Im rebuilding a 10k amp .

All the power supply fets were burnt along with gate resistors .

The drivers appear to be fine but will look at the drive signals once I get to that point .

Wondering when the fets fail is it a good practice to replace the drivers as well even if they test fine or is it spending time and money on something that tested fine

All the power supply fets were burnt along with gate resistors .

The drivers appear to be fine but will look at the drive signals once I get to that point .

Wondering when the fets fail is it a good practice to replace the drivers as well even if they test fine or is it spending time and money on something that tested fine

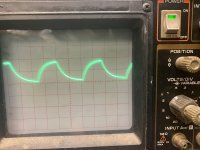

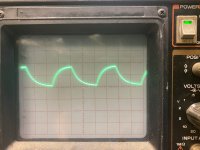

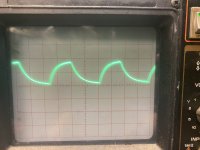

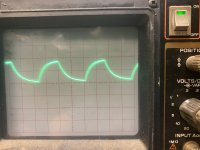

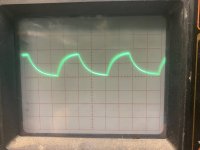

Here is what I get for drive signals on all 6 banks .

Scope set to 10us 5volts/div

Do these appear to be good drive signals or do I have defective drivers ?

Scope set to 10us 5volts/div

Do these appear to be good drive signals or do I have defective drivers ?

Attachments

-

A6521777-2BE0-49DD-B90E-6003B81C1933.jpeg445.6 KB · Views: 49

A6521777-2BE0-49DD-B90E-6003B81C1933.jpeg445.6 KB · Views: 49 -

FDA45985-D761-45AC-92FC-F2C2DD7F5A58.jpeg440.5 KB · Views: 47

FDA45985-D761-45AC-92FC-F2C2DD7F5A58.jpeg440.5 KB · Views: 47 -

831D6C51-94E5-4165-81EB-B49F49929EFF.jpeg398.3 KB · Views: 44

831D6C51-94E5-4165-81EB-B49F49929EFF.jpeg398.3 KB · Views: 44 -

95A829B5-23DC-4902-90FD-1291D0BFA44D.jpeg435 KB · Views: 55

95A829B5-23DC-4902-90FD-1291D0BFA44D.jpeg435 KB · Views: 55 -

F7A00318-446D-41AB-80CA-0D529F5F33D4.jpeg371.8 KB · Views: 48

F7A00318-446D-41AB-80CA-0D529F5F33D4.jpeg371.8 KB · Views: 48 -

F2A00892-FD43-4FBE-A2F3-54EA36110AD8.jpeg451.4 KB · Views: 55

F2A00892-FD43-4FBE-A2F3-54EA36110AD8.jpeg451.4 KB · Views: 55

You are getting almost 10V drive so I would find it hard to believe that the drivers are bad.

Is there a series R between each driver and gate? If so, look at the output waveform of the drivers before the resistors.

Is there a series R between each driver and gate? If so, look at the output waveform of the drivers before the resistors.

Drivers may be working fine by themselves but that waveform seems to show too high capacitive load, I would have expected a way "squarer" shape, with just slightly rounded leading edges.

Are you measuring with power Fets still connected?

To my eyes those drivers seem to be barely coping with load.

Are you measuring with power Fets still connected?

To my eyes those drivers seem to be barely coping with load.

The waveforms are not square because he's using a loading capacitor. It makes it more obvious when there is a weak driver,

The waveforms look OK. What you're looking for is for the waveform to all have the same amplitude. They need to go from the supply voltage for the drivers and all of the way to ground. If you had bad drivers, one or more would have a reduced amplitude and ones not going all of the way to ground would be most likely to destroy FETs when the FETs were installed.

The waveforms look OK. What you're looking for is for the waveform to all have the same amplitude. They need to go from the supply voltage for the drivers and all of the way to ground. If you had bad drivers, one or more would have a reduced amplitude and ones not going all of the way to ground would be most likely to destroy FETs when the FETs were installed.

Next question I have with this amp .

There are a total of 4 banks of outputs .

8 outputs in each bank .

Some of the outputs exploded in 2 of the banks . I removed all outputs from the 2 banks

I tested the outputs and threw the bad ones away and have enough out of the remaining outputs to make another bank .

Coils I use the remaining outputs that can out of the amp to make another bank or should I just replace them all with new ?

There are a total of 4 banks of outputs .

8 outputs in each bank .

Some of the outputs exploded in 2 of the banks . I removed all outputs from the 2 banks

I tested the outputs and threw the bad ones away and have enough out of the remaining outputs to make another bank .

Coils I use the remaining outputs that can out of the amp to make another bank or should I just replace them all with new ?

I wouldn't risk it. If the amp fails again, you won't know whether the used FETs were the problem or not. If it fails, it could destroy the power supply again.

Ok will replace them all . The other 2 banks that survived should I replace those also or should they be ok

Probably but it likely depends on what caused the amp to fail.

Does the amp currently produce audio with the two remaining banks (all other defective components, including driver ICs, removed)?

Does the amp currently produce audio with the two remaining banks (all other defective components, including driver ICs, removed)?

No it will not produce audio .

I noticed L201 is defective a 47MH inductor

Not sure if anything else is defective yet still going through the amp .

If L201 became defective would that cause the outputs to blow or is it hard to say if that is the cause

I noticed L201 is defective a 47MH inductor

Not sure if anything else is defective yet still going through the amp .

If L201 became defective would that cause the outputs to blow or is it hard to say if that is the cause

If the inductor was open, it could have prevented the protection circuit from working as it should.

Is the amp producing a rail to rail square wave?

Is the amp producing a rail to rail square wave?

Yes amp is producing rail to rail square waves.

When the outputs explode in these amps is it a good idea to replace the gate resistors even if they measure within tolorance? Or doesn’t it matter if they test fine .

I’ve heard different things some say replace them even if they test within tolorance after the amp has a catastrophic failure

When the outputs explode in these amps is it a good idea to replace the gate resistors even if they measure within tolorance? Or doesn’t it matter if they test fine .

I’ve heard different things some say replace them even if they test within tolorance after the amp has a catastrophic failure

I'd think that they're OK if within tolerance but these amps are so expensive to repair that I can't tell you definitively not to replace them.

I think, to test them, you could stress them to their limits to see how many hold without failing. If they'll all survive while dissipating their rated power, I believe that they're undamaged.

Connect 2 in series and apply 12v across the pair. This is for 39 ohm resistors. Let them remain on the supply for 30 minutes and hanging in free air so they can cool as well as possible. Do this for multiple pairs.

I think, to test them, you could stress them to their limits to see how many hold without failing. If they'll all survive while dissipating their rated power, I believe that they're undamaged.

Connect 2 in series and apply 12v across the pair. This is for 39 ohm resistors. Let them remain on the supply for 30 minutes and hanging in free air so they can cool as well as possible. Do this for multiple pairs.

Like you stated these amps are expensive to repair . I just don’t want a failure to happen when in the vehicle again . This amp was repaired awhile ago new outputs and audio driverboard . Hooked it up in the vehicle and within 5 mins blew again .

It’s something about these large amps and me that don’t get along . I replace the parts and test other parts and everything seems fine then they blow again . What am I missing here ? Am I over looking something on the repairs

It’s something about these large amps and me that don’t get along . I replace the parts and test other parts and everything seems fine then they blow again . What am I missing here ? Am I over looking something on the repairs

When you repair them for the second time, they they fail again?

When I was repairing them, they had a problem with intermittent shorts in the inductors. I don't know if it's still an issue but you should run the amps hard in the shop. That may mean investing in a large supply to power them. Buying a FLIR imager may also be a good investment.

If nothing else, you should run them until the internal components will run hot. Many will heat up running at low power where you can do things like twisting the inductors while they're hot. You should also push on various components and various points on the boards to make sure that there aren't any intermittent problems.

In my shop, no amp left without running for 3 hours. Not many showed any problems after about an hour but I had plenty of other things to do so 3 hours wasn't a big deal.

When I was repairing them, they had a problem with intermittent shorts in the inductors. I don't know if it's still an issue but you should run the amps hard in the shop. That may mean investing in a large supply to power them. Buying a FLIR imager may also be a good investment.

If nothing else, you should run them until the internal components will run hot. Many will heat up running at low power where you can do things like twisting the inductors while they're hot. You should also push on various components and various points on the boards to make sure that there aren't any intermittent problems.

In my shop, no amp left without running for 3 hours. Not many showed any problems after about an hour but I had plenty of other things to do so 3 hours wasn't a big deal.

I only rebuilt this amp once like a year ago and then put it aside . This will be the 2nd repair on this amp . So this time I will go through the output section top to bottom

Make sure that the mute/delay is keeping the output disabled (no rail-rail oscillation) until the amp fully builds rail voltage.

To check this I would place scope probe on the gate leg of the output and my meter probes on rectifiers? And make sure there is no rail to rail oscillation on the outputs until the amp fully builds rail voltage ?

or how do I do this

or how do I do this

- Home

- General Interest

- Car Audio

- Amp Question