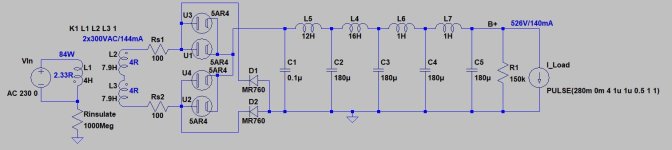

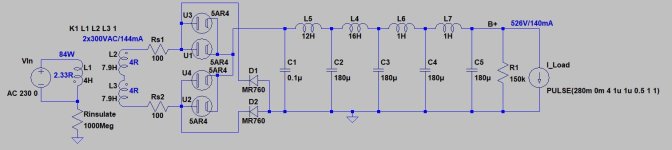

I did consider damper tubes, at first, but weighed a few pros and cons. I would need dual dampers in order to fit it all in a hybrid bridge, so that narrows down the choices as most dampers are singles. I considered 6CG3 compactron first because it is the only damper available that goes to 350mA, but that puts it right at the limit with no derate headroom in case I want to up the PT to 400mA some day. Another big consideration is that 5AR4 is still in current production widely used in guitar amps. Once I build this I can easily swap out the PT for one rated 400mA, so the rectifiers would have to exceed that anyway. In the end I settled on using parallel 5AR4 for all these reasons in a hybrid bridge, just install two tube sockets. As for timing, the B+ will arrive well later than the bias because I've found the 5AR4 tube to warm up certainly much slower than a DH rectifier like 5U4, plus they are more compact. But yes dampers were my first thought but the mechanical space I have is driving a lot of this. Space is also why I chose to try all toroid, we'll see how that works out as I dont think I've ever seen anyone use a toroid choke as an PSU input choke. Space was why I abandoned using the monster sized Hammond 193MP choke in favor of toroid chokes. That is why I figured I'd put a 400mA rated center-potted toroid as the input choke, a small 0.1 capacitor in front of it might help it from getting too punished, I wont know until I get there. I keep updating the schematic against the mechanical design with each space compromise I encounter. I just updated the schematic to reflect the fact that I will be able to fit eight DC link capacitors, four 52mm pin spaced ones and four 37.5 mm pin spaced ones, whether I use all 8 or not is up for grabs but I am keeping the schematic in synchonization with the mechanical design.

Last edited:

My last build was meant to be compact, but felt like trying to squeeze a quart into a pint pot. I had the top plate, which had had the main holes cut, and wooden case, but it was a continual battle to arrange everything to fit in the space, and still be maintainable so things like bias changes could be managed.

In some ways it has dampened my enthusiasm for another project. It felt like 1 day soldering, 6 months fettling. I did use layout diagrams and 2D drawings, but did not go to the level you have with 3D representations, so hopefully you will have less challenges along the way.

The worst part about a beautiful and complex solution like yours is that as you get closer to the end of the project, you become incredibly leveraged in terms of mistakes on the metal work side. Screwing up the countersinking of the last machine screw can ruin the appearance, negating a lot of work.

In some ways it has dampened my enthusiasm for another project. It felt like 1 day soldering, 6 months fettling. I did use layout diagrams and 2D drawings, but did not go to the level you have with 3D representations, so hopefully you will have less challenges along the way.

The worst part about a beautiful and complex solution like yours is that as you get closer to the end of the project, you become incredibly leveraged in terms of mistakes on the metal work side. Screwing up the countersinking of the last machine screw can ruin the appearance, negating a lot of work.

I would let more space for wires.

Have you considered assembling-dissasembling sequence?

Have you considered assembling-dissasembling sequence?

5AR4 vacuum rectifiers have a fairly bad reliability record, sorry to say. Many folks have resorted to adding 4007 silicon diodes in series with the anodes, to lower the risk to damage to other parts when the 5AR4 fails (rather than if). Maybe there have been some recent improvements, but it might pay to check.

Dampers are as rugged as you could want.

But they put too much heat into the internal space: nearly 25W for the heating power alone, per pair of 6xx3 types; and the socket is a nuisance to source.

I got tired of all that, so now I am running my 300Bs with a stable voltage, buffered by a source follower. Slow rise-time, after a (programmable) delay.

It dispenses with the need for chokes, but gets the 100/120Hz spur down to the low microvolt region. And getting rid of the constant mains-borne low frequency voltage steps is a definite advance.

Dampers are as rugged as you could want.

But they put too much heat into the internal space: nearly 25W for the heating power alone, per pair of 6xx3 types; and the socket is a nuisance to source.

I got tired of all that, so now I am running my 300Bs with a stable voltage, buffered by a source follower. Slow rise-time, after a (programmable) delay.

It dispenses with the need for chokes, but gets the 100/120Hz spur down to the low microvolt region. And getting rid of the constant mains-borne low frequency voltage steps is a definite advance.

The worst part about a beautiful and complex solution like yours is that as you get closer to the end of the project, you become incredibly leveraged in terms of mistakes on the metal work side. Screwing up the countersinking of the last machine screw can ruin the appearance, negating a lot of work.

I experienced this, I have a boxful of "shame" in my garage of messed-up aluminum parts! With 3D CAD I can get things down to a mm level accuracy, also I'll use slotted holes in places where I need wiggle room. For example, to mount the Coleman regulators eventually I will use a slotted hole for the PCB mounting hole, that way I don't have to worry about bending the MOSFET leads to micro accuracy to mount the TO220 to the heatsink to line up with its hole. Rods new form factor for the Coleman regulator very nice in that it only requires 2 holes and lays flat, but a slotted hole makes it a foolproof install. As for mistakes I'm having the sheet metal bent and laser cut by sending the 3D file to send-cut-send, they can do it cheaper than me with 1/1000 inch precision and I dont have a fiber laser! For the side slabs I can machine those myself of 10mm aluminum sheet, and anodize them locally here. Those slabs have a lot of M3 and M4 holes to tap and I am set up with a tapping head on my drill press for that, I can blind tap 40 M3 holes in under an hour. The front panel I'll carve from hardwood on my CNC, it's basically the same as when I do sign-making for my wife's crafts. I called this whole thing the "Ambitious" because its hard, not easy, I wanted not easy.

I would let more space for wires.

Have you considered assembling-dissasembling sequence?

I'm considering disassembly as I go. The latest change along that line was to mount the circular connector flange from the inside so the whole back is removeable and can tilt out if I leave enough primary leads. I think that any part will be relatively easily serviceable so far. As for mains soldering room, I can solder the back while its removed then tilt it back on once it's finished. I am considering the paths of all connecting wires as I go, the "messiest" ones will be connecting to the many DC link capacitors, but the PT secondaries will terminate cleanly onto the screw terminals, then the boards connect to the screw terminals, the whole raw low voltage board can be removed with no soldering iron. Mains power switch will wire from underside. The pilot lamps wire to their boards. I'm not seeing too many pitfalls so far in routing wires, but if I do I can cut another access hole to pass through, etc. I will also cut a piece of 1/16 inch acrylic to shield the bottom of the variac from fingers if the bottom aluminum cover is removed.

Last edited:

5AR4 vacuum rectifiers have a fairly bad reliability record, sorry to say.

Thanks Rod, I wasn't aware of that, those tubes are suspended 30mm above another PCB that holds the SS rectifiers and optional 0.1uF starter capacitor, I do have room there for series diodes as well. There are thousands of guitar players abusing 5AR4 in amplifiers, maybe the poor record statistically is due to the sheer volume of guitar amps intentionally designed to sag the power supply?

I would let more space for wires.

OK, I took your advice! I knew wiring up the long Pi filter would be the messiest thing to wire. So I had room to add a small board above the 1H stacked chokes that would have a bunch of screw terminals. The idea is to bring all the wires from the DC link caps, chokes, rectifier output, and output to the umbilical all to this terminal board. Then simply tie together the whole Pi filter there. Thanks for mentioning wiring, its the last step after getting the parts to all simply fit, but an important one. I also found that the larger DC link capacitors in 700V are not quite as tall as I had in earlier picture. So reduced those, there is now more breathing room to solder onto the leads of the DC link caps. I decided a while ago to not install the DC link caps onto PCB's. Because they are expensive, and if I ever want to re-use them they would be difficult to unsolder. So I'm just going to silicone rubber RTV adhesive to stick them down and add a zip tie through the slots you can see under the centerline of each DC Link cap. This terminal block will allow easier servicing as any voltage along the Pi filter can be measured, and any component can easily be taken "out of circuit" with a screw terminal to test that component individually out of circuit. I also added some wire pass-thru slots under the top terminals in order to bring all the various output wires back out to the circular umbilical connector (2nd photo). So basically all the PT secondaries move back to front via the top terminals. And all the outputs of the PSU move front to back through those slots and connect to the circular connector.

Last edited:

The Pi filter wiring (added above the 1H chokes above) might/can also be solder lugs instead of screw terminals:

@Windcrest77

What is the reason for that long CLC chain?

Usually -for power stage- cLC or cLCLC is enough.

Such long filter chains possibly necessary for -almost- steady load preamps/phono amps, but for power stage contraindicated. IMO.

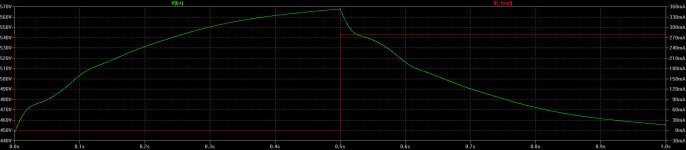

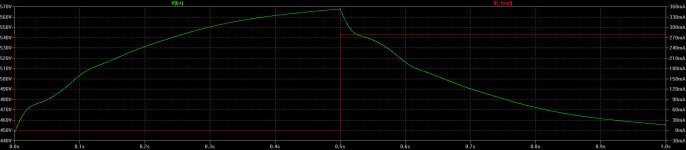

With these parameters, the PSU very "lazy", the recovery time very long, over 500ms!

On the other hand the additive choke resistances increase the B+ sagging.

-----------

BTW if you use low secondary DCR PT (toroid), must to use series resistors between secondary and rectifier tube/s/.

Read rectifier datasheet!

For example 5AR4 requires at 600V RMS (per plate) voltage at least 200R Rs if you use it with capacitor input filter. With choke input filter lesser Rs is enough.

What is the reason for that long CLC chain?

Usually -for power stage- cLC or cLCLC is enough.

Such long filter chains possibly necessary for -almost- steady load preamps/phono amps, but for power stage contraindicated. IMO.

With these parameters, the PSU very "lazy", the recovery time very long, over 500ms!

On the other hand the additive choke resistances increase the B+ sagging.

-----------

BTW if you use low secondary DCR PT (toroid), must to use series resistors between secondary and rectifier tube/s/.

Read rectifier datasheet!

For example 5AR4 requires at 600V RMS (per plate) voltage at least 200R Rs if you use it with capacitor input filter. With choke input filter lesser Rs is enough.

Thanks euro21, as to why the long chain, its just because I'm learning and I had the space basically, and PSUII analysis indicated practically no ripple. Thanks too for the added resistance knowledge, I didn't put two and two together with the toroid internal resistance. I have the perfect spot for two resistors there. I can omit the last choke and just end the chain at LCLCLC. In our earlier discussion about ringing, I found that ending the chain with only 1H helped with the ringing. I really appreciate your expertise and catching these weaknesses! Actually I have a spare wire in the umbilical too, I could possibly do an LC "parallel end split" with those two 1H chokes, then the PSU could have dual B+ outputs. Pin 2 LCLCLC and pin 7 LCLCLC I didn't like wasting that last wire (pin 7) in the umbilical this might be a good use for it. Would removing the last choke make it somewhat faster? Would reducing the 16H choke to 9H make it much faster? I do have a Toroidy 9H I can use. Also how much of a current transient is needed to push it out to 500ms? Would it recover faster if the transient were only under 5% or so? Just wondering how much of a current transient I need to actually design for if the PSU were to be used with class A amps.

Last edited:

AI suggests I reduce the choke henries and capacitor values. Being a Newby I was obsessed with ripple at the expense of recovery time. Here is AI advice.

That’s a beautifully ambitious filter, Rick—serious iron and capacitance. But that 500 ms recovery time is a clue that your energy storage and time constants are working against your transient response.

Here’s what’s likely happening and how you can tighten it up:

🔍 Why It’s Slow

Each LC stage introduces a low-pass filter with a long time constant:

- The 12 H and 16 H chokes store a lot of energy and resist rapid current changes.

- The 180 µF caps are large enough to smooth ripple but also slow to charge/discharge.

- The final 1 H stage is relatively fast, but it’s downstream of two sluggish tanks.

The result? A highly damped system with excellent ripple rejection but sluggish dynamic response.

⚡ How to Speed It Up

1.

Try scaling back the 12 H and 16 H chokes to something like 2–5 H. You’ll still get good ripple filtering, but with faster current ramp-up and less stored energy to “unwind” after a transient.

2.

Consider reducing the 180 µF caps to 100–120 µF in the first two stages. This reduces the RC time constant and speeds up voltage recovery without sacrificing too much ripple attenuation.

3.

A bleeder resistor or active load can help pull the voltage back down faster after an overshoot. This is especially useful if your transient is a sudden drop in load current.

4.

If you’re seeing ringing or overshoot, a resistor in series with the caps (or across the inductors) can help dampen the response and settle faster.

5.

You might try:

- L (2 H) – C (120 µF) – L (4 H) – C (180 µF) – L (0.5 H) – C (180 µF)

This keeps the topology but trims the inertia.

If you’re simulating this in SPICE or PSUD2, try stepping the load current and watching the voltage recovery. Want help modeling a few variations or optimizing for a specific load step? I’d love to dig in. This is right in your wheelhouse.

- Home

- Amplifiers

- Tubes / Valves

- Ambitious direct bias PSE 300B with dual PSUs