Direct drive,

your thread is pretty amazing! I follow it every now and then.

I obviously have no knowledge on how arms are built and such.

However I have a couple of curiousity:

1) I see you posting a ton of pictures with different very expensive cartridges! Are those yours?? 😱

2) If tracking error is the problem due to angle and stuff, isn't a linear tracker the optimum solution there? I have switched with great success to a VPI 10.5i to a Terminator T pro air bearing and the difference is just amazing.

I am interested to know your take on that.

My apologee in advance for my complete lack of knowledge on this subject.

your thread is pretty amazing! I follow it every now and then.

I obviously have no knowledge on how arms are built and such.

However I have a couple of curiousity:

1) I see you posting a ton of pictures with different very expensive cartridges! Are those yours?? 😱

2) If tracking error is the problem due to angle and stuff, isn't a linear tracker the optimum solution there? I have switched with great success to a VPI 10.5i to a Terminator T pro air bearing and the difference is just amazing.

I am interested to know your take on that.

My apologee in advance for my complete lack of knowledge on this subject.

Stefanoo,

May I insert my opinion?

For question one; the nicest cartridge I own is an entry level Grado with one of the channels blown... So skip number one please. 🙂

My interest in linear tracking stems from a frustration about record cutting.

The record producer owns a ten thousand dollar (guess) machine to cut records which were designed to be played on a thirty dollar turntable...

it seems to me that the record cutting machine should be of a pivot design to match the simplest design of a personal record player. But unfortunately I haven't seen that done. (with caveats of anti skating included)

Therefore, you are left with the option of a linear design for your own player.

Now, the standard choice is an air bearing. They have some huge advantages such as air bearings (high pressure) having phenomenally better stiffness than any other bearing i can think of. The most obvious disadvantage is needing to have a quiet supply of 90 psi air handy.

What seals the deal for me though is the dynamic properties of the system. Linear tonearms have hugely incongruous moments of inertia in two distinct planes.

I have always loved the simplicity of a unipivot tonearm. That or a gymballed tonearm would be the ideal choice if the track of a record were not a spiral but a circle. Unfortunately, we must reproduce the highly controlled, but non standardized movement of the driven cutter across the surface of the record, while at the same time accounting for random variations in these geometries.

With this mindset, it seems logical to separate these two behaviors to optimize the system.

Personally, I would rather invest some effort (microcontroller, motor, photodiode, etc.) in handling the tracking problem, which would free me up to choose a significantly simpler solution to the wow/warp problem.

Imagine a single crsystal, cast titanium, six inch unipivot tonearm, with a core of aerogel, and a non angled integral headshell, with a tungsten carbide disk sitting on a diamond point which is riding on a pair of ground ball bearing screws...

That is barely more extreme engineering than some of the more outlandish air bearings I have seen...........

🙂

May I insert my opinion?

For question one; the nicest cartridge I own is an entry level Grado with one of the channels blown... So skip number one please. 🙂

My interest in linear tracking stems from a frustration about record cutting.

The record producer owns a ten thousand dollar (guess) machine to cut records which were designed to be played on a thirty dollar turntable...

it seems to me that the record cutting machine should be of a pivot design to match the simplest design of a personal record player. But unfortunately I haven't seen that done. (with caveats of anti skating included)

Therefore, you are left with the option of a linear design for your own player.

Now, the standard choice is an air bearing. They have some huge advantages such as air bearings (high pressure) having phenomenally better stiffness than any other bearing i can think of. The most obvious disadvantage is needing to have a quiet supply of 90 psi air handy.

What seals the deal for me though is the dynamic properties of the system. Linear tonearms have hugely incongruous moments of inertia in two distinct planes.

I have always loved the simplicity of a unipivot tonearm. That or a gymballed tonearm would be the ideal choice if the track of a record were not a spiral but a circle. Unfortunately, we must reproduce the highly controlled, but non standardized movement of the driven cutter across the surface of the record, while at the same time accounting for random variations in these geometries.

With this mindset, it seems logical to separate these two behaviors to optimize the system.

Personally, I would rather invest some effort (microcontroller, motor, photodiode, etc.) in handling the tracking problem, which would free me up to choose a significantly simpler solution to the wow/warp problem.

Imagine a single crsystal, cast titanium, six inch unipivot tonearm, with a core of aerogel, and a non angled integral headshell, with a tungsten carbide disk sitting on a diamond point which is riding on a pair of ground ball bearing screws...

That is barely more extreme engineering than some of the more outlandish air bearings I have seen...........

🙂

I own a B&O TTwith aparallel tracking tonearm and I can confirm that it is the best way to play records... There is no distortion from the beguinning to the end of the record and no antiskating to care for.

In fact my TT has two parallel arms. One of them supports a light and light sensor and is used only to "see" if there is a record on the platter.

The other arm is very short and straight.

Both arms are mounted on a carriage that is able to slide back and forth, driven by a stepped motor and a small elastic chain.

The arm that has the cartridge can pivot minutely and there is a sensor that detects any non paralelism between the two arms and corrects this by feeding the slider stepped motor.

Very simple and effective.

Off course I can only use the dedicated B&O cartridges, so this is not very flexible, but I believe way more simple than a complex air bearing.

In fact my TT has two parallel arms. One of them supports a light and light sensor and is used only to "see" if there is a record on the platter.

The other arm is very short and straight.

Both arms are mounted on a carriage that is able to slide back and forth, driven by a stepped motor and a small elastic chain.

The arm that has the cartridge can pivot minutely and there is a sensor that detects any non paralelism between the two arms and corrects this by feeding the slider stepped motor.

Very simple and effective.

Off course I can only use the dedicated B&O cartridges, so this is not very flexible, but I believe way more simple than a complex air bearing.

nice!!

I agree linear tonearms are the best way to read vinyls.

For the air supply, I have the TT on the room next to the speaker and power amps and cable pass through dedicated holes at the bottom of the wall.

I thought at first it would have been very unpractical, instead I find it pretty easy to use.

This way I don't even hear any noisefrom the pump also get the advantage of isolating TT from vibration and also mount it on a wall mount Solid Steel and find this set up to work pretty well.

My VPI unipivolt worked really well too, but IMO not nearly as good as the linear tracking.

Considering that the T3Pro is also pretty inexpensive, I mean wouldn't it be interesting to take that design and improve it further instead of insisting of pivoted arm, which then you have to worry about antiskating force which is a pain in yout butt?

Also considering like people have mentioned here that vinyls are cut with a linear tracker machine.

Like I said I am a complete ignorant in this regard, but it sounds no brainer to me that a linear tonearm is the way to go.

I agree linear tonearms are the best way to read vinyls.

For the air supply, I have the TT on the room next to the speaker and power amps and cable pass through dedicated holes at the bottom of the wall.

I thought at first it would have been very unpractical, instead I find it pretty easy to use.

This way I don't even hear any noisefrom the pump also get the advantage of isolating TT from vibration and also mount it on a wall mount Solid Steel and find this set up to work pretty well.

My VPI unipivolt worked really well too, but IMO not nearly as good as the linear tracking.

Considering that the T3Pro is also pretty inexpensive, I mean wouldn't it be interesting to take that design and improve it further instead of insisting of pivoted arm, which then you have to worry about antiskating force which is a pain in yout butt?

Also considering like people have mentioned here that vinyls are cut with a linear tracker machine.

Like I said I am a complete ignorant in this regard, but it sounds no brainer to me that a linear tonearm is the way to go.

awolff761, It is time to get moving. Where is your own separate thread? Where is the awolff761 tangential pivot tonearm thread? Start a thread please.

new product

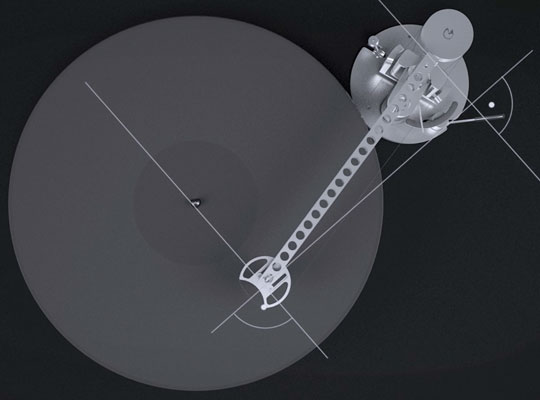

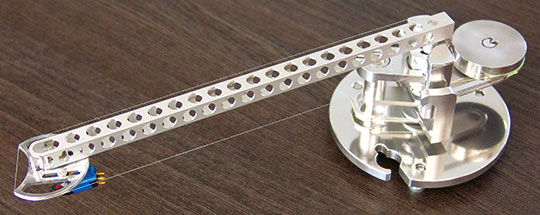

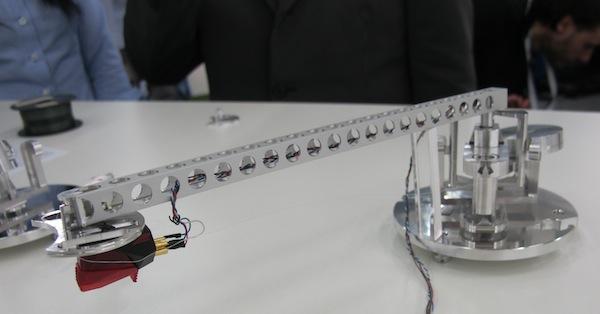

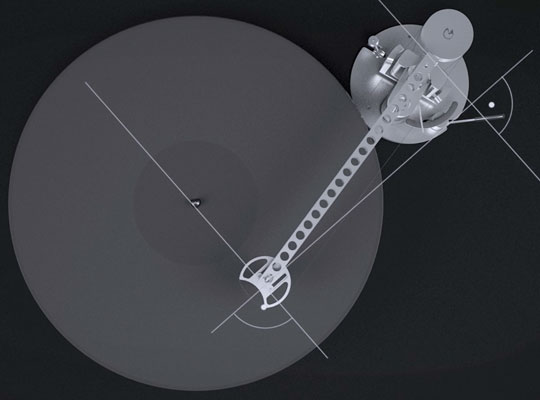

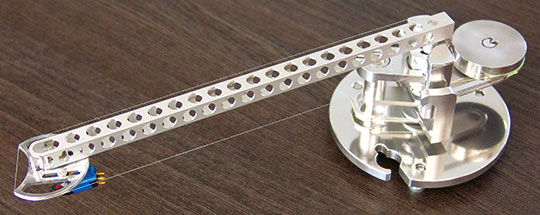

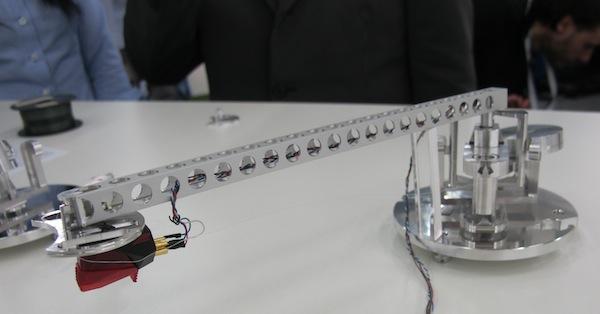

At the recent Munich High End Audio show, this new product fits the topic of this thread. The Schuch Tronic tangential arm uses strings to guide the pivoting headshell. Reminds me of the arm in post #349 and the mysterious DIY string arm.

At the recent Munich High End Audio show, this new product fits the topic of this thread. The Schuch Tronic tangential arm uses strings to guide the pivoting headshell. Reminds me of the arm in post #349 and the mysterious DIY string arm.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

I can see the advantage of eliminating rattling bearings via the string method, but how do you eliminate off axis forces? you may end up with the plane of the center of the tonearm pivot bearing at the pillar in an undesireable place. Still fascinated.

Cheers Steve

Cheers Steve

you may end up with the plane of the center of the tonearm pivot bearing at the pillar in an undesireable place.

I wish there's a better close-up picture of the base area. I can't tell if the string is located on the same place as the pivot for vertical movement. For now, it appears to be over-engineered. Let's hope we'll find out more in the future.

I blew up some pictures to see better details.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I can see two tensioned springs - neither on the plane of the pivot, but possibly equidistant from it, and what seems to be a contrarotating balance weight. Hmmm. Are we moving into the "great theoretically if stuff always worked the way it is supposed to"?

Cheers Steve

Cheers Steve

Hmmm. Are we moving into the "great theoretically if stuff always worked the way it is supposed to"?

This reminds me of your dad's quote: "The Vincent motorcycle was a collection of solutions looking for a problem."

😀

This reminds me of your dad's quote: "The Vincent motorcycle was a collection of solutions looking for a problem."

Cheers for that. Made a sunny morning even finer. All we need now is someone to explain how this arm works. My guess would be the the springs and tensioned strings would buzz at some frequencies. Happy to be proved wrong.

Cheers Steve

Seems to me the simpler solution would be to not add complexity to the design of the tone arm but rather design a device that will move the platter along a path that will keep the stylus tangent as it should be.

This device can be designed and built to keep the platter as stable as necessary for proper playback of the vinyl recording relative to the stylus and system as a whole yet still move along the required path. Something cam driven perhaps with some kind of vision system to 'see' where the stylus is located while functioning as intended.

If someone is interested in pursuing this concept contact me.

This device can be designed and built to keep the platter as stable as necessary for proper playback of the vinyl recording relative to the stylus and system as a whole yet still move along the required path. Something cam driven perhaps with some kind of vision system to 'see' where the stylus is located while functioning as intended.

If someone is interested in pursuing this concept contact me.

Can I see a bias compensation weight? Why?

Anytime the the stylus does not point to the pivot as a straight line, there will always be skating force, no matter how small even in a tangential pivot arm like the SchuchTronic or Thales Simplicity, hence the bias compensation.

simpler solution would be to not add complexity to the design of the tone arm but rather design a device that will move the platter along a path that will keep the stylus tangent as it should be.

Wouldn't it be simpler to move the base of the tonearm than moving a spinning platter? I think a servo sliding armboard or armbase is closer to the mark. This thread is focused on mechanical design but we, of course, can flirt with other schemes. Thanks for chiming in.

I see you posting a ton of pictures with different very expensive cartridges! Are those yours?? 😱

No, they're not. The pictures are all from the internet. I just accumulated all these pictures on this thread for all to ogle. After all, we all like audio porn, right? 😀

Perhaps you are right about the servo-motor driven tone arm base...I overlooked that concept. I was looking more at the multi-link or cable controlled phone cartridge pivoting systems. Cables and links just make me think of a loss in precision for stylus orientation.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms