Thank you, Doug, for your clarification.I think the reason for no skating is that the forces on the stylus cancel each other at any position if the stylus is tangent. The remaining force is stylus drag in line with the cantilever.

We are DIYers and there is no point in us being disingenuous, we must be honest with ourselvesand with each other.

I am used to calling things by their proper names, and I apologize if this is unpleasant for someone.

But our conversation is about purely technical issues, without any emotions.

Sorry, but I do not agree with you.

When I see such tonearms, the following picture appears in my head - see photo 1.

And this picture fundamentally contradicts your assumption.

The rolling force is there and has not gone away.

Another thing is that it can be compensated to some extent by friction in the bearingsand the design of the mechanism.

But it is there.

But what have we achieved even by perfectly compensating for the rolling force (which I seriously doubt)?

Even if the compensating friction force in the bearings is approximately equal to the rolling force,you and I, having solved one problem, acquire another no less difficult problem.

This problem is similar to the problem of linear TA, which Carlo is now trying to solve.

In fact, you have received a carriage similar to the carriage of a linear TA, only your carriage moves not along rails, but with the help of two levers. But the problem remains.

If I understand correctly, there is currently no solution to this problem for a linear TA.

And the only way to reduce the impact of this problem on the sound is to carefullycenter each side of the record.

This is very labor-intensive. And on top of everything else, it partially solves the problem, since the movement of thecarriage is carried out by one side of the groove, while the other side of the groove is unloaded.

With eccentricity, everything becomes really bad.

But I can't even imagine that I will center each side of the record.

Therefore, such solutions are unacceptable to me.

I am very lazy.

And in confirmation of these words, and also to demonstrate my honesty to you, I show you my record player.

Russia is vast, but for my record player there was only 0.46 x 0.45 meters.

But I am so lazy that in addition to everything else, I built a record washer into the case - it is very convenient:you don't need to go anywhere and you don't even need to move the record to listen to the washed, slightly dampside.

With respect,

DIYer AG.

Attachments

I have even less expertise in PTA's than RTA's but it occurred to me that Maybe (looking at picture 1) at the pivot end there is the mirror image of that vector diagram that counteracts? - or the equivalent thereof?..............

Sorry, but I do not agree with you.

When I see such tonearms, the following picture appears in my head - see photo 1.

And this picture fundamentally contradicts your assumption.

The rolling force is there and has not gone away.

Another thing is that it can be compensated to some extent by friction in the bearings and the design of the mechanism.

But it is there.

M

By the way.

Or maybe not.

About some of my observations of the behavior of the needle.

Only facts. And no emotions.

I will immediately stipulate that I have a negative attitude towards setting up anti-skating on a bald record,

since the skating force on a bald record and on a real record are completely different forces.

But on a bald record we have the opportunity to clearly observe the behavior of the tonearm.

That is why I will demonstrate these facts on a bald record.

I will talk about the behavior of three tonearms:

No. 1 - long, with the needle going behind the spindle;

No. 2 - short, with the needle not reaching the spindle;

No. 3 - tangential Aki Schroeder.

I installed No. 1 on the bald record first.

Everything went as expected, without surprises.

The tonearm started to move to the center - watch the video

Then #2 went.

No surprises here either.

The tonearm, as expected, stopped at the zero point - watch the video

And finally, Aki Schroeder went.

This is where surprises awaited me.

I was ready for surprises, but their scope discouraged me.

I'll explain why.

Reading the pages of this topic, I was brought up on a surprisingly simple and clear method

for assessing the presence of skating force in any tonearm.

This is the string or thread method proposed by RayK - a kind of skating force indicator.

I did this experiment and I had no doubt that Aki Schroeder has skating force.

The bald record confirmed the presence of skating force in Aki Schroeder.

But I was amazed by the force with which the tonearm pulls to the center.

It felt by handsignificantly exceeded the force of tonearm #1.

That's what amazed me.

Watch the video

Thus, being confident in the terrible rolling force, which shouldbend the thin cantilever into a ram's horn,

I very carefully lowered the needle onto the real record, preparing for the terrible.

But here the main surprise awaited me.

A miracle happened!

The needle, as if nothing had happened, cheerfully ran along the groove and behavedquietly, like a bunny.

And it showed no desire to bend or break.

I conducted tests with eccentricity up to 4 mm.

The needle behaved quietly and calmly, without showing aggression.

Watch the video 1 mm.

I listened to many records, including those with defects.

Aki Schroeder dealt with defects better than a regular rotary tonearm.

So what do we have as a bottom line?

We have serious doubts about the objectivity of tests on a bald recordand on the famous string indicator.

I have serious reasons to suspect that they are misleading uswhen testing tangential tonearms.

Where is the truth?

What do you say to this, experts?

AG.

Or maybe not.

About some of my observations of the behavior of the needle.

Only facts. And no emotions.

I will immediately stipulate that I have a negative attitude towards setting up anti-skating on a bald record,

since the skating force on a bald record and on a real record are completely different forces.

But on a bald record we have the opportunity to clearly observe the behavior of the tonearm.

That is why I will demonstrate these facts on a bald record.

I will talk about the behavior of three tonearms:

No. 1 - long, with the needle going behind the spindle;

No. 2 - short, with the needle not reaching the spindle;

No. 3 - tangential Aki Schroeder.

I installed No. 1 on the bald record first.

Everything went as expected, without surprises.

The tonearm started to move to the center - watch the video

Then #2 went.

No surprises here either.

The tonearm, as expected, stopped at the zero point - watch the video

And finally, Aki Schroeder went.

This is where surprises awaited me.

I was ready for surprises, but their scope discouraged me.

I'll explain why.

Reading the pages of this topic, I was brought up on a surprisingly simple and clear method

for assessing the presence of skating force in any tonearm.

This is the string or thread method proposed by RayK - a kind of skating force indicator.

I did this experiment and I had no doubt that Aki Schroeder has skating force.

The bald record confirmed the presence of skating force in Aki Schroeder.

But I was amazed by the force with which the tonearm pulls to the center.

It felt by handsignificantly exceeded the force of tonearm #1.

That's what amazed me.

Watch the video

Thus, being confident in the terrible rolling force, which shouldbend the thin cantilever into a ram's horn,

I very carefully lowered the needle onto the real record, preparing for the terrible.

But here the main surprise awaited me.

A miracle happened!

The needle, as if nothing had happened, cheerfully ran along the groove and behavedquietly, like a bunny.

And it showed no desire to bend or break.

I conducted tests with eccentricity up to 4 mm.

The needle behaved quietly and calmly, without showing aggression.

Watch the video 1 mm.

I listened to many records, including those with defects.

Aki Schroeder dealt with defects better than a regular rotary tonearm.

So what do we have as a bottom line?

We have serious doubts about the objectivity of tests on a bald recordand on the famous string indicator.

I have serious reasons to suspect that they are misleading uswhen testing tangential tonearms.

Where is the truth?

What do you say to this, experts?

AG.

mea culpa #2577

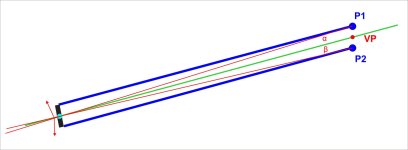

My hypotheses on the skating in a Thales Polygon were really too optimistic** (let's say it: silly).

My idea was that since the traction - stylus tip to virtual pivot - is symmetrical with respect to P1 P2, the opposite skating components - would cancel each other.

Too bad that in a Thales the virtual pivot remains completely outside from the physical pair, along the cathetus of the Thales triangle, with offset angles from 15° to < 5°. That means there's still some SF (ca half of a pivoted) decreasing from outer to inner grooves.

And since on a Pivoted half of the SF is spent to move the wand + cables and the rest becomes instead skating, here is probably all spent just to move the two wands. From that the behavior seen on the blank disc -

carlo

**Maybe influenced from the pivoted Linear Easy Pi measures - a different story

My hypotheses on the skating in a Thales Polygon were really too optimistic** (let's say it: silly).

My idea was that since the traction - stylus tip to virtual pivot - is symmetrical with respect to P1 P2, the opposite skating components - would cancel each other.

Too bad that in a Thales the virtual pivot remains completely outside from the physical pair, along the cathetus of the Thales triangle, with offset angles from 15° to < 5°. That means there's still some SF (ca half of a pivoted) decreasing from outer to inner grooves.

And since on a Pivoted half of the SF is spent to move the wand + cables and the rest becomes instead skating, here is probably all spent just to move the two wands. From that the behavior seen on the blank disc -

carlo

**Maybe influenced from the pivoted Linear Easy Pi measures - a different story

Attachments

Andre,

Thank you for honoring me by using my “string test.” It is straightforward (no pun intended) and simple. Have no doubts, the string test is telling you the truth.

I am interested in your comments about arm behavior on blank record compared to arm behavior on real record. I have some thoughts and requests for you to explore some ideas.

Whenever dealing with multiple pivots or bearing and bearing surfaces I am suspicious of friction and “stiction.” When I say stiction I mean the tendency for static friction to be high but once the object starts to move the dynamic friction is lower. I’m suggesting the possibility that, when you lower the arm onto a groove, the arm and cantilever forces reach an equilibrium point and the stylus drag force is unable to pull the cantilever further forward enough to severely deflect it, the “terrible” condition you were prepared to see but didn’t happen.

In your 4th video I observed little or no forward motion of the arm with 1mm eccentricity as the cartridge moved left-right. I wonder if, in this situation, the arm is pivoting on only a secondary bearing and not all bearings are moving in unison. This could be caused by a combination of factors, including stiction, bearing looseness/play etc.

If you would, please indulge me/us with an experiment and another video? Here’s what I’d ask you to do. Repeat your 4th video playing the eccentricity with the arm tracking the outermost groove near the lead-in and a second test at the innermost groove near the runout. This should present the most severe conditions. However, make a top/down video of the arm pivots and cam linkage. The movement of these should be smooth and in harmony with the cartridge moving left/right as it follows the eccentricity. I suspect this would reveal any stiction or looseness in the pivot bearings and cam follower. I don’t mean any of this as a criticism, but like you I am curious to find an explanation for what you observed.

Question: the record in your video #1 and #2 looked to me like it was grooved??

I enjoyed reading your thoughts and observations.

Ray K

Thank you for honoring me by using my “string test.” It is straightforward (no pun intended) and simple. Have no doubts, the string test is telling you the truth.

I am interested in your comments about arm behavior on blank record compared to arm behavior on real record. I have some thoughts and requests for you to explore some ideas.

Whenever dealing with multiple pivots or bearing and bearing surfaces I am suspicious of friction and “stiction.” When I say stiction I mean the tendency for static friction to be high but once the object starts to move the dynamic friction is lower. I’m suggesting the possibility that, when you lower the arm onto a groove, the arm and cantilever forces reach an equilibrium point and the stylus drag force is unable to pull the cantilever further forward enough to severely deflect it, the “terrible” condition you were prepared to see but didn’t happen.

In your 4th video I observed little or no forward motion of the arm with 1mm eccentricity as the cartridge moved left-right. I wonder if, in this situation, the arm is pivoting on only a secondary bearing and not all bearings are moving in unison. This could be caused by a combination of factors, including stiction, bearing looseness/play etc.

If you would, please indulge me/us with an experiment and another video? Here’s what I’d ask you to do. Repeat your 4th video playing the eccentricity with the arm tracking the outermost groove near the lead-in and a second test at the innermost groove near the runout. This should present the most severe conditions. However, make a top/down video of the arm pivots and cam linkage. The movement of these should be smooth and in harmony with the cartridge moving left/right as it follows the eccentricity. I suspect this would reveal any stiction or looseness in the pivot bearings and cam follower. I don’t mean any of this as a criticism, but like you I am curious to find an explanation for what you observed.

Question: the record in your video #1 and #2 looked to me like it was grooved??

I enjoyed reading your thoughts and observations.

Ray K

Hello Ray and thanks for joining the conversation.

I did your string test and the arm did move although less than a comparable pivoting arm of the same length. I did some drawings and found the same angles Carlo did - the angle from the stylus to the virtual pivot is 15 degrees at the outer grooves and decreases to 5 degrees at the inner grooves.

Even 15 degrees is only about 80% of the offset of a 275 mm Baerwald aligned pivot arm so as you and Carlo suggest, the small remaining SD force is not enough to overcome inertia, friction, or wires.

Carlo, thanks for posting the Thales drawing. I completely forgot about the virtual Thales P.

I was so pleased with my arm, I thought I was eating a free physics and geometry lunch. Ain't no such thing.

Andrey Grigorievich, your Aki Schroeder blank record videos are very interesting. I thought the outer to inner forces would be opposite of what the videos seem to show. I also really like your very clever built in cleaner.

Doug

I did your string test and the arm did move although less than a comparable pivoting arm of the same length. I did some drawings and found the same angles Carlo did - the angle from the stylus to the virtual pivot is 15 degrees at the outer grooves and decreases to 5 degrees at the inner grooves.

Even 15 degrees is only about 80% of the offset of a 275 mm Baerwald aligned pivot arm so as you and Carlo suggest, the small remaining SD force is not enough to overcome inertia, friction, or wires.

Carlo, thanks for posting the Thales drawing. I completely forgot about the virtual Thales P.

I was so pleased with my arm, I thought I was eating a free physics and geometry lunch. Ain't no such thing.

Andrey Grigorievich, your Aki Schroeder blank record videos are very interesting. I thought the outer to inner forces would be opposite of what the videos seem to show. I also really like your very clever built in cleaner.

Doug

Hi Ray.

I'm glad you joined the conversation. No one can shed light on the situation better than you.

We have a saying: "It's better to lose with a smart man than to find with a fool."

I hope that together we can get to the truth.

I'll answer you paragraph by paragraph.

______"Whenever dealing with multiple pivots"...

"Sticking" - we call it "the friction of rest", and dynamic friction is just "friction", but it is specified which

material is rubbing on which, for example steel on steel, steel on bronze, steel on ice, etc.

I disagree with your last suggestion and I'll explain why.

I always set up anti-skating as follows: I watch the needle carefully from the front at the moment of contact with the groove.

I adjust the anti-skating so that there is a barely noticeable shift of the needle to one side, and then

I readjust the anti-skating so that the needle swings to the other side. After that, I move the setting to the middle position.

And when the anti-skating force is adjusted correctly, then when the needle touches the groove, no shift is noticeable.

Why am I saying this? Here's why.

If you turn off the anti-skating, then the bend of the cantilever when playing a record is clearly visible to the naked eye.

If you turn on the anti-skating, then the bend is not visible.

I specifically looked at the deviation of the needle at the moment of contact with the Aki Schroeder and did not detect any deviation.

Then the question arises: with a weaker skating force on a regular tonearm WITHOUT anti-skating, the bend of the cantilever is clearly visible,

then where did the more terrible force go in the Aki Schroeder? Why does the needle not deflect anywhere at the moment of contact? And what's more, no deviation is visible when playing the record.

How do you explain this fact?

________"In your 4th video"...

It was as if I had a premonition of your appearance and answered some of your questions in advance.

In order not to write a lot of letters, please read my post #2563, and also watch my video in post #2543.

In this video, you can clearly see how the bearing rolls back and forth along the rail with eccentricity.

In addition, I must inform you that I treat the tonearm bearings with special care: they are washed in gasoline,

run in kerosene, lubricated in a special way and pre-loaded during assembly.

That is why there is no play on the two axes of the tonearm, there is no rattling and the rotation of the levers occurs with a light breeze.

The only unloaded bearing with a diameter of 5 mm rolls on the rail, but the play in it is very small and can be neglected.

__________"If you would, please indulge me/us with an experiment"...

I can't. To my great regret.

I worked on this tonearm a year ago and after it many other designs were made.

They are all disassembled into parts and lying around in a box. Some parts are reused.

I can reassemble and adjust the tonearm for the experiment, and also shoot interesting videos from a tripod, but I will do this

after Adelmo returns from vacation.

Like me, he turned out to be a curious person and would not mind doing similar shooting of his Schroeder LT clone for comparison.

So I'm waiting for him. Without him, I am too lazy to reassemble the tonearm.

Besides, Aki Schroeder does not fit into my new concept and is of purely academic interest to me.

But, so as not to upset you too much, I will show you a video of another tonearm, different in design from Aki Schroeder, but outwardly

similar to it. Pay attention to the end of the video, Aki Schroeder behaves exactly the same - back and forth, back and forth...

_________"Question: the record in your video #1 and #2 looked to me like it was grooved??"

I can only envy the sharpness of your eyes, I did not even pay attention to this.

Yes, indeed, this is not a real bald record.

This is cellophane film for a bouquet of flowers, cut with scissors to the size of the record.

I could not find anything more suitable for a bald record in my house, my wife helped out.

AG.

I'm glad you joined the conversation. No one can shed light on the situation better than you.

We have a saying: "It's better to lose with a smart man than to find with a fool."

I hope that together we can get to the truth.

I'll answer you paragraph by paragraph.

______"Whenever dealing with multiple pivots"...

"Sticking" - we call it "the friction of rest", and dynamic friction is just "friction", but it is specified which

material is rubbing on which, for example steel on steel, steel on bronze, steel on ice, etc.

I disagree with your last suggestion and I'll explain why.

I always set up anti-skating as follows: I watch the needle carefully from the front at the moment of contact with the groove.

I adjust the anti-skating so that there is a barely noticeable shift of the needle to one side, and then

I readjust the anti-skating so that the needle swings to the other side. After that, I move the setting to the middle position.

And when the anti-skating force is adjusted correctly, then when the needle touches the groove, no shift is noticeable.

Why am I saying this? Here's why.

If you turn off the anti-skating, then the bend of the cantilever when playing a record is clearly visible to the naked eye.

If you turn on the anti-skating, then the bend is not visible.

I specifically looked at the deviation of the needle at the moment of contact with the Aki Schroeder and did not detect any deviation.

Then the question arises: with a weaker skating force on a regular tonearm WITHOUT anti-skating, the bend of the cantilever is clearly visible,

then where did the more terrible force go in the Aki Schroeder? Why does the needle not deflect anywhere at the moment of contact? And what's more, no deviation is visible when playing the record.

How do you explain this fact?

________"In your 4th video"...

It was as if I had a premonition of your appearance and answered some of your questions in advance.

In order not to write a lot of letters, please read my post #2563, and also watch my video in post #2543.

In this video, you can clearly see how the bearing rolls back and forth along the rail with eccentricity.

In addition, I must inform you that I treat the tonearm bearings with special care: they are washed in gasoline,

run in kerosene, lubricated in a special way and pre-loaded during assembly.

That is why there is no play on the two axes of the tonearm, there is no rattling and the rotation of the levers occurs with a light breeze.

The only unloaded bearing with a diameter of 5 mm rolls on the rail, but the play in it is very small and can be neglected.

__________"If you would, please indulge me/us with an experiment"...

I can't. To my great regret.

I worked on this tonearm a year ago and after it many other designs were made.

They are all disassembled into parts and lying around in a box. Some parts are reused.

I can reassemble and adjust the tonearm for the experiment, and also shoot interesting videos from a tripod, but I will do this

after Adelmo returns from vacation.

Like me, he turned out to be a curious person and would not mind doing similar shooting of his Schroeder LT clone for comparison.

So I'm waiting for him. Without him, I am too lazy to reassemble the tonearm.

Besides, Aki Schroeder does not fit into my new concept and is of purely academic interest to me.

But, so as not to upset you too much, I will show you a video of another tonearm, different in design from Aki Schroeder, but outwardly

similar to it. Pay attention to the end of the video, Aki Schroeder behaves exactly the same - back and forth, back and forth...

_________"Question: the record in your video #1 and #2 looked to me like it was grooved??"

I can only envy the sharpness of your eyes, I did not even pay attention to this.

Yes, indeed, this is not a real bald record.

This is cellophane film for a bouquet of flowers, cut with scissors to the size of the record.

I could not find anything more suitable for a bald record in my house, my wife helped out.

AG.

I thought the outer to inner forces would be opposite of what the videos seem to show.

That's what I'd like to find out.

I hope Ray can help me solve this issue.

AG.

I would be happy to answer your question if I understood it.is yourTT a floating type or a not floating type?

Tks n rgds

What is "floating type" and "non-floating type"?

Please decipher this.

And what are those mysterious letters you write at the bottom?

AG.

Hi Andrey,

Rega P2 is non floating type.

Thorens TD150 it is a floating type.

TKS n rgds mena thanks and regards

Adelmo

Rega P2 is non floating type.

Thorens TD150 it is a floating type.

TKS n rgds mena thanks and regards

Adelmo

Andre,

I agree with your method of adjusting anti-skating.

The video in post #2563 is shaky and it is difficult to see small movements.

The video in post #2589 deliberately masks the pivot area and I can’t see the linkage or bearings.

I have many interests competing for my time. I will wait to see what you work out with Adelmo before getting back to this conversation.

Ray K

I agree with your method of adjusting anti-skating.

The video in post #2563 is shaky and it is difficult to see small movements.

The video in post #2589 deliberately masks the pivot area and I can’t see the linkage or bearings.

I have many interests competing for my time. I will wait to see what you work out with Adelmo before getting back to this conversation.

Ray K

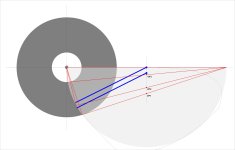

Meanwhile,

I took another look at Frank Schroder's US Patent and I see something that might be interesting. Compare the guide track orientation and shape on the right side of the main pivot compared to AKI's guide cam on the left side of the main pivot, and think in terms of skating forces. Does anyone else see it?

Ray K

I took another look at Frank Schroder's US Patent and I see something that might be interesting. Compare the guide track orientation and shape on the right side of the main pivot compared to AKI's guide cam on the left side of the main pivot, and think in terms of skating forces. Does anyone else see it?

Ray K

Hi Adelmo

These automatic translators and your abbreviations are driving me crazy.

And I thought that TT is a tangential tonearm and racked my brains wondering what kind of tonearm I have - floating or not.

But it turns out TT is a turntable.

I'll have to write down all the abbreviations on a piece of paper.

The manufacturer of my turntables uses a floating type of TT on spring suspensions.

But I don't like dangling TTs and remove the springs and install TTs on soft rubber.

I use TT Unitra Fonika - Poland, manufactured in the 1970s.

I have roller-belt and belt models.

If you have any questions, feel free to ask.

Thank you and resets for the transcript.

AG.

These automatic translators and your abbreviations are driving me crazy.

And I thought that TT is a tangential tonearm and racked my brains wondering what kind of tonearm I have - floating or not.

But it turns out TT is a turntable.

I'll have to write down all the abbreviations on a piece of paper.

The manufacturer of my turntables uses a floating type of TT on spring suspensions.

But I don't like dangling TTs and remove the springs and install TTs on soft rubber.

I use TT Unitra Fonika - Poland, manufactured in the 1970s.

I have roller-belt and belt models.

If you have any questions, feel free to ask.

Thank you and resets for the transcript.

AG.

Ray

I used the same stick in several different designs.

In post 2589, the stick is the same as in Aki Schroeder, but the mechanism is different.

That's why I hid this mechanism so that it wouldn't confuse us.

But at the end of this video, you can clearly see that the stick moves back and forth.

On Aki Schroeder, the stick also moves back and forth in unison with the eccentricity.

I'm also waiting for Adelmo to return from vacation rested and in a good moodand we'll

shoot a video together with a tripod in good lightingand at the right angles.

And then we'll figure out together where that damn rolling force disappeared to.

I'm not going to defend the honor of the uniform, I'm interested in the truth.

By the way, I'm also on vacation now.

It's 40 degrees, my brain is melting.

AG.

I used the same stick in several different designs.

In post 2589, the stick is the same as in Aki Schroeder, but the mechanism is different.

That's why I hid this mechanism so that it wouldn't confuse us.

But at the end of this video, you can clearly see that the stick moves back and forth.

On Aki Schroeder, the stick also moves back and forth in unison with the eccentricity.

I'm also waiting for Adelmo to return from vacation rested and in a good moodand we'll

shoot a video together with a tripod in good lightingand at the right angles.

And then we'll figure out together where that damn rolling force disappeared to.

I'm not going to defend the honor of the uniform, I'm interested in the truth.

By the way, I'm also on vacation now.

It's 40 degrees, my brain is melting.

AG.

Hi Andrey,Hi Adelmo

These automatic translators and your abbreviations are driving me crazy.

And I thought that TT is a tangential tonearm and racked my brains wondering what kind of tonearm I have - floating or not.

But it turns out TT is a turntable.

I'll have to write down all the abbreviations on a piece of paper.

The manufacturer of my turntables uses a floating type of TT on spring suspensions.

But I don't like dangling TTs and remove the springs and install TTs on soft rubber.

I use TT Unitra Fonika - Poland, manufactured in the 1970s.

I have roller-belt and belt models.

If you have any questions, feel free to ask.

Thank you and resets for the transcript.

AG.

The reason I asked what kind of turntable you use, floating or non floating, is because according to my experience a tangent Tonearm like the LT TA from Frank Schroeder is not suitable for floating turntable. At the beginning I also used a floating turntable and I was unable to well seta zero skating since any minimal change the levelling was producing skating with my tonearm. I made a much more rigid suspension but also was not optimal. So I decided to use a Lenco L 75, made the plinth heavy ( 27 Kg) stable levelling of turntable and with an optimal levelling of turntable and also tonearm it worked well.

Best regards

Adelmo

Hi,Meanwhile,

I took another look at Frank Schroder's US Patent and I see something that might be interesting. Compare the guide track orientation and shape on the right side of the main pivot compared to AKI's guide cam on the left side of the main pivot, and think in terms of skating forces. Does anyone else see it?

Ray K

View attachment 1481233

below a question for the Andrey TA I asked:

Can you guys explain to me what are the advantage having the guiding cam in the opposite place comparing to the Frank Schroeder LT TA?. Sorry for asking but I am a bit slow understanding things.

Best regards

Adelmo

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms