I have ever done to any speaker.....But where the proof for you are others.....

.But I have done a lot of mods on my Stages unbuzzzing bass panels...an just putting new foam on the top an bottem Mdf runs....changed the tone...So for ME the fixs Added mass... at my house ...well change the sound.....

still I would do the Fix if there no were to go with Stages..............hehe...glad it works for you....

Last edited:

I am the author of the external foam mod contributed to the old Apogee forum some 12 years or so ago. I would like to report since that mod I have not heard one buzz out of my Duettas used in my home theater as the front channels.

Yes indeed. I remember that excellent repair procedure as well. 12 years and still working well. How about that! 🙂

Will had the idea of attaching weatherstripping on the side portions of the top pieces such that the edge contacted the ribbons and restored some edge damping. This didn't address the rear face of the transducer, but seemingly the damping on the front effectively provided a decent percentage of "fix."

Dave.

No, it won't. In fact, I think it would make the removable process easier by (sort of) coagulating the old foam.

Fairy nuff. Never done that so had assumed there was a solvent that would dissolve the glue off the old foam. If its good old fashioned elbow grease that changes things.

Really? Is this something in the past as I have seen nothing on this thread to back this up. It would be nice if we could not dig up some old fight from 5 years ago and stay in the present.

Who wants to fight?

Has anyone compared factory fresh foam with silicon? I guess not (and never will) so there is no way of telling how significant it is. It would be very interesting to find this out.

Unimportant to me, concerning the fact, that I have nice speakers at home, which are absolutely not enjoyable.

Who cares about factory state then? I don't!

To each its own.

Measurements?

I did, else I wouldn't mention it.

Burried on a dyed HD.

But I can tell you, what I used and how I measured:

Behringer DCX2496 as a source for pink noise

Calibrated measuring microphone

Pointing mike towards the lower part of the foil from very nearfield (some inches away)

If my mind serves me well, I measured the strongest peak arround 34Hz

Did this before and after

A lot of people here try to argue, without having own practical experiences...

Last edited:

Bill, if you ever removed this terrible sticky, crumbled old foam and its glue?

Read what Davey says, he did.

A lot of people here try to argue, without having own practical experiences...

As I just posted I haven't. And probably never will. I have however refoamed cone units and there most people use solvent to take the glue off. I jumped to a conclusion, Davey corrected me, all is good. I am not trying to argue. I have never seen a group of people closer to violent agreement! Just trying to tease the facts out so we all end up understanding more.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Apogee Stage – substitute for woofer panel, ideas/suggestions