Hello everyone

The next day I mounted the membrane A3 and did a measurement, and the response was upward of approximately 5 dB from 40 Hz to 1 kHz

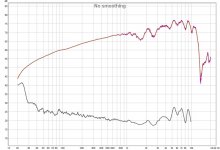

Unfortunately it was late and I did not save the measure promising to do it again the next day.. The result, to my surprise, was this

memb A3 2day after.jpg

At this point I realized that it is a problem of polymerization of polyurethane, or because I used solvent, which is not provided in the data sheet, or why complete curing, solvent-free, it has after seven days, or for some other reason I will investigate later.

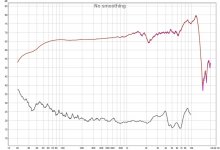

By the time I wanted to see if by washing of the membrane something changed, and I got lucky: I washed the membrane first with alcohol and a soft brush, then with water, dried and then I put on the hot plate at 100 ° C for 1h. Then I left to rest after 5h and the result was this:

memb A3 5h after treatment.jpg

During the 5 hours I did other measures and I could see that the curve is straightened a little every hour.

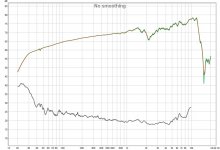

To be sure I have found the cause of the changes of the responses I have adopted the same washing for the previous membrane (A2), and the behavior is the same. In fact, as you can see the response came back similar to one of the first measure

memb A2 24h after treatment.jpg

Now I think about how to proceed. I had the idea that if I did the 5 mm wide strips of aluminum instead of 9 I made a whole band. But this is another story

The next day I mounted the membrane A3 and did a measurement, and the response was upward of approximately 5 dB from 40 Hz to 1 kHz

Unfortunately it was late and I did not save the measure promising to do it again the next day.. The result, to my surprise, was this

memb A3 2day after.jpg

At this point I realized that it is a problem of polymerization of polyurethane, or because I used solvent, which is not provided in the data sheet, or why complete curing, solvent-free, it has after seven days, or for some other reason I will investigate later.

By the time I wanted to see if by washing of the membrane something changed, and I got lucky: I washed the membrane first with alcohol and a soft brush, then with water, dried and then I put on the hot plate at 100 ° C for 1h. Then I left to rest after 5h and the result was this:

memb A3 5h after treatment.jpg

During the 5 hours I did other measures and I could see that the curve is straightened a little every hour.

To be sure I have found the cause of the changes of the responses I have adopted the same washing for the previous membrane (A2), and the behavior is the same. In fact, as you can see the response came back similar to one of the first measure

memb A2 24h after treatment.jpg

Now I think about how to proceed. I had the idea that if I did the 5 mm wide strips of aluminum instead of 9 I made a whole band. But this is another story

Attachments

hi Lupi

have you seen Raymond's thread ?

http://www.diyaudio.com/forums/full-range/156466-one-only-full-range-amt.html

i'd love to have a amt bass........

best

Otangelo

have you seen Raymond's thread ?

http://www.diyaudio.com/forums/full-range/156466-one-only-full-range-amt.html

i'd love to have a amt bass........

best

Otangelo

Hello angeloitacare

Yes, I saw that thread some time before starting my AMT, but I could not find useful information, nor was able to see a graph of the response of AMT with axis scales readable, even with the help of a lens. Also the use of a horn with cutoff frequency 20 Hz I excluded from my intentions. With all due respect to the work of Raymond that seems remarkable, my personal idea it is that define "full-range" a driver with a flat response that starts at 100 Hz mean to be satisfied easy.

Returning to the membrane A3 I must say that the problem seemed solved however is not: After a few days the response came back with the slope between 30Hz and 1 KHz. I'm investigating, but it will take some time. For now the only thing I am pretty sure is that the changes depend on the polyurethane rubber. So if anyone is planning to use that material is advised.

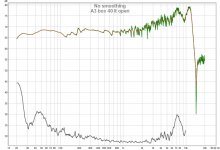

However I was able to listen to music with the driver with the membrane A3 put in a box of 40 liters with open back. I am reluctant to praise what I do, but I must say that the work I did was worth it. This is the response with mic to 1 cm. I tried with mic 50 cm but there are too many resonances of the room. When the time comes I'll put some absorbent panel.

A3 box 40 lt open.jpg

Bass was outstanding. On the high range I heard something better, like spatial effect, only with a driver electrostatic; someone has noticed this difference between AMT and eletrostatics?

best

lupi

Yes, I saw that thread some time before starting my AMT, but I could not find useful information, nor was able to see a graph of the response of AMT with axis scales readable, even with the help of a lens. Also the use of a horn with cutoff frequency 20 Hz I excluded from my intentions. With all due respect to the work of Raymond that seems remarkable, my personal idea it is that define "full-range" a driver with a flat response that starts at 100 Hz mean to be satisfied easy.

Returning to the membrane A3 I must say that the problem seemed solved however is not: After a few days the response came back with the slope between 30Hz and 1 KHz. I'm investigating, but it will take some time. For now the only thing I am pretty sure is that the changes depend on the polyurethane rubber. So if anyone is planning to use that material is advised.

However I was able to listen to music with the driver with the membrane A3 put in a box of 40 liters with open back. I am reluctant to praise what I do, but I must say that the work I did was worth it. This is the response with mic to 1 cm. I tried with mic 50 cm but there are too many resonances of the room. When the time comes I'll put some absorbent panel.

A3 box 40 lt open.jpg

Bass was outstanding. On the high range I heard something better, like spatial effect, only with a driver electrostatic; someone has noticed this difference between AMT and eletrostatics?

best

lupi

Attachments

Hi Lupi

Raymond send me his amt's for a while for listening and evaluation. I made measurements. I should have posted them here at DIY audio somewhere. If i remember correctly they were playing down to 150hz, with a rising response and a peak somewhere between 8 and 10khz, and starting to fall at 12khz or so.

I did like the performance, very natural, as is a hallmark for amt's.

If you have something mature, and willing to make more than just one pair for your own enjoyment, i might be interested to buy a pair of yours.

Otangelo

Raymond send me his amt's for a while for listening and evaluation. I made measurements. I should have posted them here at DIY audio somewhere. If i remember correctly they were playing down to 150hz, with a rising response and a peak somewhere between 8 and 10khz, and starting to fall at 12khz or so.

I did like the performance, very natural, as is a hallmark for amt's.

If you have something mature, and willing to make more than just one pair for your own enjoyment, i might be interested to buy a pair of yours.

Otangelo

Hi Otangelo

At the moment I have nothing mature, and I'm still checking the reliability of the main component. With the box I mentioned in my previous post I just wanted to make sure it was worth it (remember that the microphone was 1 cm), but it is only an initial test, because my goal is a bigger driver.

My intention in fact was to build only a pair for me, as I have no commercial ambitions. However, when I arrive at a final result ("final result" in HIFI sounds strange) I expect that I will have to build some other pair for other friends who had heard that box and have already asked to me. At that point, practical problems aside, I'll be happy to make a couple extra for another member of DIY audio.

If you remember where you posted the measures of Raymond's AMT I would be grateful if I did know

Greetings

lupi

At the moment I have nothing mature, and I'm still checking the reliability of the main component. With the box I mentioned in my previous post I just wanted to make sure it was worth it (remember that the microphone was 1 cm), but it is only an initial test, because my goal is a bigger driver.

My intention in fact was to build only a pair for me, as I have no commercial ambitions. However, when I arrive at a final result ("final result" in HIFI sounds strange) I expect that I will have to build some other pair for other friends who had heard that box and have already asked to me. At that point, practical problems aside, I'll be happy to make a couple extra for another member of DIY audio.

If you remember where you posted the measures of Raymond's AMT I would be grateful if I did know

Greetings

lupi

Hello everyone

Finally they came to light the reasons for those seemingly random responses. As I used a new material I was convinced that he was the problem, but I found that it does not.

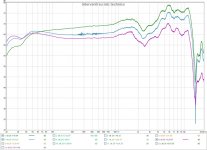

The fault lies with the microphone, which is affected by ambient humidity (RH). The microphone is part of the instrument TECHNICS "audio frequency analyzer SH 8000", and is the version A. The following measures summarize what I tested (the curves are shifted a little for clarity):

The first figure summarizes the tests made on the membrane: Before treatment (dark green line), cooling to -22 ° C for 15 '(blue line), heating at 100 ° C for 10' (light green line), water atomization directly on the membrane and drying the droplets (light brown line).

treatments on membrane.jpg

Having checked the small influence of the treatments on the membrane I passed to check the microphone:

The second figure summarizes the treatments made: Before treatment (green line), the flow of hot air at about 70 °C for 5' on the top of mic (blue line), drying for 1 night with silica-gel (cyan line).

mic technics.jpg

During this time the environmental conditions (temperature and RH) Have remained fairly constant, and therefore had no impact on the other components. It 'clear that the humidity has a major influence, and when I have time I will see why. For now I'm going to keep the mic in a dry place and pull it out only when I need it. The variations of the response in still air are rather slow, and for a period of one hour I can feel comfortable. I am convinced that the right response is that in dry air because I made comparisons with other 4 microphones, which are economic, but until a few KHz gave all the same trend of the technics dried.

In conclusion, I withdraw all the reservations I had done on this polyurethane rubber. Moreover are many years which is used in various applications.

lupi

Finally they came to light the reasons for those seemingly random responses. As I used a new material I was convinced that he was the problem, but I found that it does not.

The fault lies with the microphone, which is affected by ambient humidity (RH). The microphone is part of the instrument TECHNICS "audio frequency analyzer SH 8000", and is the version A. The following measures summarize what I tested (the curves are shifted a little for clarity):

The first figure summarizes the tests made on the membrane: Before treatment (dark green line), cooling to -22 ° C for 15 '(blue line), heating at 100 ° C for 10' (light green line), water atomization directly on the membrane and drying the droplets (light brown line).

treatments on membrane.jpg

Having checked the small influence of the treatments on the membrane I passed to check the microphone:

The second figure summarizes the treatments made: Before treatment (green line), the flow of hot air at about 70 °C for 5' on the top of mic (blue line), drying for 1 night with silica-gel (cyan line).

mic technics.jpg

During this time the environmental conditions (temperature and RH) Have remained fairly constant, and therefore had no impact on the other components. It 'clear that the humidity has a major influence, and when I have time I will see why. For now I'm going to keep the mic in a dry place and pull it out only when I need it. The variations of the response in still air are rather slow, and for a period of one hour I can feel comfortable. I am convinced that the right response is that in dry air because I made comparisons with other 4 microphones, which are economic, but until a few KHz gave all the same trend of the technics dried.

In conclusion, I withdraw all the reservations I had done on this polyurethane rubber. Moreover are many years which is used in various applications.

lupi

Attachments

- Status

- Not open for further replies.