One of the more distinctive problems with the IGBT modules is this:I'm not sure about specifically the graphene variant but Panasonic's PGS (pyrolytic graphite sheet) which functions quite similar is available at places like Mouser.

You can buy the larger sheets and cut them to the size that you need. Most of the sizes are actually prepared for specific IGBT and Thyristor module layouts.

I bought a sheet of their soft PGS to try but didn't get around to trying it due to the lack of insulation.

I tried Sekisui 5760 instead, the performance isn't world class but very good for the dollar. The generic silicone sheets were worse. Downside is that it is a really effective adhesive, the devices needed careful lifting with a scraper after being clamped.

When they build them the first thing they do is bond the silicon chips to the DBC substrates (direct bond copper). The next thing they do after test, is bond the substrates to the copper baseplate.. One of the more significant things here, is that the TCE of the alumina substrate is about 4 to 6 ppm/deg C, while the copper baseplate is 16.6. As a result, many of the modules have a bow introduced as a result of the differential expansions of the materials. Consequently, when the package is bolted to the heatsink, the actual heat path directly under the semiconductors is not forced against the heatsink due to the curvature introduced by the different expansion coefficients.

This is one of the basic engineering problems that is easily forgotten by the current generation of "thermal engineers" with their papers. I cringe at the incompetence.

jn

> Could you please share your reference for Keratherm?

> None of my usual suppliers seems to carry such an item.

Keratherm Transistor Insulators – diyAudio Store

Kerafol Thermally Conductive Films from Conrad Electronic International

Patrick

Thanks

I'm not sure about specifically the graphene variant but Panasonic's PGS (pyrolytic graphite sheet) which functions quite similar is available at places like Mouser.

You can buy the larger sheets and cut them to the size that you need. Most of the sizes are actually prepared for specific IGBT and Thyristor module layouts.

I bought a sheet of their soft PGS to try but didn't get around to trying it due to the lack of insulation.

I tried Sekisui 5760 instead, the performance isn't world class but very good for the dollar. The generic silicone sheets were worse. Downside is that it is a really effective adhesive, the devices needed careful lifting with a scraper after being clamped.

After coming back from the PC world (where you expect the best solutions to heat problems) the best thermal pads are fujipoly (Especially the extreme ones, the GR ones work well but they're kinda expensive so i use ceramic alumina but they don't work as well as alumina ceramic with GOOD THERMAL PASTE as a insulation/thermal pad) bar the LM thermal pads which are obviously not the right choice.

Isn't sekisui 5760 a double sided thermal tape?

...

i use ceramic alumina but they don't work as well as alumina ceramic with GOOD THERMAL PASTE as a insulation/thermal pad)

...

Elbow grease is the best to my knowledge and availability.

.

Attachments

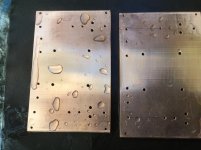

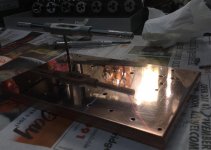

Finish itself is no warranty to good thermal performance. Besides roughness one needs flatness.

I don’t have any access to a milling machine.

All I can do is using my elbow grease an a know-how attitude to wet sanding the copper heat spreader on a thick glass plate.

The flatness is evaluated by mirror finished surface with minimum visual distortion of reflected image.

Cheers

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Amplifier heatsink thermal interface experiments