How do you reuse?I will corrugate the bass panels but the mid/twt ribbons get cleaned and reused

Usually when you replace you damage the very delicate tails removing them from the double sided tape.

Also are you re corrugating the MRT?

Acetone and it wasn’t fun either. There was a slight crinkle on the back side twt and I

will either stretch it slightly or first try and fix the area the best I can. At the worst just buy new

If I can find some .0005” foil that is tempered then it would make sense to redo them all but not sure where

I can find a fine pitch corrugator

here’s a picture I found years ago that would be ideal. This might have been a member on diyaudio

but it’s been a long time since then -

will either stretch it slightly or first try and fix the area the best I can. At the worst just buy new

If I can find some .0005” foil that is tempered then it would make sense to redo them all but not sure where

I can find a fine pitch corrugator

here’s a picture I found years ago that would be ideal. This might have been a member on diyaudio

but it’s been a long time since then -

Attachments

Yeah new ribbon would be much better.Acetone and it wasn’t fun either. There was a slight crinkle on the back side twt and I

will either stretch it slightly or first try and fix the area the best I can. At the worst just buy new

If I can find some .0005” foil that is tempered then it would make sense to redo them all but not sure where

I can find a fine pitch corrugator

here’s a picture I found years ago that would be ideal. This might have been a member on diyaudio

but it’s been a long time since then -

If you have damaged the small tails that wrap round to the opposite side of the mounting point it makes like for like replacement impossible.

The price of the MRT ribbons is quite reasonable.

Bass on the other hand is quite a different story.

Risky business

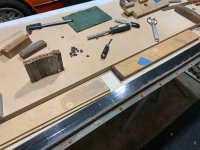

To get to the minus return strips properly so I can replace with copper foil and get rid of the rust at the same time,

decided to split the magnet sections.

They are in attraction and best way was to support the magnet width first and remove the allen screws on one side and pull straight up

like a hinge on top of those rectangular support posts

Putting it back will be another challenge..

To get to the minus return strips properly so I can replace with copper foil and get rid of the rust at the same time,

decided to split the magnet sections.

They are in attraction and best way was to support the magnet width first and remove the allen screws on one side and pull straight up

like a hinge on top of those rectangular support posts

Putting it back will be another challenge..

Attachments

Why bother replacing the AL foil returns?

The difference is insignificant and it allows AL-AL connections.

The difference is insignificant and it allows AL-AL connections.

I plan on soldering the connections instead of the bolt & stainless steel washer interface

plus I have 3X wider copper foil than the stock .0035” alum. strip so why not while I,m

there getting rid of all that rust ?

I think Clarisys does the same thing from pictures of certain models so I’ll follow their

example

plus I have 3X wider copper foil than the stock .0035” alum. strip so why not while I,m

there getting rid of all that rust ?

I think Clarisys does the same thing from pictures of certain models so I’ll follow their

example

Fair enough.

The MRT was previously installed so it was under just the right amount of tension and then trimmed at the connection points at both ends.

How do you intend to solder to the refurbished ribbon?

I would expect you will have no spare ribbon to play with.

Also don’t forget Lenz’s law……

The MRT was previously installed so it was under just the right amount of tension and then trimmed at the connection points at both ends.

How do you intend to solder to the refurbished ribbon?

I would expect you will have no spare ribbon to play with.

Also don’t forget Lenz’s law……

The first 1 ohm pair I rebuilt had extremely loose mids and twts (post#236 pics) and the only

consequence was at first very brash sounding for a few hours then plateauing down and then

continued smoothing out over the next 80 hours or so.

After material relaxation from playing they became smooth as silk and fatigue free ever since

I will have to check my notes but I think I used 60 grams on the mid and 40 on each twt section

and lost about 2 inches in length so IMO these can be stretched and reused- just play them hard

and they come around just fine

consequence was at first very brash sounding for a few hours then plateauing down and then

continued smoothing out over the next 80 hours or so.

After material relaxation from playing they became smooth as silk and fatigue free ever since

I will have to check my notes but I think I used 60 grams on the mid and 40 on each twt section

and lost about 2 inches in length so IMO these can be stretched and reused- just play them hard

and they come around just fine

- Home

- Loudspeakers

- Planars & Exotics

- Anyone making Apogee bass panels?