Watch out with the GU81s- sockets are pricey, and I have to wonder how long these tubes will remain available. Not very helpful for a push-pull project either, but probably would make a killer HF amp.

Also, can anyone comment on the recent crop of 572Bs? As I understand it the Chinese tubes have gotten a lot better in the last five or ten years. Keep in mind that this is going to be an easier life than what most of these tubes are being used for. RF parts and DX Engineering are both selling 572Bs. These will probably have additional QC above what the regular Chinese tubes get.

You may also want to look at the 805 tube, also in production. This isn't a "zero bias" tube, so it may be more suitable.

Also, can anyone comment on the recent crop of 572Bs? As I understand it the Chinese tubes have gotten a lot better in the last five or ten years. Keep in mind that this is going to be an easier life than what most of these tubes are being used for. RF parts and DX Engineering are both selling 572Bs. These will probably have additional QC above what the regular Chinese tubes get.

You may also want to look at the 805 tube, also in production. This isn't a "zero bias" tube, so it may be more suitable.

Some random thoughts..... I've had in mind a 813 PP project for a few years, & have been collecting the parts for it now and again. I have several good 813's and recently bought two big 500VA 240v/12v - big ampage (can't remember exact figure) tfmrs to rewind into OPT's. The idea behind this amp build is to build it for fun and as a design challenge, not because I need 500w.

Here's a few thoughts I've had on building big valve amps... first off it would be easier to build such an amp if we limit it's frequency range to drive the low end of things, so I'm thinking bi or tri amping, makes winding an OPT easier if we don't have to worry about HF. Having two OPT's one for the lows, one for the high's makes winding less problematic.

Regarding the power supply I have a big 1000VA toroid, so winding by hand is possible. Rather than wind one EHT winding I'd wind several lower voltage windings stacked on top of another, each properly insulated from it's neighbor of coarse, see attached. This makes finding caps easier too. Double insulated wire is easily available.

For the OP stage heaters I'd like to experiment with SMPSU's to keep weight down, but harmonics may make this untenable. Re weight, we'd have to build a separate PSU. I built a stereo 120w amp and struggled to lift it, so the PSU has to be separate. As EHT rated interconnects are rare and very expensive it makes sense to house amps and PSU's in a 19" rack on wheels, PSU hard wired to the amps.

The PSU and amps will have to have several protection circuits built in and insulation considerations have to be in the forefront of our heads, EHT PSU housing has to be double insulated and sealed, no open type construction as is usual.

Having waffled on about EHT PSU's it actually makes sense and it's cheaper in some respects to parallel multiple valves, than use two or more big valves. No EHT needed, less turns on the OPT. Every stage added brings down Z pri so we can wind with thicker gauge wire too.

The whole thing will need cooling too, but ultra quiet PC fans are readily available. Lastly to drive the OP stage either anode choke loads or some sand is going to be needed, but haven't got that far in thinking just yet.

Here's a few thoughts I've had on building big valve amps... first off it would be easier to build such an amp if we limit it's frequency range to drive the low end of things, so I'm thinking bi or tri amping, makes winding an OPT easier if we don't have to worry about HF. Having two OPT's one for the lows, one for the high's makes winding less problematic.

Regarding the power supply I have a big 1000VA toroid, so winding by hand is possible. Rather than wind one EHT winding I'd wind several lower voltage windings stacked on top of another, each properly insulated from it's neighbor of coarse, see attached. This makes finding caps easier too. Double insulated wire is easily available.

For the OP stage heaters I'd like to experiment with SMPSU's to keep weight down, but harmonics may make this untenable. Re weight, we'd have to build a separate PSU. I built a stereo 120w amp and struggled to lift it, so the PSU has to be separate. As EHT rated interconnects are rare and very expensive it makes sense to house amps and PSU's in a 19" rack on wheels, PSU hard wired to the amps.

The PSU and amps will have to have several protection circuits built in and insulation considerations have to be in the forefront of our heads, EHT PSU housing has to be double insulated and sealed, no open type construction as is usual.

Having waffled on about EHT PSU's it actually makes sense and it's cheaper in some respects to parallel multiple valves, than use two or more big valves. No EHT needed, less turns on the OPT. Every stage added brings down Z pri so we can wind with thicker gauge wire too.

The whole thing will need cooling too, but ultra quiet PC fans are readily available. Lastly to drive the OP stage either anode choke loads or some sand is going to be needed, but haven't got that far in thinking just yet.

Attachments

Last edited:

There is a good way to do HV interconnects. Take a look at how Glassman high voltage power supplies do it. It uses a UHF connector modified so that the center conductor makes contact about 3-10" inside the chassis. You then use a piece of RG-213 cable. Make sure you get the stuff with a solid polyethylene dielectric (rather than foam). This is about the only way to do HV connections that isn't ridiculously dangerous.

I should note that this is not an idiot-proof connector, since someone could hypothetically power up the power supply and touch the center conductor when the cable is disconnected, but when in use it is solid and will not arc. This is the only sensible HV connector I have seen so far.

I should note that this is not an idiot-proof connector, since someone could hypothetically power up the power supply and touch the center conductor when the cable is disconnected, but when in use it is solid and will not arc. This is the only sensible HV connector I have seen so far.

Attachments

Watch out with the GU81s- sockets are pricey, and I have to wonder how long these tubes will remain available. Not very helpful for a push-pull project either, but probably would make a killer HF amp.

Also, can anyone comment on the recent crop of 572Bs? As I understand it the Chinese tubes have gotten a lot better in the last five or ten years. Keep in mind that this is going to be an easier life than what most of these tubes are being used for. RF parts and DX Engineering are both selling 572Bs. These will probably have additional QC above what the regular Chinese tubes get.

You may also want to look at the 805 tube, also in production. This isn't a "zero bias" tube, so it may be more suitable.

The DXE 572b tubes got great reviews but are now marked as unavailable, not sure if that is temporary or permanent. The RFP tubes seem to get mixed reviews. The far east RF-scale power tubes seem to have gotten a lot better in a relative sense, from where they'd started, but that's not hard, and any indications that I have found still seem to indicate that reliability (or even consistency) is a pale shadow of the former originals. Unlike receiving tubes, the failures can be spectacular with internal elements collapsing into one another and taking out not only the tube itself but also other costly circuit components. I say this as someone who is keeping a very active eye out for some good spare 572b tubes to acquire and set aside as extras for a TenTec 411 Centaur HF amp.

Watch out with the GU81s- sockets are pricey, and I have to wonder how long these tubes will remain available. Not very helpful for a push-pull project either, but probably would make a killer HF amp.

The GU81 sockets are odd and are pricey compared to many other sockets, but with how cheap the tubes are, compared to their ratings, if it's a long-run keeper, you'd not be doing badly. For audio applications it would almost be hard to place stress on a GU81. Long run availability of any very large tubes other than maybe 3-500z's is a huge question mark- the 3-500z is likely to stay available longer than most simply because it is so widely used. 811A is probably another that won't go entirely away for a long time, for the same reason, although, again, quality is a bigger question.

... Also, can anyone comment on the recent crop of 572Bs? ...

They are probably okay as 811A's in a vertical mount.

I notice RF Parts has 572B that are vertical only, and some that can be used horizontal. AFAIK, all real 572B or 811A can be used either way. That suggests to me that QC on the new stuff is dismal.

As stated, a plate to grid short in one of these things and you can have a real bad day, real fast. No way I would use any of the new tubes in something like my 30L-1, even if they were rated for horizontal use.

The time to lay in a good stock of 572B's was about ten to fifteen years ago. I have read / heard the last bunches of U.S. made Cetron ( Richardson ) 572B and 811A were not all that great. All of my NOS U.S. 572B predate that era, but all of my U.S. made NOS 811A are the Richardson tubes. There are still some NOS Ryazan 811A floating around. My experience with these sold under the real St. Petersburg Svetlana brand is very good. If I had something that used 811A, and didn't have a good stock of 811A or 572B already, I would probably be getting the Ryazan tubes while I could.

I have not heard great things about Richardson tubes. Several people at the lab have expressed some significantly negative opinions about the lifespan and reliability of the Ignitrons that Richardson has made.

I suspect that in audio service the current crop of 572Bs would hold up fine. They are mounted vertically and probably won't be pushed to the bleeding edge nearly as often. The one thing to watch out for is that some tubes will become gassy if they are not run hard regularly. I believe the 3-500Z is one of those, I do not know if that is the case with the 572B.

I have no experience with the current crop of 805s, but that may be another tube to look at- lower mu may be a better fit for audio service and I would expect that the reliability would be better as well.

What I have heard, which may be a load of crap, is that the large Chinese tubes have gotten a lot better within the last year.

Not to sidetrack things too much, but has anyone here run a GU81 in RF service? I've looked at them with interest. At 700W plate dissipation I would expect you could get legal limit out of a single tube.

I suspect that in audio service the current crop of 572Bs would hold up fine. They are mounted vertically and probably won't be pushed to the bleeding edge nearly as often. The one thing to watch out for is that some tubes will become gassy if they are not run hard regularly. I believe the 3-500Z is one of those, I do not know if that is the case with the 572B.

I have no experience with the current crop of 805s, but that may be another tube to look at- lower mu may be a better fit for audio service and I would expect that the reliability would be better as well.

What I have heard, which may be a load of crap, is that the large Chinese tubes have gotten a lot better within the last year.

Not to sidetrack things too much, but has anyone here run a GU81 in RF service? I've looked at them with interest. At 700W plate dissipation I would expect you could get legal limit out of a single tube.

I think any 811 or 572 tube where they say you can horizontal mount would probably better off vertical.

If I were using low efficiency speakers then 811a or 572b would be my choice. I had an amplifier with 811a push pull back when I was younger and would still do it if my preference was not for horns as low as I can have them.

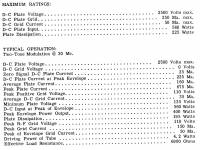

I would go with a copy of the Altec 1570B and maybe go mosfet drive instead of the 6w6 tubes. You want to get a smaller mosfet that has a little less gate capacitance if you do.

What do you have for speakers and do you plan to bi-amp? Output transformer gets a little easier if you are skipping the first two octaves.

If I were using low efficiency speakers then 811a or 572b would be my choice. I had an amplifier with 811a push pull back when I was younger and would still do it if my preference was not for horns as low as I can have them.

I would go with a copy of the Altec 1570B and maybe go mosfet drive instead of the 6w6 tubes. You want to get a smaller mosfet that has a little less gate capacitance if you do.

What do you have for speakers and do you plan to bi-amp? Output transformer gets a little easier if you are skipping the first two octaves.

Man, the new Chinese 805s feel rather impressive. They are rather heavy compared to an old stock American 805 and the glass is visibly significantly thicker.

The 1570 is a cool amp, definitely worth cloning (with a bigger OPT).

The 1570 is a cool amp, definitely worth cloning (with a bigger OPT).

You can't beat the Gotham amp and a Grampian cutterhead for mono disk recording on a variable pitch Scully lathe......the Gotham amp used 3B28 gas rectifiers for the HT supply...The power supply was separate from the power amplifier...

H713 my 811a amplifier had a separate power supply with a regular UHF connector.

My dad gave me flack about it though I know at one time he had a 4000v 1A power supply for something like a 4-400 power amplifier

Was for maybe 80 or 160 meters having the same sort of connector.

My dad gave me flack about it though I know at one time he had a 4000v 1A power supply for something like a 4-400 power amplifier

Was for maybe 80 or 160 meters having the same sort of connector.

Try to mount those directly heated tubes vertical if possible. Filament sag is bad news with horizontally mounted 8005's like in the MI200 McIntosh amp. Filament craps out, pieces of filament short to grid, worst case small piece of filament gets to the anode.

Element sag was a big problem in transmitters and amplifiers using horizontally mounted power tubes. Big problem with EL34's in particular. The rectifier tubes (5U4, 5R4GY, etc.) didn't take to horizontal mounting well. Output tubes such as the 833A, 4-400A, 3CX2500F3, and all of the water cooled tubes (207, 891, etc.) required vertical mounting, along with all of the mercury vapor or gas rectifier tubes...One common modification was to take an elbow (plumbing fitting), male and female (octal or 4 pin) socket fittings to make a 90 deg fitting to convert to vertical mount....

Element sag was a big problem in transmitters and amplifiers using horizontally mounted power tubes. Big problem with EL34's in particular. The rectifier tubes (5U4, 5R4GY, etc.) didn't take to horizontal mounting well. Output tubes such as the 833A, 4-400A, 3CX2500F3, and all of the water cooled tubes (207, 891, etc.) required vertical mounting, along with all of the mercury vapor or gas rectifier tubes...One common modification was to take an elbow (plumbing fitting), male and female (octal or 4 pin) socket fittings to make a 90 deg fitting to convert to vertical mount....

...the 3-500z is likely to stay available....

OMG! Party! That will break the lease!

Attachments

H713 my 811a amplifier had a separate power supply with a regular UHF connector.

My dad gave me flack about it though I know at one time he had a 4000v 1A power supply for something like a 4-400 power amplifier

Was for maybe 80 or 160 meters having the same sort of connector.

Eh... I've seen them arc. Not saying it can't work, but I'm not as comfortable with it. Maybe at 1200 V it would be okay, but much over that and I wouldn't trust it. Those modified connectors (not sure what they get called- I always referred to them as a "deepwell" HV connector) are easy enough to make and seem to be as safe as an HV connector can be realistically made. No matter what it won't be idiot proof. There is no such thing as an idiot-proof 2 kV 1A power supply, but it's important to do what is possible to minimize the danger.

I should note that RG-213 with a solid PE dielectric will usually hold off well in excess of its rating. I've seen it used at 60 kV before without issue. That said, I don't recommend using it that high. As a side note, the stuff with the foam dielectric does not hold of anywhere close to that kind of voltage.

Last edited:

I built an 811a audio amp { Grampian 100watt ] for a friend used Russian 811a’s he used it for 20 years, same tubes, then decide he preferred 572’s, the Chinese one’s lasted 18 months. The Russian 811a’s were still good.

Later versions of the Chinese 572 have so far lasted 4 years.

Later versions of the Chinese 572 have so far lasted 4 years.

There is no such thing as an idiot-proof 2 kV 1A power supply

It's called an "idiot poof" power supply.

I built an 811a audio amp { Grampian 100watt ] for a friend used Russian 811a’s he used it for 20 years, same tubes, then decide he preferred 572’s, the Chinese one’s lasted 18 months. The Russian 811a’s were still good.

Later versions of the Chinese 572 have so far lasted 4 years.

The early Chinese 572Bs were hot garbage from what I've heard. I know several people who had them poof within three months in RF service. It seems as though people at that factory have gotten their act together recently, since I haven't heard nearly as many complaints.

Nice for the info so far.

It's very helpful on making decisions.

That GU-81 tube looks rather nice also. 😱 what a beast. It's cheaper and can handle a lot more.

Plate voltage could be around the same but as a first estimate the Ra-a for the OPT can be a little less, so easier to wind.

Needs a stable 600v for the G2.

But with the same voltage of around 1.8kv it could do close to 1kw I think.

It can handle 450w continues plate dissipation so bias could be high.

one of those antek transformers could almost deliver the needed filament current. (gu-81 needs 12.6v and 11A, antek toroid delivers only 10A). could use 2 of those transformers for one monoblock. Don't know if the extra 1A for the filament would be a big problem as the HV of the transformers would be overkill.

I will not use MV rectifiers as I think that is really dangerous in a living room.

What about the 3b28? uses xenon and doesn't need a warm up time..... doesn't look to bad.

Thanks for the HV connector tip. I have seen this a lot on RF amps with 5kv supplies....

Another option would be to get everything in one chassis.

Gonna have to search to find some fuses rated for that voltage also.

And a last thing, it would be easier to drive as it is not a zero grid bias tube

Could be a better choice maybe?

It's very helpful on making decisions.

That GU-81 tube looks rather nice also. 😱 what a beast. It's cheaper and can handle a lot more.

Plate voltage could be around the same but as a first estimate the Ra-a for the OPT can be a little less, so easier to wind.

Needs a stable 600v for the G2.

But with the same voltage of around 1.8kv it could do close to 1kw I think.

It can handle 450w continues plate dissipation so bias could be high.

one of those antek transformers could almost deliver the needed filament current. (gu-81 needs 12.6v and 11A, antek toroid delivers only 10A). could use 2 of those transformers for one monoblock. Don't know if the extra 1A for the filament would be a big problem as the HV of the transformers would be overkill.

I will not use MV rectifiers as I think that is really dangerous in a living room.

What about the 3b28? uses xenon and doesn't need a warm up time..... doesn't look to bad.

Thanks for the HV connector tip. I have seen this a lot on RF amps with 5kv supplies....

Another option would be to get everything in one chassis.

Gonna have to search to find some fuses rated for that voltage also.

And a last thing, it would be easier to drive as it is not a zero grid bias tube

Could be a better choice maybe?

The 3b28 does need a warmup of at least 20 seconds. They look nice though you have to expect them to flicker a little. Sort of like looking at a string of LED Christmas lights that have poor line filtering.

- Home

- Amplifiers

- Tubes / Valves

- Anyone tried 572b in PP (High Voltage 1500-2000v)