Warning: Noob questions incoming. I'm planning on investing quite a bit of time and effort into the construction of a beautiful cabinet, so I need some help deciding on the material. When it comes to MDF, I'm a bit concerned about it absorbing moisture from the air over time or that the construction might not be as strong as plywood and could get wobbly over the years. Plywood should be a superior choice in that regard, but I'm unsure how its lesser density and uniformity affect performance.

If I go with MDF, would applying a sealant on the inside and veneers and finish on the outside seal it hermetically, making it last longer? I'm planning on keeping the speakers for a really long time, so longevity and build quality are important factors to me. Perhaps I'll even fit Anthology III inside the enclosure in the distant future 🙃.

Also, how difficult is it to maintain the speaker and replace the dampening on the inside, since it's probably the first thing that will rot out over the years? Another question I have is regarding the slightly rounded edges that are on most of the Anthology builds. How would the speaker fare without the roundover? I've read that the roundover is too small to have a significant effect on refraction, but I figured it would be best to ask you guys.

Thank you for reading!

If I go with MDF, would applying a sealant on the inside and veneers and finish on the outside seal it hermetically, making it last longer? I'm planning on keeping the speakers for a really long time, so longevity and build quality are important factors to me. Perhaps I'll even fit Anthology III inside the enclosure in the distant future 🙃.

Also, how difficult is it to maintain the speaker and replace the dampening on the inside, since it's probably the first thing that will rot out over the years? Another question I have is regarding the slightly rounded edges that are on most of the Anthology builds. How would the speaker fare without the roundover? I've read that the roundover is too small to have a significant effect on refraction, but I figured it would be best to ask you guys.

Thank you for reading!

I use the constrained layer approach that’s discussed in the video, it makes a really dead panel. I use 1/2” MDF with 1/2” ply on the outside and sound absorbing glue to hold them together. Sometimes I make three layers and use thick 1/4” veneer on the exterior. But, if I had to choose one material it would be good birch plywood, not the cheap stuff! Plywood or MDF will last a long time without any finish, but I recommend using a polyurethane top coat to seal the box from water and stains. If you live in a humid climate without air conditioning then you might want to finish the inside of the enclosures too, it can’t hurt. As a furniture maker I can say that wood, regardless of the finish, will expand and contract with the seasons.Warning: Noob questions incoming. I'm planning on investing quite a bit of time and effort into the construction of a beautiful cabinet, so I need some help deciding on the material. When it comes to MDF, I'm a bit concerned about it absorbing moisture from the air over time or that the construction might not be as strong as plywood and could get wobbly over the years. Plywood should be a superior choice in that regard, but I'm unsure how its lesser density and uniformity affect performance.

If I go with MDF, would applying a sealant on the inside and veneers and finish on the outside seal it hermetically, making it last longer? I'm planning on keeping the speakers for a really long time, so longevity and build quality are important factors to me. Perhaps I'll even fit Anthology III inside the enclosure in the distant future 🙃.

Also, how difficult is it to maintain the speaker and replace the dampening on the inside, since it's probably the first thing that will rot out over the years? Another question I have is regarding the slightly rounded edges that are on most of the Anthology builds. How would the speaker fare without the roundover? I've read that the roundover is too small to have a significant effect on refraction, but I figured it would be best to ask you guys.

Thank you for reading!

The damping on the inside won’t need any maintenance if you use fiberglass or rock wool. If you use lambs wool or other natural fibers you can get pests in your speakers and things will grow in there. Just use fiberglass or acoustistuff.

The slightly rounded edges are a purely esthetic choice, it looks nice. At 1,000hz you need a 3” or larger round over, to cover the midrange you would need massive round overs. It’s pointless unless you are making a sphere. You can have sharp edges if you want. I’ve found it’s better to treat the listening room, stop the first reflection by using draperies and put down a good carpet.

Warning: Noob questions incoming. I'm planning on investing quite a bit of time and effort into the construction of a beautiful cabinet, so I need some help deciding on the material. When it comes to MDF, I'm a bit concerned about it absorbing moisture from the air over time or that the construction might not be as strong as plywood and could get wobbly over the years. Plywood should be a superior choice in that regard, but I'm unsure how its lesser density and uniformity affect performance.

Plywood is stiffer in bending and the superior engineering material in that some passenger carrying aeroplanes are made out of plywood. I certainly wouldn't want to fly in an aeroplane made out of MDF! In truth both materials can be used to make high quality speaker cabinets if the design works with their material properties. Neither material has sufficient internal damping for a high quality cabinet and this needs to be added either by extensional or constrained layer damping (the latter is better if properly designed). Perhaps the best wooden material in terms of high strength and high damping is compressed resin soaked plywood which they used to use for making tanks. It is unfortunately very expensive and rapidly blunts tools.

Also, how difficult is it to maintain the speaker and replace the dampening on the inside, since it's probably the first thing that will rot out over the years?

Taking the woofers out usually gives sufficient access to the damping material and crossovers. Might be worth checking the crossover size to be sure. As mentioned above modern synthetic materials tend to last much longer than many of the materials commonly used in the past.

Another question I have is regarding the slightly rounded edges that are on most of the Anthology builds. How would the speaker fare without the roundover? I've read that the roundover is too small to have a significant effect on refraction, but I figured it would be best to ask you guys.

The baffle dimensions are important but with the edges that far from the drivers small roundovers are unlikely to significantly alter the size of the bumps and dips due to diffraction off the baffle edges.

High quality Plywood Beech. Not birch.

Mdf is too soft (also with bracing) and will absorbed some tiny cone movements that ought to be making it to your ears not cabinet.

1. Delignit Tankwood -Best

2. Plywood Beech

3. Plywood birch

4. Mdf

5. Particle board

Mdf is too soft (also with bracing) and will absorbed some tiny cone movements that ought to be making it to your ears not cabinet.

1. Delignit Tankwood -Best

2. Plywood Beech

3. Plywood birch

4. Mdf

5. Particle board

There are several manufacturers around making similar products so not really.Delignit Tankwood -Best

Permali in the uk fx.

Thanks you all for a bunch of replys <3 So nice to run into such a wonderful and helpful community!

@noamgeller How come Beech? I've seen it in stores, but never looked at it twice since everyone is raving on about birch wood

@noamgeller How come Beech? I've seen it in stores, but never looked at it twice since everyone is raving on about birch wood

Beech and oak are some of the more dense woods. Beech has a higher density then birch making it heavier. Depending on the plywood quality you get of course.How come Beech?

The Tankwood is being made from Beech plywood and resin.

Mdf is nothing more the compressed paper.

Tankwook made by the German company Delignit is the best from what I know. There are other companies in the Uk and Poland, but from what I understand they are not as good.

Of course, bracing is extremely important as well.

Paper is made from wood.Mdf is nothing more the compressed paper.

MDF is nothing more than compressed wood.

MDF is significantly denser than plywood, but not as stiff.

Density and stiffness both matter.

Lots of tradeoffs in speaker building.

The old wood material game ... I actually measured it and the differences are surprisingly small:

These are all methodes to give a very good cabinet.

The wider the radius the lower does it work - and the wider the baffle you get difraction at lower frequencies already. But you also have a lot of space for roundovers with a wide baffle, so just do it and one problem less in speaker design.

A carpet or draperies ... only help for very high frequencies. Not for 1-3kHz where you will get big influences from corners. So no, it needs a proper absorber to influence these.

You can also use 2mm iron sheet on the inside and use flexible wood floor glue. Greenglue would be perfect but more epensive. Or just 40-50mm wood.I use 1/2” MDF with 1/2” ply on the outside and sound absorbing glue to hold them together.

These are all methodes to give a very good cabinet.

I'm useing sheep wool for ages now. I even have some sheep wool from very old vintage speakers here which is perfectly fine, at least 50 years old. The natural oils are protecting the wool and it's VERY unlikely you get pests and for sure nothing will grow there!The damping on the inside won’t need any maintenance if you use fiberglass or rock wool. If you use lambs wool or other natural fibers you can get pests in your speakers and things will grow in there. Just use fiberglass or acoustistuff.

Yes - you need BIG roundovers! Depending on your baffle size. But not 3" - at normal wide speakers 20-25mm are already fine, with my latest 40cm wide build I used 32mm and I only could measure a hint of edge influence - 35-40mm would be perfect.The slightly rounded edges are a purely esthetic choice, it looks nice. At 1,000hz you need a 3” or larger round over, to cover the midrange you would need massive round overs. It’s pointless unless you are making a sphere. You can have sharp edges if you want. I’ve found it’s better to treat the listening room, stop the first reflection by using draperies and put down a good carpet.

The wider the radius the lower does it work - and the wider the baffle you get difraction at lower frequencies already. But you also have a lot of space for roundovers with a wide baffle, so just do it and one problem less in speaker design.

A carpet or draperies ... only help for very high frequencies. Not for 1-3kHz where you will get big influences from corners. So no, it needs a proper absorber to influence these.

The topic of material

Overall that is a video wherew you need to more know than the presenter to know where what he is saying is based on reality or what is misinformation (more than a smattering of that)

I gave up using MDF nearly 2 and a half decades ago. I have formed a conclusion that it should only be used for building loudspeakers if it is the only material you can get.

A cabinet as “resonace free” as a properly done constrained layer can be made much more simply than a constrained layer which is difficult to execute. I expect that constrined layer has some application to OBs since you largely have a big piece of wood flapping in the breeze.

dave

High quality Plywood Beech. Not birch.

The actual material is not as important as the number of plies.

Excepting bamboo plyood, the best of which is the leading sheet material (made from plants) we have used for buikldibg loudspeakers. It has the added benefit of no need for veneer. It is not cheapo thou.

dave

are some of the more dense woods.

Dense is not an asset you really want unless it is a side effect of greater stiffness (the stranded/fossilized bamboo ply for instance.

We built a set of Gary Oak µFonkens, one was heavier than a pair of the samne built from Western Red Cedar. Tha latter worked better.

dave

I actually measured it and the differences are surprisingly small:

I have seen lots of measures. But construction topology makes a difference.

Evewrything resonates. My goal in constructing enclosuers is to push potential resonances up high enuff in frequency (and higher the Q the better) above where the music is likely to excite those (potential) resonances. If they are not excited it is as if they do not exist.

Not that the plywood resonates higher in frequency.

Studying the physics, the 2nd order curve below is easy to supporert, but there are arguments for the forth order curve. The placemnt of the curve is based on what i have seen in measurements but it is still somehat arbitary.

dave

you need BIG roundovers! Depending on your baffle size

There was a couple good studies in aXP (Speaker Builder?) that showed 4” is required to get significantly low but even a small round-over helps.

Note thay a chamfer is pretty much as effective and moire space efficient. ie a max chamfer on an 18mm material box will be more effective than the max roundover.

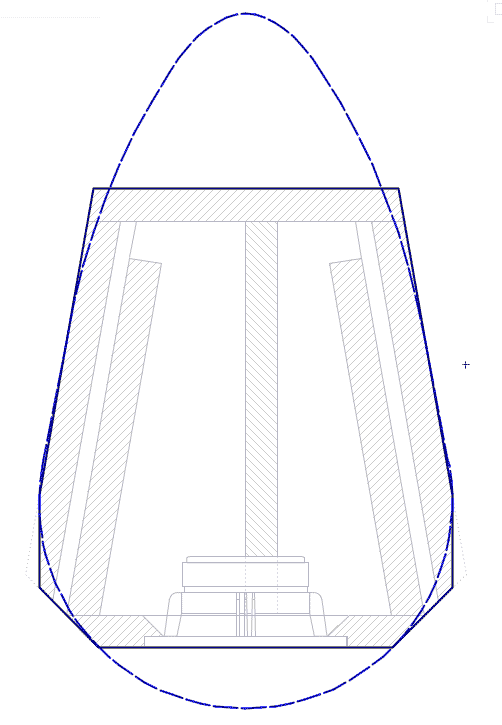

We have done experiments that taking things to extremes has benefits in terms of reducing the loudspeaker’s diffraction signature. Ours was the evolution of the miniOnken to end up with the trrapezoid versions (the µFonken shown earlier are an example), but we also see things like the B&W teardrop, the Fujitsu 10 ellisoid, and many spherical boxes (many made from IKEA Blanda bowls).

Below is the plan of a trapezoid (i know they actually end up with 8 afer chamfers are added) with a tear drop superimposed. The approximation has proven to work well.

dave

- Home

- Loudspeakers

- Multi-Way

- Anthology II in MDF or Plywood?