The Halbach tunnel's external fields are shorted out, one of the benefits as well as using less magnetics for a stronger field on one side. The rods are simpler and will work great as they already work well on LTs.

The Halbach tunnel's external fields are shorted out, one of the benefits as well as using less magnetics for a stronger field on one side. The rods are simpler and will work great as they already work well on LTs.

That's great to know. In a design like that, it encourages me even more to stick to the Dynavector lengths then: long carriage and short vertical arm.

The Halbach channel reminds me of a Pioneer PL-L1000 turntable I had before. It had a servo parallel arm with a straight linear motor on the carriage to follow groove left AND right, including eccentric record. Perhaps the electronics were wonky and it tended to overshoot and acting berzerk. That's why I never trust servo arms that follow eccentric records. Other tables I owned like Yamaha PX2 and PX3 worked like the Rabco are much better and more stable. That Pioneer arm would've been great on a Halbach tunnel though because I always thought the rollers were never that smooth, probably it didn't use high quality ball bearings.

Or two balls in one channel and one in the other. Still a triangle. Four rods does have the advantage that you can space the triangle out for greater stability.

Niffy

Niffy

Or two balls in one channel and one in the other. Still a triangle. Four rods does have the advantage that you can space the triangle out for greater stability.

Yes, that arrangement would work too. I was simply thinking no two balls could touch each other in a 3 channel arrangement and I also like the symmetry (stability) of it.

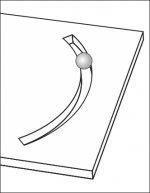

Can this rolling ball idea can be expanded to the guiding mechanism too in a curved channel?

DD,

Yes. I realized that arm tube should be long enough to avoid magnetic field. Actually, I tried magnetic levitation linear arm without success due to limitations of diy. If 2wice can get the halbach tunnel bearing worked, it will be great. Anyway, I just want to point out the potential use of halbach tunnel bearing.

Yes. I realized that arm tube should be long enough to avoid magnetic field. Actually, I tried magnetic levitation linear arm without success due to limitations of diy. If 2wice can get the halbach tunnel bearing worked, it will be great. Anyway, I just want to point out the potential use of halbach tunnel bearing.

The problem with balls design is not how many balls or so on. The most important part is how to control the balls so all balls remain a constant position with each other. The design in other linear arm thread didn’t have effective measure to do it so in my opinion, it was not a completed design. It is same here.

Last edited:

Not beeing a buddhist I have some difficulty to believe in levitation, so no hi-tech bearings for me. (what a shame)

Unfortunately, if ball bearings are suspected of chattering, the linear ones are in jail from a while ago: more play to slide. The best, recirculating ones, are a dancing carousel.

However, it must be considered that here we have only the weight force (shaft+CW), and a bit of side force.

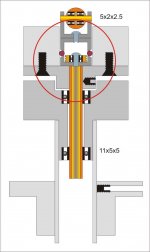

Here is where I came: self-centered, and always under load (a 30 ° slope should hopefully divide the load properly), and above all feasible with my small circular saw. Better with delrin balls (to compensate the tolerances) if i'll find (i have just 3 and 5)

carlo

balls in bearings are never in contact with each other, another reason for the cage

Unfortunately, if ball bearings are suspected of chattering, the linear ones are in jail from a while ago: more play to slide. The best, recirculating ones, are a dancing carousel.

However, it must be considered that here we have only the weight force (shaft+CW), and a bit of side force.

Here is where I came: self-centered, and always under load (a 30 ° slope should hopefully divide the load properly), and above all feasible with my small circular saw. Better with delrin balls (to compensate the tolerances) if i'll find (i have just 3 and 5)

carlo

balls in bearings are never in contact with each other, another reason for the cage

Attachments

Anyway, with variable horizontal effective length, horizontal effective mass will vary too. Question is, how much, and if it will affect sound... I'm not so good with math to make assessment, maybe someone on this thread will make calculations.

Not beeing a buddhist I have some difficulty to believe in levitation, so no hi-tech bearings for me. (what a shame)

Unfortunately, if ball bearings are suspected of chattering, the linear ones are in jail from a while ago: more play to slide. The best, recirculating ones, are a dancing carousel.

However, it must be considered that here we have only the weight force (shaft+CW), and a bit of side force.

Here is where I came: self-centered, and always under load (a 30 ° slope should hopefully divide the load properly), and above all feasible with my small circular saw. Better with delrin balls (to compensate the tolerances) if i'll find (i have just 3 and 5)

carlo

balls in bearings are never in contact with each other, another reason for the cage

With the three balls in two/three channels all three balls are constantly loaded so there would be no chatter. It's when you use conventional ball race type bearings that have loose unloaded balls that you get chatter.

Niffy

Thats what I was thinking to implement. A simple precision laser/machine cut (Arc or circle segment) in 4/5 mm metal plate and a bearing ball on top of it and another mirror image plate on top of plate should work I guess. See attached pic.Can this rolling ball idea can be expanded to the guiding mechanism too in a curved channel?

-x-

Another thinking is some how to lower the strength of halbach tunnel and lightly rest some part of tube on the base to have mechanical ground. (Like verdier turntable which has semi magnetic levitated platter but the bearing touches the base.

Regards

Attachments

Niffy, could be done in an arm like mine? really i can't figure out. i know the double rod instead of the V groove used in many products (in the smallest, or cheaper) but never seen the 3 balls solution. May you post a sketch, please?

thanks carlo

Fully agree with your words about "grounding" resonances

thanks carlo

Fully agree with your words about "grounding" resonances

Anyway, with variable horizontal effective length, horizontal effective mass will vary too. Question is, how much, and if it will affect sound... I'm not so good with math to make assessment, maybe someone on this thread will make calculations.

Could you explain this a bit more for me please?

Does the effective weight of the tonearm change when it travels forward, even though the verticle pivot is "static"?

How does the forward motion change that weight?

Anyone have a pointer to the calculations for that please?

Not only the effective mass varies (which affects arm resonance frequency), but also stylus pressure force.

Not only the effective mass varies (which affects arm resonance frequency), but also stylus pressure force.

I can accept an argument for effective mass changing but not the stylus force.

Can you explain further please?

I call horizontal pivot that for the horizontal rotation and vertical the other one. I hope it is right, but many say the opposite - some confusion around.

In these terms my arm (and also that of 2wice, I think) has a constant length with respect to the vertical pivot (which moves 36 mm) and therefore a constant vertical effective mass

instead it has a variable length (260 - 296 = 13%) with respect to the horizonyal pivot (which is stationary with respect to the spindle), and hence a variable horizontal effective mass.

imho - carlo

VTF is constant (fixed distance from vert pivot), it took me a week to find the solution....(see graphs posted, mine e by 2wice)

In these terms my arm (and also that of 2wice, I think) has a constant length with respect to the vertical pivot (which moves 36 mm) and therefore a constant vertical effective mass

instead it has a variable length (260 - 296 = 13%) with respect to the horizonyal pivot (which is stationary with respect to the spindle), and hence a variable horizontal effective mass.

imho - carlo

VTF is constant (fixed distance from vert pivot), it took me a week to find the solution....(see graphs posted, mine e by 2wice)

Last edited:

Well, this is a 2-arm balance. The weights are constant: pickup + headshell vs. counterweight. But the length of the arms are changing in this construction.I can accept an argument for effective mass changing but not the stylus force.

Can you explain further please?

NOCDPLS- Yes, your definitions are completely identical to mine. With 13% change of length, what will be percentage of horizontal effective mass change? Remnants of my ancient math skills make it difficult to calculate.😡

Well, this is a 2-arm balance. The weights are constant: pickup + headshell vs. counterweight. But the length of the arms are changing in this construction.

This is incorrect, the length of mine is constant, 150mm to verticle pivot, 250mm to end of the carriage.

Even though the verticle pivot moves forward there is no way for the tracking force to change. there is only one balance, the verticle pivot.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms